Method for customizing core and shell of integrated ceramic mold of hollow turbine blade

A technology for turbine blades and ceramic castings, which is applied in the directions of castings, cores, and casting components, and can solve the problems of air-film hole diameter reduction, eccentric core perforation defects, installation errors, etc., so as to improve porosity and improve sintering. the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] The method for customizing the core shell of the hollow turbine blade integrated ceramic mold includes the following steps:

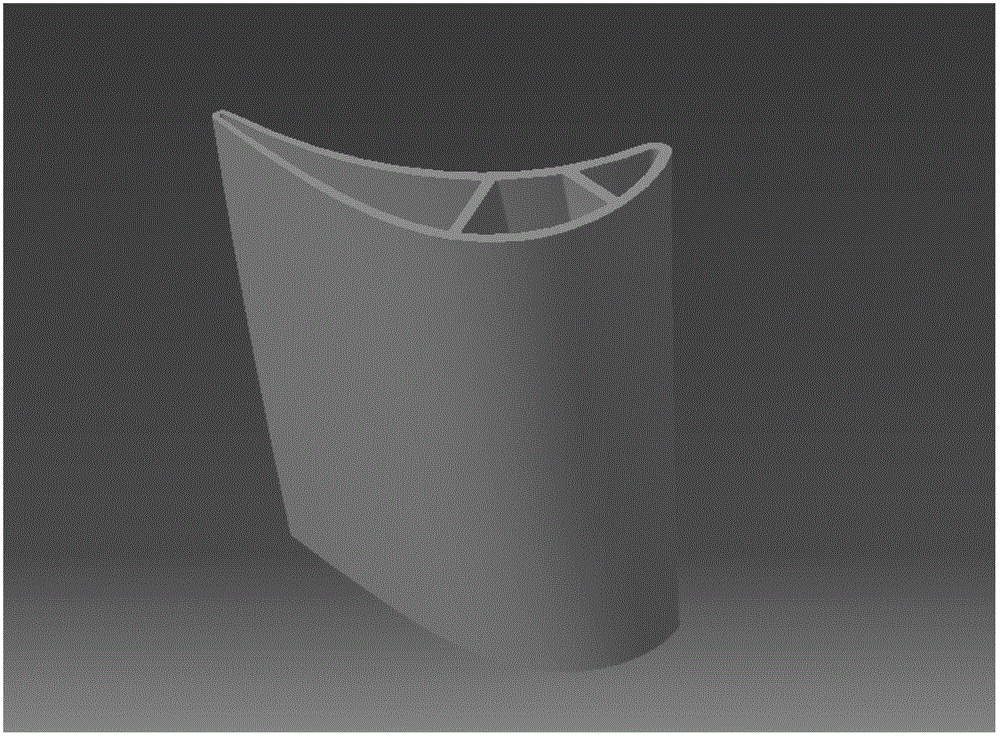

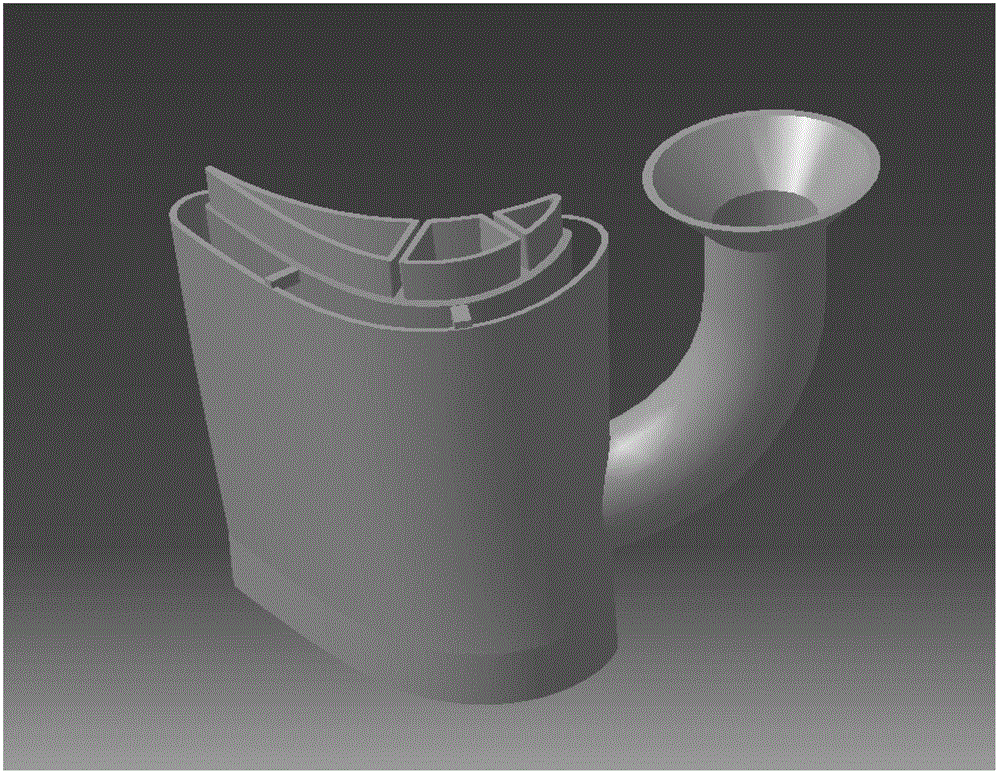

[0059] 1) The hollow turbine blade resin mold is made by light-curing rapid prototyping equipment, and the resin used for molding is 8981 resin. The resin mold is designed with 4 gates, one of which is used to pour the shell, and 3 are used to pour the core, the prototype of the light-cured blade (simplified) and the CAD model of the resin mold are as follows figure 1 , figure 2 shown.

[0060] 2) Based on the gel injection molding process, making ceramic slurry:

[0061] First, dissolve the organic monomer AM (acrylamide) and the cross-linking agent MBAM (N,N′-methylenebisacrylamide) into deionized water according to the mass ratio of 24:1, and then add an appropriate amount of dispersant (the dispersant is added The amount is 2% of the mass of the powder), stirred and dissolved, and prepared into a premixed solution with an organic concentr...

Embodiment 2

[0072] The method for customizing the core shell of the hollow turbine blade integrated ceramic mold includes the following steps:

[0073] 1) The hollow turbine blade resin mold is made by light-curing rapid prototyping equipment, and the resin used for molding is 8981 resin. The resin mold is designed with 4 gates, one of which is used for pouring the shell, and the other 3 are used for pouring the core.

[0074] 2) Based on the gel injection molding process, making ceramic slurry:

[0075] First, dissolve the organic monomer AM (acrylamide) and the cross-linking agent MBAM (N,N′-methylenebisacrylamide) into deionized water according to the mass ratio of 24:1, and then add an appropriate amount of dispersant (the dispersant is added The amount is 2% of the mass of the powder), stirred and dissolved, and prepared into a premix with an organic concentration of 20%.

[0076] 2) Weigh powder 1 and powder 2 according to a certain ratio, and stir and mix the powder in the contai...

Embodiment 3

[0085] The method for customizing the core shell of the hollow turbine blade integrated ceramic mold includes the following steps:

[0086] 1) The hollow turbine blade resin mold is made by light-curing rapid prototyping equipment, and the resin used for molding is 8981 resin. The resin mold is designed with 2 gates, one for pouring the shell and one for pouring the core.

[0087] 2) Based on the gel injection molding process, making ceramic slurry:

[0088] First, dissolve the organic monomer AM (acrylamide) and the cross-linking agent MBAM (N,N′-methylenebisacrylamide) into deionized water according to the mass ratio of 24:1, and then add an appropriate amount of dispersant (the dispersant is added The amount is 2% of the mass of the powder), stirred and dissolved, and prepared into a premix with an organic concentration of 20%.

[0089] 2) Weigh powder 1 and powder 2 according to a certain ratio, and stir and mix the powder in the container evenly;

[0090] In parts by m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com