Microfluid conveying and atomizing device

An atomization device and microfluidic technology, applied in the direction of electric solid devices, semiconductor devices, semiconductor/solid device components, etc., can solve problems such as inability to meet thin requirements, complex structure, and large volume of suction pumps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Some typical embodiments embodying the features and advantages of the present invention will be described in detail in the following description. It should be understood that the present invention can have various changes in different aspects, which do not depart from the scope of the present invention, and the descriptions and icons therein are essentially for illustrative purposes, rather than limiting the present invention. invention.

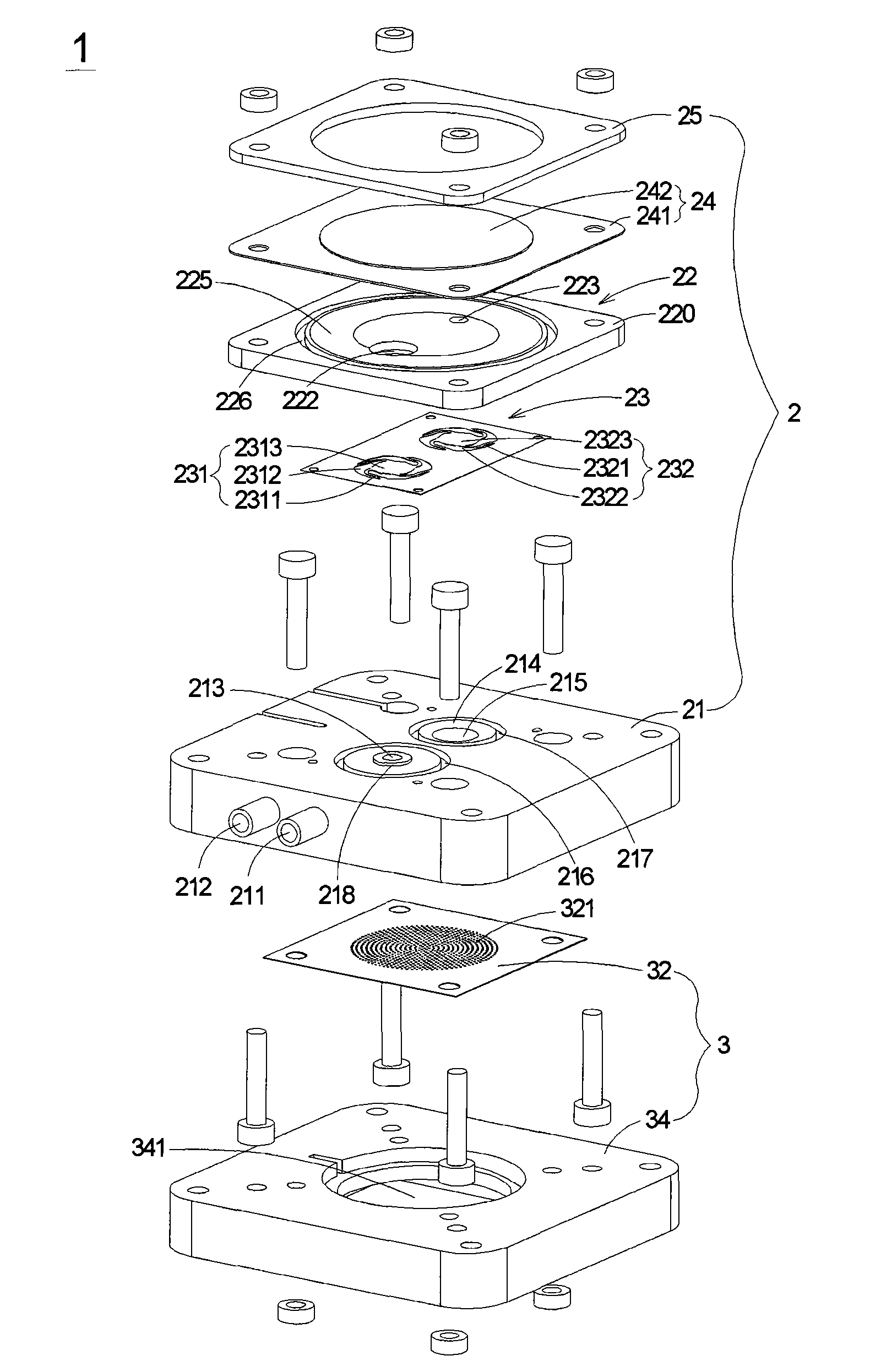

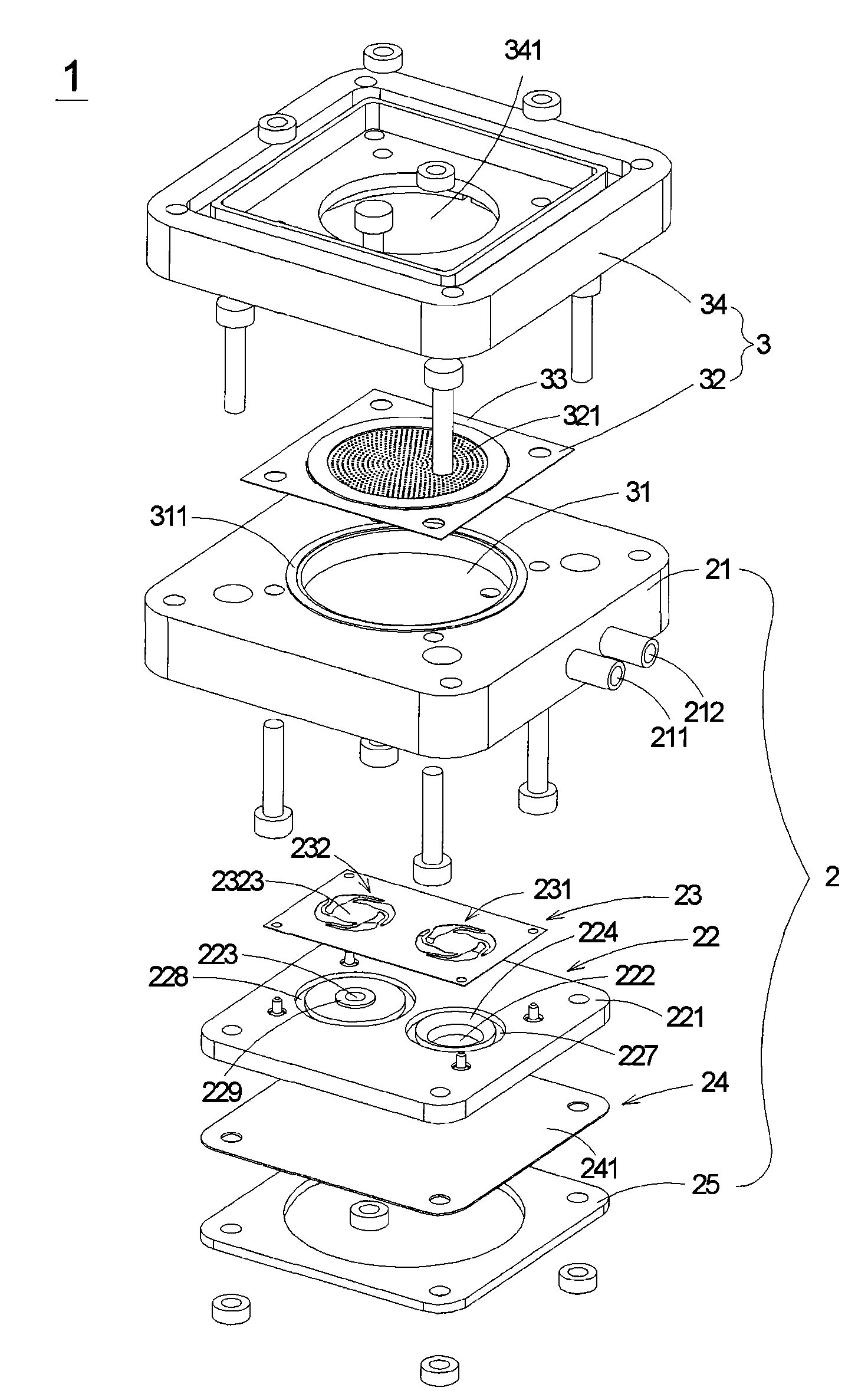

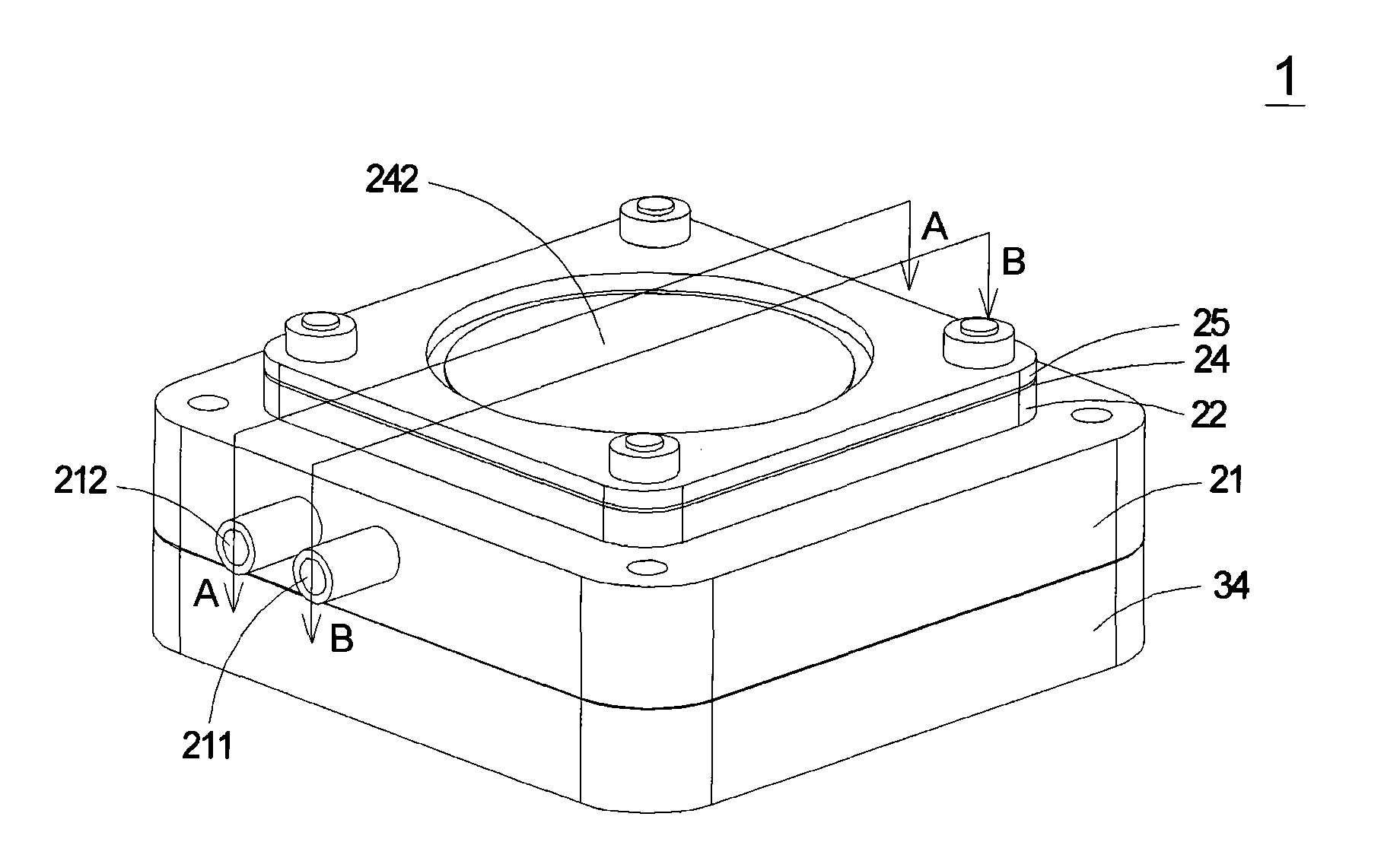

[0020] See Figure 1A and Figure 1B ,among them Figure 1A It is a schematic diagram of the front exploded structure of the microfluid delivery and atomization device of a preferred embodiment of the present invention, Figure 1B Then Figure 1A As shown in the figure, the microfluidic transport and atomization device 1 of the present invention is mainly composed of a microfluidic transporter 2 combined with an atomizer 3, wherein the microfluidic transporter 2 is mainly composed of The valve body seat 21, the valve body cover 22, the valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com