Bonding agent and preparing method thereof

A kind of binder, a certain amount of technology, applied in the preparation of binder, phosphate binder field, can solve the problem of loss of bond strength, etc., achieve fast curing speed, good moisture resistance, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with specific examples, but the present invention is not limited to the following examples.

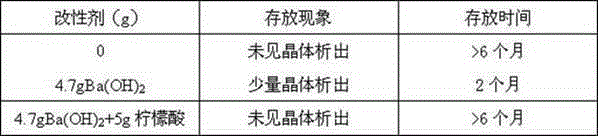

[0012] A binder, the binder is a phosphate binder, the weight percentage of each component is: the phosphate content is 60%~63%, the iron oxide powder content is 12%~15%, the polyvinyl alcohol content It is 14%~17%, and the boron content is 8.5%~9.5%. Through orthogonal test, the weight percentage of phosphate is 62.5%, the weight percentage of iron oxide powder is 12.5%, the weight percentage of polyvinyl alcohol is 15.62%, and the weight percentage of boron is 9.38%. The overall performance of the binder is the best. The relevant test data table as follows.

[0013]

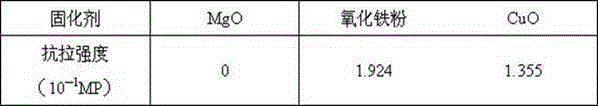

[0014] Table 1 Binder stability

[0015]

[0016] Table 2 Average bond strength of different curing agents

[0017] Under the premise of ensuring the thermal curing of the phosphate binder, when the polyvinyl alcohol is selected at a concentration of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com