Abrasion resistance tester of part bearing axial pushing force

A wear-resistant test and axial thrust technology, applied in the testing of mechanical components, testing of machine/structural components, measuring devices, etc., can solve problems such as thrust rings and thrust bearings being easily damaged

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

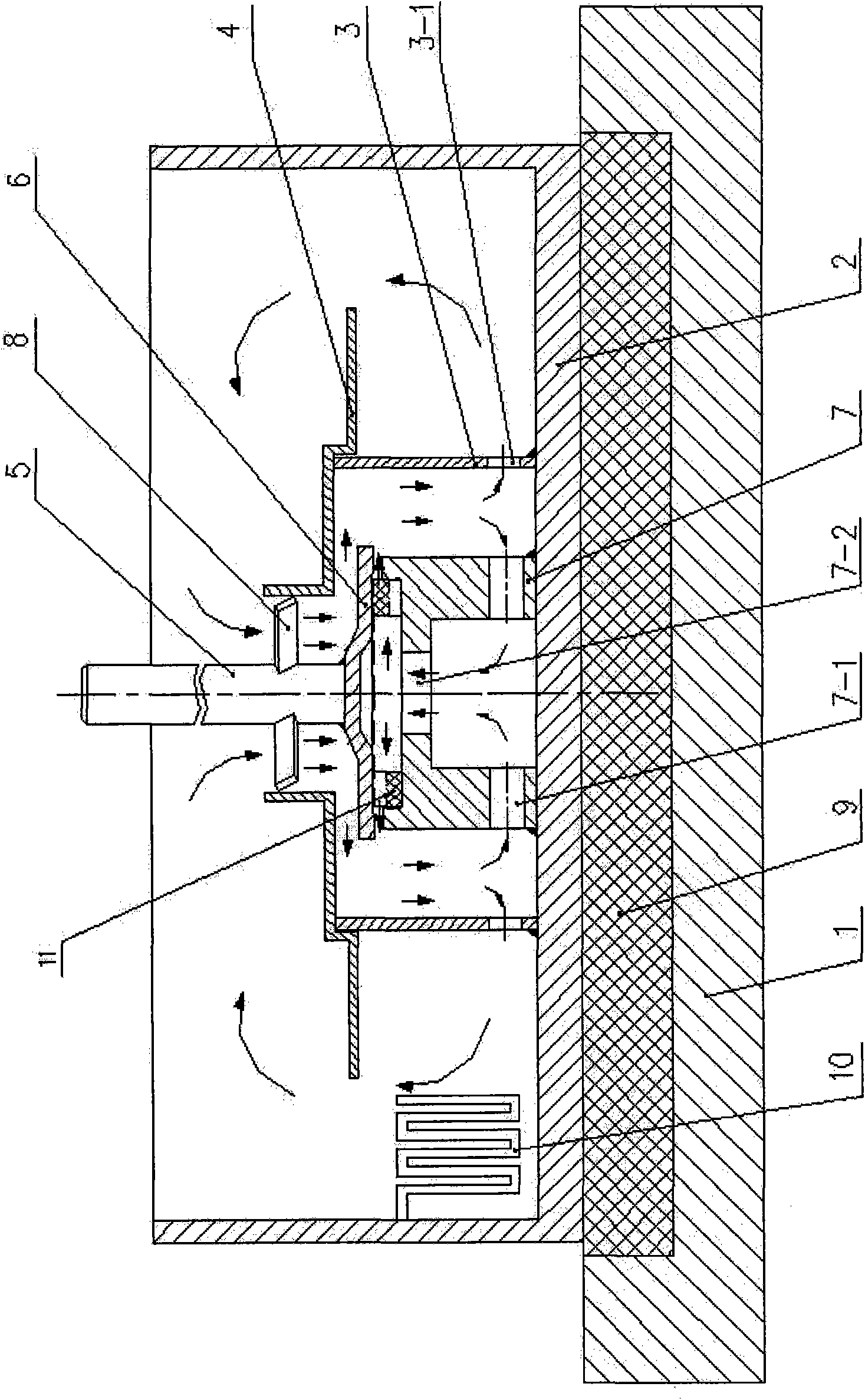

[0014] Embodiment 1: as figure 1 As shown, a wear-resisting test device for components bearing axial thrust, the test device includes a base 1, a shell 2 arranged on the base 1, set in the inner cavity of the shell 2 and has a through hole a3 -1 middle partition 3, baffle 4, drive shaft 5, counter piece A6 and counter piece B7 with through hole b7-1 and through hole c7-2, wherein the baffle 4 is arranged on the Above the middle partition 3, to separate the inner chamber of the housing 2 into two relatively independent working chambers inside and outside; the driving shaft 5 is arranged between the deflectors 4, and its lower end is fixedly connected to the The counterpart A6; the counterpart B7 is correspondingly arranged below the counterpart A6 and fixed on the housing 2; the drive shaft 5 is fixedly provided with a blade 8; the blade 8 is adjacent to the drive shaft 5 Set with the fixed end of the counterpart A6; the blade 8 is arranged obliquely in the horizontal directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com