Patents

Literature

31results about How to "Strength meets" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dry-mixed mortar prepared from hot furnace slag and preparation method of dry-mixed mortar

The invention discloses dry-mixed mortar prepared from hot furnace slag and a preparation method of the dry-mixed mortar. The dry-mixed mortar comprises the following components in parts by mass: 200-750 parts of an inorganic cementitious material, 280-900 parts of medium sand, 500-1220 parts of hot furnace slag sand and 2-7.5 parts of an additive, wherein the inorganic cementitious material comprises the following components in percentage by mass: 50-65% of cement, 25-30% of hot furnace slag power, 5-10% of blast furnace slag fine powder and 5-10% of limestone fine powder; the additive is cellulose; the hot furnace slag is nickel ore smelting slag; after the hot furnace slag is sieved, the hot furnace slag with the particle sizes of 0.6-2.36 mm is the hot furnace slag sand. All the components are measured according to the formula, and then mixed and stirred to obtain the dry-mixed mortar. According to the preparation method, the process is simple; dry-mixed mortar with the grade of M5-M30 can be prepared; the rate of multipurpose utilization of the hot furnace slag can be remarkably increased; environmental pollution is reduced; social and economic benefits are obvious.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Foam concrete capable of pumping and chemically foaming and production method of foam concrete

The invention discloses foam concrete capable of pumping and chemically foaming and an on-site construction production method. The foam concrete comprises the following materials in parts by weight: 75-500 parts of concrete, 20-120 parts of an active mixing material, 40-300 parts of water, 15-50 parts of an adjusting agent, 30-90 parts of a foaming agent and 2-10 parts of a micro foam agent. The volume weight of the prepared foam concrete is 100-600kg / M<3>; the heat conductivity coefficient of the foam concrete is as low as 0.020W / M.DEG C; the strength of the foam concrete can reach 5Mpa. By virtue of the production method, the advantages of cast-in-situ physical foaming and chemical foaming make an organic combination to form a novel construction method; the production method is relatively high in production efficiency, flexible to operate and relatively wide in application; the foam concrete can be made into high-strength product materials with different shapes; the heat-insulating construction of buildings can be effectively completed with high efficiency and low cost.

Owner:河南华泰新材科技股份有限公司

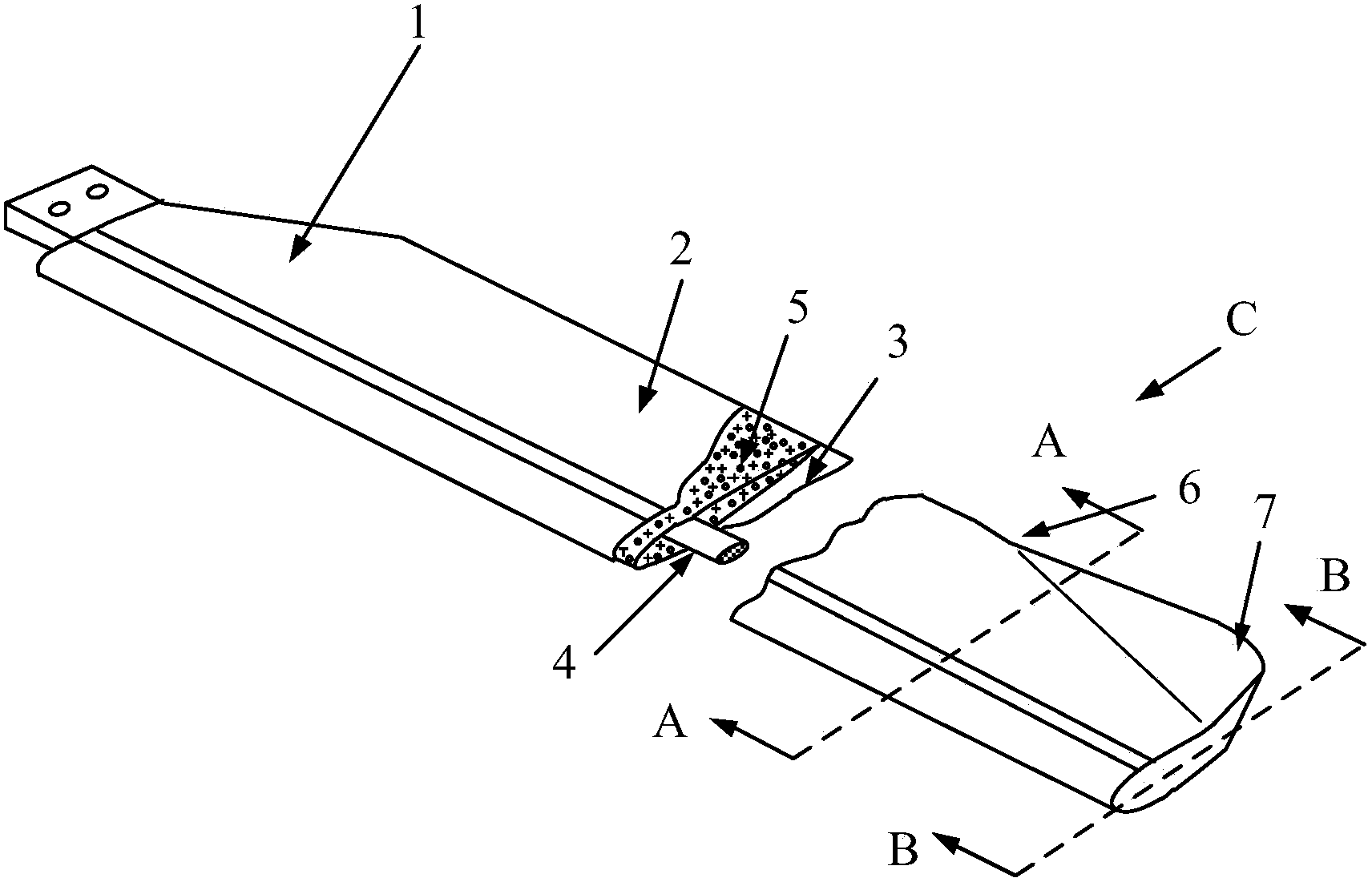

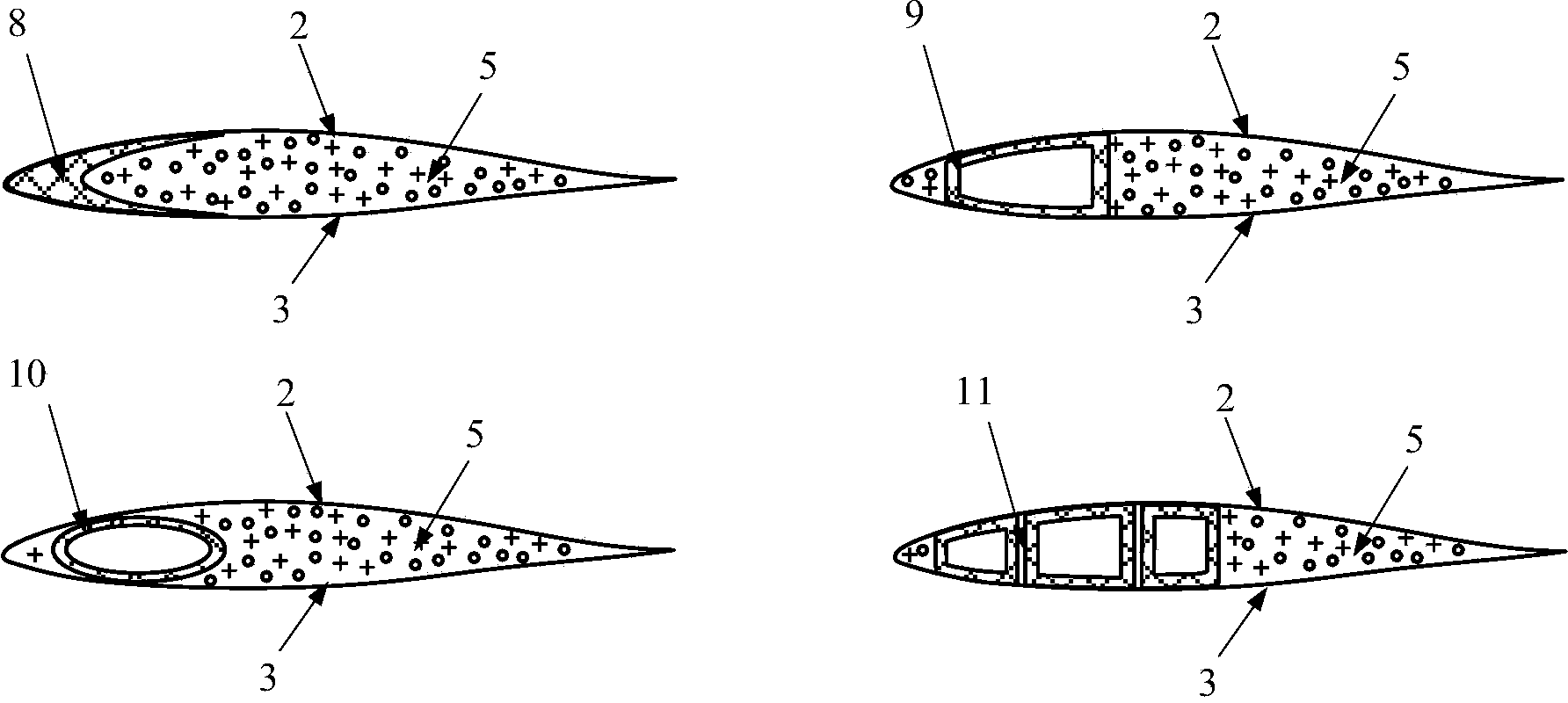

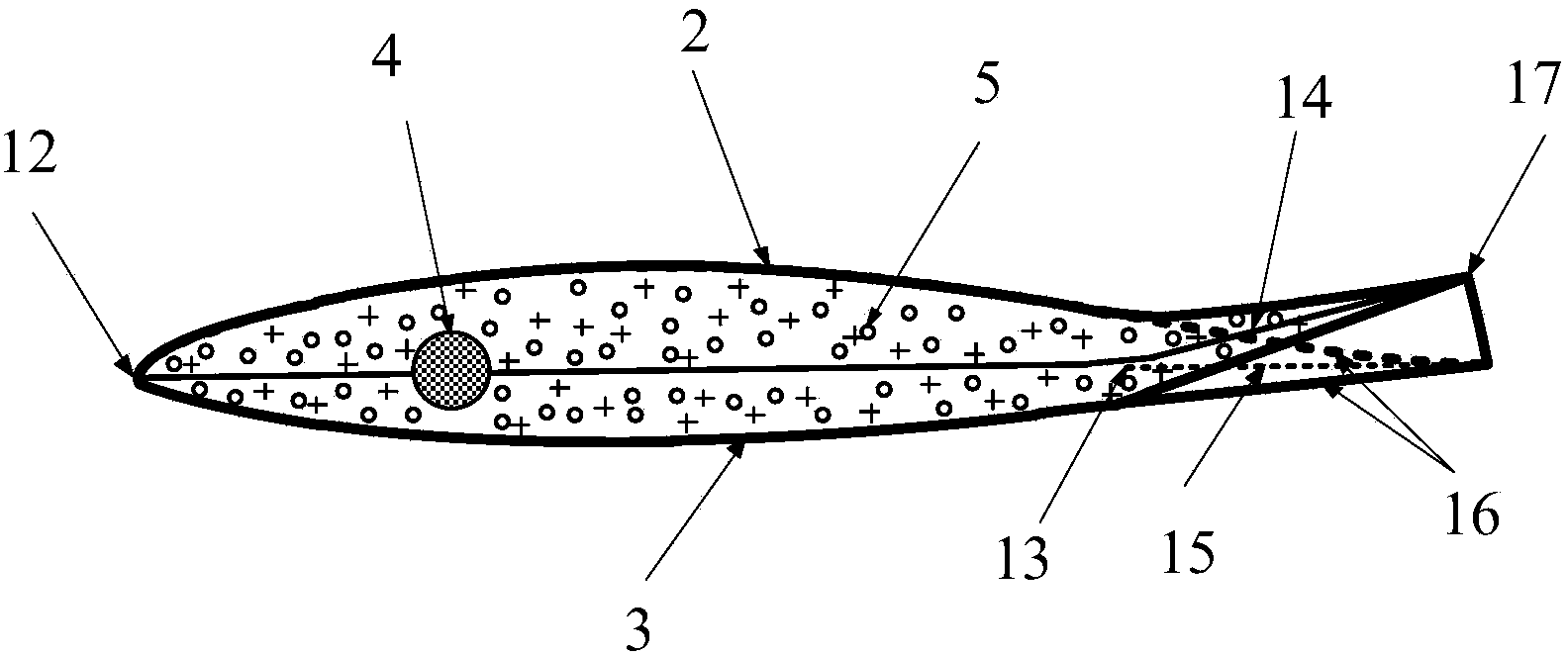

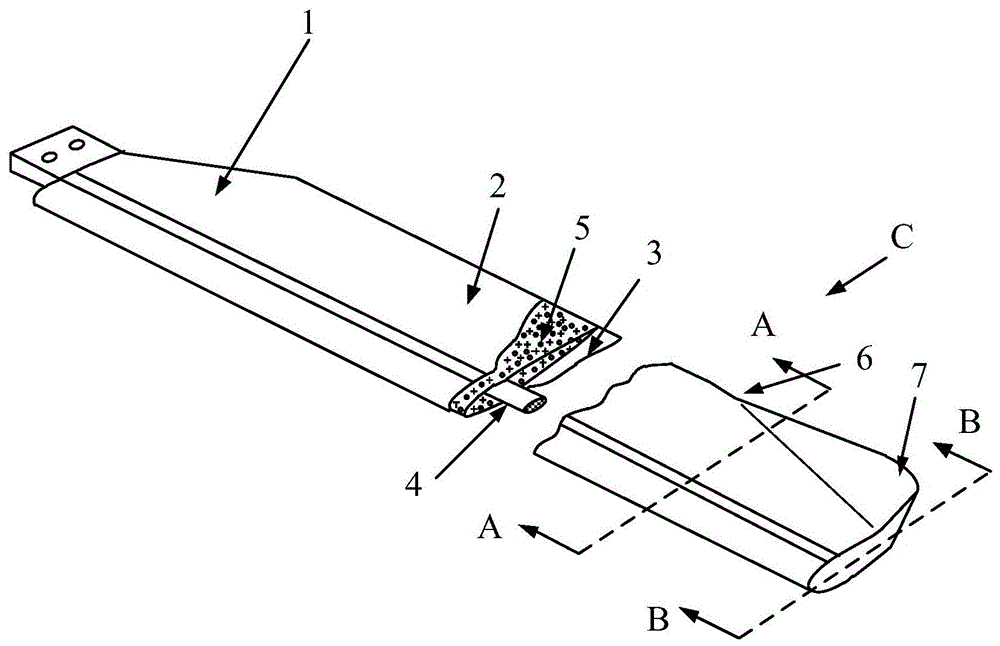

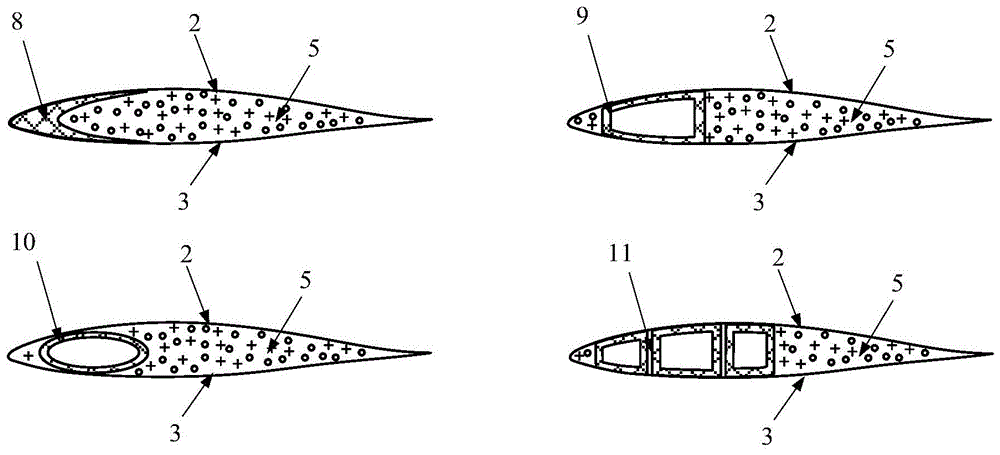

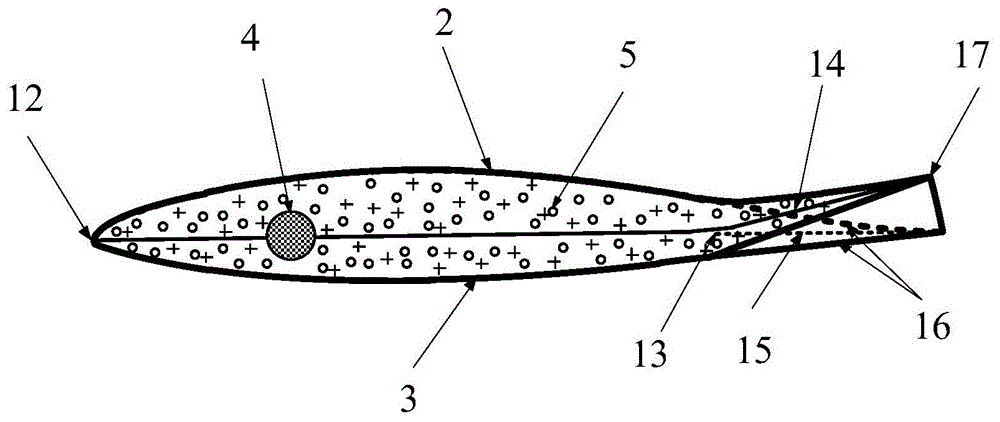

Rotor blade structure design capable of inhibiting rotation chattering of tilt rotor

InactiveCN104002966ASuppression of swing chatterIncreased rotational flutter speedRotocraftRadial positionFront edge

The invention discloses a rotor blade structure capable of inhibiting the rotation chattering of a tilt rotor, belonging to the technical field of tilt rotors. The rotor blade structure comprises a blade girder, a skin and a filler core; on the basis that the position of the girder, the wing shape of the blade and the torsion angle are maintained not to be changed, middle chord lines on all cross sections are bended upwards by a certain angle at the part which is a certain distance away from a front edge point from some radial position of a blade to the tip; meanwhile, the skin and the filler are bended upwards by the same angle; the lengths of the bended parts are linearly increased along with the increment of the radial position. After the rotor blade structure is used, the shearing gas power in a rotor wing shimmy surface can be effectively reduced, and the system damping is improved, so that the rotor blade structure has a good effect of inhibiting the rotation chattering and is capable of effectively accelerating the speed of the rotation chattering. The structure meets the basic performance requirement of the rotor blade structure of the tilt rotor and is simple in structure, and the weight of the blade is not increased.

Owner:BEIHANG UNIV

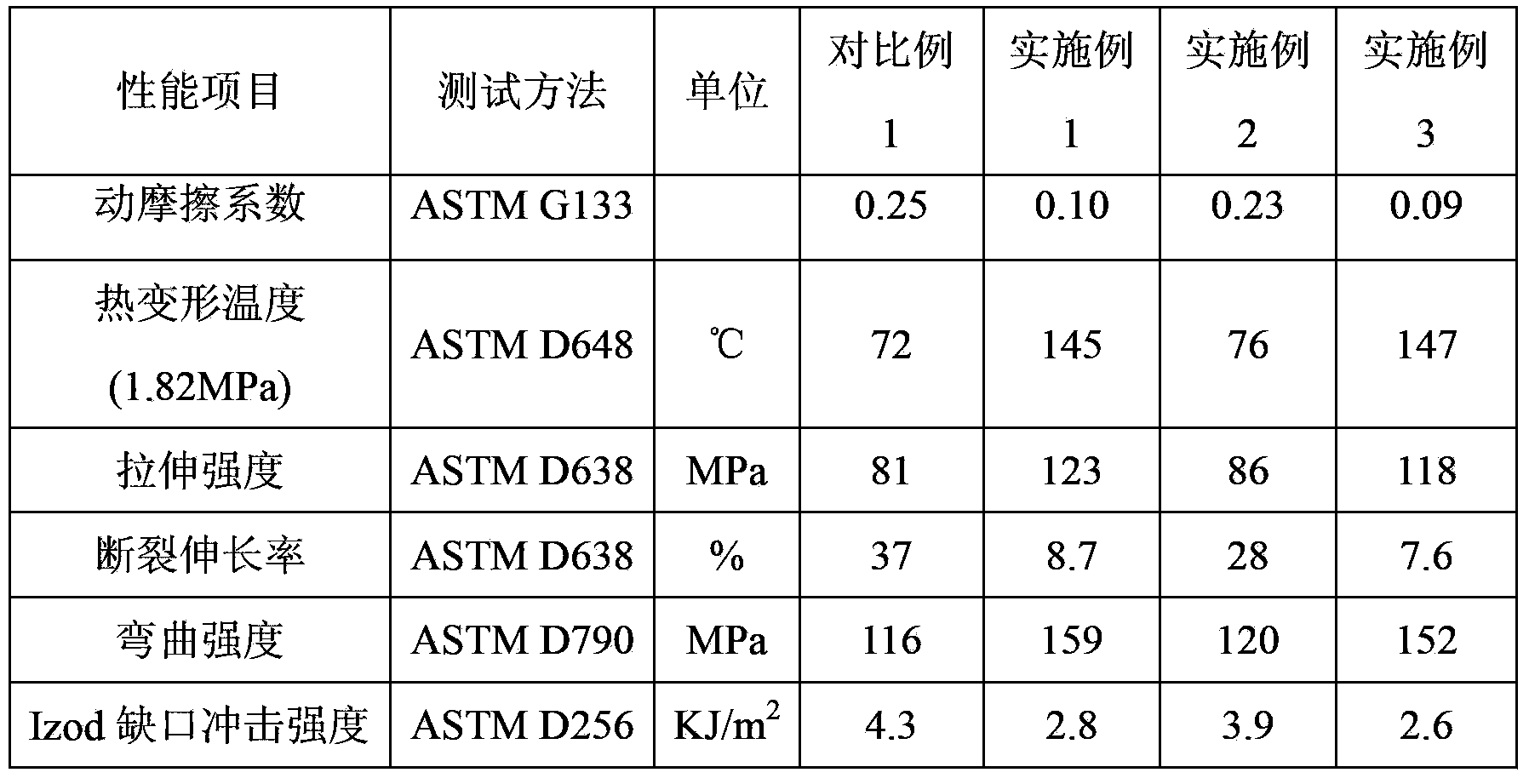

Reinforced wear-resistant nylon 66 composite material and preparation method thereof

InactiveCN104250439AGood compatibilityImprove mechanical propertiesHeat deflection temperatureWear resistant

The invention belongs to the technical field of reinforced wear-resistant nylon composite materials, and relates to a reinforced wear-resistant nylon 66 composite material and a preparation method thereof. The composite material includes 100 parts of nylon 66 salt, 1-10 parts of aramid pulp, 0.1-1 part of an end capping agent, 0.05-0.2 pars of a nucleating agent and 30-60 parts of deionized water. The interface adhesion between aramid fiber and a nylon 66 matrix is improved through an in situ polymerization process to improve the mechanical properties and the wear resistance of the composite material. The reinforced wear-resistant nylon 66 composite material prepared in the invention has better mechanical properties and wear resistance, higher thermal deformation temperature and better dimensional stability than the pure nylon 66 matrix, has good interface adhesion, and has higher extrusion reinforcement strength than nylon 66 aramid fiber, and the method is simple, is easy to carry out, and is suitable for large-scale industrial production.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

Shaddock peel based biodegradable plastic and preparation method thereof

The present invention discloses a shaddock peel based biodegradable plastic, which is characterized by being prepared from the following materials by weight: 25-35 parts of shaddock peel, 2-4 parts of lotus root starch, 5-10 parts of potato starch, 3-5 parts of sawdust, 3-5 parts of montmorillonite soil, 1-2 parts of carrageenan, 10-15 parts of polyethylene, 1-2 parts of a silane coupling agent KH-550, 1-2 parts of glucose, 1-2 parts of urea, 2-4 parts of sesame oil, 1-2 parts of sea buckthorn oil, 1-2 parts of micro microcrystalline cellulose and 10-15 parts of a compound additive. The biodegradable plastic has the advantages of high degradation rate, high degradation speed, good flexibility and strength meeting the usage requirement, simple production technology, effectively reduction of white pollution, and high environmental and economic benefits.

Owner:HEFEI ALL ROUND POLYMER MATERIAL FACTORY

Polyurethane integrated plate produced by mold embedded with reclaimed material and production process thereof

InactiveCN102173024ARealize large-scale industrial productionAvoid the pitfalls of fragile machineryCovering/liningsClimate change adaptationPolymer scienceInsulation layer

The invention discloses a production process for a polyurethane integrated plate by a mold embedded with a reclaimed material. The production process comprises the following steps of: separating the mold into a low-density decorative layer mold cavity and a high-density heat insulation layer mold cavity through a movable baffle, adding a decorative layer polyurethane material by using a foaming machine, and foaming and molding to form a polyurethane decorative layer; and curing, turning the mold, extracting the baffle, adding the polyurethane reclaimed material, adding a heat insulation layerpolyurethane material into the mold by using the foaming machine, making the material infiltrate the reclaimed material and fully fused with the reclaimed material to coat the reclaimed material, andfoaming on the surface of the molded decorative layer to form the polyurethane heat insulation layer. The production process solves the problem that the polyurethane reclaimed material cannot be utilized on a large scale, the production cost of a polyurethane decorative insulation board is greatly reduced, production procedures are reduced, the loss of production machines is reduced, and large-scale industrial production is realized.

Owner:鲁宁 +1

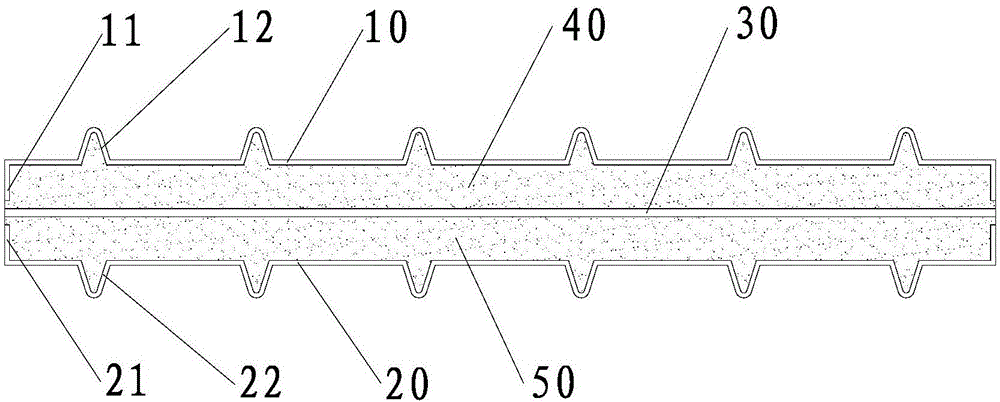

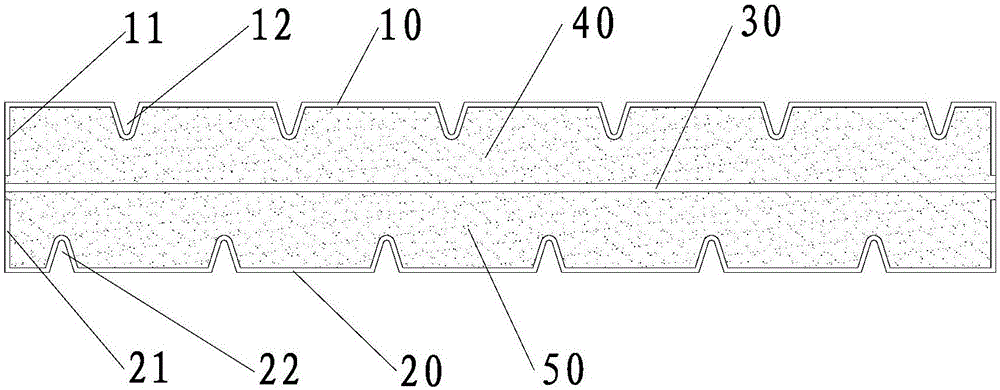

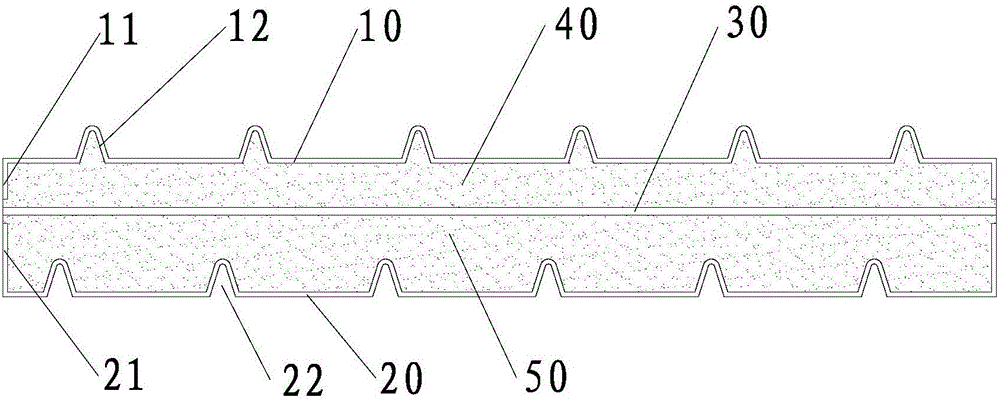

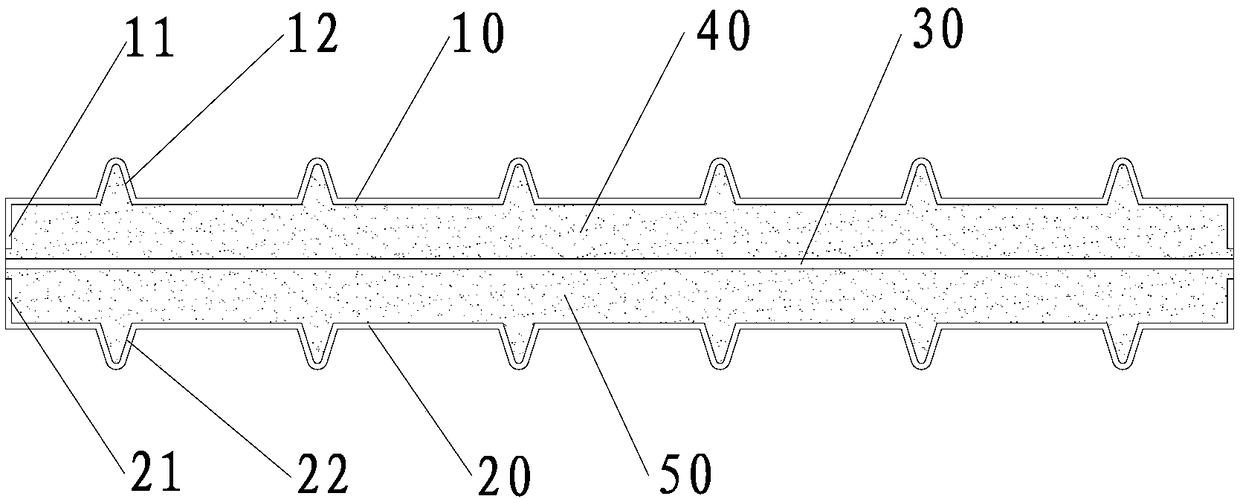

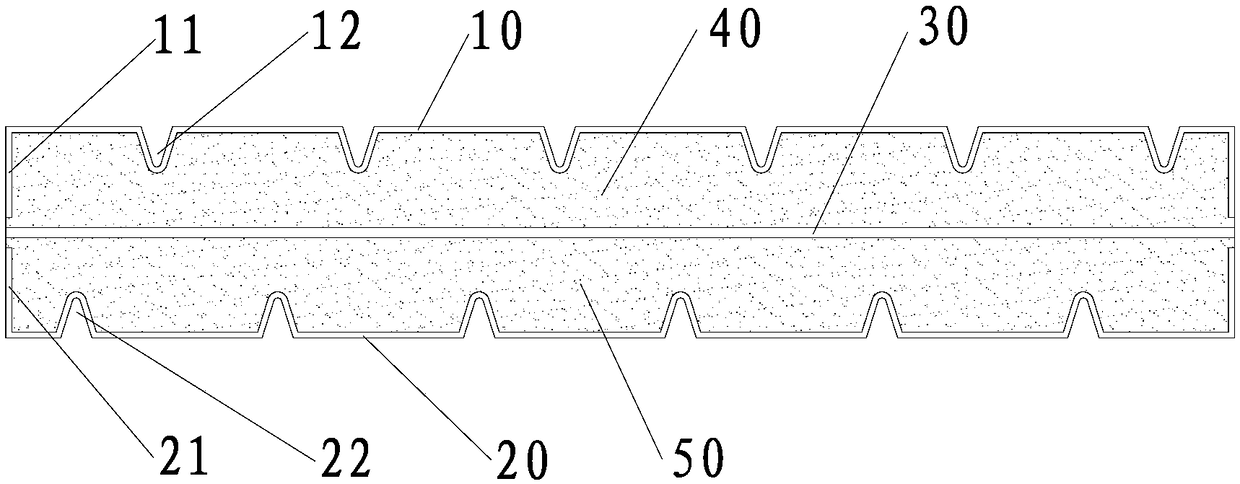

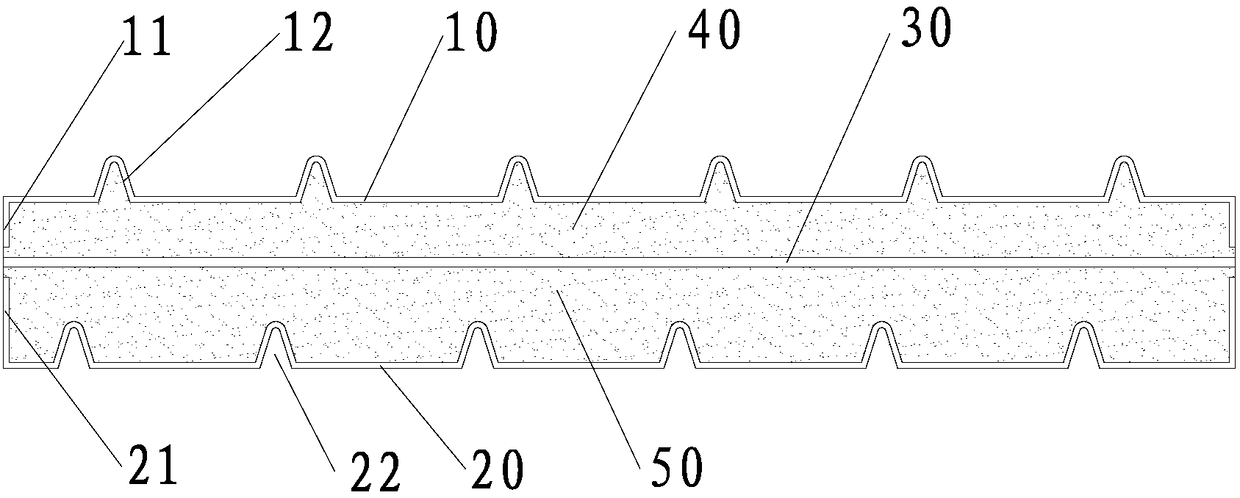

Foam concrete sandwich color wall steel plate and production technique thereof

ActiveCN106088456ANon-flammableNot easy to ageConstruction materialCeramic shaping apparatusToxic gasFoam concrete

The invention provides a foam concrete sandwich color wall steel plate and a production technique thereof. The foam concrete sandwich color wall steel plate comprises a first steel plate layer, a second steel plate layer, a cement paste layer, a first foam concrete layer and a second foam concrete layer, wherein the first steel plate layer and the second steel plate layer are parallel; the cement paste layer is located between the first steel plate layer and the second steel plate layer; the space between the first steel plate layer and the cement paste layer is filled with the first foam concrete layer; and the space between the second steel plate layer and the cement paste layer is filled with the second foam concrete layer. The production technique comprises the steps of die-filling, pouring, die disassembling, combining, forming and the like. The foam concrete layers are adopted as a sandwich material and are not prone to combustion, and compared with traditional sandwich materials, the foam concrete layers are relatively hard and not prone to aging, the fracture resistance is relatively good, and the service life is relatively long. In addition, the foam concrete layers and the cement paste layer are used as the sandwich material, the effect that the sandwich color wall steel plate has the strength as traditional EPS composite wallboards is ensured, and no toxic gas is emitted at high temperatures.

Owner:QUANZHOU HONGYI BUILDING MATERIAL MACHINERY

Biodegradable plastic using mushroom residue as raw material and preparation method thereof

The present invention discloses a biodegradable plastic using mushroom residue as the raw material. The biodegradable plastic is characterized by being prepared from the following raw materials by weight: 20-30 parts of mushroom residue, 10-15 parts of polyethylene, 0.5-1 part of rice bran oil, 6-8 parts of palm oil, 1-2 parts of magnesium stearate, 3-5 parts of peanut seedling powder, 1-2 parts of peanut protein powder, 5-10 parts of peanut shell powder, 3-5 parts of pumice powder, 2-4 parts of guar gum, 1-2 parts of a silane coupling agent KH-550 and 10-15 parts of a compound additive. The biodegradable plastic has the advantages of high degradation rate, high degradation speed, good flexibility and strength meeting the usage requirement; the main raw materials have abundant sources, low cost and good economic performance; and the invention saves energy, uses wastes, can effectively reduce white pollution, and has high environmental and economic benefits.

Owner:HEFEI ALL ROUND POLYMER MATERIAL FACTORY

Biodegradable plastic taking egg shells as raw materials and preparation method of biodegradable plastic

The invention discloses biodegradable plastic taking egg shells as raw materials. The biodegradable plastic is characterized by being prepared from the following raw materials in parts by weight: 20-30 parts of egg shells, 10-15 parts of polyethylene, 10-15 parts of glutinous rice flour, 5-10 parts of bean curd residue powder, 4-8 parts of pineapple leaves, 3-5 parts of xanthan gum, 2-4 parts of sodium caseinate, 0.1-0.2 part of calcium propionate, 1-2 parts of sodium polyacrylate, 4-6 parts of castor oil, 1-2 parts of a silane coupling agent KH-550 and 10-15 parts of a compound auxiliary agent. The biodegradable plastic disclosed by the invention is high in degradation rate and high in degradation speed, also has good flexibility and strength which meets the use requirements, is simple in production process, ensures that white pollution can be effectively reduced, and has relatively high environmental and economic benefits.

Owner:HEFEI ALL ROUND POLYMER MATERIAL FACTORY

Kelp powder biodegradable plastic and preparation method thereof

The present invention discloses a kelp powder biodegradable plastic, which is characterized by being prepared from the following raw materials by weight: 20-30 parts of kelp powder, 10-15 parts of corn starch, 3-5 parts of corn gluten meal, 3-5 parts of bentonite, 3-5 parts of light calcium carbonate, 10-15 parts of polyethylene, 4-8 parts of linseed oil, 1-2 parts of sucrose, 1-2 parts of humic acid, 0.1-0.2 part of potassium chloride, 1-2 parts of a silane coupling agent KH-550 and 10-15 parts of a compound additive. The biodegradable plastic has the advantages of high degradation rate, high degradation speed, good flexibility and strength meeting the usage requirement, simple production technology, effective reduction of white pollution, and high environmental and economic benefits.

Owner:HEFEI ALL ROUND POLYMER MATERIAL FACTORY

A configuration design of rotor blades for suppressing rotary flutter of tiltrotor aircraft

InactiveCN104002966BSuppression of swing chatterIncreased rotational flutter speedRotocraftConfiguration designRadial position

The invention discloses a rotor blade structure capable of inhibiting the rotation chattering of a tilt rotor, belonging to the technical field of tilt rotors. The rotor blade structure comprises a blade girder, a skin and a filler core; on the basis that the position of the girder, the wing shape of the blade and the torsion angle are maintained not to be changed, middle chord lines on all cross sections are bended upwards by a certain angle at the part which is a certain distance away from a front edge point from some radial position of a blade to the tip; meanwhile, the skin and the filler are bended upwards by the same angle; the lengths of the bended parts are linearly increased along with the increment of the radial position. After the rotor blade structure is used, the shearing gas power in a rotor wing shimmy surface can be effectively reduced, and the system damping is improved, so that the rotor blade structure has a good effect of inhibiting the rotation chattering and is capable of effectively accelerating the speed of the rotation chattering. The structure meets the basic performance requirement of the rotor blade structure of the tilt rotor and is simple in structure, and the weight of the blade is not increased.

Owner:BEIHANG UNIV

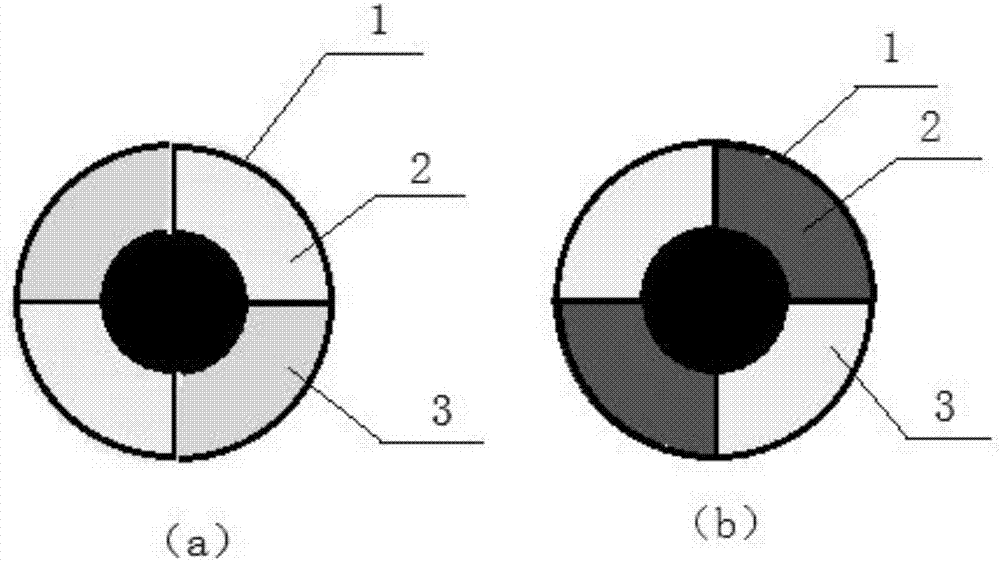

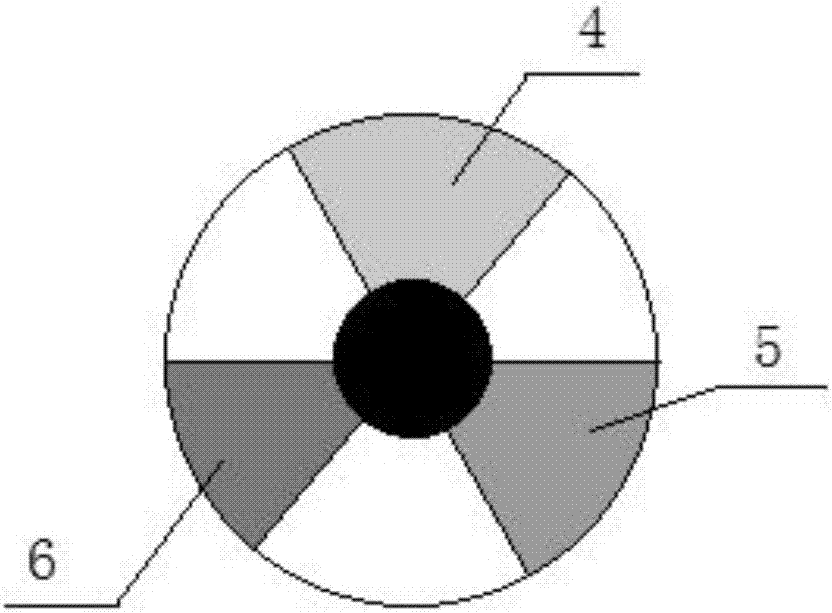

Colour-changeable electric wire insulation sleeve, colour-changeable electric wire and electric wire manufacturing method

PendingCN107230523ADiscoloration reversibleSensitive to discolorationInsulated cablesInsulated conductorsPhotochromismMaterials science

The invention relates to a colour-changeable electric wire insulation sleeve, and is characterized in that the colour-changeable electric wire insulation sleeve is a colour-changeable electric wire insulation sleeve, the colour of which is changed overall, or a colour-changeable electric wire insulation sleeve comprising one or more colour-changeable strips. The invention further relates to a colour-changeable electric wire adopting the colour-changeable electric wire insulation sleeve, and a manufacturing method of the colour-changeable electric wire. Photochromism of a sleeve outside an electric wire can be realized; therefore, the sleeve has enjoyment and experience in the use process; furthermore, product performances thereof accord with the properties of the electric wire, such as the insulation property and the strength; and thus, the sleeve has good market prospect.

Owner:深圳讯道实业股份有限公司

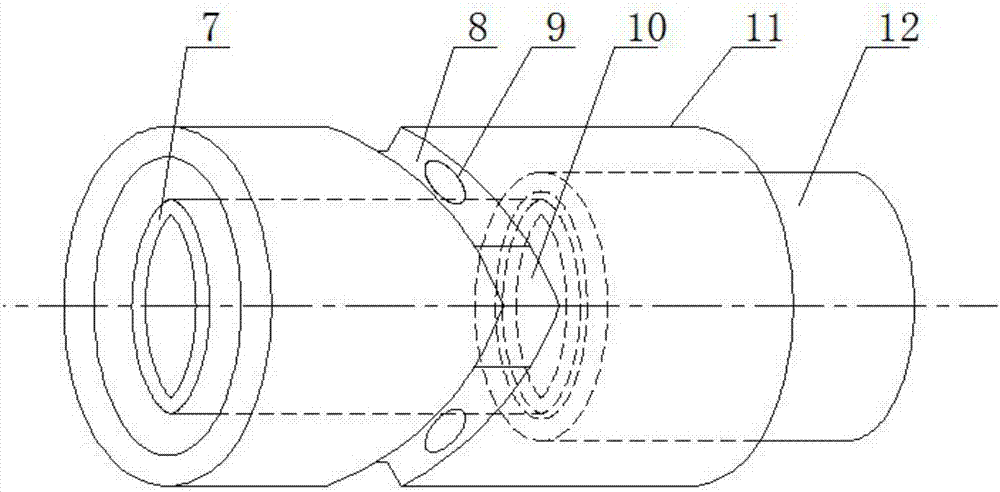

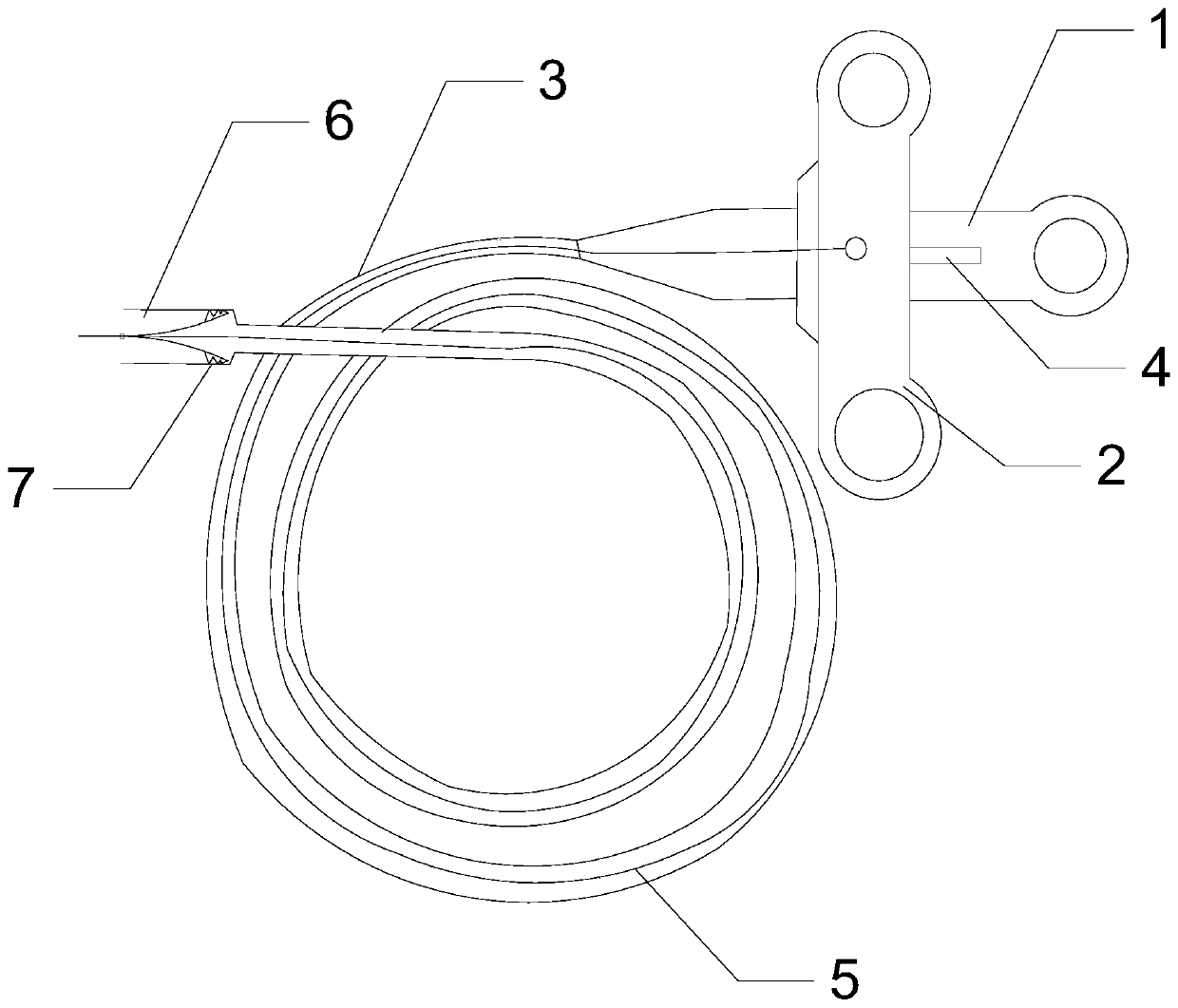

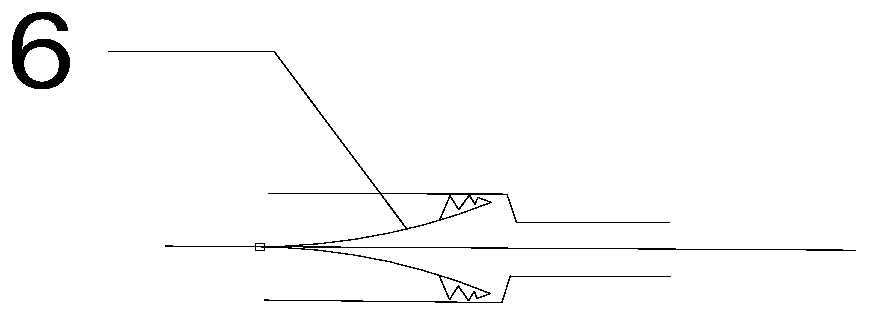

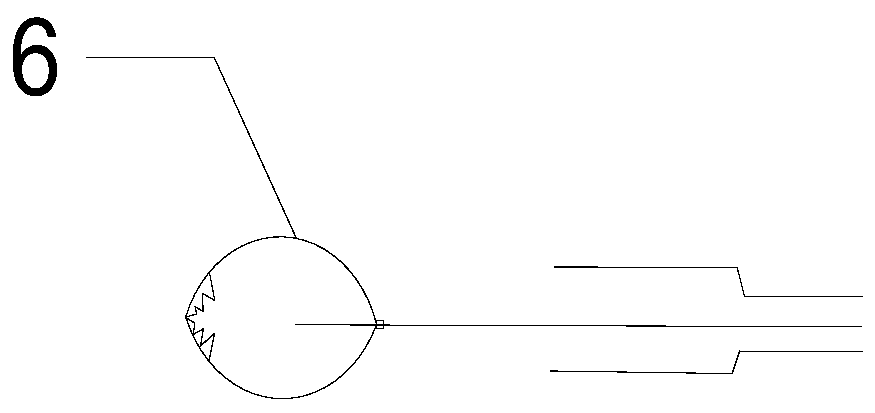

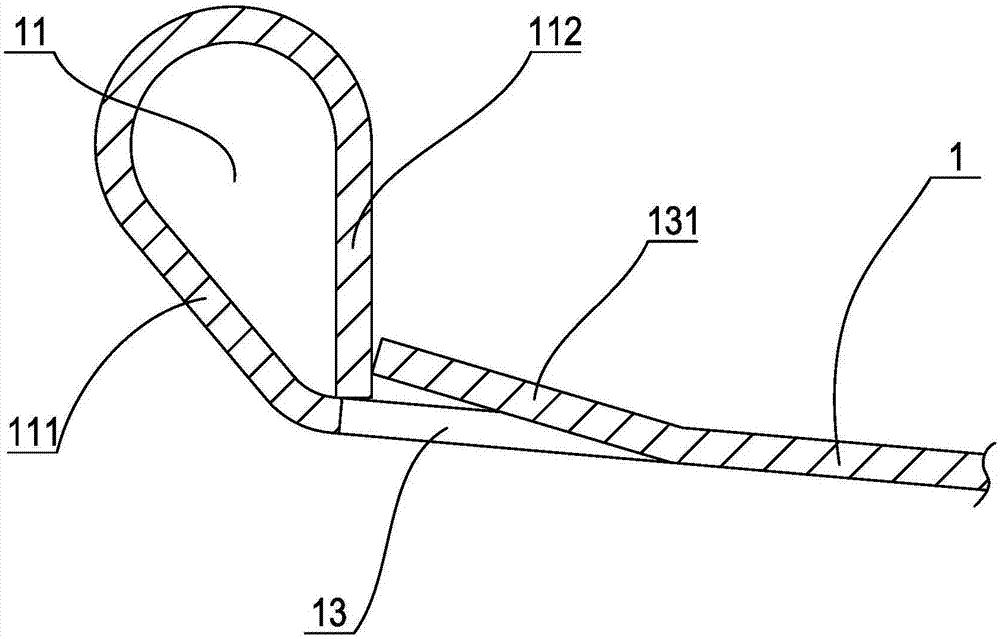

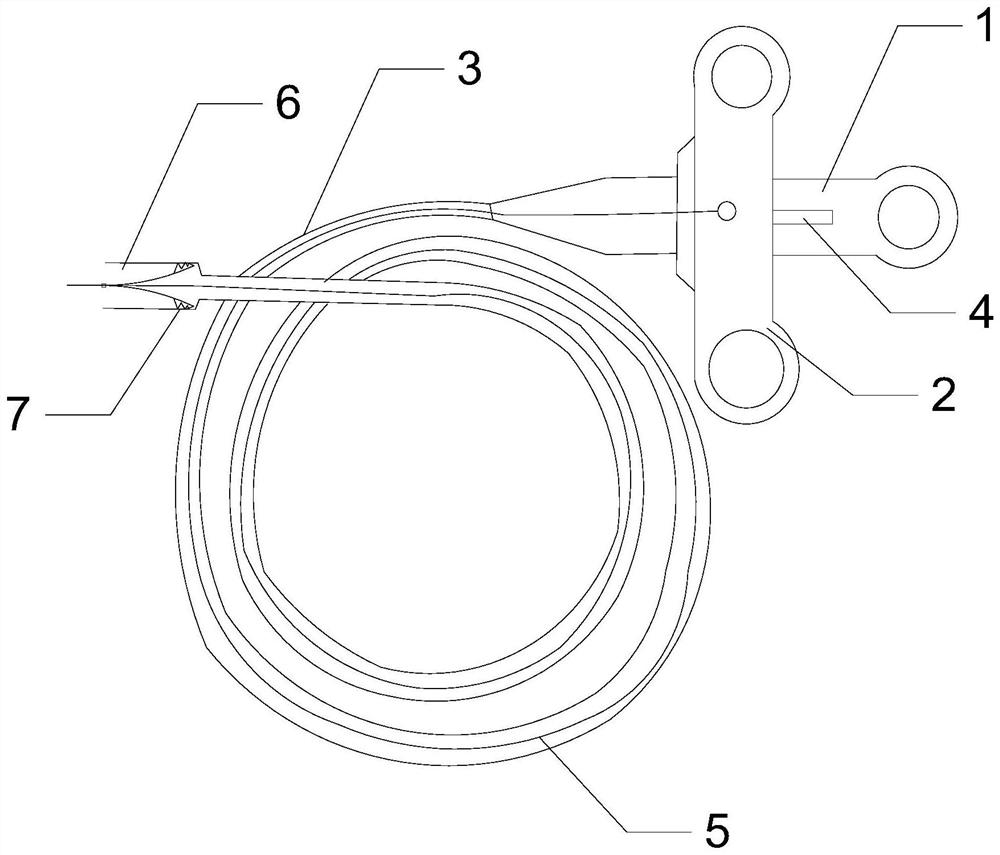

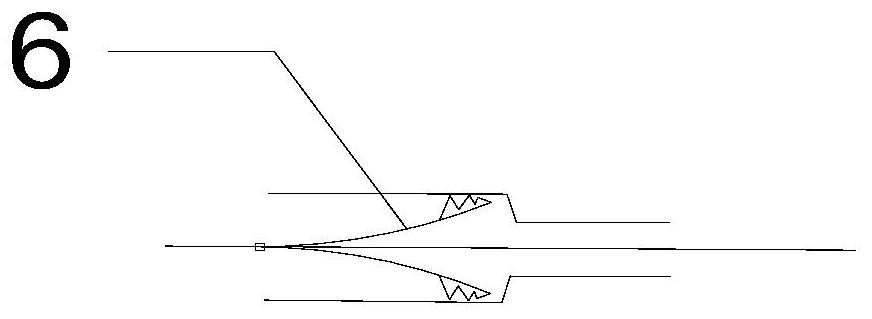

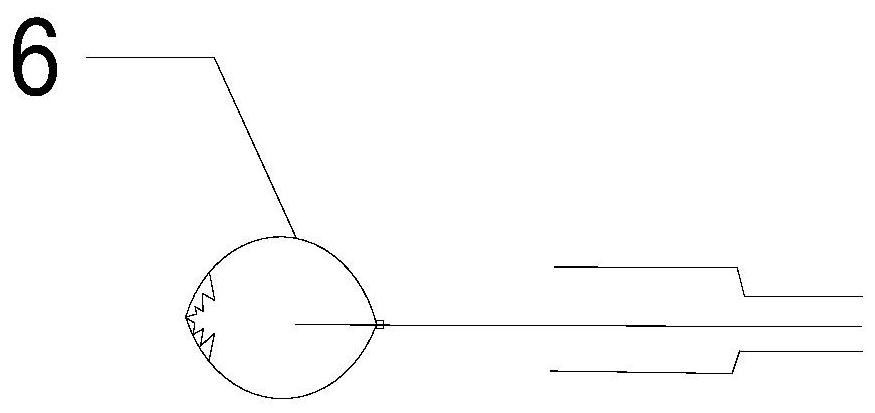

Foreign matter withdrawing claw under digestive endoscopy

The invention relates to a foreign matter withdrawing claw under a digestive endoscopy. The foreign matter withdrawing claw under a digestive endoscopy comprises a handle and a sheath, wherein the tail end of the handle is fixed to the near end of the sheath; guide wires are arranged in the sheath in a penetrating manner; a sliding rail is arranged on the handle; a ring for drawing back or pushingthe guide wires to move in the sheath is arranged on the sliding rail in a sliding manner, and is fixed to the near ends of the guide wires; the far end positions of the guide wires are connected with a capturing umbrella; the capturing umbrella is elastic hook claws on which the guide wires are uniformly arranged in the circumferential direction; the initial state of the hook claws in the sheathis that the hook backs face the guide wires; and under a relaxed state, the claw tips of the hook claws outside the sheath extend towards the guide wires, and the hook claws are propped at the claw tips. The foreign matter withdrawing claw under a digestive endoscopy disclosed by the invention has the beneficial effects that to foreign matters including polyps and the like which are far from an outlet of a natural cavity channel, under the situation that the foreign matters cannot be withdrawn or drawn out with a conventional apparatus through a plier channel, the foreign matter withdrawing claw under a digestive endoscopy can be used for attempting quick and safe withdrawing under the situation that endoscopy withdrawing is not or slightly performed.

Owner:SHANGHAI CHANGHAI HOSPITAL

A production process of foam concrete sandwich color steel wallboard

ActiveCN106088456BNon-flammableNot easy to ageConstruction materialCeramic shaping apparatusFoam concreteToxic gas

The invention provides a foam concrete sandwich color wall steel plate and a production technique thereof. The foam concrete sandwich color wall steel plate comprises a first steel plate layer, a second steel plate layer, a cement paste layer, a first foam concrete layer and a second foam concrete layer, wherein the first steel plate layer and the second steel plate layer are parallel; the cement paste layer is located between the first steel plate layer and the second steel plate layer; the space between the first steel plate layer and the cement paste layer is filled with the first foam concrete layer; and the space between the second steel plate layer and the cement paste layer is filled with the second foam concrete layer. The production technique comprises the steps of die-filling, pouring, die disassembling, combining, forming and the like. The foam concrete layers are adopted as a sandwich material and are not prone to combustion, and compared with traditional sandwich materials, the foam concrete layers are relatively hard and not prone to aging, the fracture resistance is relatively good, and the service life is relatively long. In addition, the foam concrete layers and the cement paste layer are used as the sandwich material, the effect that the sandwich color wall steel plate has the strength as traditional EPS composite wallboards is ensured, and no toxic gas is emitted at high temperatures.

Owner:QUANZHOU HONGYI BUILDING MATERIAL MACHINERY

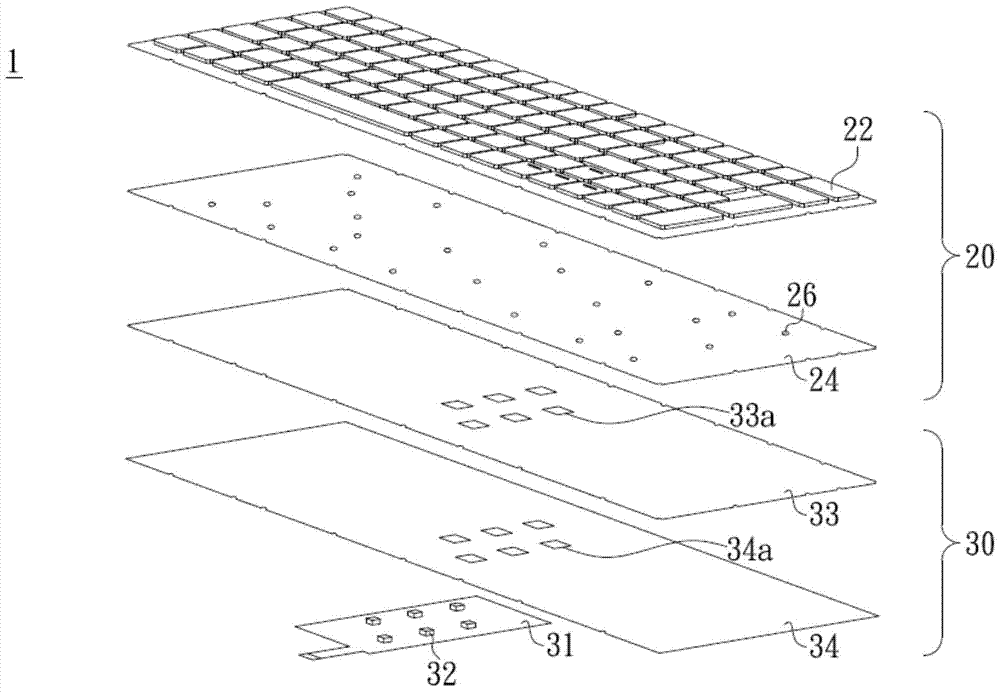

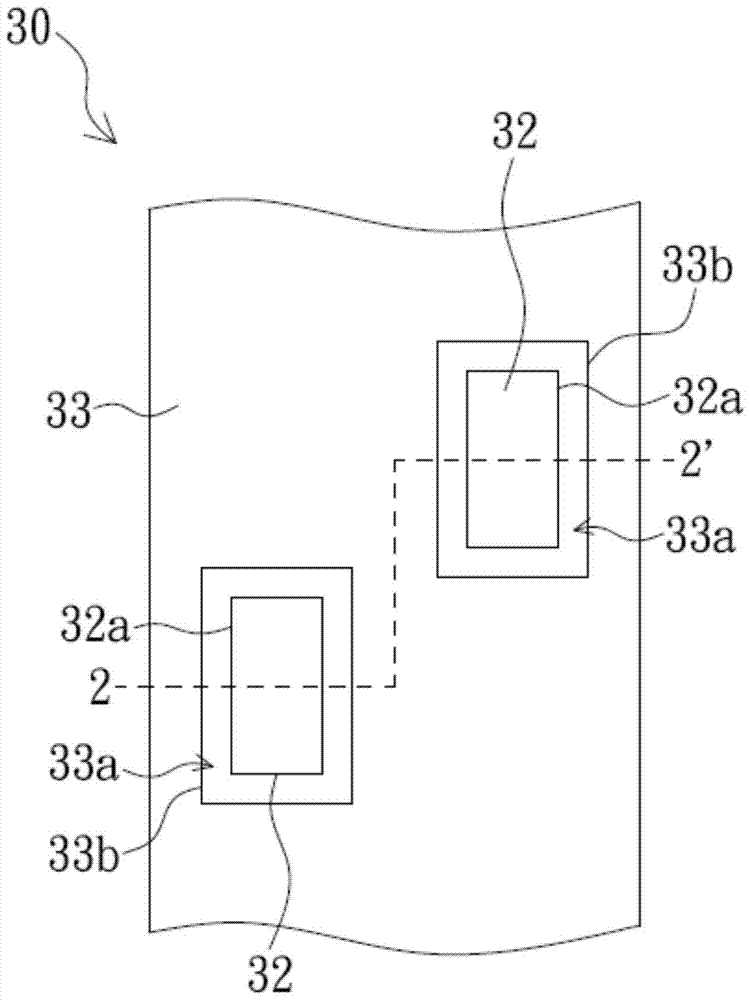

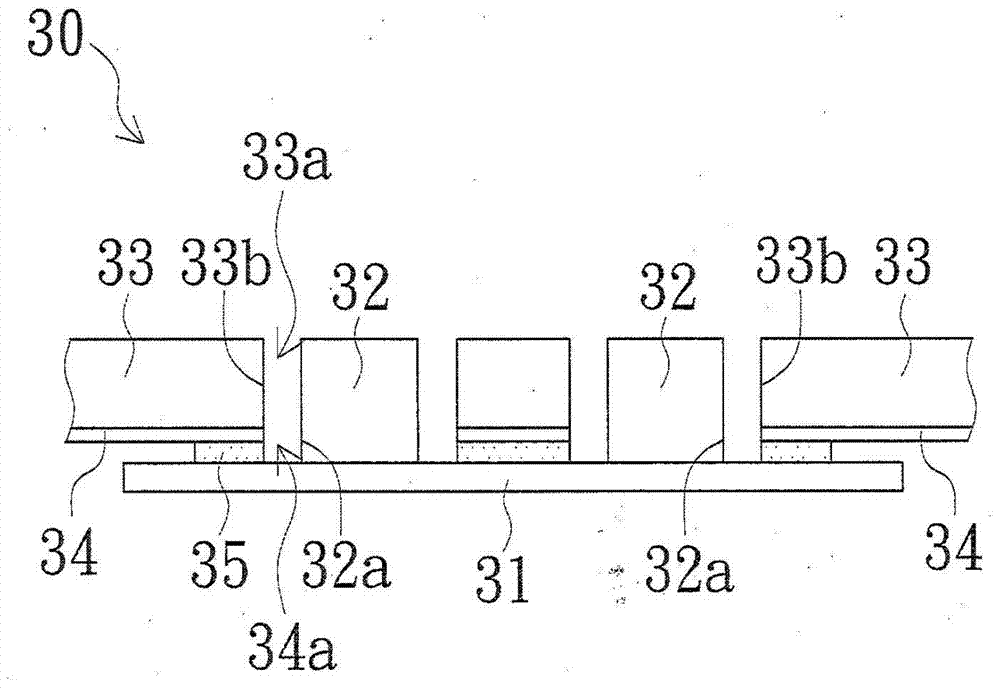

Luminous module and luminous keyboard

ActiveCN105118722BImprove luminous performanceAvoid halo phenomenonLegendsElectric switchesLight guideOptoelectronics

Owner:DARFON ELECTRONICS (SUZHOU) CO LTD +1

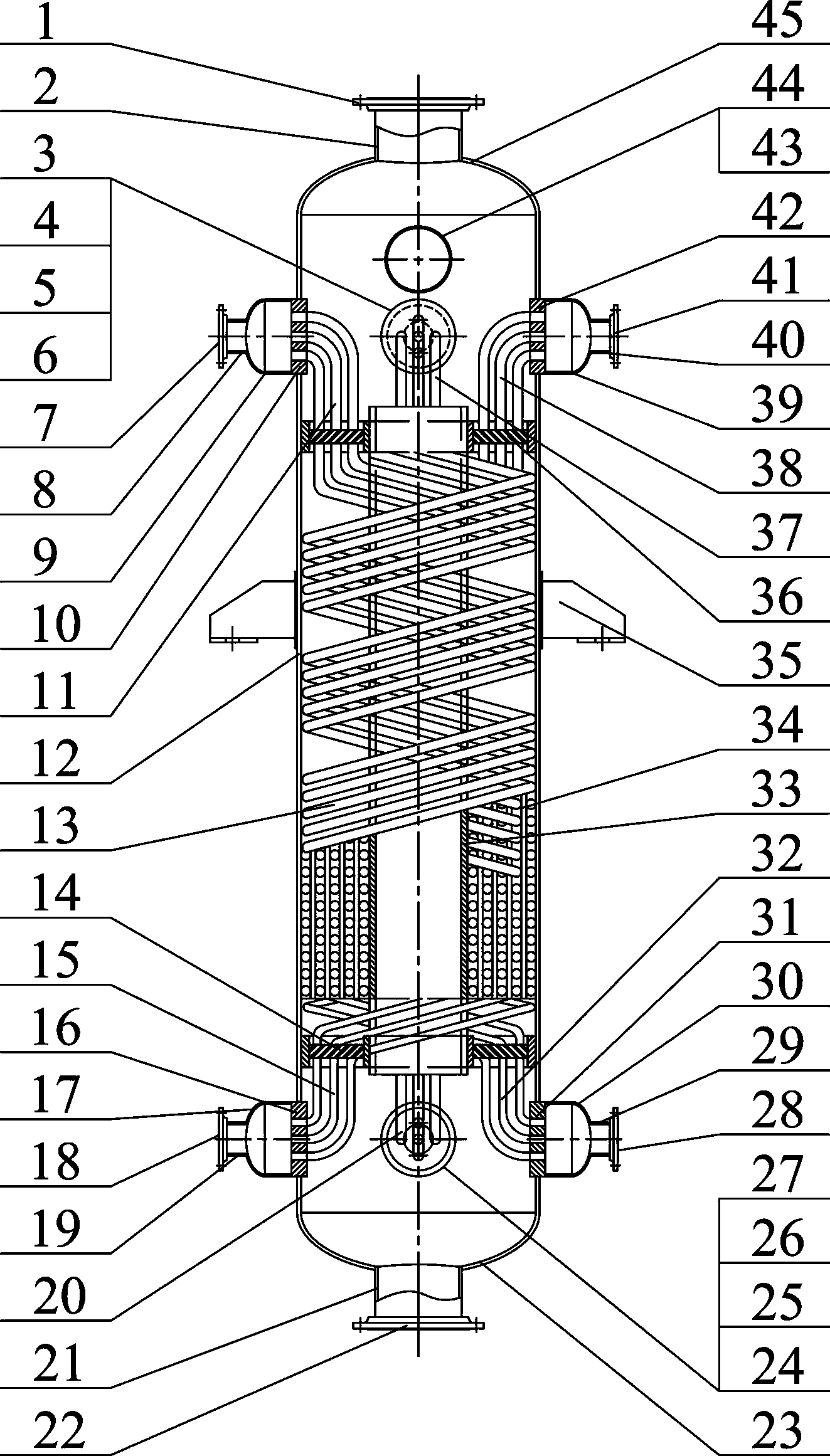

Three-stream spiral wound type heat exchange equipment for secondary refrigeration and low-temperature liquefaction of LNG (liquefied natural gas)

InactiveCN102538388BCompact structureLarge heat transfer temperature differenceSolidificationLiquefactionThree levelSpiral wound

Owner:张周卫

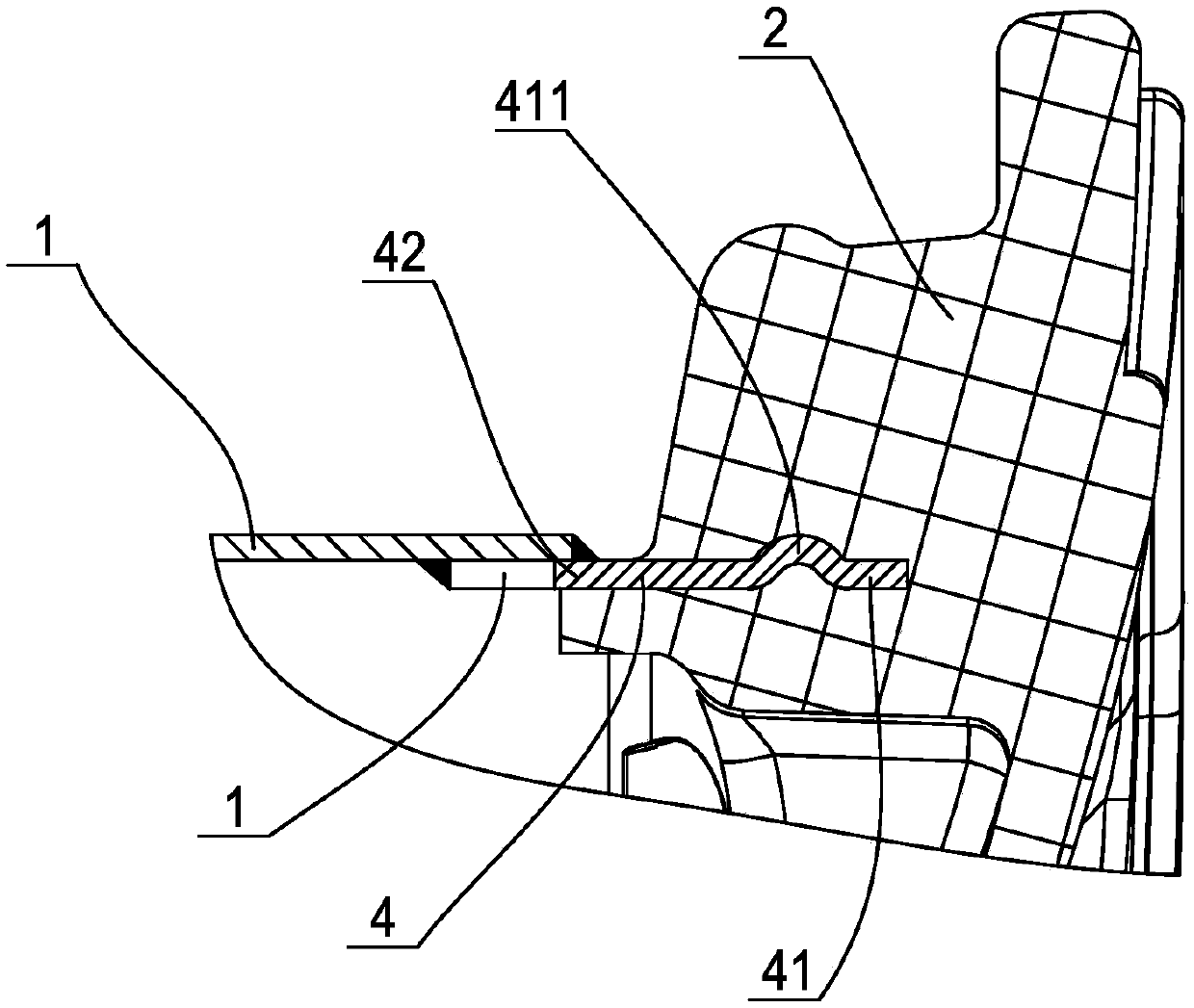

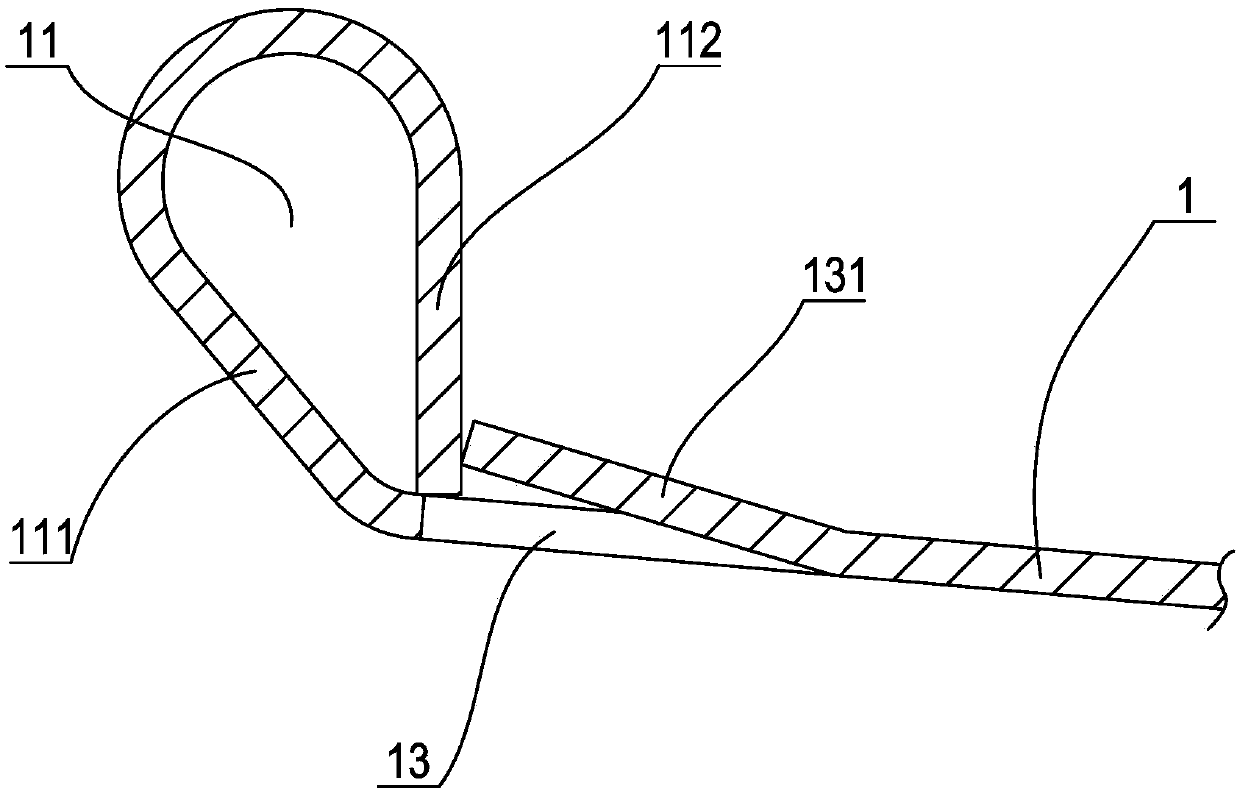

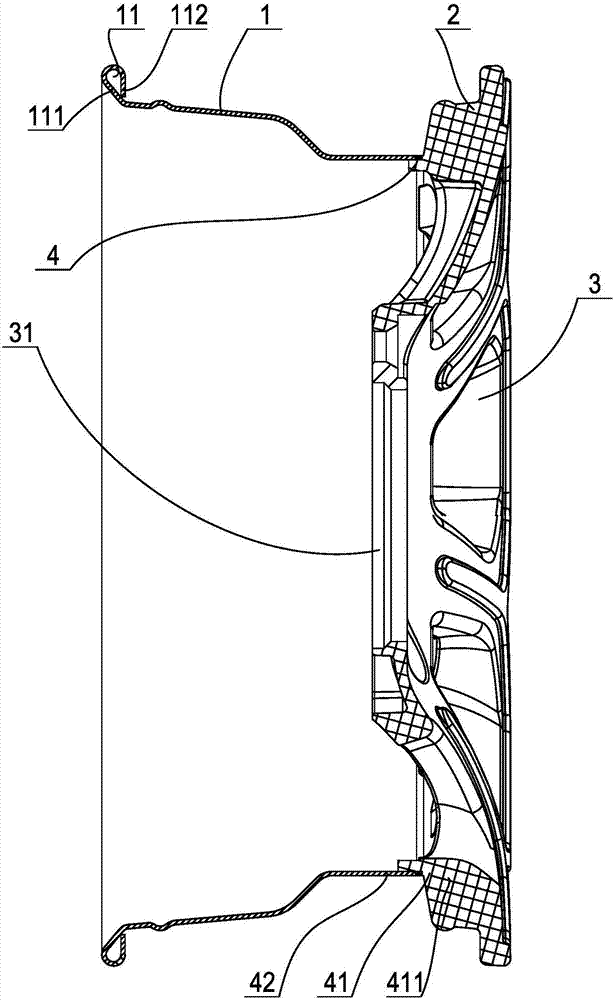

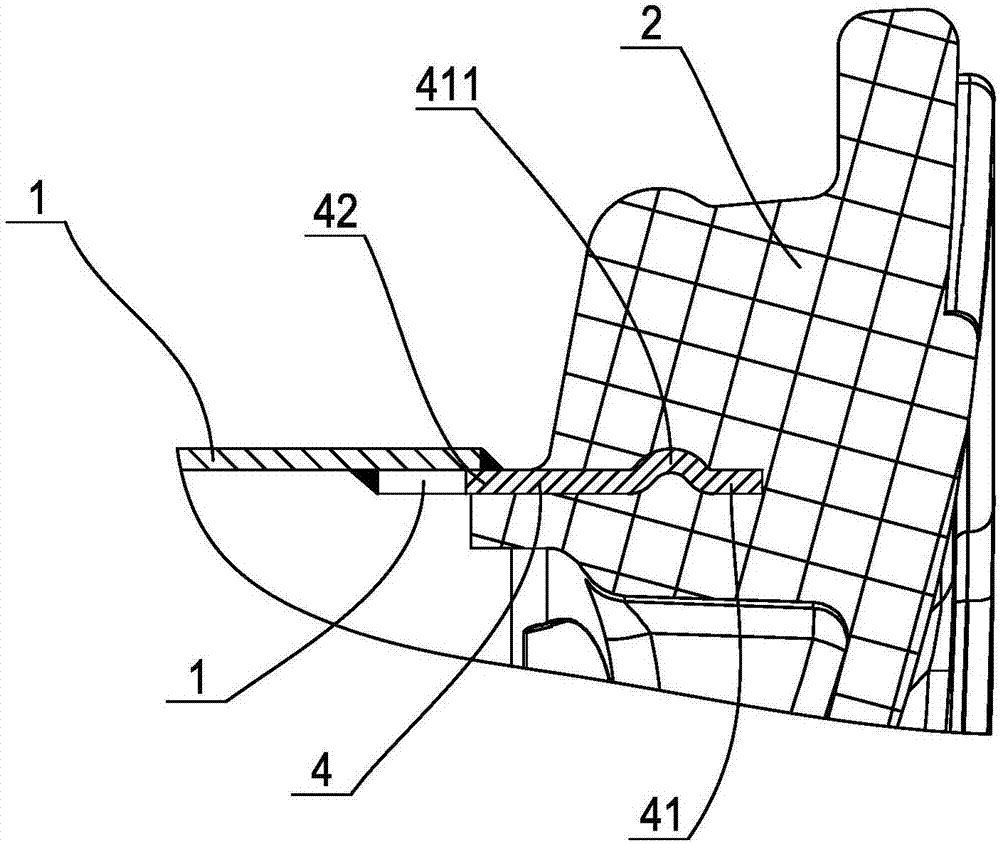

Composite aluminum rim and manufacturing method

ActiveCN107309607BShaping without addingEasy to processRimsWheel manufactureManufacturing cost reductionDie casting

The invention discloses a composite aluminum rim and a manufacturing method thereof. The composite aluminum rim comprises a left ring body molded by punching, a right ring body molded by die casting and a web plate; a connecting part molded by rolling is arranged in the right ring body; each of the two abutting ends of the connecting part is provided with a plurality of rectangular notches, and rectangular convex blocks adapted to the corresponding rectangular notches; a rectangular sawtooth is formed between every two adjacent rectangular notches; a rectangular groove is formed between every two adjacent rectangular convex blocks; the connecting part comprises an embedded section connected with the right ring body, and a welding section welded with the left ring body; when the right ring body and the web plate are subjected to die-casting molding, the connecting part is connected with a mould core of a die-casting molding mould in a sleeving manner, so that an adjustment gap is formed between the end of each rectangular convex block and the bottom of one corresponding rectangular notch, and an adjustment gap is formed between the end of each rectangular sawtooth and the bottom of one corresponding rectangular groove; and reinforced connecting blocks are formed in the adjustment gaps. With the adoption of the scheme, the intensity of the composite aluminum rim can be guaranteed, the production efficiency can be improved and thus the manufacturing cost is reduced, the quality grade of the composite aluminum rim can be raised effectively, and the composite aluminum rim meets the requirements of a high-quality vehicle.

Owner:台州市风驰车轮有限公司

Composite aluminum rim and manufacturing method thereof

ActiveCN107309607AShaping without addingEasy to processRimsWheel manufactureManufacturing cost reductionDie casting

The invention discloses a composite aluminum rim and a manufacturing method thereof. The composite aluminum rim comprises a left ring body molded by punching, a right ring body molded by die casting and a web plate; a connecting part molded by rolling is arranged in the right ring body; each of the two abutting ends of the connecting part is provided with a plurality of rectangular notches, and rectangular convex blocks adapted to the corresponding rectangular notches; a rectangular sawtooth is formed between every two adjacent rectangular notches; a rectangular groove is formed between every two adjacent rectangular convex blocks; the connecting part comprises an embedded section connected with the right ring body, and a welding section welded with the left ring body; when the right ring body and the web plate are subjected to die-casting molding, the connecting part is connected with a mould core of a die-casting molding mould in a sleeving manner, so that an adjustment gap is formed between the end of each rectangular convex block and the bottom of one corresponding rectangular notch, and an adjustment gap is formed between the end of each rectangular sawtooth and the bottom of one corresponding rectangular groove; and reinforced connecting blocks are formed in the adjustment gaps. With the adoption of the scheme, the intensity of the composite aluminum rim can be guaranteed, the production efficiency can be improved and thus the manufacturing cost is reduced, the quality grade of the composite aluminum rim can be raised effectively, and the composite aluminum rim meets the requirements of a high-quality vehicle.

Owner:台州市风驰车轮有限公司

A kind of phosphating steel wire processing technology

The invention discloses a phosphatized steel wire processing technology and belongs to the field of steel wire production. The technology solves the problem that the existing phosphatized steel wire production technology has a high processing cost, large patenting energy consumption and a high later maintenance cost. The technology comprises S1, arranging three cooling tanks connected orderly, S2, orderly putting a quenching solution A, air and a quenching solution B into the three cooling tanks and S3, orderly feeding steel wires output by a blast furnace into the three cooling tanks. The technology realizes a low production cost, has small energy consumption and realizes a low product later maintenance cost and environmental protection and health effects.

Owner:MAANSHAN FASTEN SCI & TECH CO LTD

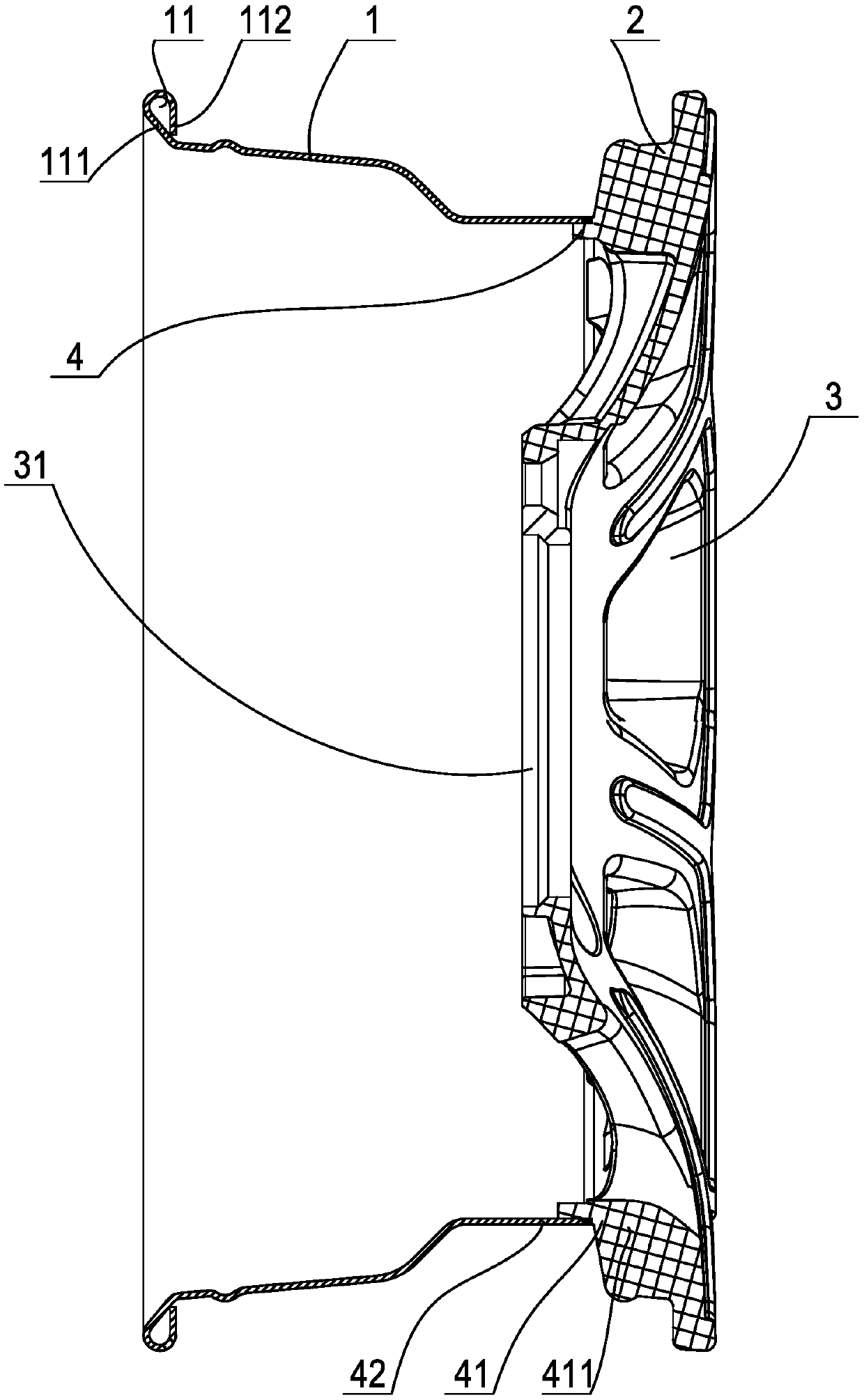

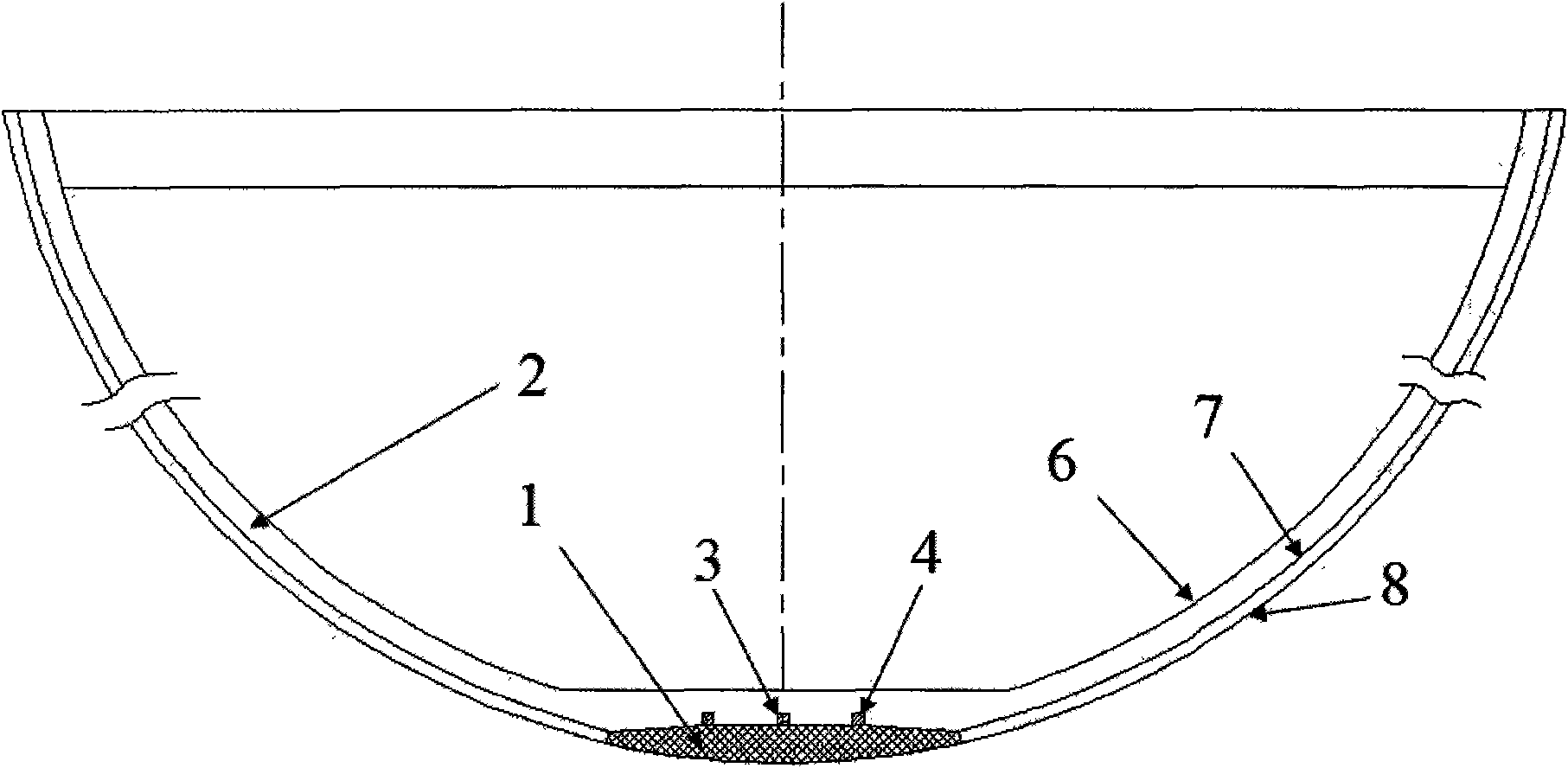

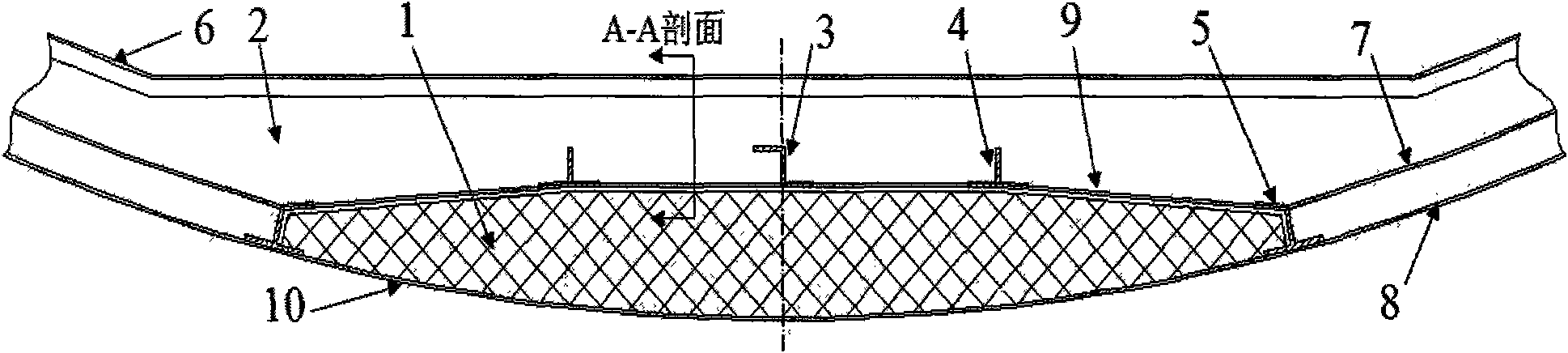

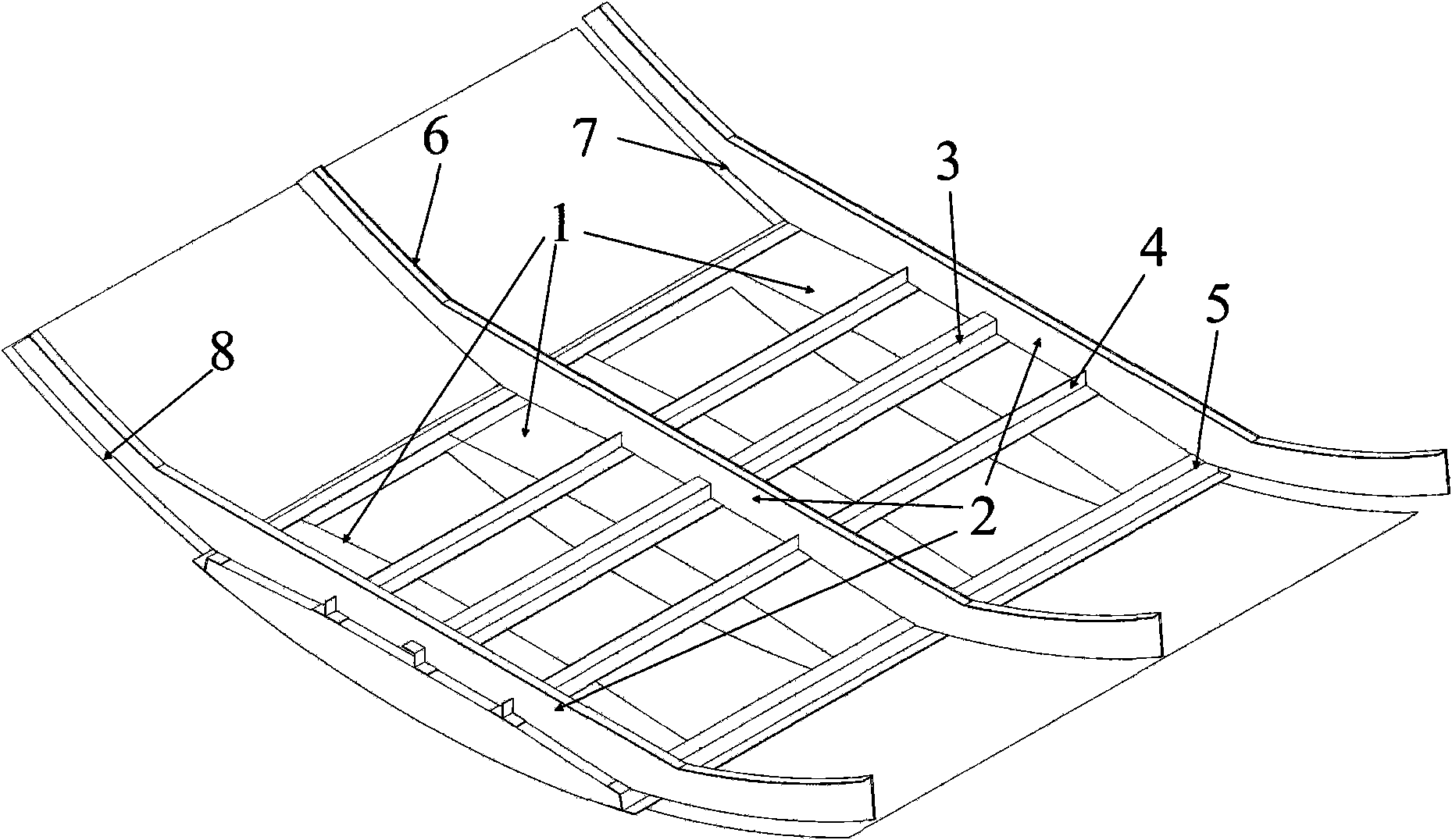

Civil aircraft fuselage bottom structure based on impact strength tests

The invention discloses a civil aircraft fuselage bottom structure considering impact strength, comprising bulkheads, outer panel skin, long purlins and foam; on the foundation of arc-shaped fuselage bulkheads, the contour of the fuselage remains unchanged, upper architraves and lower architraves of the bulkheads are hoisted upwards, the arc shape of the bulkhead bottom is changed to the flatbottom shape, the lower part of each bulkhead is symmetrically provided with a piece of foam, the ends at the two sides of the foam are provided with non-closed-angle-shaped structures in certain height, the lower part of the foam is supported by ventral outer panel skin, the top and sides of the foam adopt the outer panel skin for supporting, the two sides and the top of the foam are provided with long purlin structures which have the function of longitudinal reinforcement. The fuselage bottom foam structure of the invention can greatly improve the crash resistance of the fuselage structure, the new structure consisting of the outer panel skin and the foam contributes to bearing distributed load, as a result, the fuselage bottom structure of the invention not only has good crash resistance against ground crash but also has good crash resistance against water surface impact accidents.

Owner:BEIHANG UNIV

A foreign body removal claw under digestive endoscopy

The invention relates to a foreign matter withdrawing claw under a digestive endoscopy. The foreign matter withdrawing claw under a digestive endoscopy comprises a handle and a sheath, wherein the tail end of the handle is fixed to the near end of the sheath; guide wires are arranged in the sheath in a penetrating manner; a sliding rail is arranged on the handle; a ring for drawing back or pushingthe guide wires to move in the sheath is arranged on the sliding rail in a sliding manner, and is fixed to the near ends of the guide wires; the far end positions of the guide wires are connected with a capturing umbrella; the capturing umbrella is elastic hook claws on which the guide wires are uniformly arranged in the circumferential direction; the initial state of the hook claws in the sheathis that the hook backs face the guide wires; and under a relaxed state, the claw tips of the hook claws outside the sheath extend towards the guide wires, and the hook claws are propped at the claw tips. The foreign matter withdrawing claw under a digestive endoscopy disclosed by the invention has the beneficial effects that to foreign matters including polyps and the like which are far from an outlet of a natural cavity channel, under the situation that the foreign matters cannot be withdrawn or drawn out with a conventional apparatus through a plier channel, the foreign matter withdrawing claw under a digestive endoscopy can be used for attempting quick and safe withdrawing under the situation that endoscopy withdrawing is not or slightly performed.

Owner:SHANGHAI CHANGHAI HOSPITAL

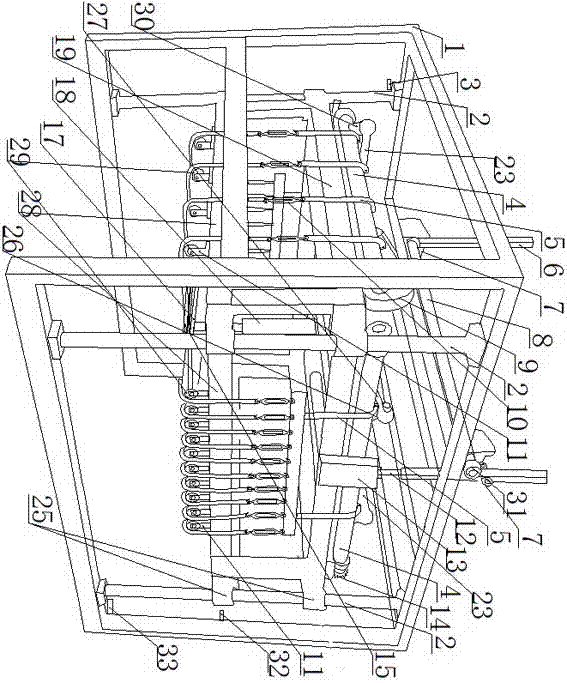

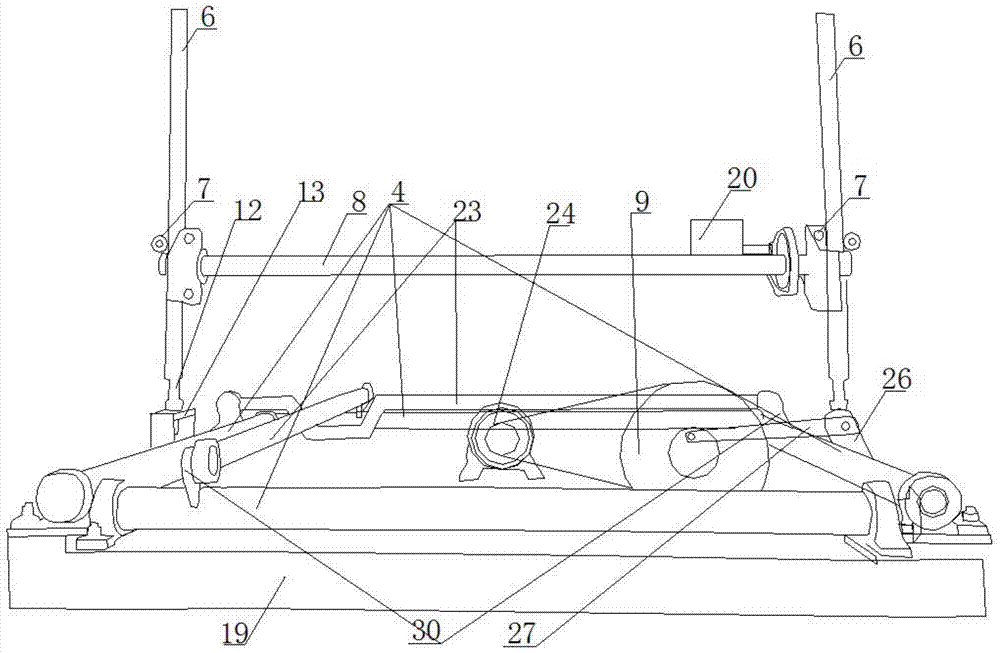

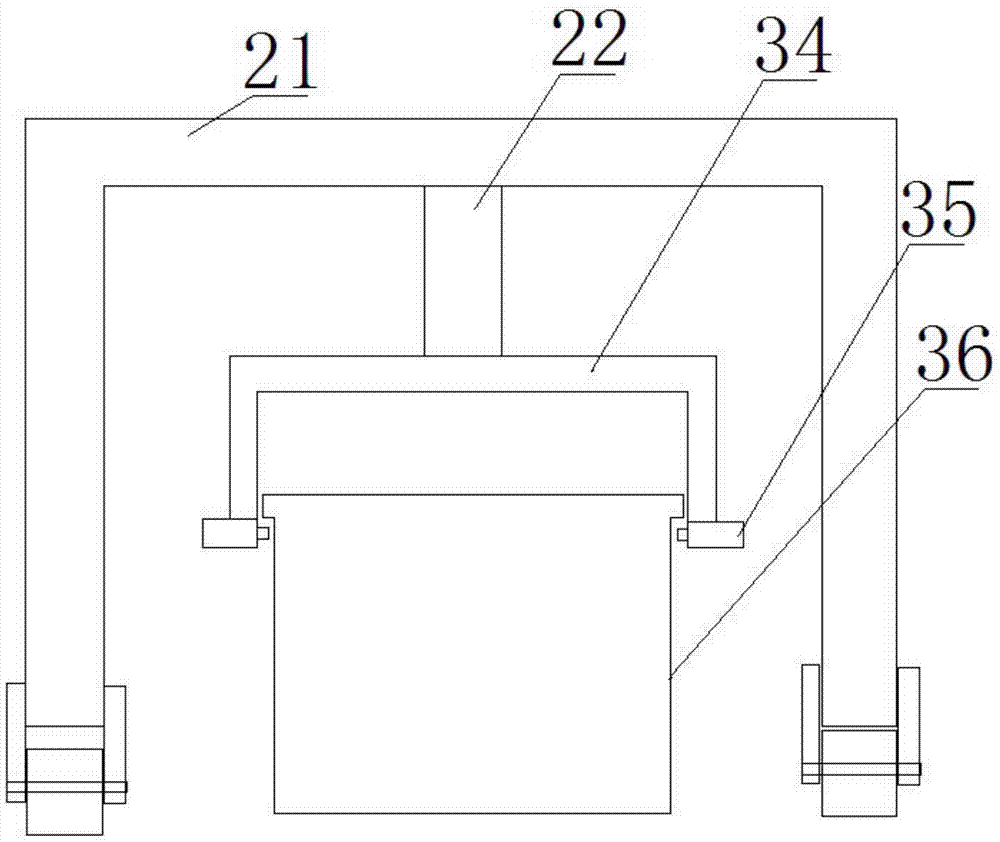

A kind of non-steaming foam concrete, block production method and special cutting equipment

ActiveCN104529311BGuaranteed decentralizationGuaranteed dispersion stabilityDischarging arrangementCement mixing apparatusFoam concreteFoaming agent

The invention discloses steaming-free foam concrete, a production method of steaming-free foam concrete building blocks and dedicated cutting equipment. The steaming-free foam concrete comprises, by weight, 150 parts to 400 parts of cement, 20 parts to 200 parts of mixed materials, 50 parts to 300 parts of water, 15 parts to 50 parts of regulators and five parts to 15 parts of foaming agents. The strength of the building blocks can be improved fast and is large, and above all, the heat preservation, heat insulation and water prevention performance is good, investment cost is low, production efficiency is high, and cutting efficiency is high.

Owner:河南华泰新材科技股份有限公司

Degradable master batch

The invention discloses a degradable master batch, which consists of the following components: 5%-75% of starch, 5%-50% of carbon dioxide polymer, 5%-30% of polyvinyl alcohol, 1%-10% of compatilizer and 1%-15% of plasticizer (all are based on weight percent). The device disclosed by the invention is nontoxic, harmless, clean and pollution-free, and has the advantages of low cost, simplicity in technique, complete degradation and excellent performance.

Owner:上海舟利包装材料有限公司

A kind of submerged heat slag dry-mixed mortar and its preparation method

The invention discloses dry-mixed mortar prepared from hot furnace slag and a preparation method of the dry-mixed mortar. The dry-mixed mortar comprises the following components in parts by mass: 200-750 parts of an inorganic cementitious material, 280-900 parts of medium sand, 500-1220 parts of hot furnace slag sand and 2-7.5 parts of an additive, wherein the inorganic cementitious material comprises the following components in percentage by mass: 50-65% of cement, 25-30% of hot furnace slag power, 5-10% of blast furnace slag fine powder and 5-10% of limestone fine powder; the additive is cellulose; the hot furnace slag is nickel ore smelting slag; after the hot furnace slag is sieved, the hot furnace slag with the particle sizes of 0.6-2.36 mm is the hot furnace slag sand. All the components are measured according to the formula, and then mixed and stirred to obtain the dry-mixed mortar. According to the preparation method, the process is simple; dry-mixed mortar with the grade of M5-M30 can be prepared; the rate of multipurpose utilization of the hot furnace slag can be remarkably increased; environmental pollution is reduced; social and economic benefits are obvious.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Polyurethane integrated plate produced by mold embedded with reclaimed material and production process thereof

InactiveCN102173024BRealize large-scale industrial productionAvoid the pitfalls of fragile machineryCovering/liningsClimate change adaptationInsulation layerHigh density

The invention discloses a production process for a polyurethane integrated plate by a mold embedded with a reclaimed material. The production process comprises the following steps of: separating the mold into a low-density decorative layer mold cavity and a high-density heat insulation layer mold cavity through a movable baffle, adding a decorative layer polyurethane material by using a foaming machine, and foaming and molding to form a polyurethane decorative layer; and curing, turning the mold, extracting the baffle, adding the polyurethane reclaimed material, adding a heat insulation layer polyurethane material into the mold by using the foaming machine, making the material infiltrate the reclaimed material and fully fused with the reclaimed material to coat the reclaimed material, and foaming on the surface of the molded decorative layer to form the polyurethane heat insulation layer. The production process solves the problem that the polyurethane reclaimed material cannot be utilized on a large scale, the production cost of a polyurethane decorative insulation board is greatly reduced, production procedures are reduced, the loss of production machines is reduced, and large-scale industrial production is realized.

Owner:鲁宁 +1

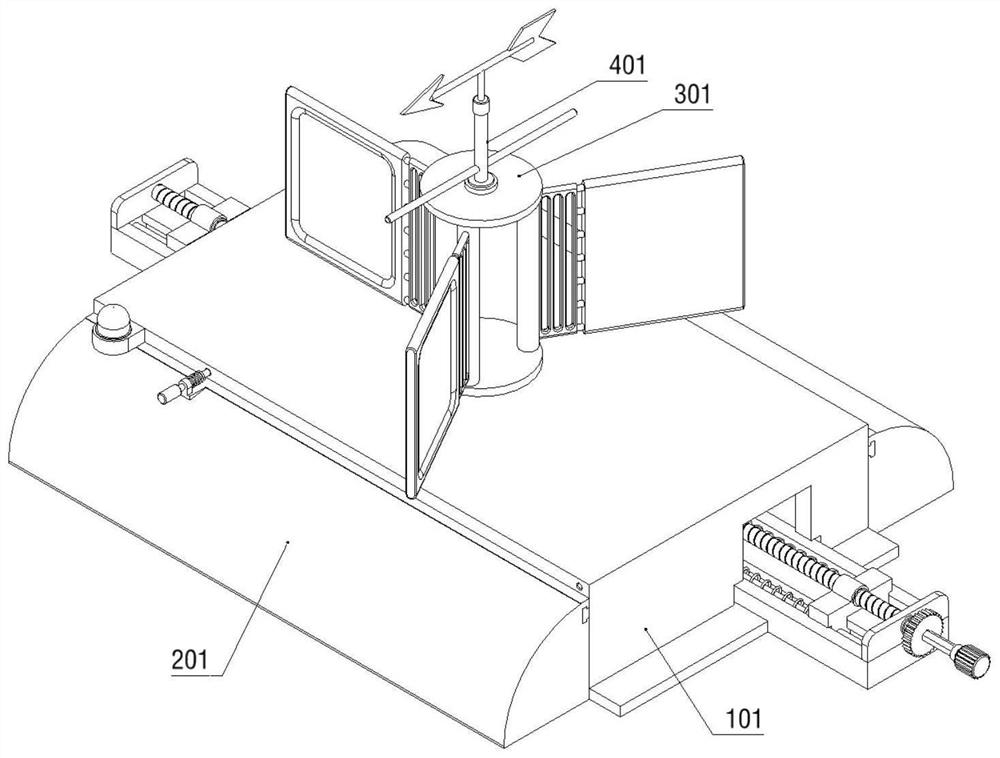

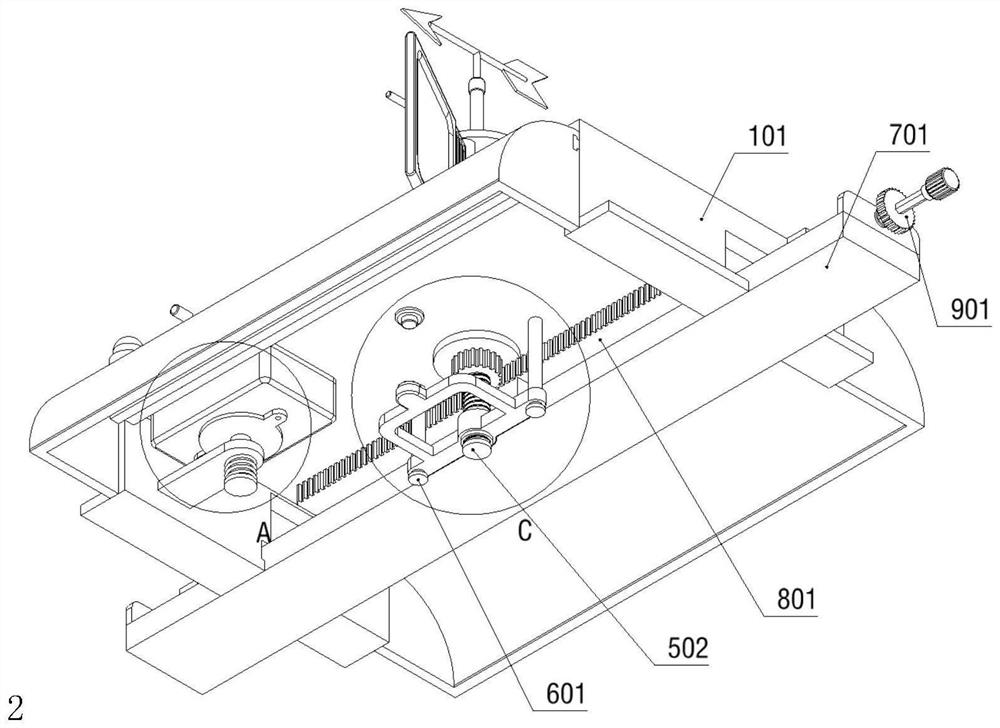

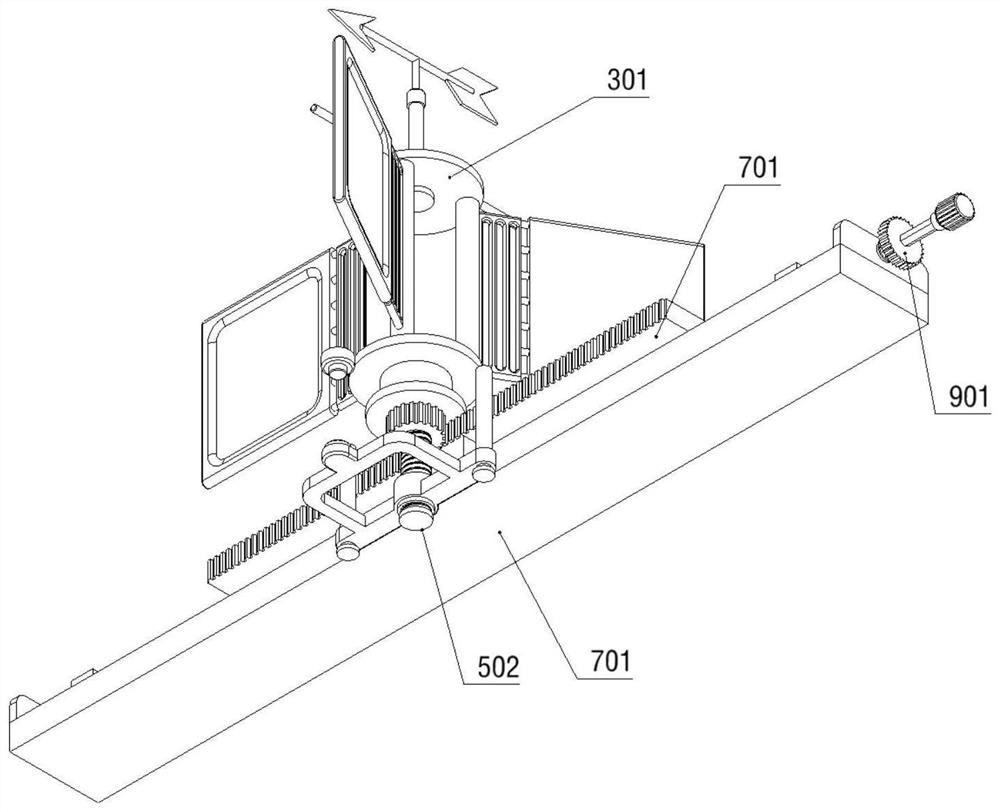

Wind power monitoring and controlling device for tower crane in constructional engineering

InactiveCN114314392AExtended service lifeEasy to observe the wind directionCranesVisual monitoringMarine engineering

The invention provides a construction engineering tower crane wind power monitoring control device, and relates to the technical field of construction safety, the construction engineering tower crane wind power monitoring control device comprises an installation control part, and the installation control part is slidably connected with two protection flow guiding devices; the mounting control part is rotationally connected with a wind power driving device; the wind power driving device is fixedly connected with a visual monitoring part; the bottom of the wind power driving device is fixedly connected with a lifting driving part; the lifting driving part is in threaded connection with a floating control part; the floating control part is mounted at the bottom of the mounting control part; the installation control part is fixedly connected with an adjusting installation part, real-time monitoring can be achieved, meanwhile, wind power alarm grading is adjustable, the service life is longer, wind direction observation is more convenient, the overall protection effect is better, and the problems that an existing wind power monitoring control device cannot rapidly achieve wind power alarm adjustment, wind power influences at different heights are not convenient to adjust, and the like are solved. The protection effect is poor, and the service life is shortened.

Owner:王先锋

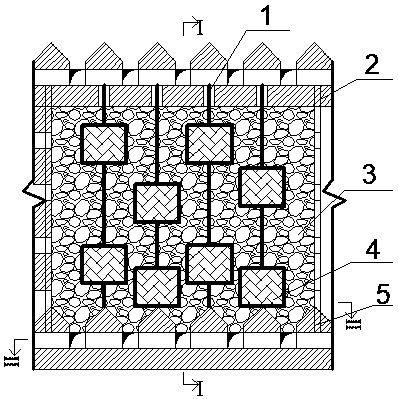

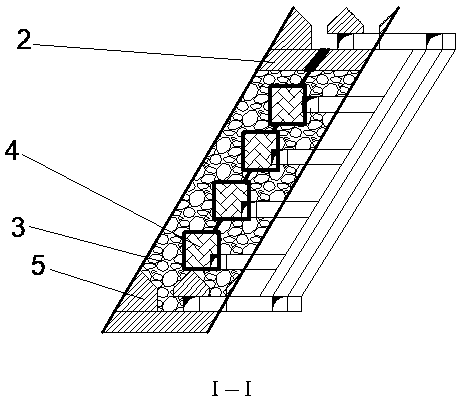

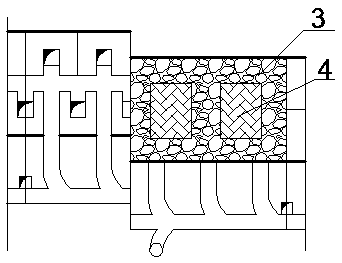

Truss-type filling method for underground mined-out area

InactiveCN110566269APrevent dangers such as falling rocksEnsure personal safetyMaterial fill-upSlurryEnvironmental geology

The invention discloses a truss-type filling method for an underground mined-out area. The truss-type filling method comprises the following steps that a, risks of falling rocks and wall caving of themined-out area are eliminated; b, drilling hole division in a plum blossom state mode is conducted on a mined-out area top plate (2); c, a drilling hole (1) with the diameter being 400 mm is drilledin the drilling hole position divided by the step b; e, a plurality of internal-tension rubber capsules (4) mutually communicating with the tails are lowered into the mined-out area through the drilling hole (1); d, the inner parts of the internal-tension rubber capsules (4) are filled with water; f, the mined-out area is filled with filling slurry with high cement-sand ratio; g, a filling body formed in the step f is maintained; and h, the internal-tension rubber capsules (4) are recycled. According to the truss-type filling method for the underground mined-out area, the problems that mine excavation limit of years is long, the mined-out area is large, a great deal of materials are required in filling, the mining cost is increased, and large financial burden is brought for mine enterprises can be avoided.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

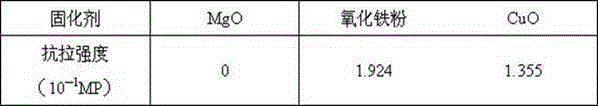

Bonding agent and preparing method thereof

InactiveCN106311960ASimple preparation processImprove reliabilityFoundry mouldsFoundry coresPhosphate loadingBrown iron oxide

The invention discloses a bonding agent. The bonding agent is a phosphate bonding agent and comprises, by weight percent, 60% to 63% of phosphate, 12% to 15% of iron oxide powder, 14% to 17% of polyvinyl alcohol and 8.5% to 9.5% of boron, wherein the comprehensive performance of the bonding agent with the weight percent of the phosphate being 62.5%, the weight percent of the iron oxide powder being 12.5%, the weight percent of the polyvinyl alcohol being 15.62%, and the weight percent of the boron being 9.38% is best. The bonding agent has the beneficial effects that compared with the prior art, the preparing technology is simple, reliability is high, on the basis of sufficiently utilizing the excellent characteristics of high strength, easy collapsibility, environment friendliness and no gas generation of the phosphate bonding agent, the moisture absorption defect of the phosphate is removed, and a thermal curing mold core sand system which is high in curing speed, good in humidity resistance and capable of meeting the casting technology in strength can be improved.

Owner:姚伟

Degradable starch-based plastic masterbatch and preparation method thereof

The invention relates to degradable starch-based plastic masterbatch and a preparation method thereof. The degradable starch-based plastic masterbatch is prepared from the following raw materials in part by weight: 40 to 70 parts of starch, 10 to 20 parts of light calcium carbonate, 2 to 10 parts of fine aggregate, 13 to 25 parts of plastic materials, 1 to 5 parts of compatilizer, 1 to 5 parts oflubricant, 1 to 5 parts of modifier and 1 to 5 parts of degradation promoter. The light calcium carbonate and the fine aggregate are added into the degradable starch-based plastic masterbatch, so that the use level of synthetic polymers is reduced greatly; and through the preparation under the reasonable process condition, the quality of products is improved, and the cost is reduced by 45 percenton the premise of ensuring the degradation effect.

Owner:孙彦升

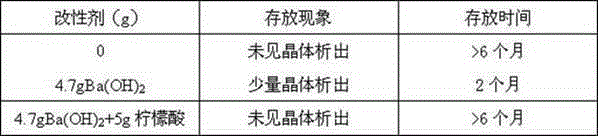

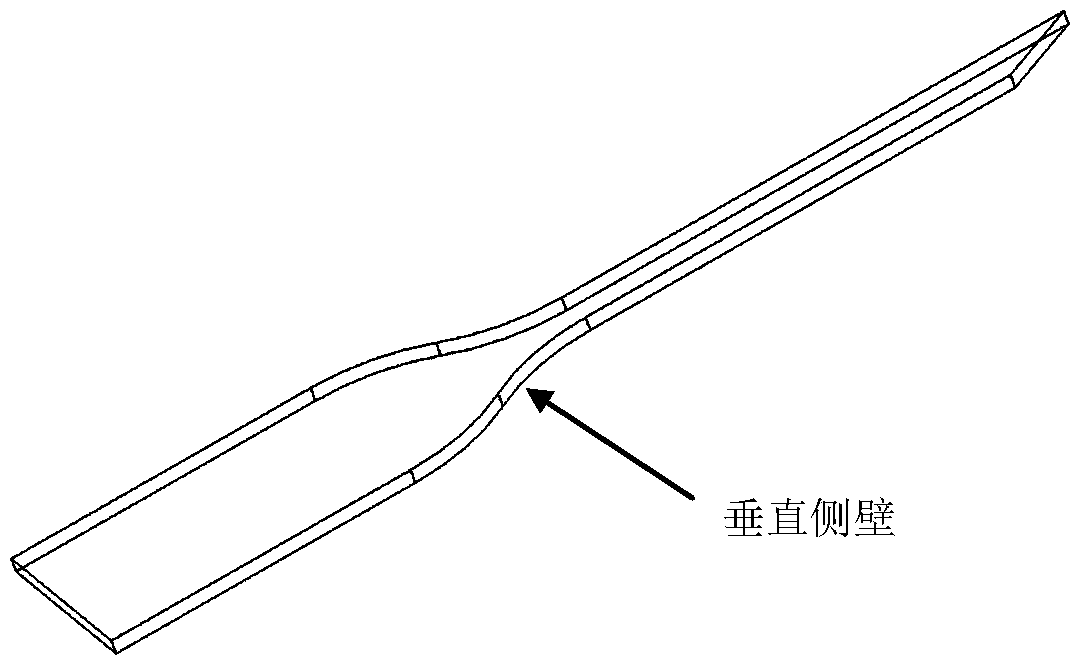

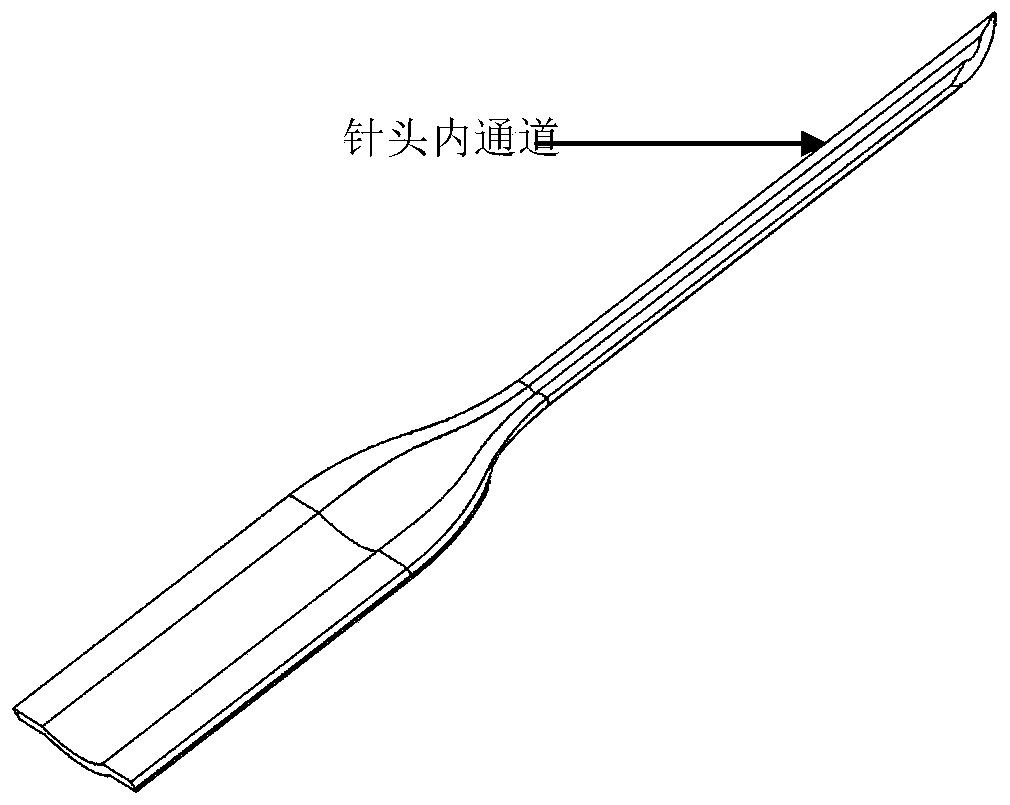

A kind of hollow metal microneedle and batch preparation method thereof

The invention provides a hollow metal microneedle and a batch preparation method thereof. The steps are: (1) sputtering a metal seed layer on a substrate as a conductive layer; (2) electroplating a metal layer on the conductive layer as a release layer; (3) (4) electroplating metal to fill the pattern, making the first layer of microneedles, and then sputtering the metal seed layer; (5) throwing the photoresist on the metal seed layer and patterning; (6) ) The patterned photoresist is properly baked; (7) The metal seed layer is sputtered; (8) The photoresist is thrown off and patterned, and the metal is electroplated to make the second layer of microneedles; (9) The glue is removed to release the microneedles. The present invention adopts the micro-machining technology, and overcomes the difficulty that the traditional injection needle production technology is difficult to manufacture extremely fine needles in batches.

Owner:SHANGHAI JIAO TONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com