Storage container for substrate and substrate conveying device for the storage container

A technology for storing containers and substrates, applied in lighting and heating equipment, conveyor objects, transportation and packaging, etc., can solve the problems of difficult transfer of substrates, complex structure of cover parts, close proximity of container main body, etc., and achieve a simplified structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

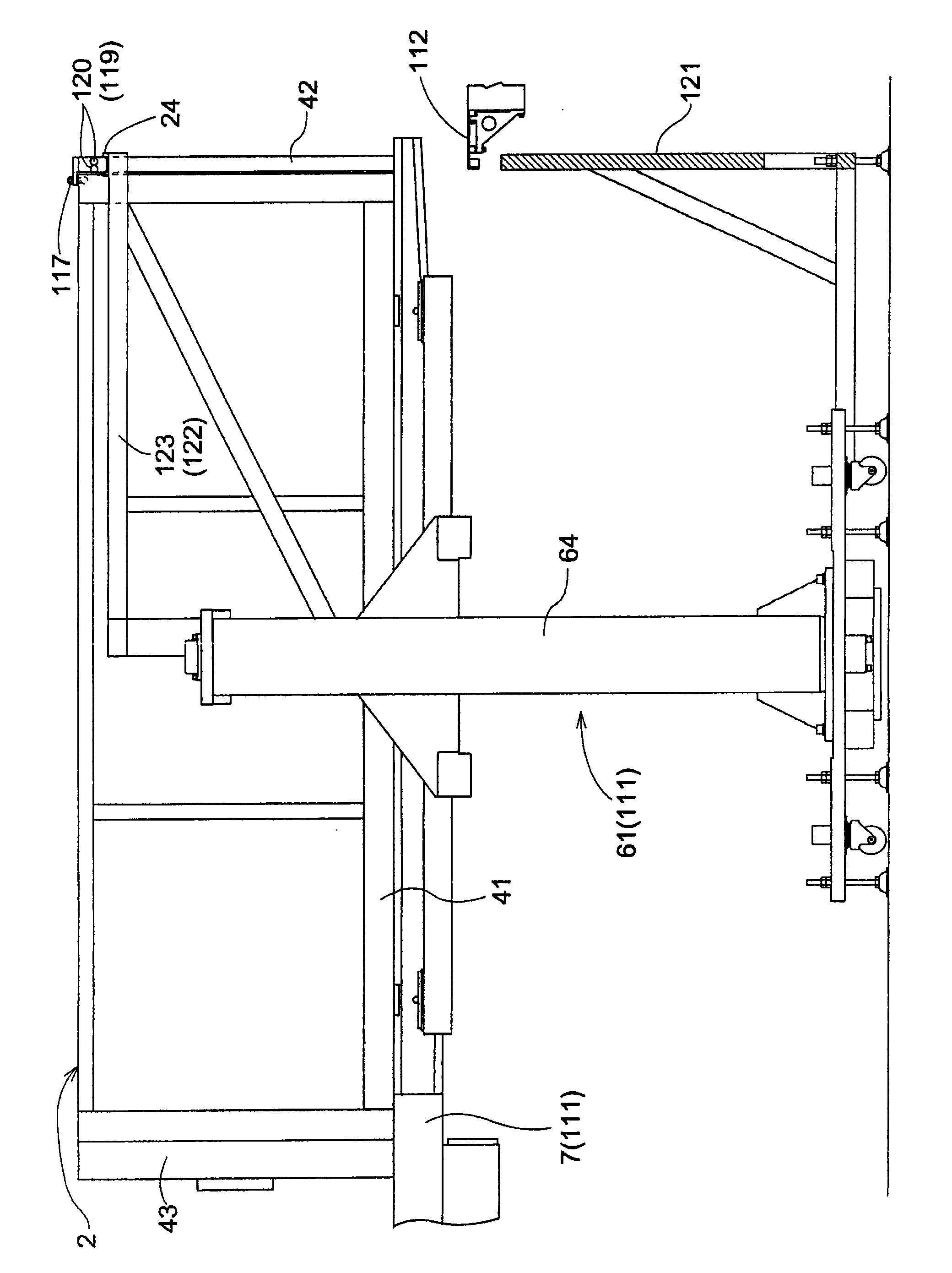

[0134] like figure 1 As shown, the substrate transport equipment is provided with: a container transport mechanism 111 for transporting a storage container 2 as a substrate storage container; a substrate transfer device 112 for transferring a substrate 1 relative to the storage container 2 transported by the container transport mechanism 111 .

[0135] Furthermore, the substrate transfer device 112 is configured to take out the substrate 1 from the storage container 2 conveyed by the container conveyance mechanism 111 and store the substrate 1 in the storage container 2, and is configured to transfer the substrate 1 from the storage container 2. 1 and storage of the substrate 1 in the storage container 2.

[0136] In addition, the substrate of this embodiment is a rectangular substrate used for a glass substrate of a liquid crystal display or a plasma display, or the like.

[0137] [storage container]

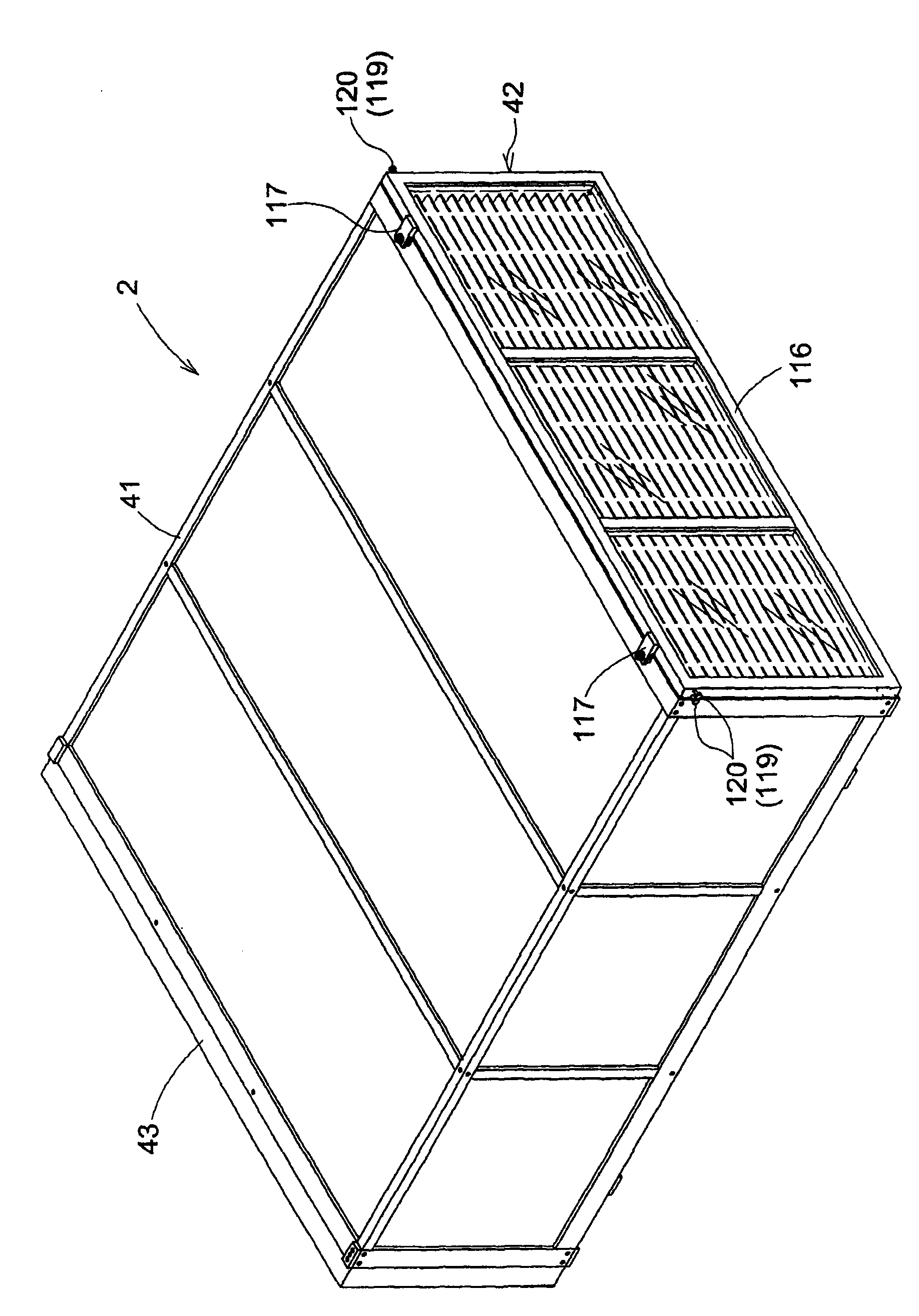

[0138] like figure 1 and figure 2 As shown, the storage container 2 ...

no. 2 approach 》

[0194] "Second embodiment" plate-shaped body support type

[0195] Hereinafter, a second embodiment of a substrate transfer facility to which the substrate storage container of the present invention is applied will be described with reference to the drawings.

[0196] In addition, since the second embodiment has the same configuration as the first embodiment except for the configuration of the supported portion 119, the same reference numerals are attached to the same configurations as those of the first embodiment to omit description, and the main description is different from that of the first embodiment. way of composition.

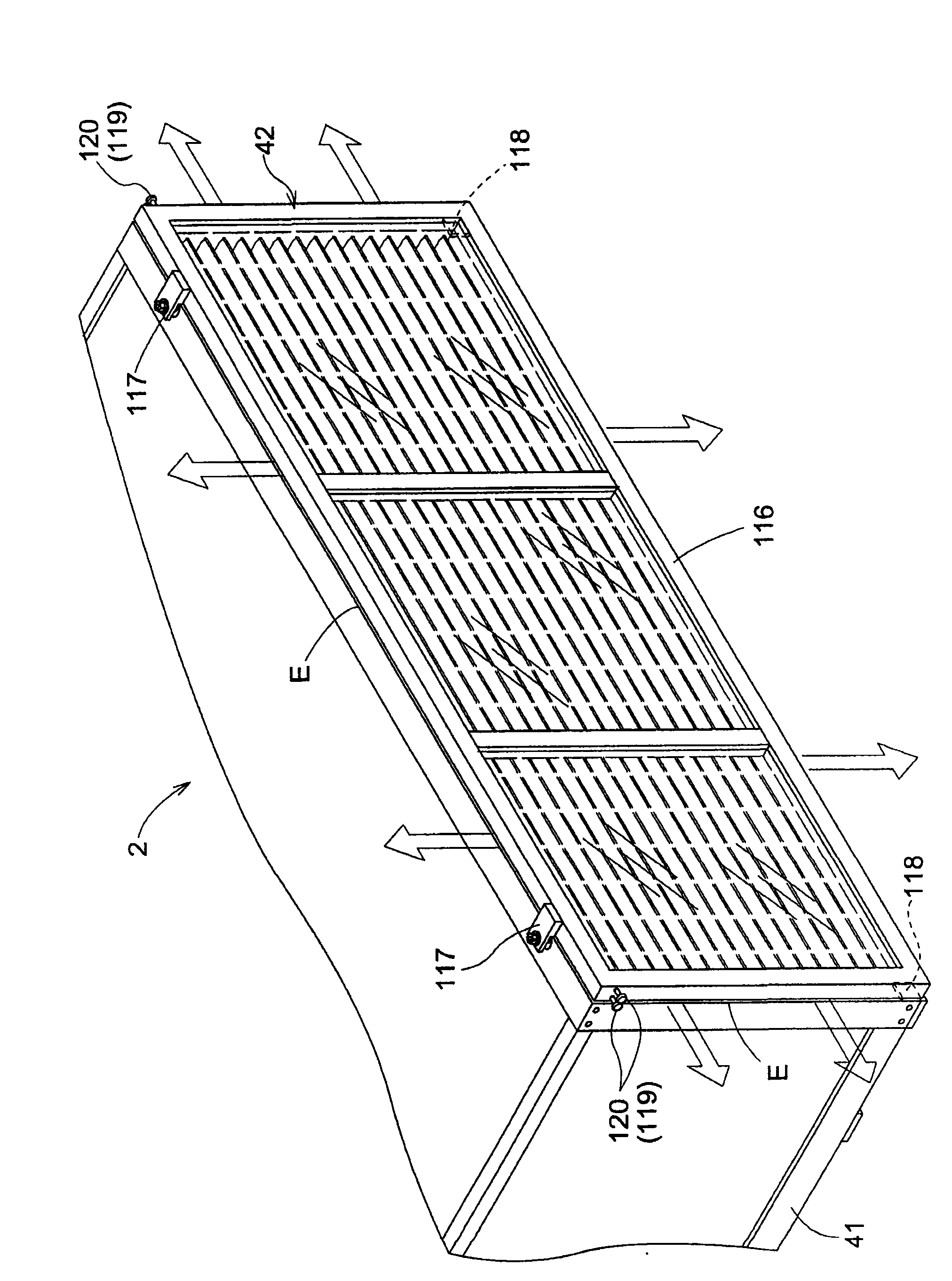

[0197] like Figure 8 As shown, on the lid member 42 , supported portions 119 are provided in a state in which they protrude from the lid body 116 outward in the width direction and the container body side on both sides in the width direction of the upper end portion of the lid body 116 .

[0198] The supported portion 119 is formed of a plate-shaped...

no. 3 approach 》

[0201] "Third Embodiment" frame support type

[0202] Hereinafter, a third embodiment of a substrate transfer facility to which the substrate storage container of the present invention is applied will be described with reference to the drawings.

[0203] In addition, since the third embodiment has the same configuration as the first embodiment except for the configurations of the engaging portion 114, the engaged portion 115, the supported portion 119, and the receiving support body 123, it is the same as the first embodiment. The same reference numerals are attached to the configurations, and the description thereof will be omitted, and the configurations different from the first embodiment will be mainly described.

[0204] like Figure 20 As shown, the engaged portion 115 of the lid member 42 is constituted by an engaged frame 46 provided on the upper end portion of the lid body 116 in a state protruding from the lid member 42 toward the container body side. .

[0205] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com