Decorating film, shell applying same and manufacturing method of shell

A production method and decorative film technology, applied in decorative arts, special decorative structures, chemical instruments and methods, etc., can solve the problems of loss of soft touch, leather paint layer does not have wear resistance, etc., to achieve better use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

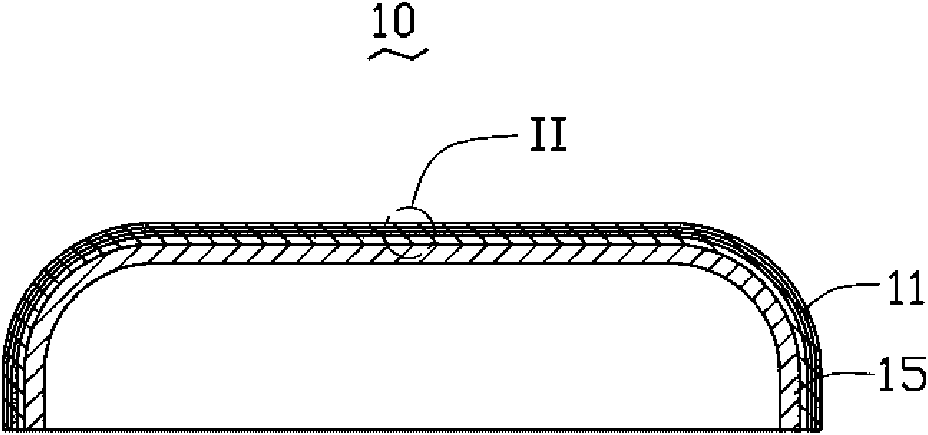

[0017] see figure 1 As shown, the housing 10 according to the preferred embodiment of the present invention includes an outer layer 11 and a base layer 15 bonded to the outer layer 11 .

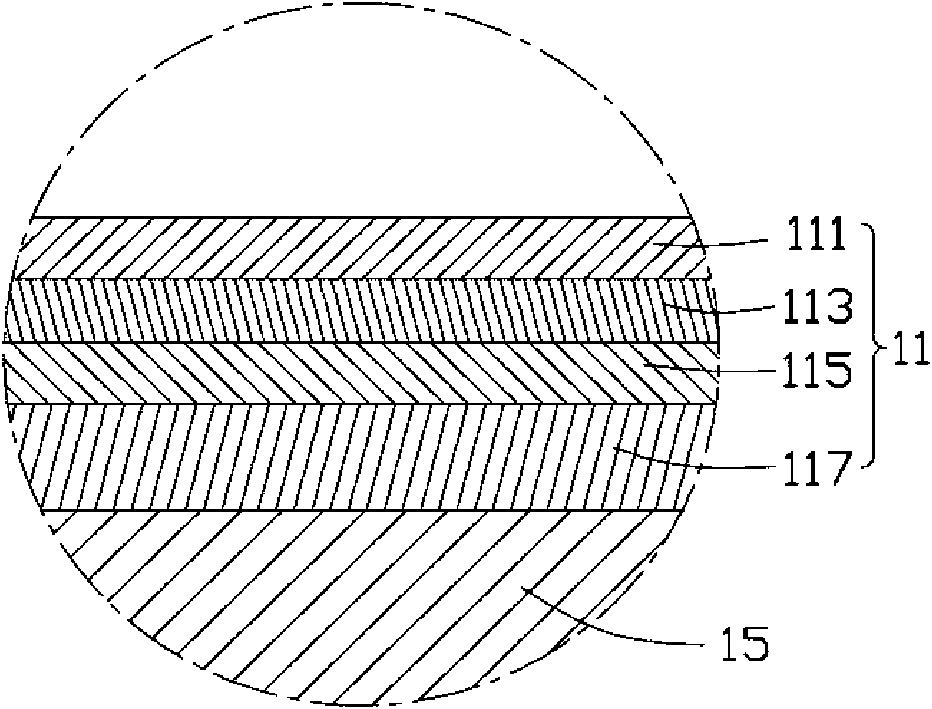

[0018] see further figure 2 As shown, the outer surface layer 11 includes a decorative film and a decorative layer 117, the decorative film includes a first film layer 111, a soft touch layer 113 combined with the first film layer 111 and a second touch layer combined with the soft touch layer 113 Two film layers 115 . The decoration layer 117 is disposed on the surface of the second film layer 115 opposite to the soft touch layer 113 .

[0019] The first film layer 111 is made of transparent plastic, which can be selected from polypropylene (PP), polyamide (PA), polycarbonate (PC), polyethylene terephthalate (PET) or polyacrylic acid. Any of methyl acrylate (PMMA).

[0020] The soft touch layer 113 can be a soft silicone layer, and the soft silicone has a soft touch and is transparent. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com