Core sand mixing process, heated core box core-making process and sand core prepared therefrom

A hot core box and mixing technology is applied in the core sand mixing process, the hot core box core making process and the field of the sand core prepared, which can solve the problems of large mold wear, etc., and achieves a small amount of resin, good collapsibility, The effect of reducing casting costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

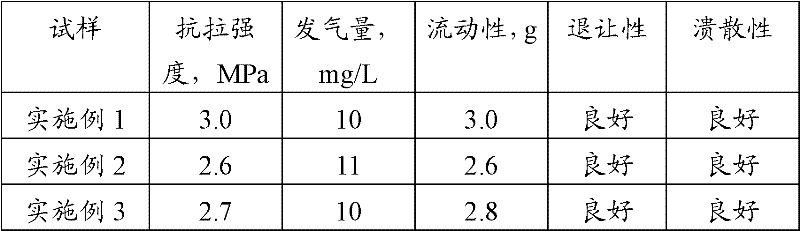

Embodiment 1

[0036] 1) Take ceramic sand and calcined sand and mix them evenly in a sand mixer according to the mass ratio of 4:6. The ceramic sand is produced by Mihe Hongda White Cement Factory in Gongyi City, the model is AFS, and the calcined sand is Chengde Xucheng modeling material. Ltd. production.

[0037] Aqueous solution of urotropine is added to the mixture of ceramic sand and calcined sand. The preparation method of aqueous solution of urotropine is to put urotropine into water at about 50 DEG C to form a supersaturated solution. Then add 301 phenolic resins produced by Changle Hengchang Chemical Co., Ltd. and mix evenly. The quality of 301 phenolic resins is 2.0% of the total mass of ceramic sand and calcined sand. The quality of urotropine in the urotropine aqueous solution is 301 phenolic resins. 22% of resin mass.

[0038] 2) Use the MRB40 core shooter of Suzhou Mingzhi Foundry Equipment Co., Ltd. to set the mixed core sand into shape, and then heat and solidify. The sand ...

Embodiment 2

[0042] 1) Take ceramic sand and calcined sand and mix them evenly in a sand mixer according to the mass ratio of 5:5. The ceramic sand is produced by Mihe Hongda White Cement Factory in Gongyi City, the model is AFS, and the calcined sand is Chengde Xucheng modeling material. Ltd. production.

[0043]Add YCG 103 sulfonic acid curing agent produced by Zhucheng Yongchuang Foundry Material Co., Ltd. to the mixture of ceramic sand and calcined sand, then add YC600 furan resin produced by Zhucheng Yongchuang Foundry Material Co., Ltd. and mix evenly. The quality of YC600 furan resin is The total mass of ceramic sand and calcined sand is 2.2%, and the mass of YCG-103 sulfonic acid curing agent is 25% of the mass of YC600 furan resin.

[0044] 2) Use the MRB40 core shooter of Suzhou Mingzhi Foundry Equipment Co., Ltd. to set the mixed core sand into shape, and then heat and cure it. The sand shooting pressure is 0.5Mpa, the holding temperature is 250°C, and the mold is released after...

Embodiment 3

[0048] 1) Take ceramic sand and calcined sand and mix them evenly in a sand mixer according to the mass ratio of 6:4. The ceramic sand is produced by Mihe Hongda White Cement Factory in Gongyi City, the model is AFS, and the calcined sand is Chengde Xucheng modeling material. Ltd. production.

[0049] Add HTW-208 amine curing agent produced by Suzhou Shengjie Special Resin Co., Ltd. to the mixture of ceramic sand and calcined sand, and then add HTW-608 epoxy resin produced by Suzhou Shengjie Special Resin Co., Ltd. and mix evenly. HTW- The mass of 608 epoxy resin is 2.5% of the total mass of ceramic sand and calcined sand, and the mass of HTW-208 amine curing agent is 28% of the mass of HTW-608 epoxy resin.

[0050] 2) Use the MRB40 core shooter of Suzhou Mingzhi Foundry Equipment Co., Ltd. to set the mixed core sand into shape, and then heat and solidify. The sand shooting pressure is 0.4Mpa, the holding temperature is 240°C, and the mold is released after curing for 120s.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flame retardant | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| angle factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com