Hybrid power assembly performance matching test bench

A hybrid power, test bench technology, applied in the direction of vehicle testing, machine/structural component testing, measuring devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

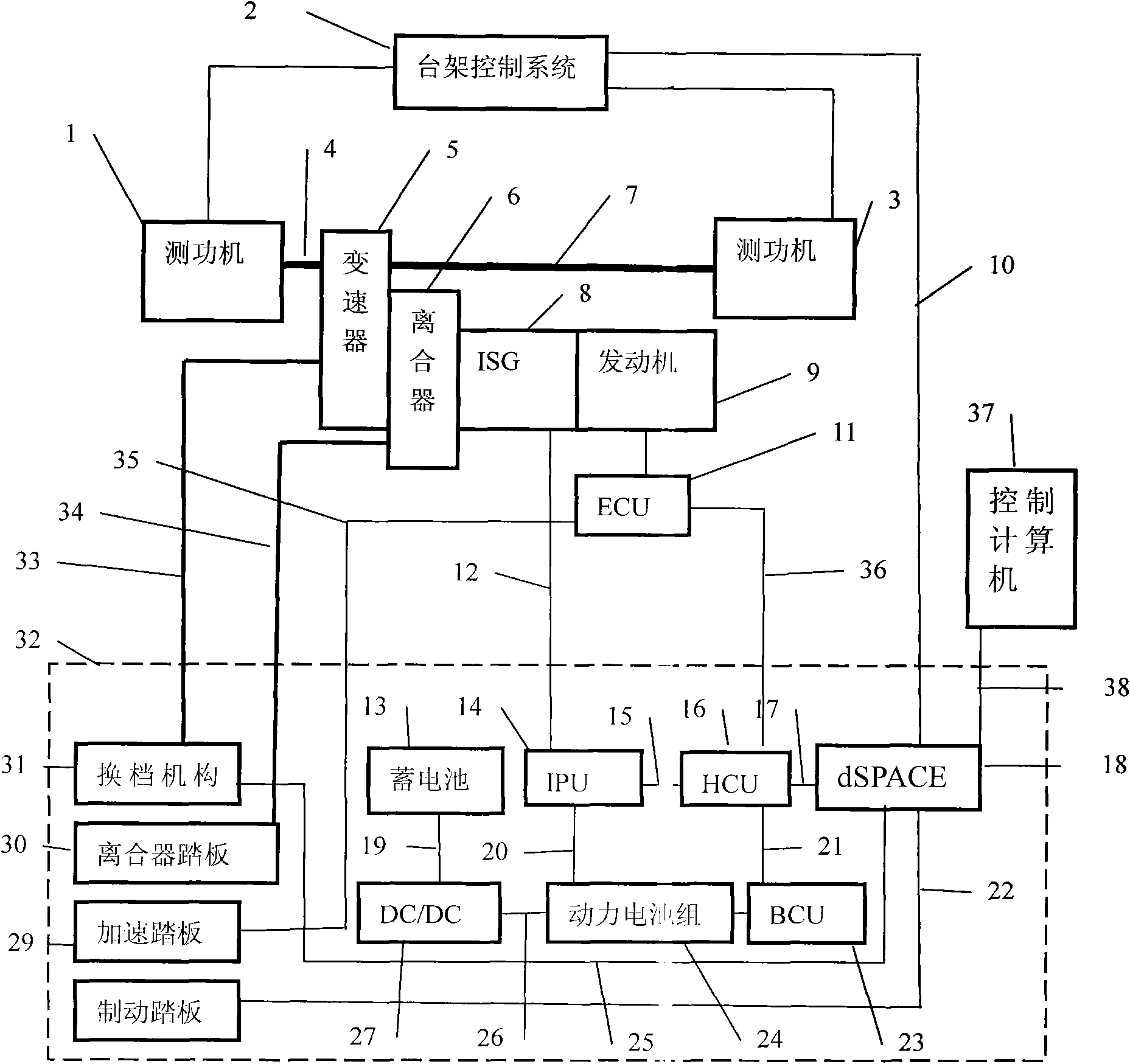

[0011] The technical solution of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0012] see figure 1 , the hybrid powertrain is formed by connecting the engine 9, the integrated power generation / electric motor ISG 8, the clutch 6 and the transmission 5 in the following form: the ISG 8 of the power generation / electric integrated motor includes two parts, the stator and the rotor, and the stator is installed on the engine with bolts 9 rear end face, the rotor is installed on the rear end face of the crankshaft of the engine 9 with bolts, and rotates together with the crankshaft; the friction plate of the clutch 6 is closely attached to the surface of the flywheel fixed on the rotor; the transmission 5 is connected with the clutch 6 through a spline shaft. The hybrid powertrain is respectively connected to the two first and second dynamometers 1 and 3 through the first and second vehicle axle shafts 4 and 7 connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com