Oilstone feeding device of honing machine

A technology of feeding device and honing machine, which is used in honing machine tools, grinding drive devices, grinding machine parts, etc. Feed sensitivity and accuracy, large bearing capacity and transmission range, and small loss between gears

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings, but the present embodiments are not intended to limit the present invention, and any similar structures and similar changes of the present invention should be included in the protection scope of the present invention.

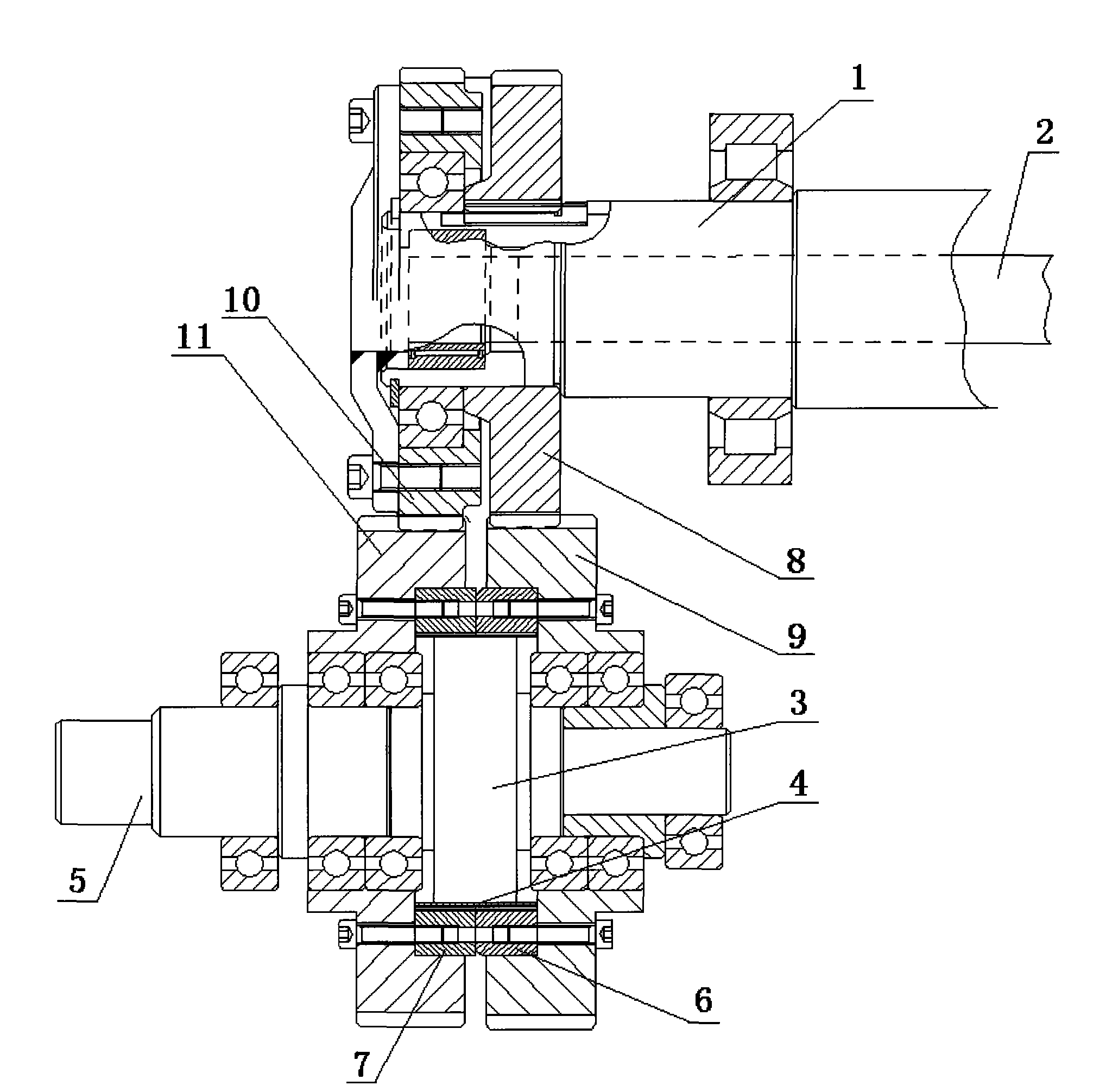

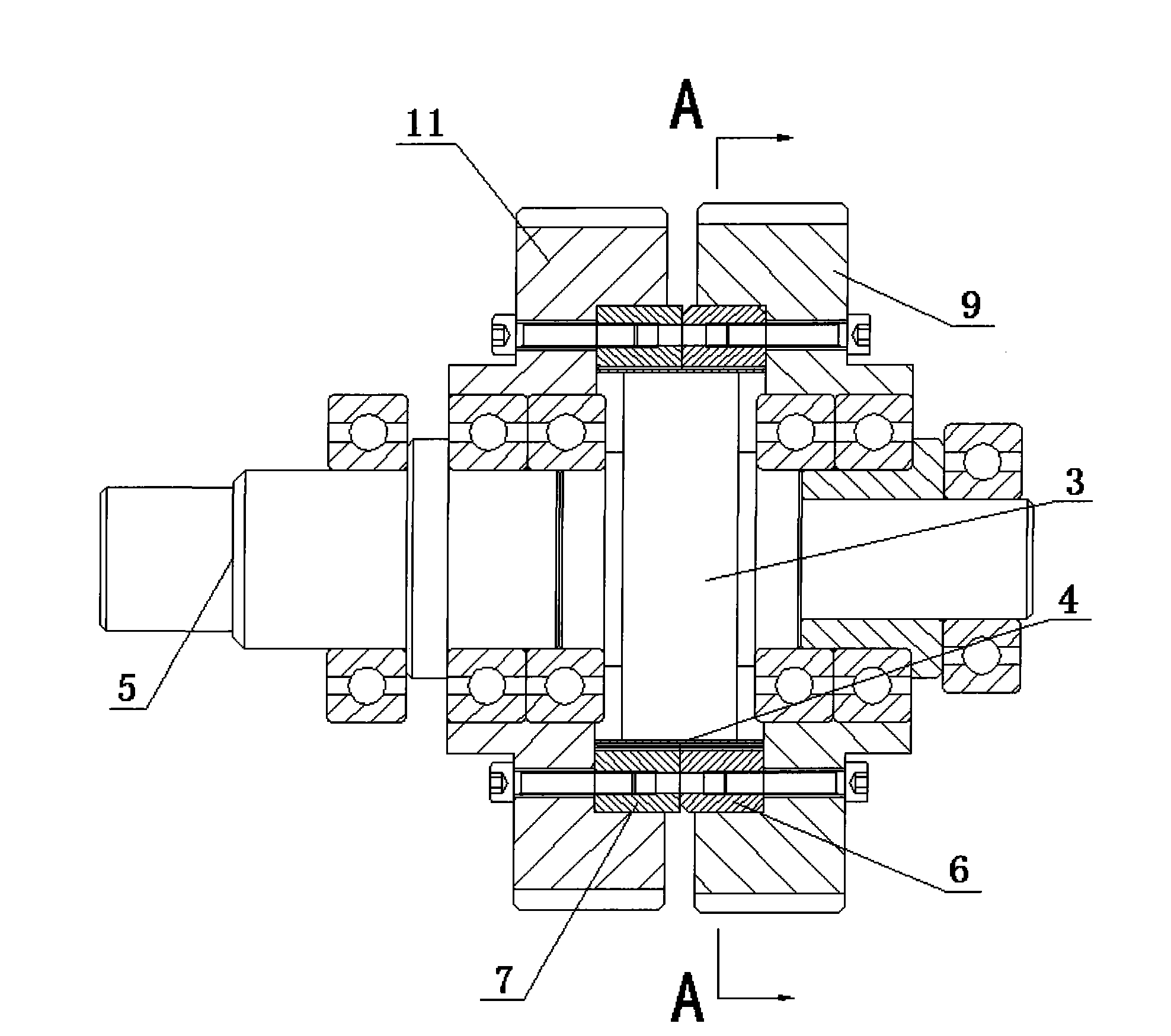

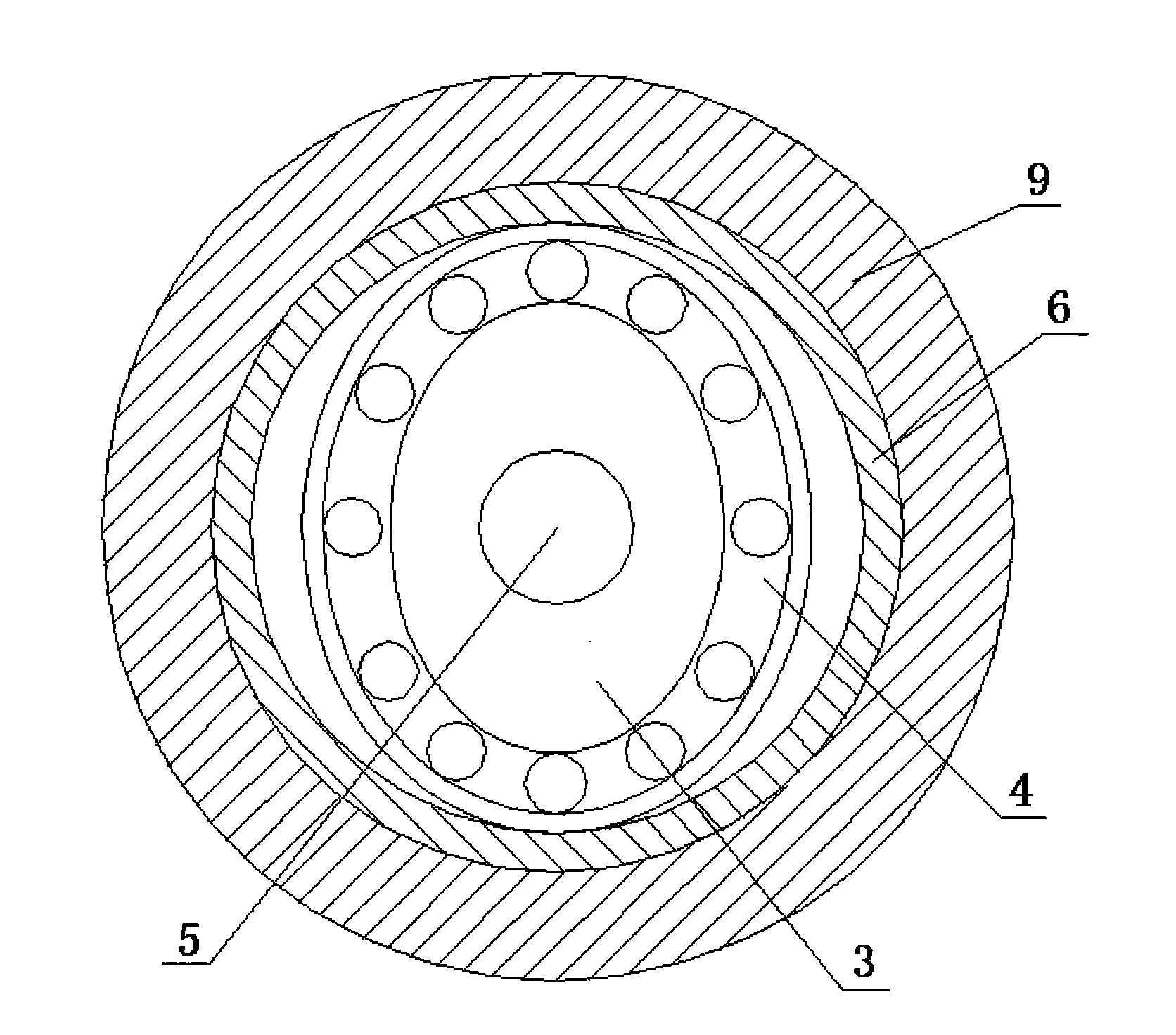

[0010] Such as Figure 1-Figure 3 As shown, the embodiment of the present invention provides a honing machine whetstone feeding device. The honing machine includes a power output shaft 1 and a whetstone feeding shaft 2. 3. The flexible spline 4 with external teeth, the rigid spline with internal teeth, the control shaft 5 is fixedly connected to the cam 3, the flexible spline 4 is connected with the rigid spline, and can elastically deform with the rotation of the cam 3 , the rigid wheel is composed of a main rigid wheel 6 and a slave rigid wheel 7 which are independently connected to the power output shaft 1 and the oilstone ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com