Organic compounds

A product, the technology of staurosporine, applied in the direction of organic chemistry, can solve problems such as differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

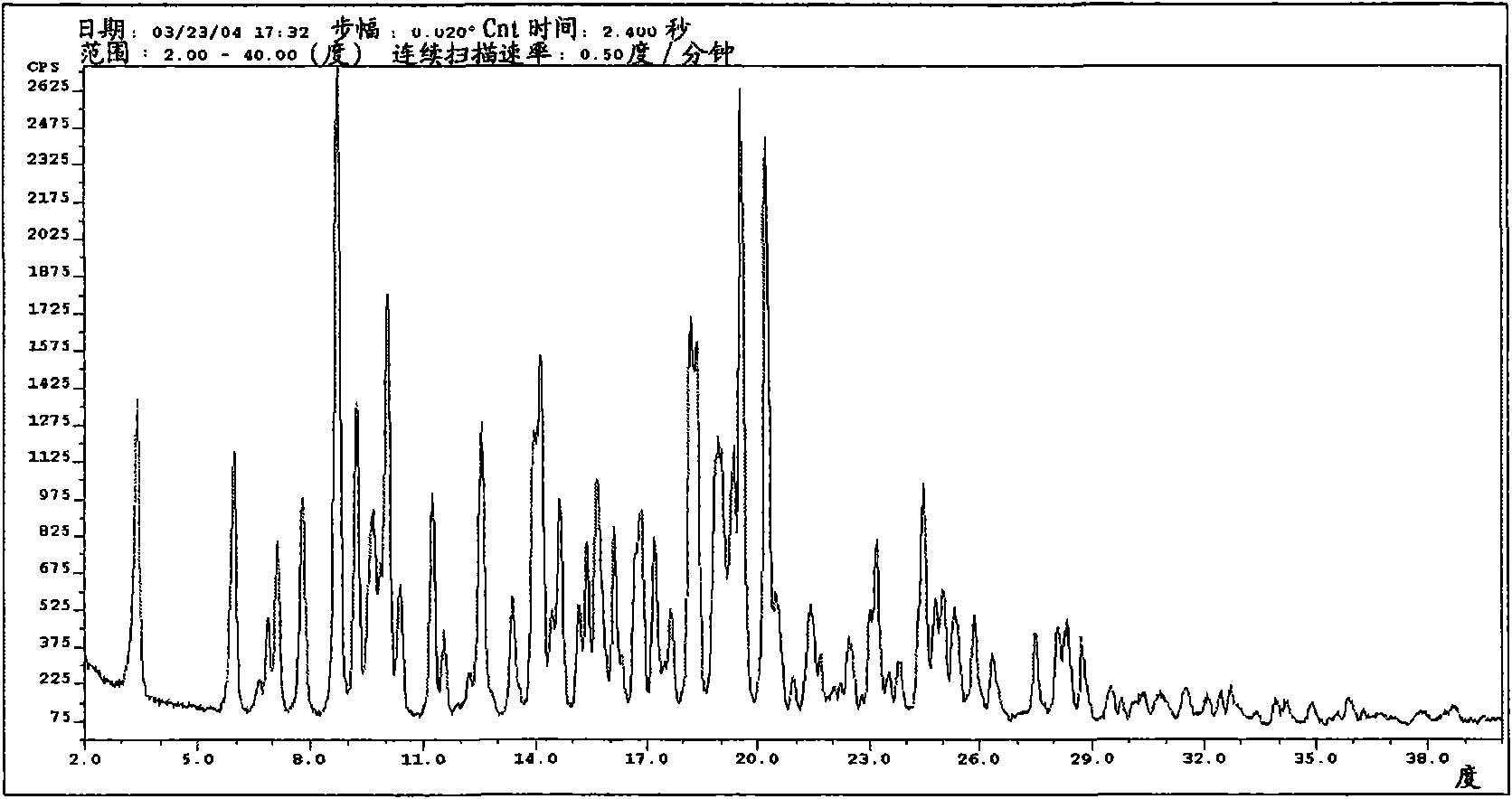

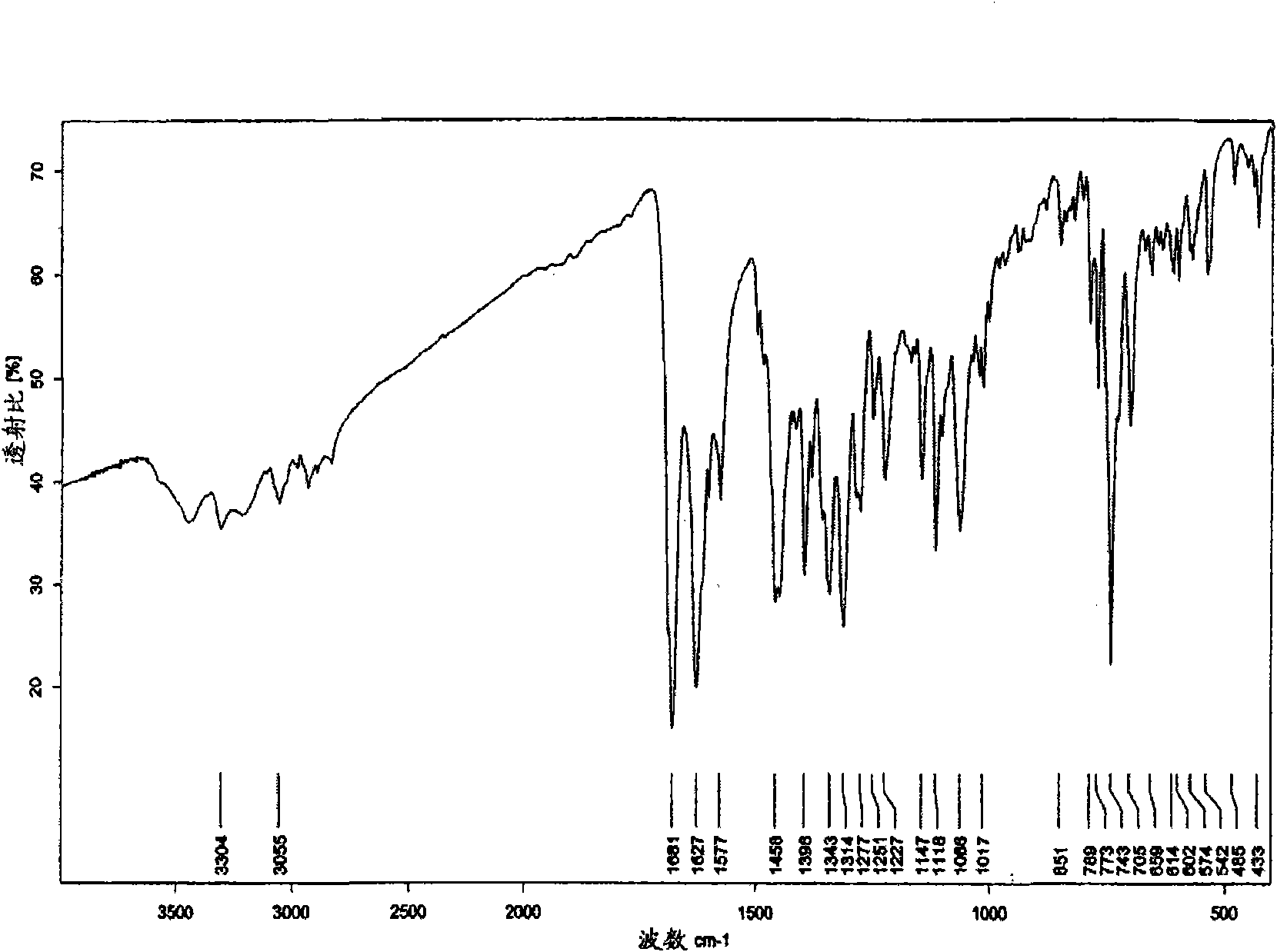

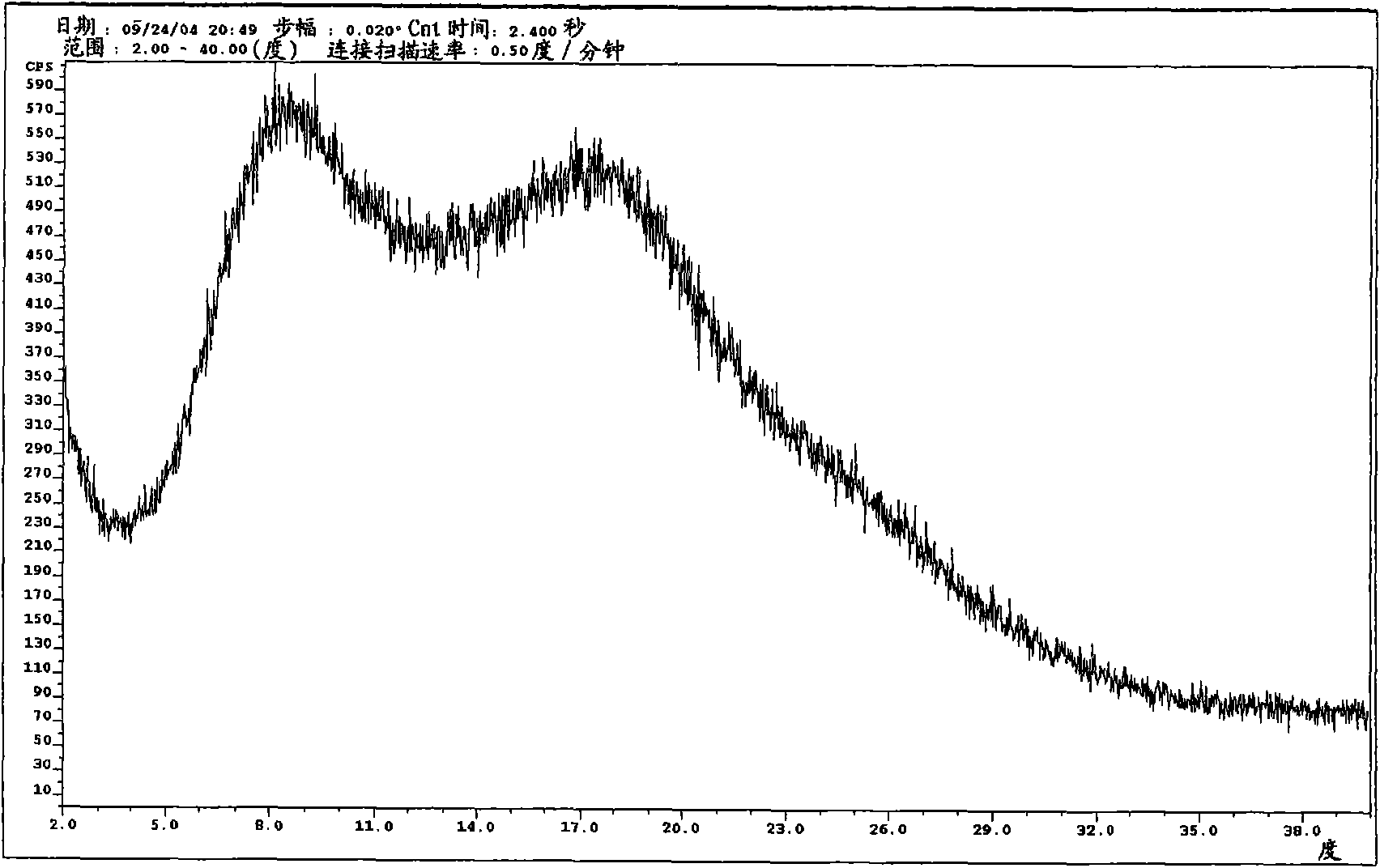

Image

Examples

Embodiment 1

[0092] Example 1 Purification of Staurosporine B1 to Staurosporine B2 Using Methanesulfonic Acid and Triethylamine

[0093] Add staurosporine B1 and ethanol into the reactor. The suspension was heated to about 70°C. Methanesulfonic acid was added to the suspension, and the resulting solution was aged. Activated charcoal and Hyflo are added and the mixture is aged. Filter the suspension, and wash the filter device and filter cake with ethanol several times. The clear filtered solution was transferred to another reactor and cooled to 60 °C. Triethylamine diluted with ethanol was slowly added to the reaction mixture. Afterwards, the suspension was cooled to about 20°C and aged. Staurosporine B2 was separated by filtration. The product was washed several times with ethanol.

Embodiment 2

[0094] Example 2 Purification of Crude Staurosporine B1 to Staurosporine B2 by Crystallization

[0095] Add staurosporine B1 and benzyl alcohol into the reactor. The suspension was heated to about 85°C and aged. Activated carbon and Hyflo were added to the solution and the mixture was aged again. The suspension was filtered at about 90°C. The filter unit and filter cake were washed several times with benzyl alcohol. The clear filtrate was transferred to another reactor and cooled to about 70°C. Staurosporine B2 suspended in ethanol was added to the solution as a seed crystal. After that, ethanol was added to the suspension, and the suspension was aged and then cooled to about 0°C. The suspension was aged again at about 0°C for at least 2 h. Staurosporine B2 was separated by filtration. The product was washed several times with ethanol.

Embodiment 3

[0096] Example 3 Benzylation of staurosporine B2 to prepare substantially amorphous N-benzoyl-staurosporine

[0097] Add staurosporine B2 with benzoic anhydride, ethanol and water to the reactor. The reaction mixture was heated to about 70°C and aged. The solution was filtered, and the filter unit and filter cake were washed with ethanol several times. The filtrate was transferred to another reactor and cooled to about 60°C. Water was slowly added to the solution. Amorphous N-benzoyl-staurosporine was added to the solution as seed crystals. The suspension was aged, then cooled to 20°C and aged again. N-Benzoyl-staurosporine was isolated by filtration. The wet cake of N-benzoyl-staurosporine was washed several times with absolute ethanol. The wet filter cake was resuspended in ethanol in the filter unit, aged at about 25°C, then cooled to about 0-5°C, and aged again. The processing steps can be repeated multiple times. N-benzoyl-staurosporine was isolated by filtratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com