Anti-skid device of rail wheel type ballast raking equipment

An anti-skid device and a technology of a muck remover, which is applied in the direction of earth movers/shovels, construction, etc., can solve problems such as the wheel rails of the muck remover detached from the rails, the excavator cannot work normally, and the excavation efficiency of the muck remover is reduced. Achieve quick and convenient installation and disassembly, increase working stability, and improve excavation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

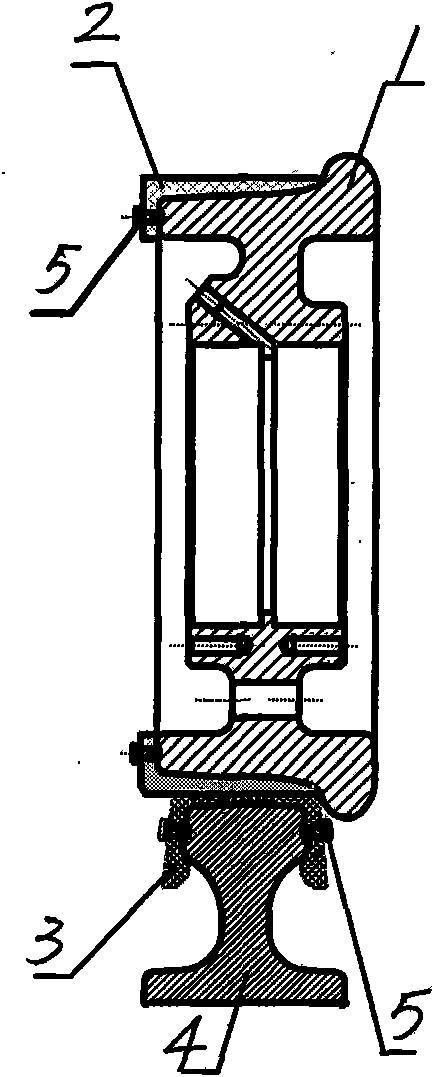

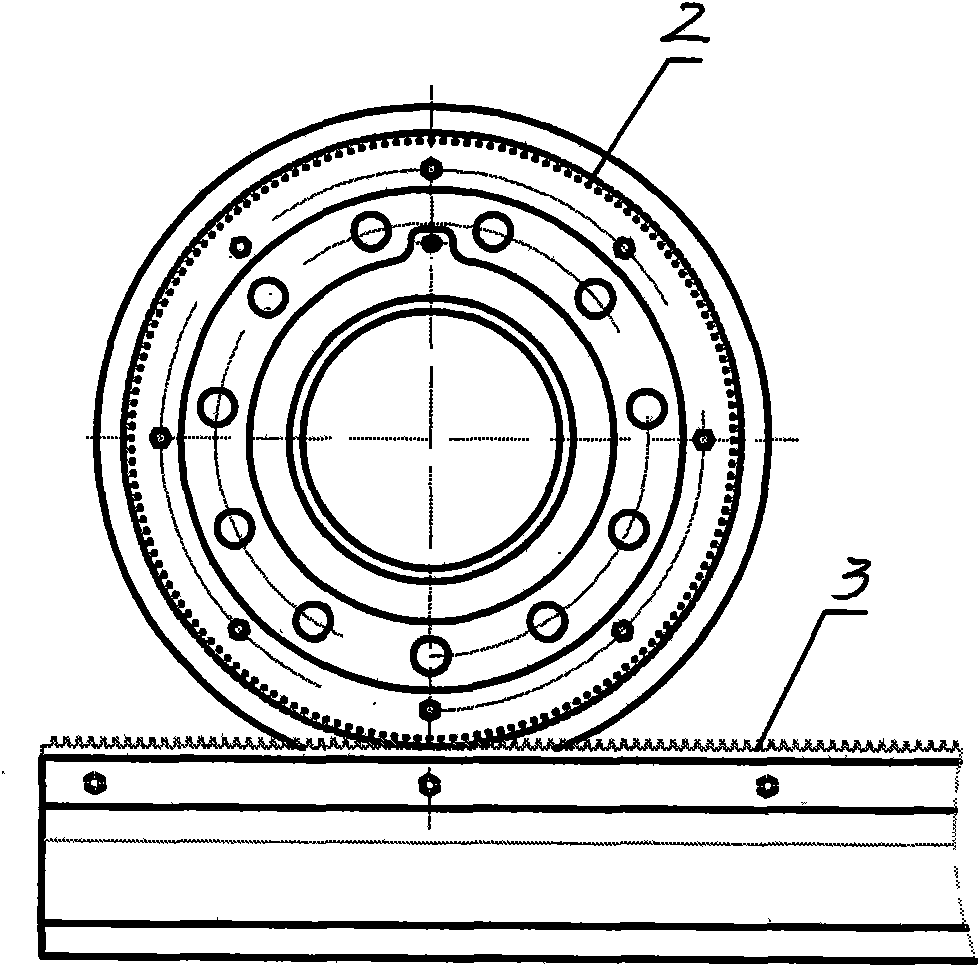

[0010] exist figure 1 Among them, the anti-skid device of the rail-wheel type mucking machine includes rail wheels 1 that are movably fixed on both ends of the rotating shaft of the rail-wheel type mucking machine. A rail wheel tooth-shaped sleeve 2 is fixedly arranged with bolts 5 distributed at intervals, and the rail wheel tooth-shaped sleeve and the outer circumferential surface of the rail wheel are matched with a small gap, and the tooth profile on the rail wheel tooth-shaped sleeve can be Cylindrical teeth, trapezoidal teeth or serrated teeth, rail soft tooth sleeves 3 are fixedly installed on the working surface of the rail 4 matched with the rail wheel. 5. Fixed on both sides of the rail soft gear sleeve, the rail wheel tooth profile matches the rail soft gear sleeve tooth shape, and the rail wheel tooth profile and rail soft gear sleeve are made of plastic or rubber with good wear resistance .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com