Reinforced wear-resistant nylon 66 composite material and preparation method thereof

A composite material and nylon technology, applied in the field of enhanced wear-resistant nylon 66 composite material and its preparation, can solve the problems of high glass fiber wear-resistant agent addition, increased composite material density, poor interface force, etc., and achieve good mechanical properties , Improve compatibility, good dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

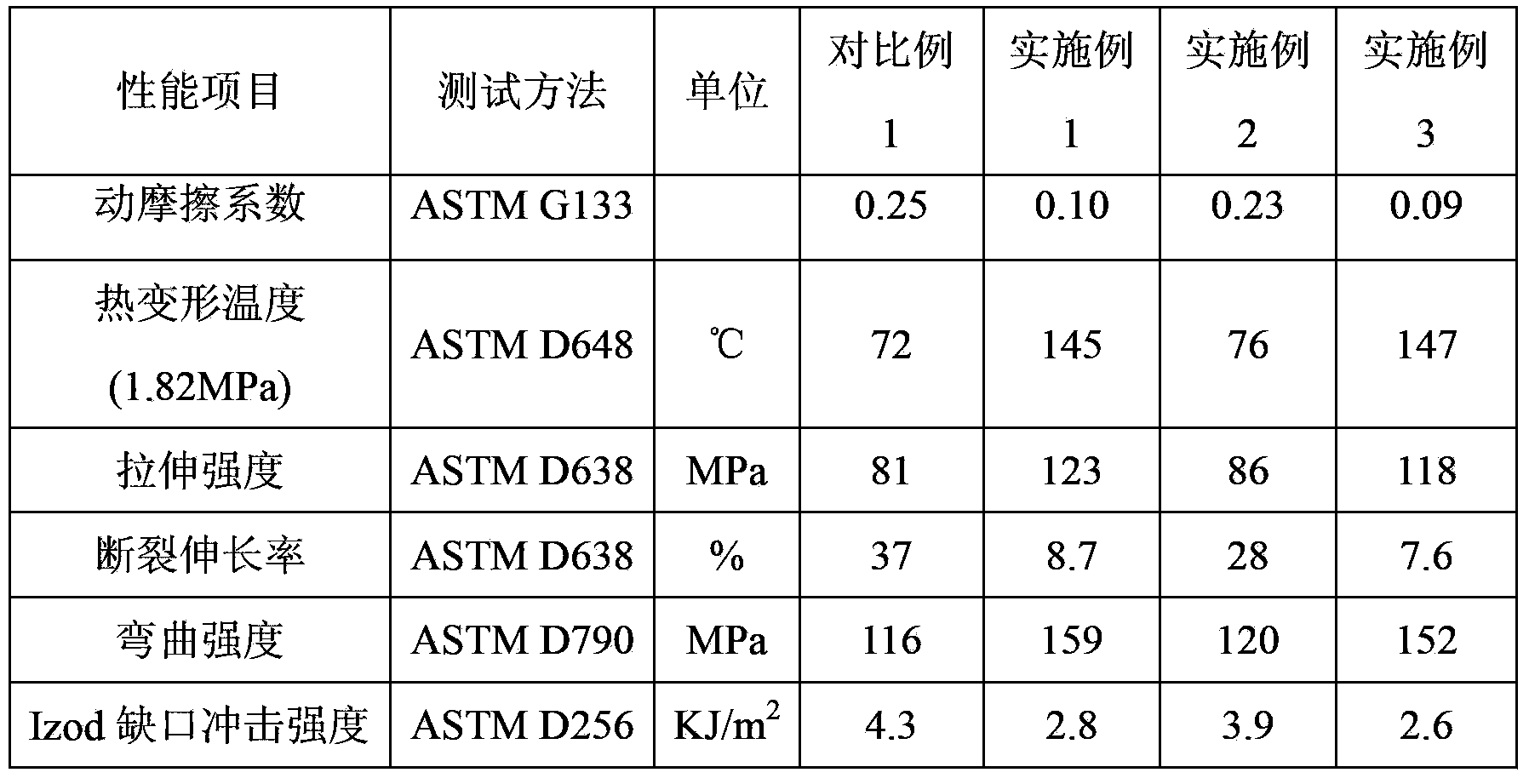

Examples

Embodiment 1

[0030] 1) Weigh 100 parts by weight of nylon 66 salt, 8 parts by weight of aramid fiber 1414 pulp with a length of 0.5-1.5mm and a water content of 5%-12%, 0.5 parts by weight of acetic acid, and mix the above Components are added to the autoclave;

[0031] 2) Weigh 50 parts by weight of deionized water and 0.1 parts by weight of nano-titanium dioxide and dissolve them in deionized water to prepare a solution. Stir the prepared solution under ultrasound for 1-2 hours, and then add it to the high pressure In the reactor;

[0032] 3) Replace the air in the high-pressure reactor with nitrogen for at least three times, and then pass in nitrogen as a reaction protection gas; keep the pressure at 1.7MPa and 230°C for 2 hours, then release the pressure to normal pressure, and raise the temperature at the same time , the temperature does not exceed 280°C, react at normal pressure for 30 minutes, and vacuumize for 30 minutes, discharge and pelletize.

Embodiment 2

[0034] 1) Weigh 100 parts by weight of nylon 66 salt, 1 part by weight of aramid fiber 1414 pulp with a length of 0.5-1.5mm and a water content of 5%-12%, 0.1 parts by weight of acetic acid, and mix the above Components are added to the autoclave;

[0035] 2) Weigh 30 parts by weight of deionized water and 0.02 parts by weight of nano-titanium dioxide and dissolve them in deionized water to prepare a solution. Stir the prepared solution under ultrasound for 1-2 hours, and then add it to the high pressure In the reactor;

[0036] 3) Replace the air in the high-pressure reactor with nitrogen for at least three times, and then pass in nitrogen as a reaction protection gas; keep the pressure at 1.5MPa and 210°C for 2 hours, then release the pressure to normal pressure, and raise the temperature at the same time , the temperature does not exceed 280°C, react at normal pressure for 30 minutes, and vacuumize for 30 minutes, discharge and pelletize.

Embodiment 3

[0038] 1) Weigh 100 parts by weight of nylon 66 salt, 10 parts by weight of aramid fiber 1414 pulp with a length of 0.5-1.5 mm and a water content of 5%-12%, and 1 part by weight of acetic acid, and mix the above Components are added to the autoclave;

[0039] 2) Weigh 60 parts by weight of deionized water and 0.3 parts by weight of nano-titanium dioxide and dissolve them in deionized water to prepare a solution. Stir the prepared solution under ultrasound for 1-2 hours, and then add it to the high pressure In the reactor;

[0040] 3) Replace the air in the high-pressure reactor with nitrogen for at least three times, and then pass in nitrogen as a reaction protection gas; keep the pressure at 1.8MPa and 240°C for 3 hours, then release the pressure to normal pressure, and raise the temperature at the same time , the temperature does not exceed 280°C, react at normal pressure for 30 minutes, and vacuumize for 30 minutes, discharge and pelletize.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com