Bidirectional composite deflection tilting gravity casting method and device thereof

A technology of gravity casting and displacement, which is applied in the field of two-way compound displacement tilting gravity casting method and its device, can solve the problems that cannot meet the casting requirements of special-shaped complex castings, etc., and can reduce pores, improve feeding state, and improve The effect of casting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

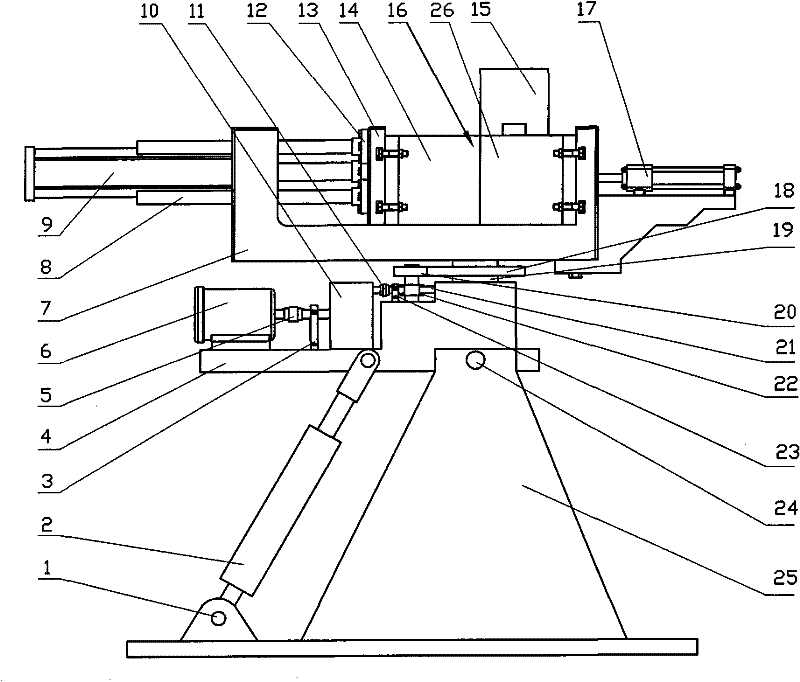

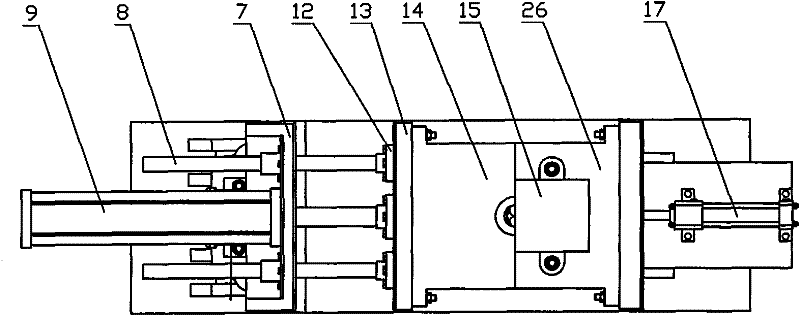

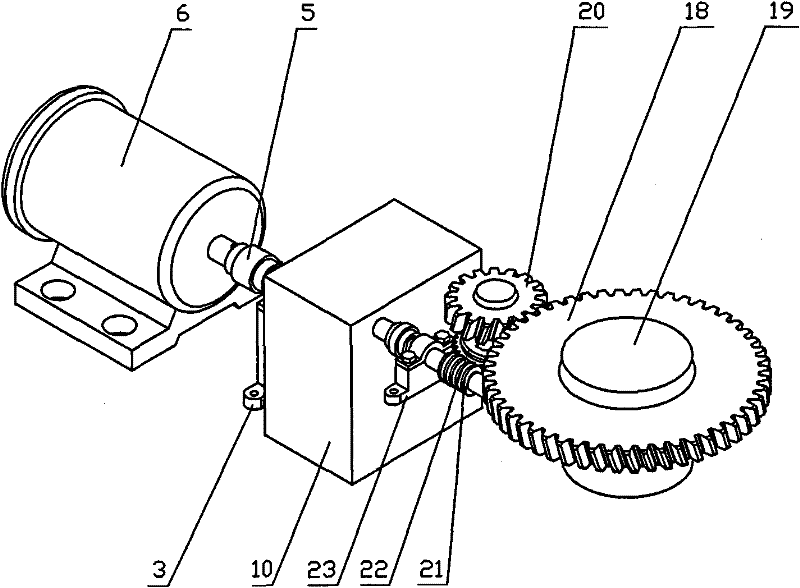

[0031] A two-way compound displacement and tilting gravity casting method. The casting mold and the sprue cup fixed on it can control the two-way compound movement of tilting and turning on the casting machine table. The position that is horizontal or at a certain inclination angle to the mold gradually turns to the upper position of the mold, and the sprue cup fills the mold with molten metal during the movement. The specific casting steps are as follows: a. The casting mold and the working table of the casting machine are in a horizontal state, the casting mold is closed, and a certain amount of molten metal is injected into the sprue cup; Move from a horizontal state to a vertical state, during which filling and pouring is performed; c, the mold is fixed in a vertical position, and the casting is solidified and cooled; d, after solidification and cooling, the mold is reset to a horizontal state; e, the mold is opened and taken out casting. The filling and pouring in step b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com