Electrobath capable of being used for continuous electrolysis to synthesize butanedioic acid

A technology of electrolytic synthesis and succinic acid, which is applied in electrolytic process, electrolytic components, electrolytic organic production, etc., and can solve problems such as short circuit, electrode slime accumulation, and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

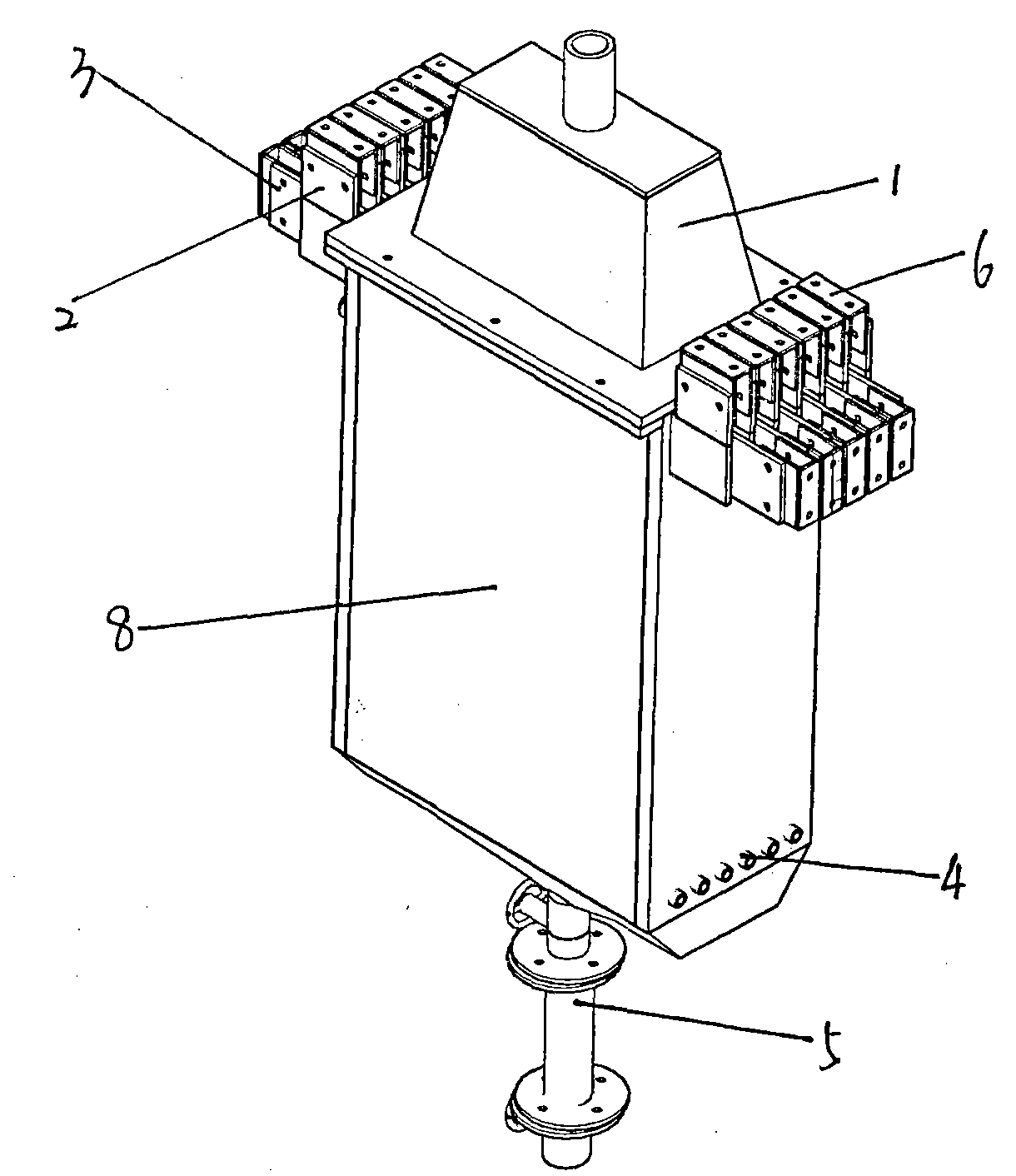

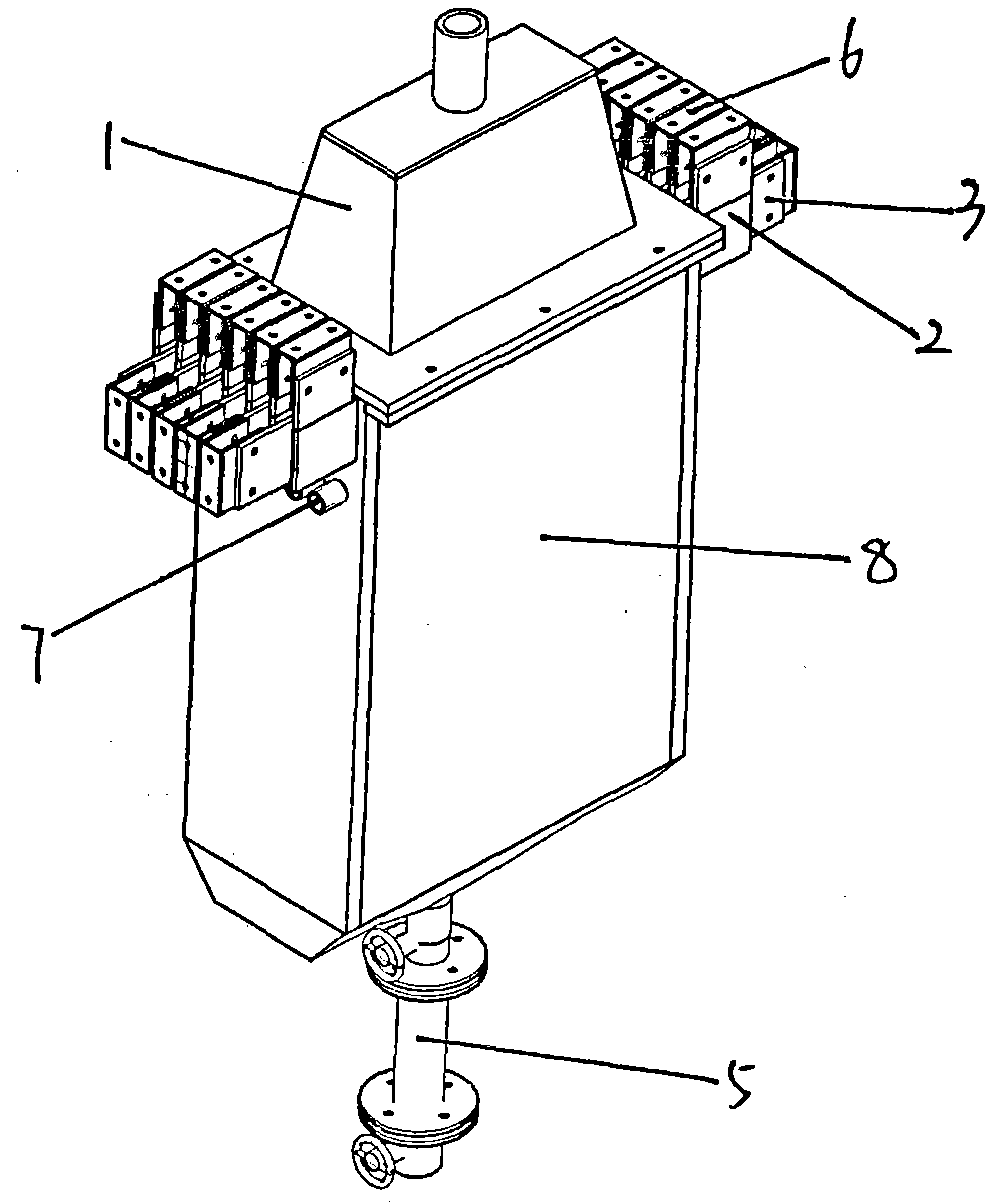

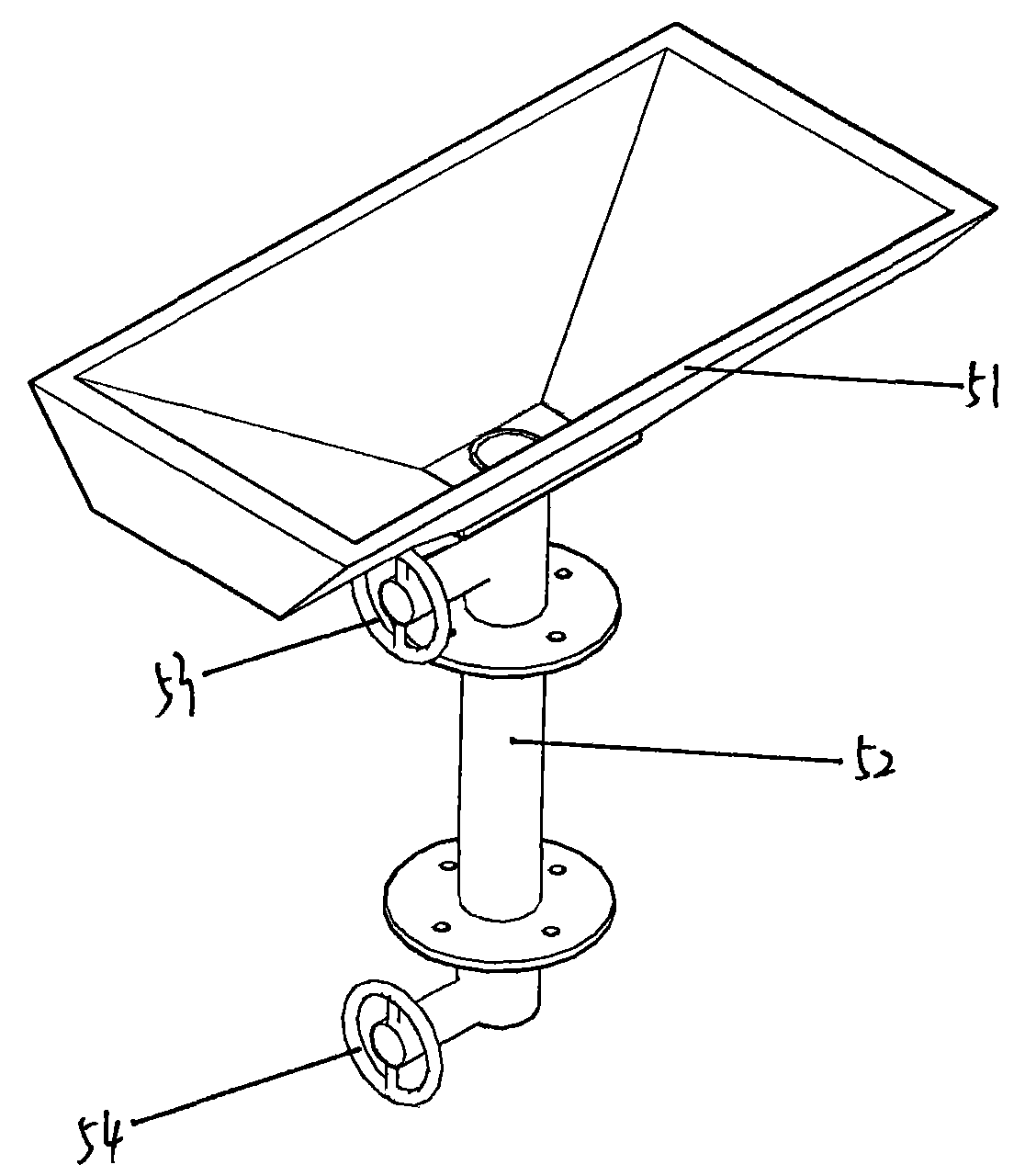

[0022] refer to Figure 1-5 , an electrolytic cell that can be used for continuous electrolytic synthesis of succinic acid, comprising a casing 8, a cathode 3, and an anode 2, the casing 8 is provided with an electrolyte inlet 4 and an electrolyte outlet 7, and the casing 8 is connected to There is a gas collector 1, and an electrode slime collector 5 is connected to the bottom of the box body 8. The electrode slime collector 5 includes a mud collection chamber 51, and the outlet of the mud collection chamber 51 is connected to an electrode slime storage chamber 52. The mud storage chamber 52 is provided with a valve.

[0023] The inner wall of the mud collecting chamber 51 is inclined.

[0024] The valves include an inlet valve 53 and an outlet valve 54 .

[0025] The bottom of the outer wall of the mud collecting chamber 51 is provided with a horizontal bottom surface.

[0026] There is no diaphragm between the cathode 3 and the anode 2.

[0027] The electrolyte inlet 4 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com