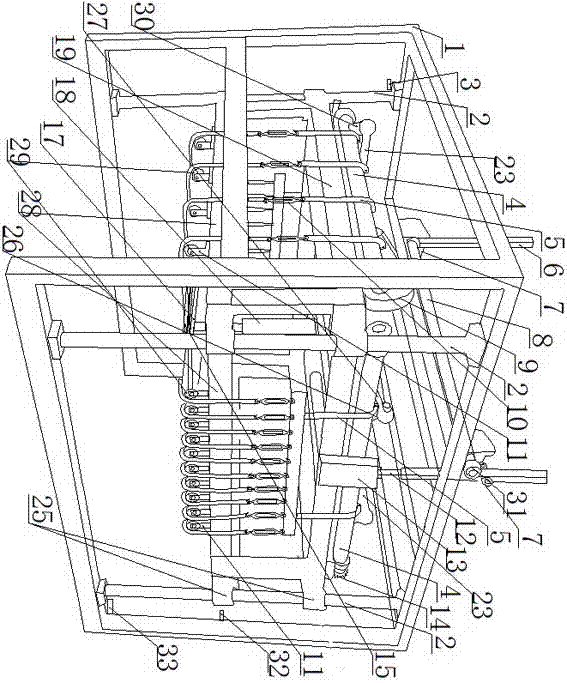

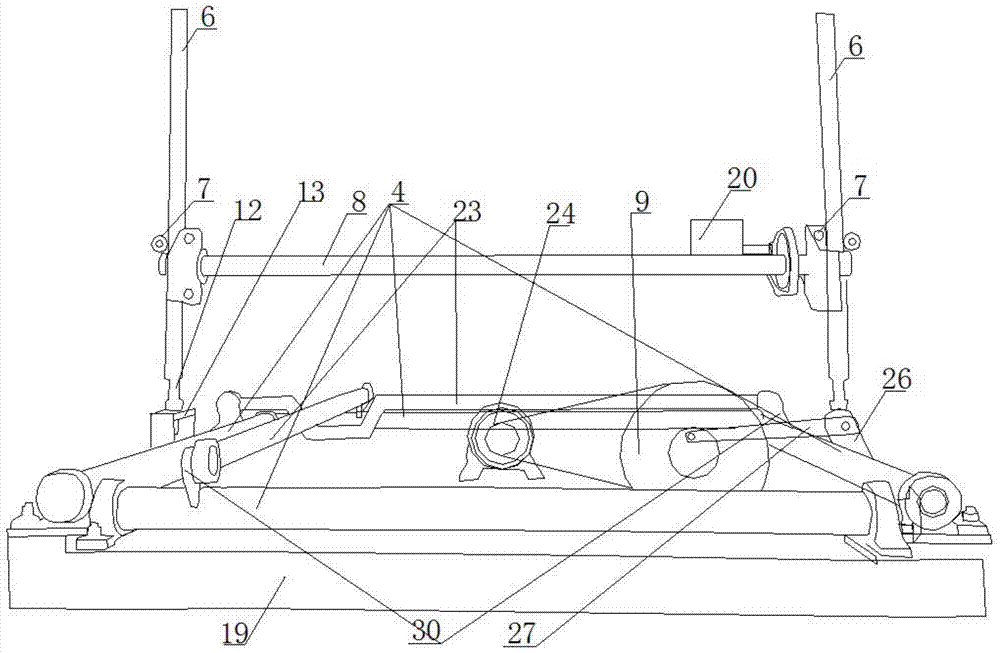

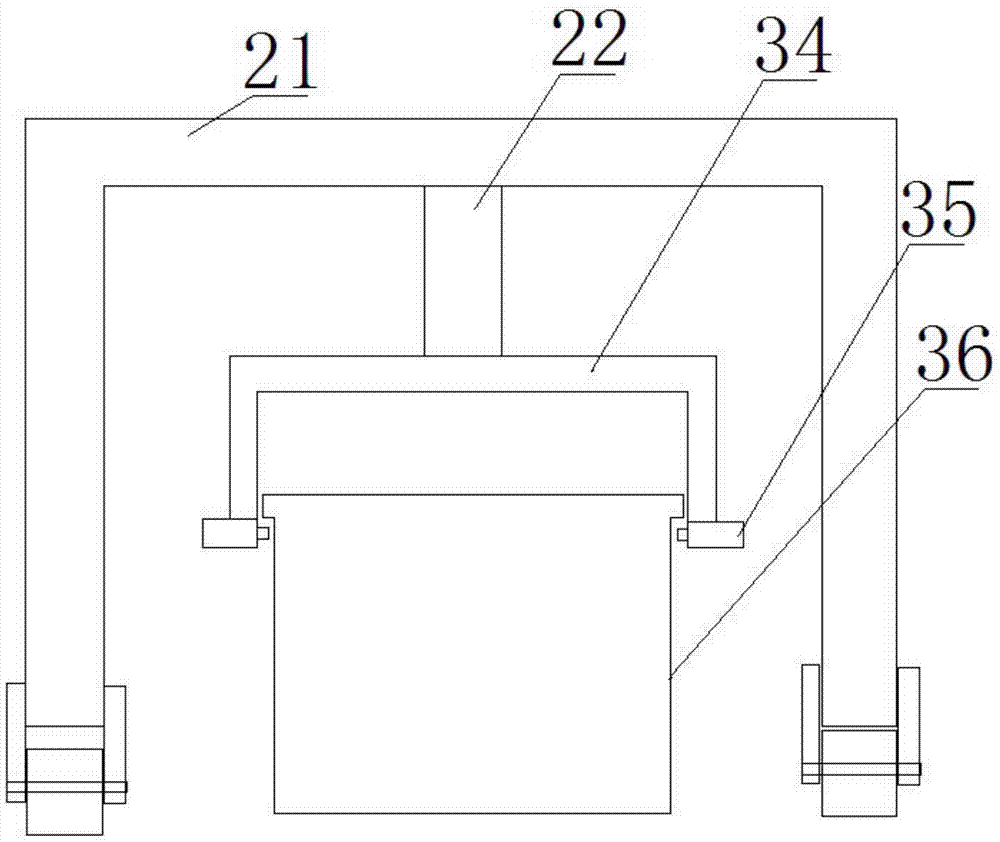

A kind of non-steaming foam concrete, block production method and special cutting equipment

A foamed concrete and cutting equipment technology, which is applied to clay preparation devices, chemical instruments and methods, applications, etc., can solve the problems of insufficient strength, delayed cement hydration, and inability to dismantle the formwork, so as to increase the hardness and thermal insulation performance, improve the Strength and durability, effect of ensuring dispersion stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] A pumping chemical foaming foam concrete, comprising the following components by weight: cement: 150 parts, granulated blast furnace slag: 20 parts, water: 80 parts, water reducing agent: 10 parts, rubber powder: 5 parts, hair Foaming agent: 5 parts.

Embodiment 2

[0055] A pumping chemical foaming foam concrete, comprising the following components by weight: cement: 400 parts, granulated blast furnace slag: 200 parts, water: 300 parts, water reducing agent: 30 parts, rubber powder 20 parts, foaming Dosage: 15 parts.

Embodiment 3

[0057] A pumped chemical foaming foam concrete, comprising the following components by weight: cement: 250 parts, granulated blast furnace slag: 100 parts, water: 250 parts, water reducing agent: 20 parts, rubber powder: 15 parts, hair Foaming agent: 10 parts.

[0058] A method for producing steam-free foamed concrete blocks, comprising the following process steps:

[0059] a. Block making:

[0060] 1. Cement and sand fall into the silo of the slurry mixer, carry out dry mixing, stir for 1-3 minutes, open the butterfly valve of the water weighing hopper, start to discharge water, and add other materials of foam concrete to the metering silo through the feeder Within 1-3 minutes, continue to stir;

[0061] 2. Start the solenoid valve switch, put the raw materials into the slurry mixer to stir the slurry, close the metering bin, and at the same time, the feeder continues to load and enter the metering bin;

[0062] 3. After the slurry is uniform, the solenoid valve switch is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com