Differential Planar Capacitive Sensor Array Measuring Method of Particle Velocity Distribution

A technology of capacitive sensor and particle velocity, which is applied in fluid velocity measurement, velocity/acceleration/impact measurement, measuring device, etc., can solve the problems of inability to obtain pipeline cross-section, low frequency selectivity of velocity field distribution spatial filtering, etc., and achieve improvement space Frequency selectivity, convenient signal processing, and the effect of improving space selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

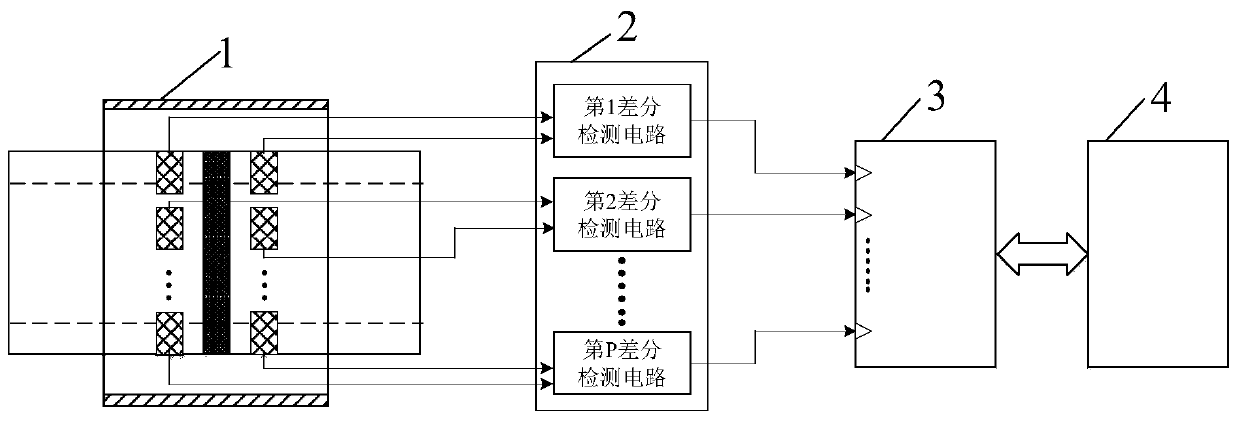

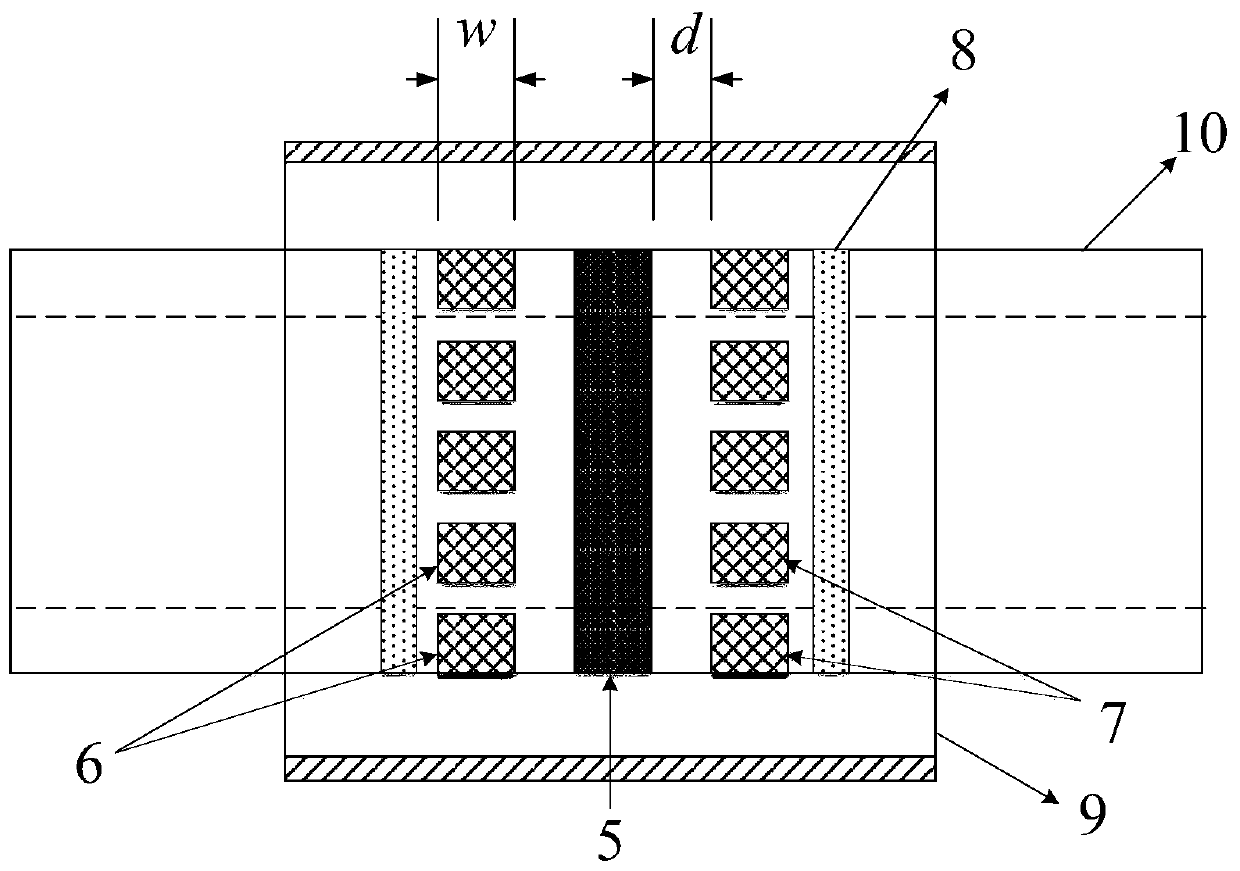

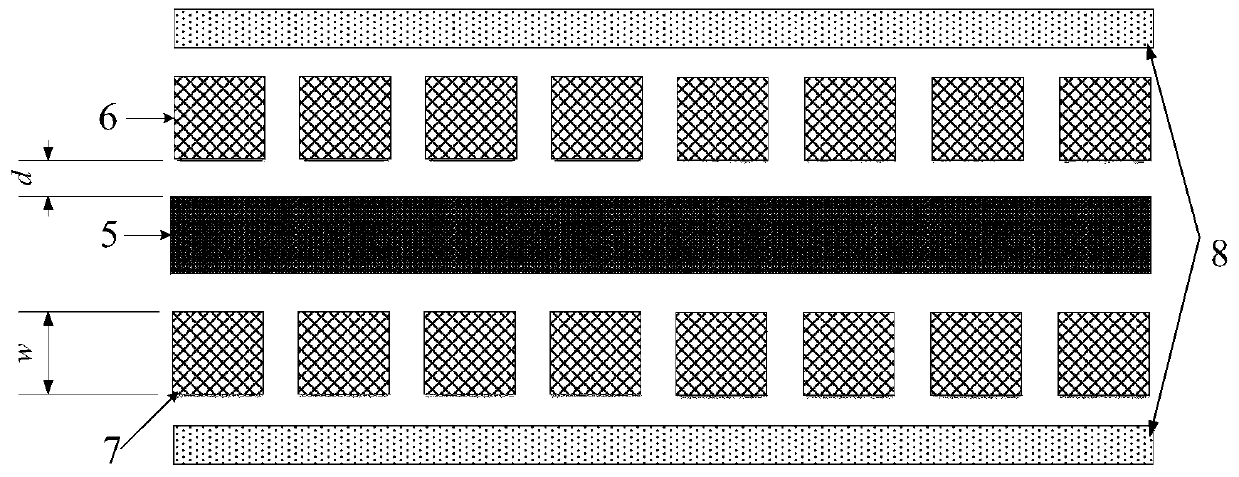

[0066] A method for measuring a differential planar capacitive sensor array for particle velocity distribution, using a differential planar capacitive sensor array measuring device for particle velocity distribution, including a measuring probe 1, an insulated measuring pipeline 10, and a capacitance differential detection circuit 2 , a data acquisition card 3 and a computer 4 for analyzing the frequency spectrum of the output signal of the data acquisition card and determining the frequency bandwidth, and then calculating and obtaining the particle velocity of the gas-solid two-phase flow. The measuring probe includes an electrode array and a metal shield 9 arranged on the outer wall of the insulating pipe, and the electrode array includes a ring-shaped excitation electrode 5, 2×8 arc-shaped induction electrodes, and 2 electrodes used to define the axis of the sensor. The axial protection electrode 8 in the sensitive range has 8 rows of arc-shaped sensing electrode arrays alon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com