Device for reducing drag between high-speed multiple unit trains

A technology of high-speed EMUs and drag reduction devices, applied in the fields of air resistance reduction technology, railway car body, transportation and packaging, etc., can solve the problems of air resistance increase, diversion and disturbance, etc., to reduce air resistance, reduce air diversion, The effect of good curve passing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

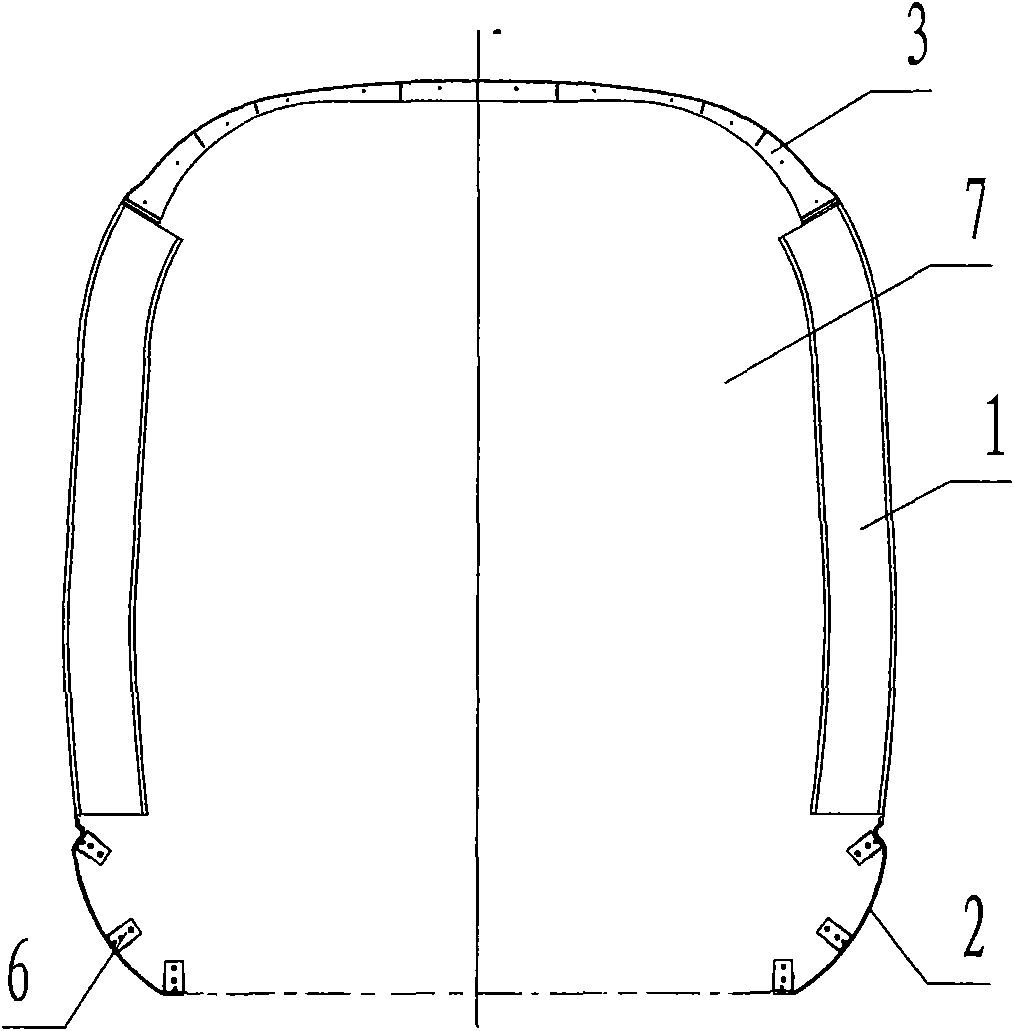

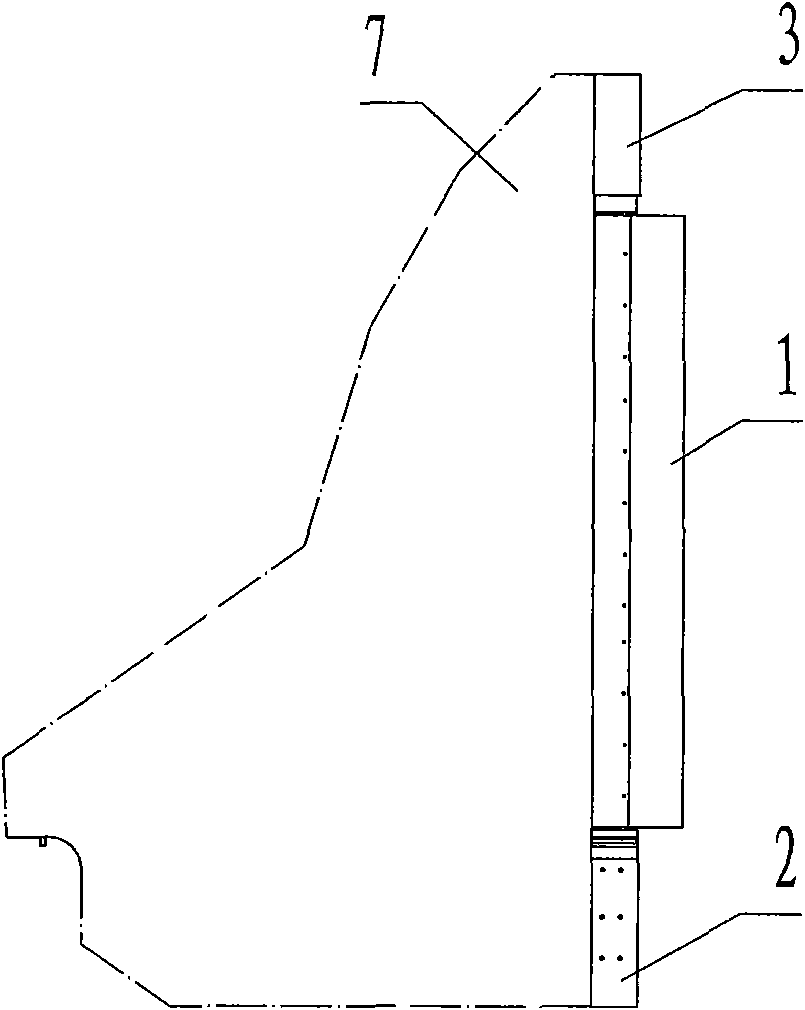

[0023] see figure 1 , figure 2 , the present invention comprises three parts of the vehicle-to-vehicle top deflector 3, the bottom deflector 2, and the side windshield 1. By increasing the side windshield 1, the vehicle body can be streamlined, reducing airflow disturbance and reducing air resistance; by increasing the top deflector 3 and the bottom deflector 2, the distance between vehicles can be shortened and air diversion can be reduced.

[0024] see image 3 , Figure 4 , the top deflector 3 is welded by aluminum plate, and is installed on the roof by bolts.

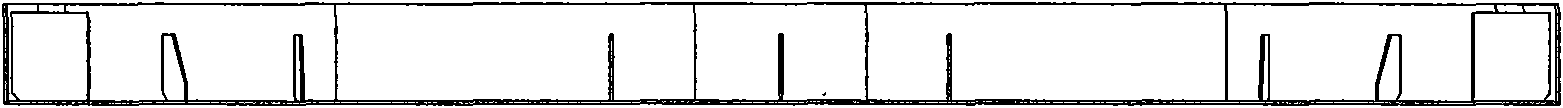

[0025] see Figure 5 ~ Figure 7 , The side windshield 1 is composed of a capsule frame 4 and a rubber capsule 5, and the rubber capsule 5 is fixed on the capsule frame 4 by bolts. The capsule frame 4 is installed on the car body end wall by bolts. After the vehicle is connected, the rubber capsules 5 of the two side windshields are closely attached to make the appearance of the vehicle body streamlined, reduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com