Clamping and holding assembly and manufacturing method thereof

A manufacturing method and component technology, applied in the manufacture of contact boxes/bases, electrical components, connecting components, etc., can solve the problems of multiple processes and high manufacturing costs, reduce manufacturing costs, improve efficiency, reduce assembly and installation shafts, etc. Process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

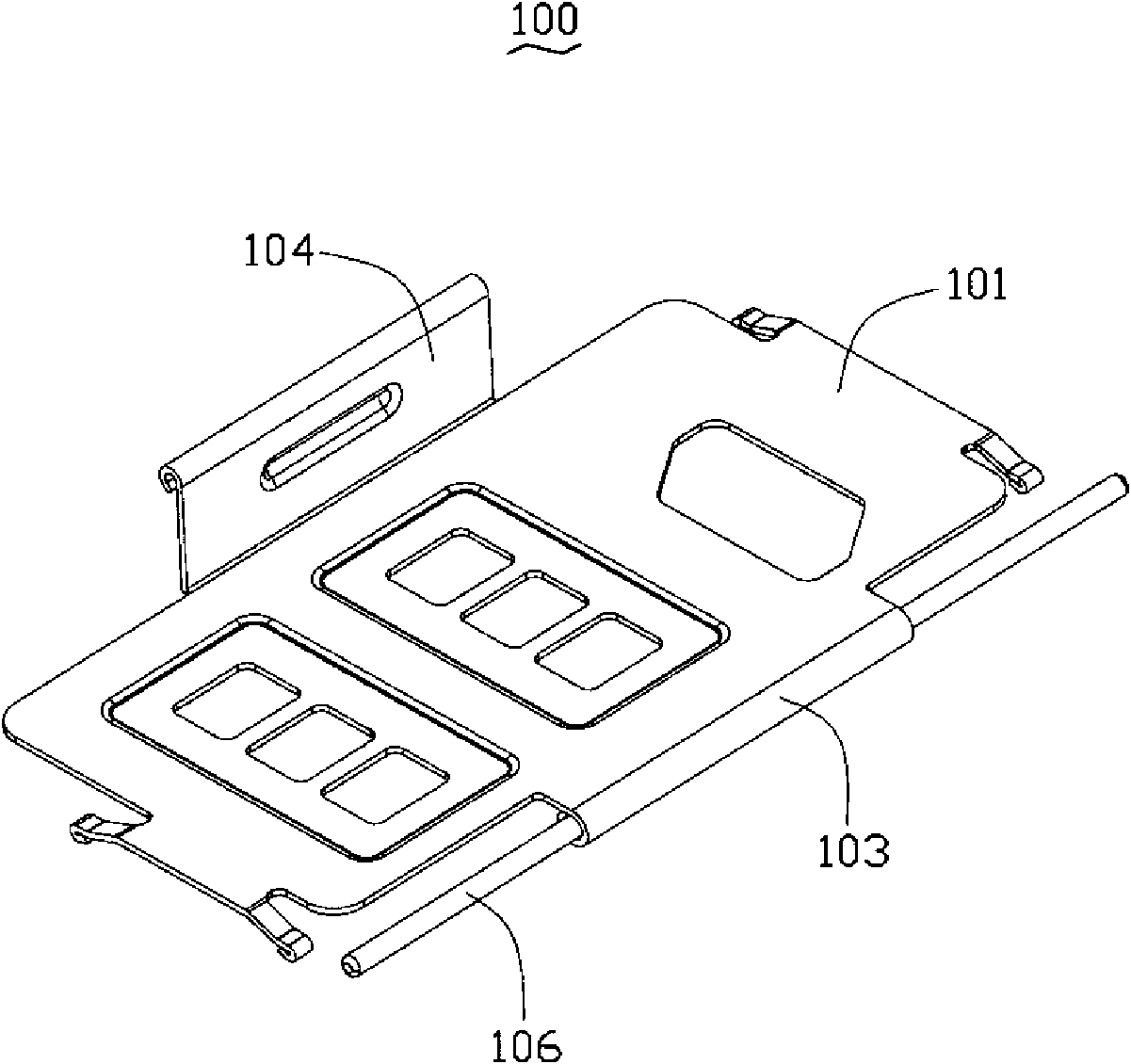

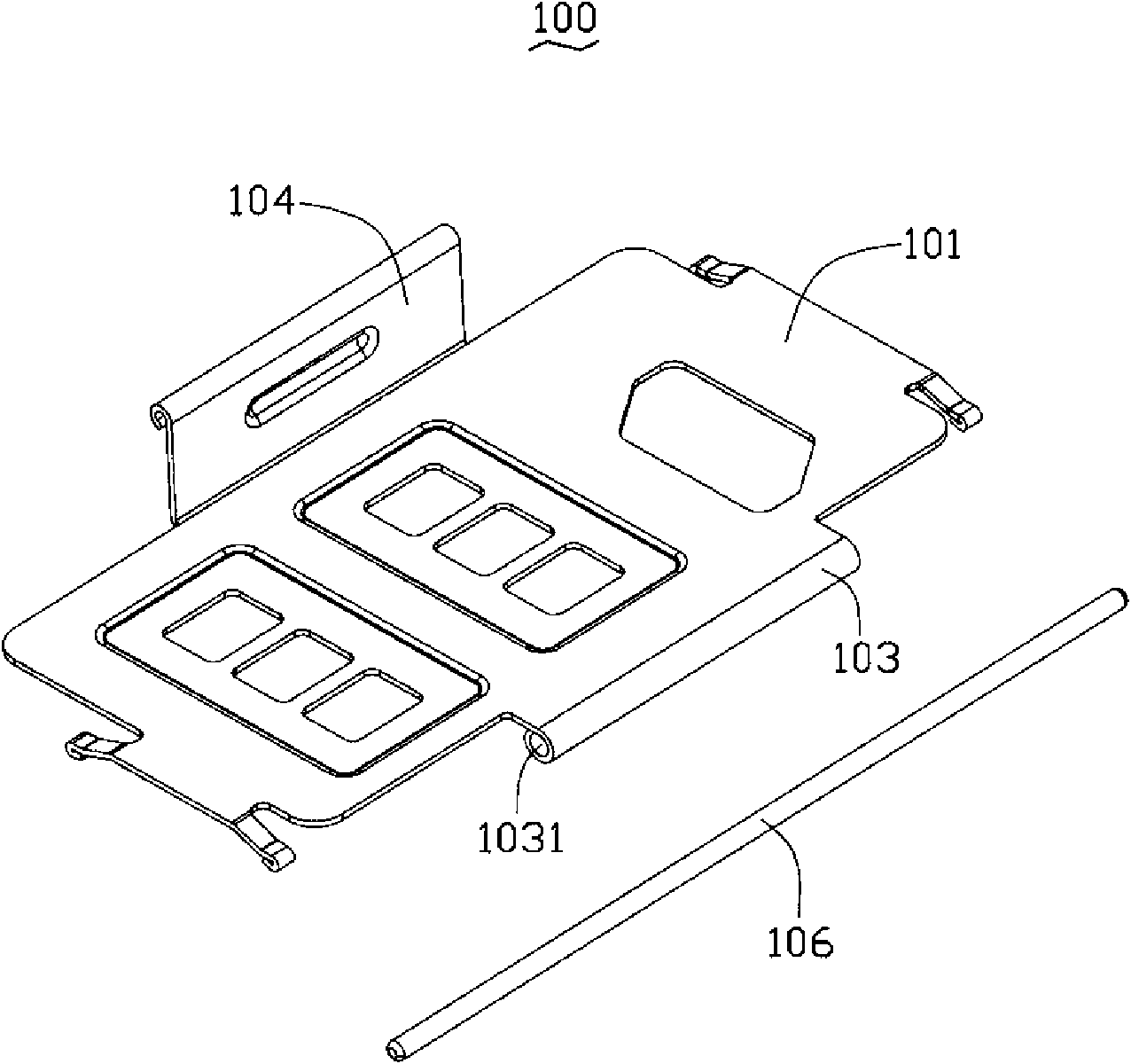

[0025] The clamping assembly of the preferred embodiment of the present invention is applied to a portable electronic device, and this embodiment is described by taking a cover assembly for installing a SIM card of a mobile phone as an example. The mobile phone includes a body, and the holding component is rotatably connected with the body.

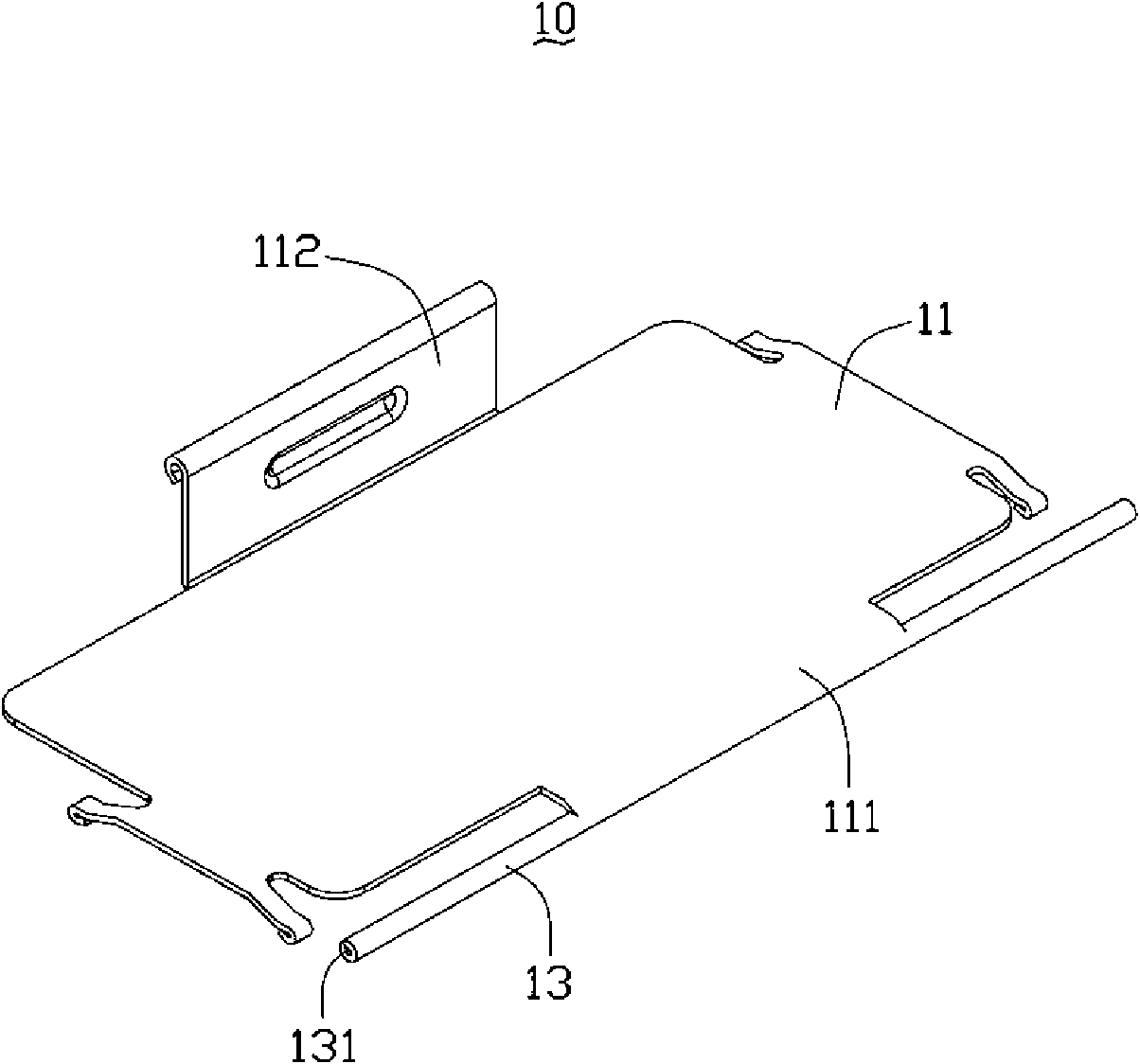

[0026] see image 3 , the clamping component 10 of the present invention is formed by stamping a single-piece base material, which includes a cover plate 11 and a rotating shaft 13 . The cover plate 11 is roughly rectangular, with a connecting plate 111 extending approximately in the middle of one side, and a clamping portion 112 extending from the other opposite side of the cover plate 11, the clamping portion 112 is used to engage with the clamping portion on the body. Snap together. The rotating shaft 13 is obtained by rounding the edge of the connecting plate 111 of the cover plate 11 , thereby forming a rotating shaft hole 131 in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com