Optical fiber fluid temperature measurement method and system for engine pipeline digital twin model

A fluid temperature measurement and engine technology, which is applied to thermometers, thermometers, measuring devices, etc. with physical/chemical changes, which can solve the influence of the internal space of the pipeline, the inaccurate temperature parameter values, and the inability to truly simulate the temperature parameters of the fluid in the pipeline, etc. problem, to achieve the effect of strong authenticity and small occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

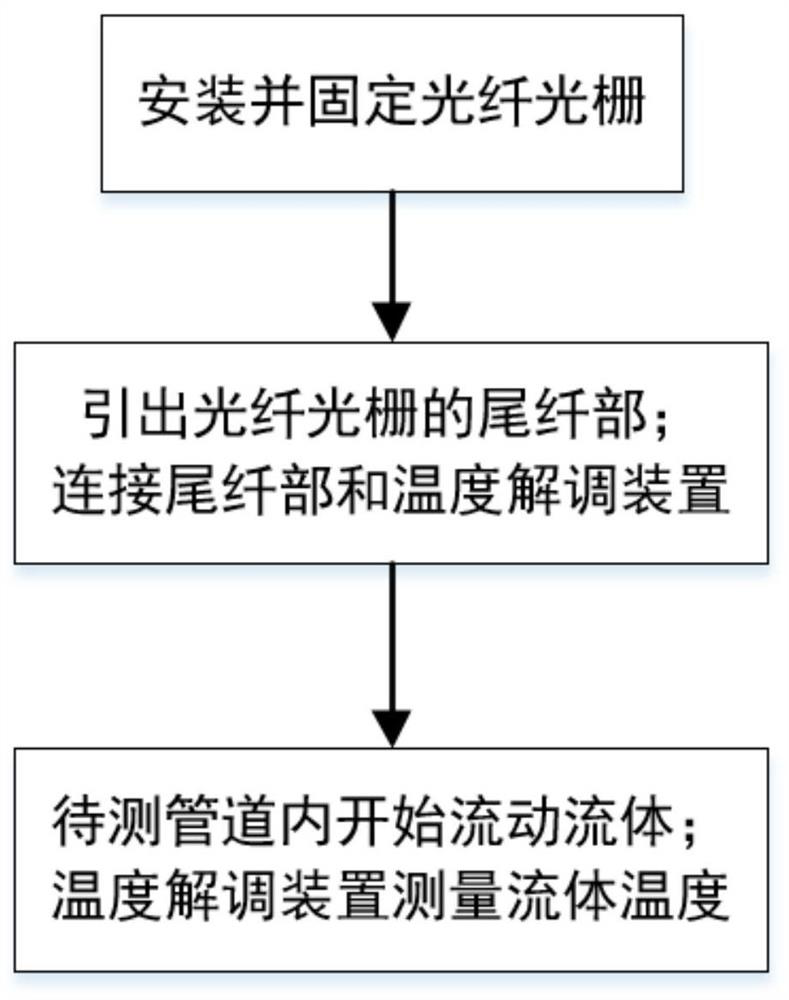

[0046] The embodiment is basically as attached figure 1 , figure 2 Shown: A fiber optic fluid temperature measurement method for a digital twin model of an engine pipeline, including the following steps:

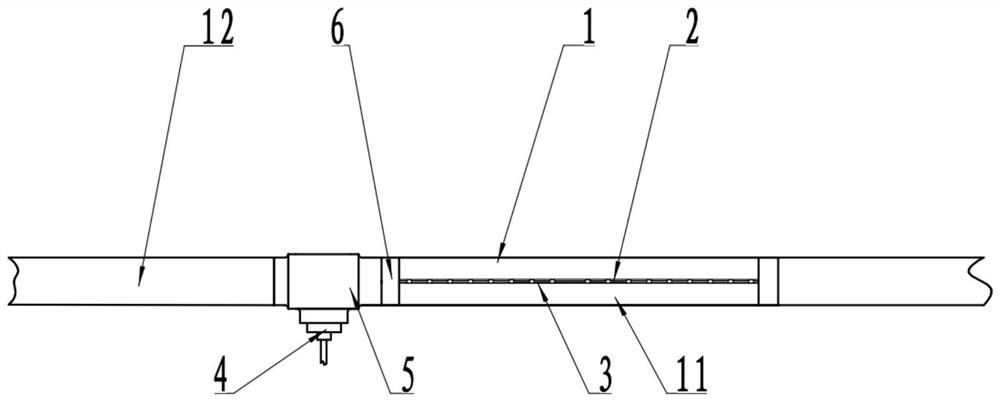

[0047] Step 1: install the fiber grating 2 so that the fiber grating 2 passes through the pipeline 1 to be tested and does not touch the inner pipe wall of the pipeline 1 to be tested; fix the fiber grating 2 .

[0048] When fixing the fiber grating 2, the fiber grating 2 is fixed by using a triangular fixing frame 6, and the triangular fixing frame 6 is arranged at the end and tail of the temperature measuring section 11 of the pipeline 1 to be tested. When installing the fiber grating 2, the position of the fiber grating 2 is also adjusted so that the axis of the fiber grating 2 is parallel to the axis of the pipeline to be tested 1, and the distance between the axis of the fiber grating 2 and the axis of the pipeline to be tested is a preset distance. In this embodimen...

Embodiment 2

[0066] This embodiment provides a fiber optic fluid temperature measurement method for a digital twin model of an engine pipeline, which is the same as the method described in Embodiment 1, so details are not repeated here.

[0067] This embodiment also provides a fiber optic fluid temperature measurement system for the digital twin model of the engine pipeline. On the basis of Embodiment 1, a temperature alarm module and a calibration module are added to the temperature demodulation device. The temperature alarm module Both the calibration module and the calibration module are located in the signal processing device. The temperature alarm module is used to monitor the temperature of each temperature collection point on the fiber grating 2. When the temperature value is abnormal, it will immediately give an alarm in the form of voice notification or SMS notification. Specifically, when the temperature of the fluid in the pipeline exceeds the threshold temperature, an alarm is i...

Embodiment 3

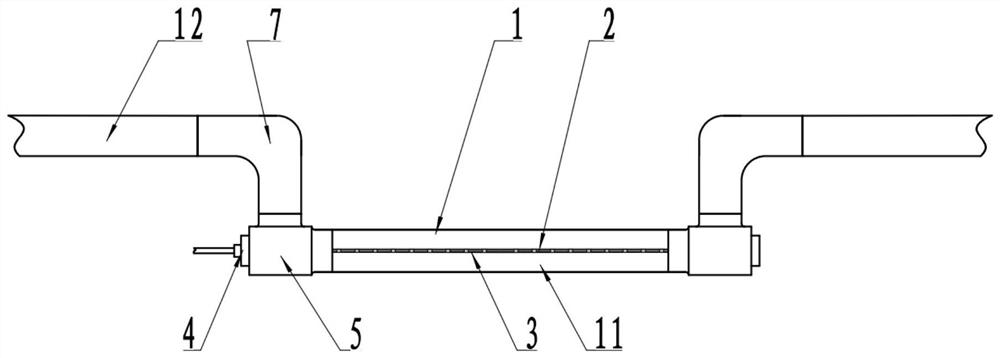

[0070] as attached image 3 As shown, the fiber optic fluid temperature measurement method for the digital twin model of the engine pipeline is based on the first embodiment, and the installation and connection methods of the fiber grating 2 in steps 1 and 2 are changed.

[0071] Step 1: install the fiber grating 2 so that the fiber grating 2 passes through the pipeline 1 to be tested and does not touch the inner pipe wall of the pipeline 1 to be tested; fix the fiber grating 2 .

[0072] When fixing the fiber Bragg grating 2, a three-way connector 5 is used to fix the pipe, and a three-way connector 5 is installed at the end and tail of the temperature measurement section 11. The temperature measuring section 11 of the measuring pipe 1, the non-temperature measuring section 12 and the lead-out part of the pigtail part of the fiber Bragg grating 2. At the same time, when the non-temperature-measuring section 12 of the pipeline 1 to be tested is connected, the non-temperature-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com