Feeding device in steel processing device

A technology for processing equipment and steel, applied in the field of machinery, can solve the problems such as the inability of the roller shaft to work continuously, the low utilization rate of the roller table, and the low processing efficiency, and achieve the effect of saving operation time, improving processing efficiency and sufficient operation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

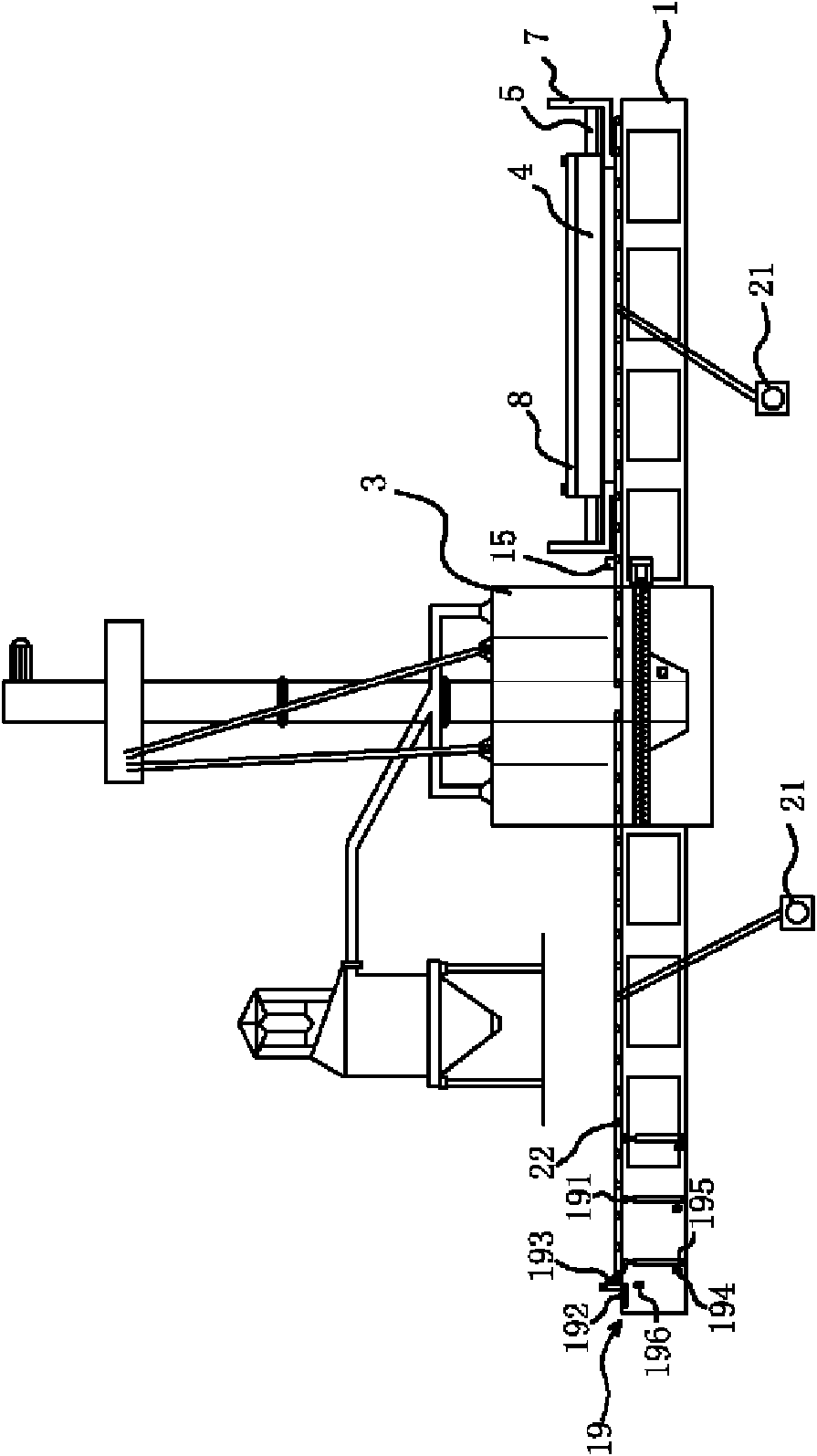

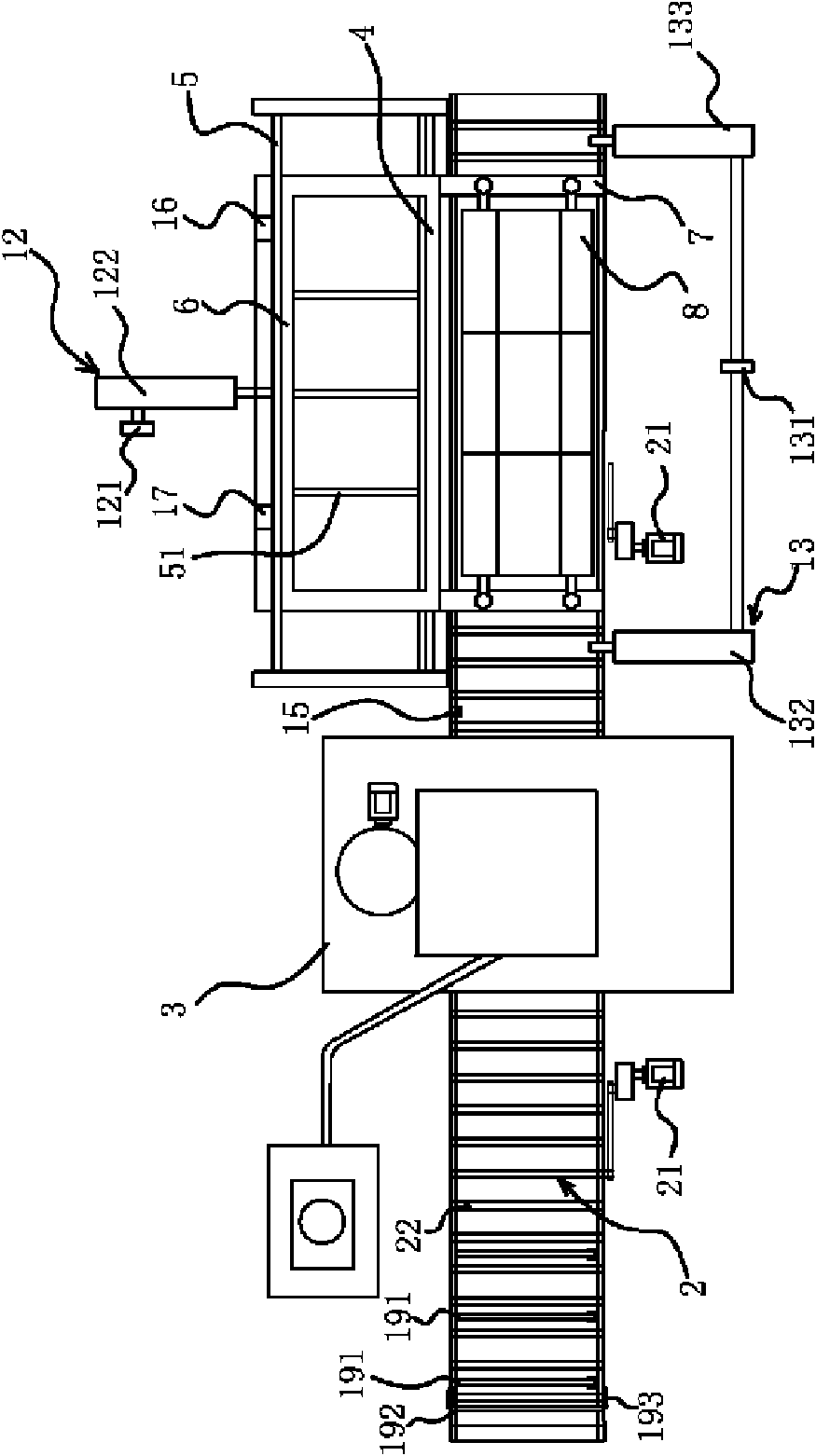

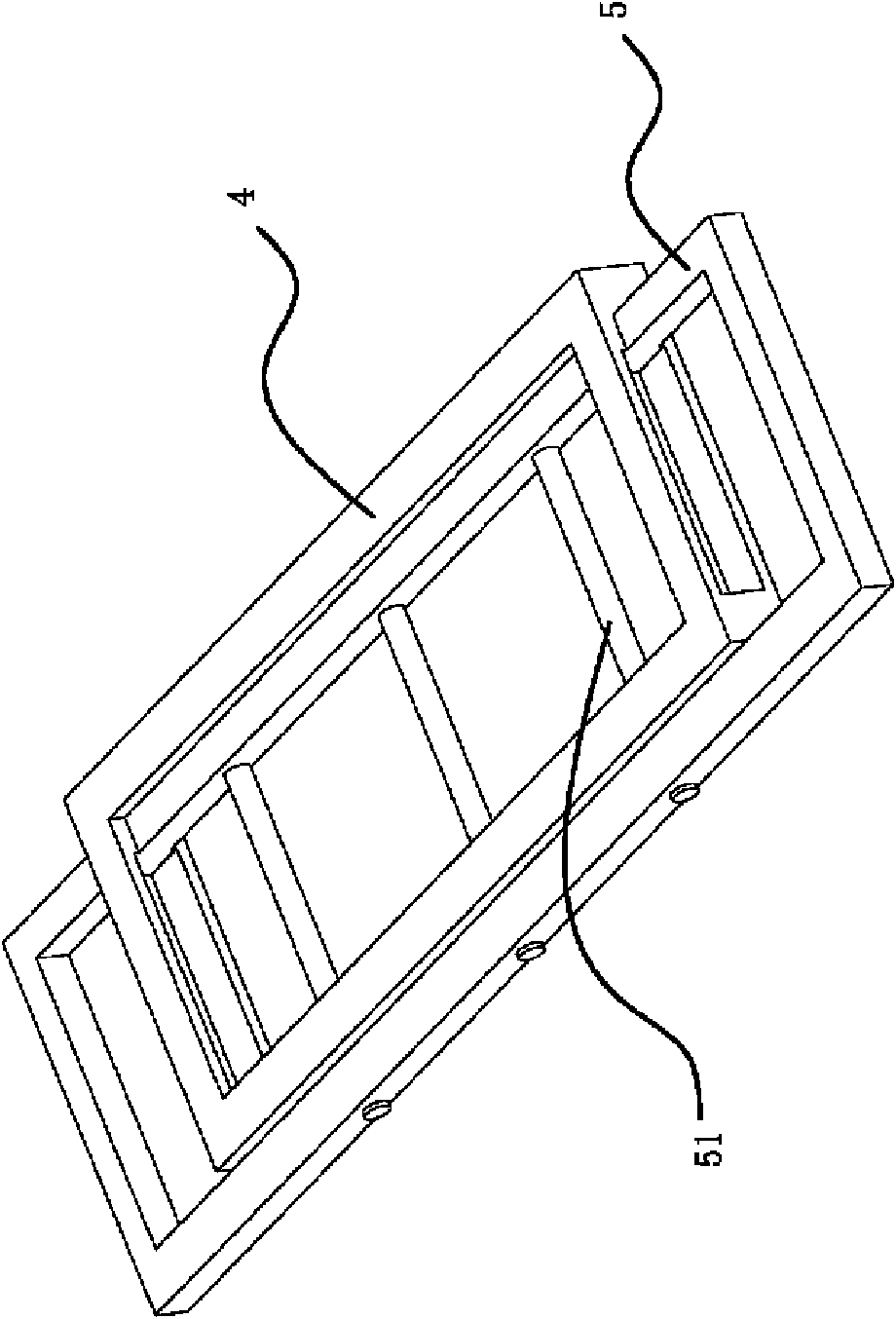

[0033] Such as figure 1 and figure 2 As shown, the steel processing equipment includes a frame 1 , a conveying mechanism 2 installed on the frame 1 capable of conveying steel to be processed, and a processing chamber 3 . The feeding device is arranged at the feeding place of the conveying mechanism 2, and the upper part of the conveying mechanism 2 is provided with a feeding bracket 4, and a flat loading part 5 for placing steel materials to be processed is arranged in the feeding bracket 4, The material carrier 5 can move back and forth along the horizontal direction, and the upper part of the material carrier 5 is provided with a blocking member 6 that blocks the steel to be processed and allows the steel to be processed to drop onto the conveying mechanism 2 .

[0034] The conveying mechanism 2 includes a roller shaft 22 driven by a motor 21 through a chain to rotate, and each roller shaft 22 is horizontally and parallelly arranged on the frame 1, and the roller shaft 22 ...

Embodiment 2

[0045] Such as Figure 5 As shown, the structure and principle of this embodiment are basically the same as that of Embodiment 1. The difference is that the blocking member 6 in this embodiment is fixed above one side of the conveying mechanism 2, and the loading member 5 is located on the other side of the conveying mechanism 2. The top of one side is connected with the power mechanism three 14, and the power mechanism three 14 can push the material carrier 5 to move relative to the feeding bracket 4 and make the steel to be processed fall onto the conveying mechanism 2 under the blocking of the stopper 6. One side of the blocking part 6 is provided with an induction switch three 18 that can contact the side of the loading part 5 when all the steel materials to be processed on the loading part 5 fall, the induction switch three 18 is connected with the power mechanism three 14, and When the material part 5 is in contact with the induction switch, it can generate a control sig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com