Patents

Literature

33results about How to "Product thin" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

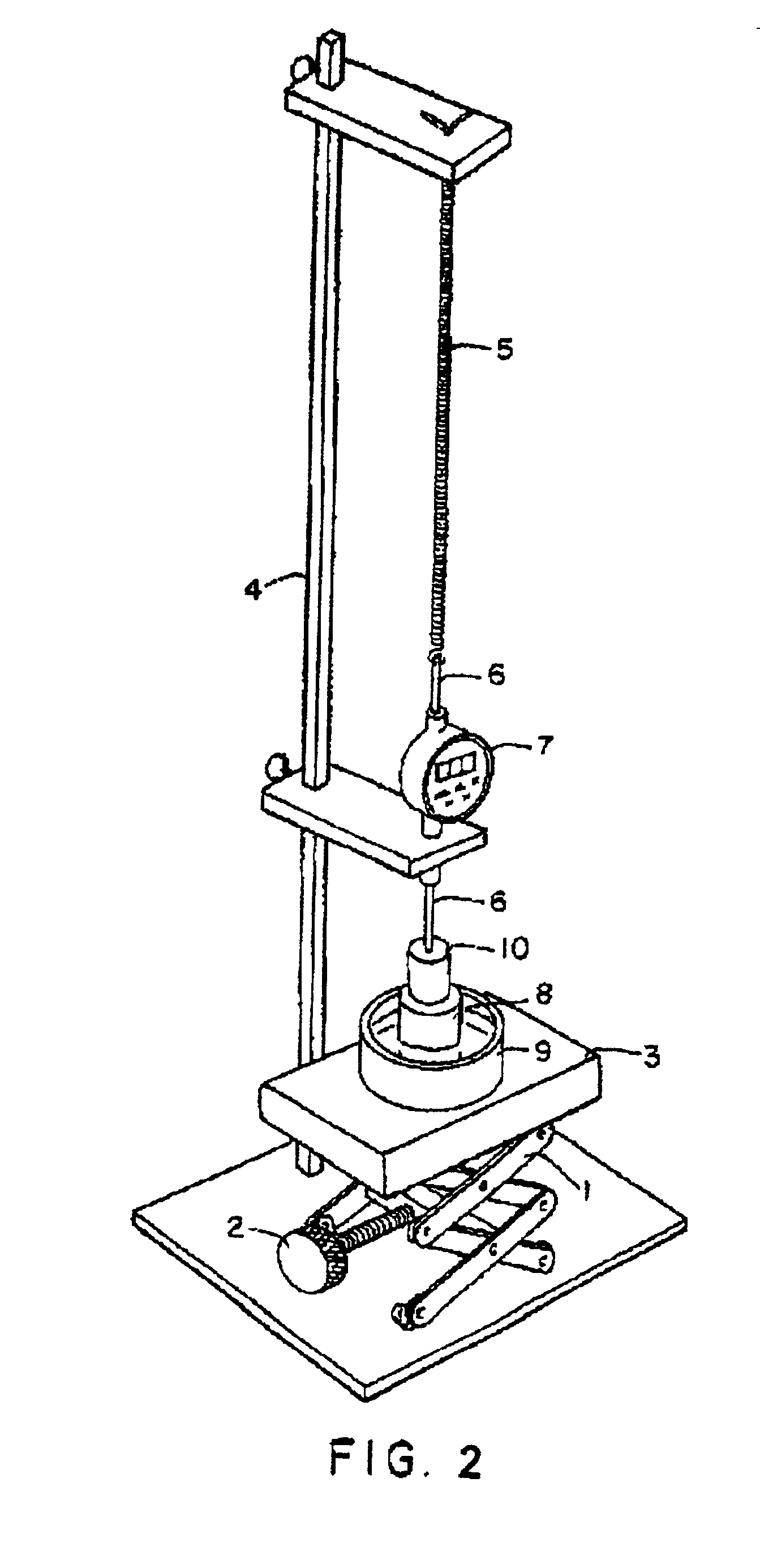

Absorbent composition containing transitional crosslinking points

InactiveUS6998367B2Controlled fluid absorption rateImproved fluid distributionOther chemical processesBaby linensSwelling capacityWater insoluble

A water insoluble, water swellable absorbent composition exhibiting a free swell absorbency of at least 15 g / g and an Absorbency Change of greater than or equal to 15% upon saturation. The absorbent composition includes both permanent crosslinking points and transitional crosslinking points. The absorbent composition has a high free swell capacity as well as a high absorbency under load.

Owner:KIMBERLY-CLARK WORLDWIDE INC

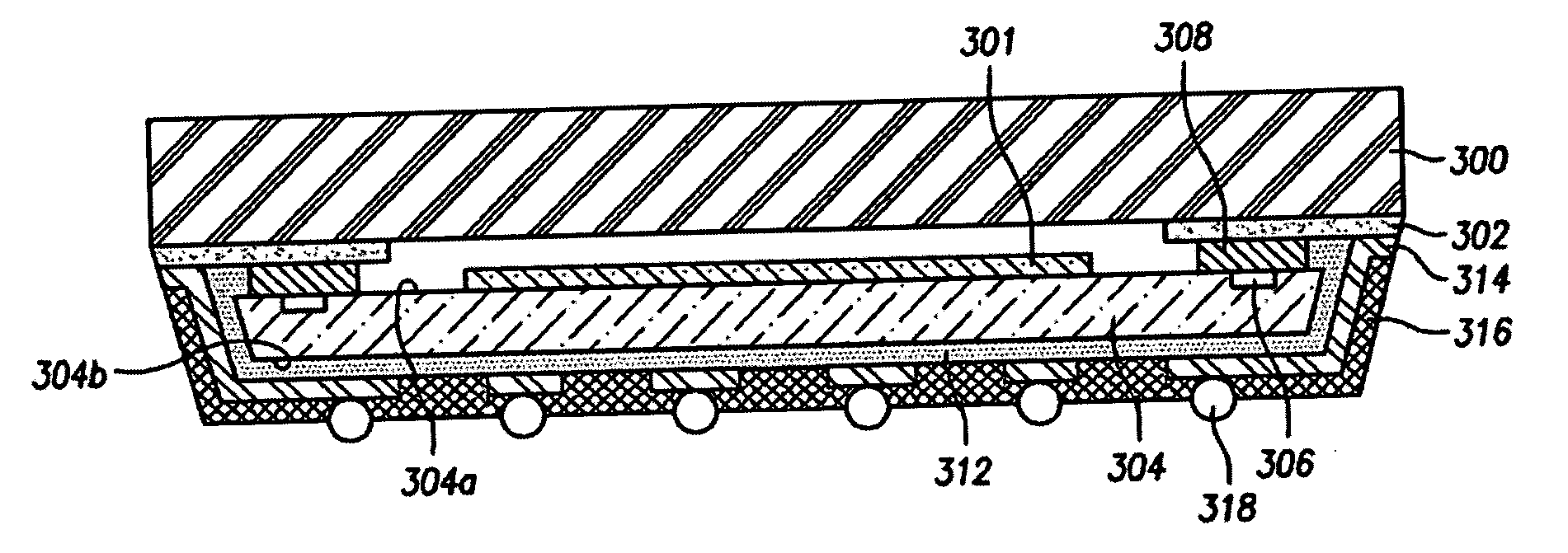

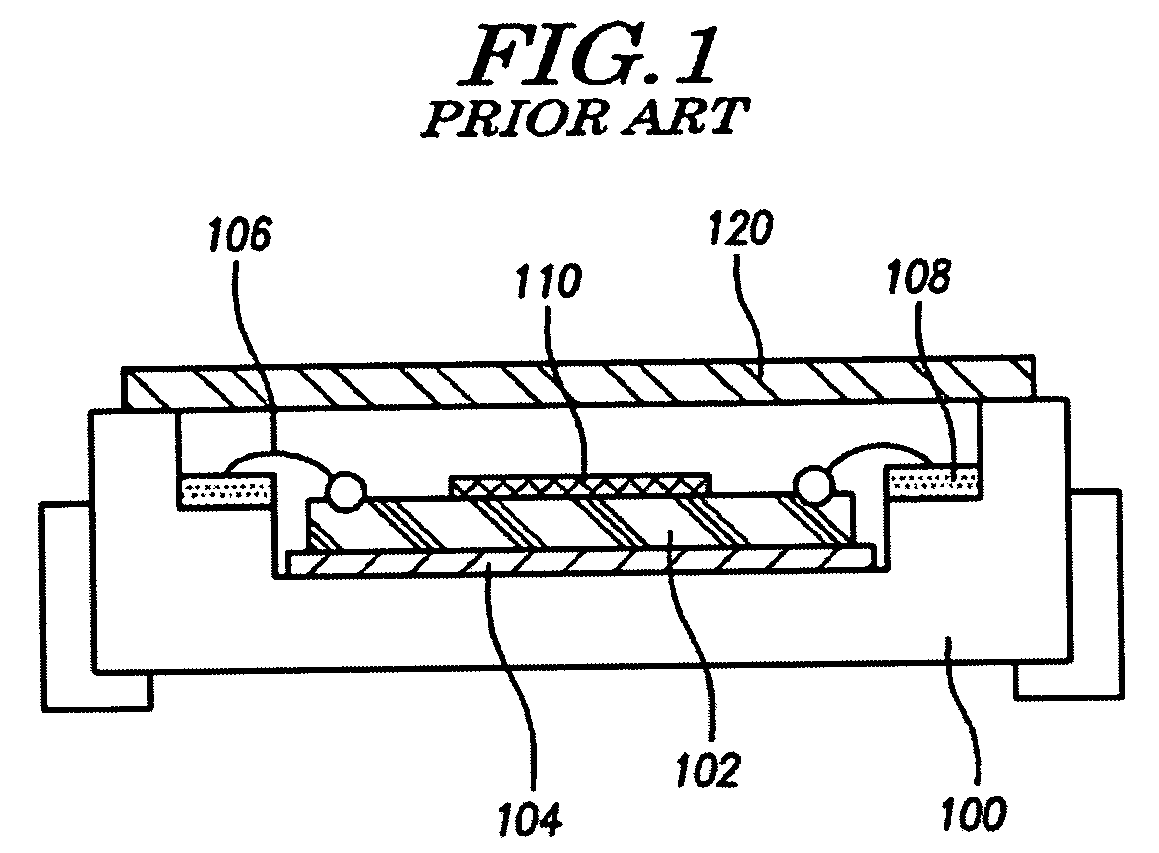

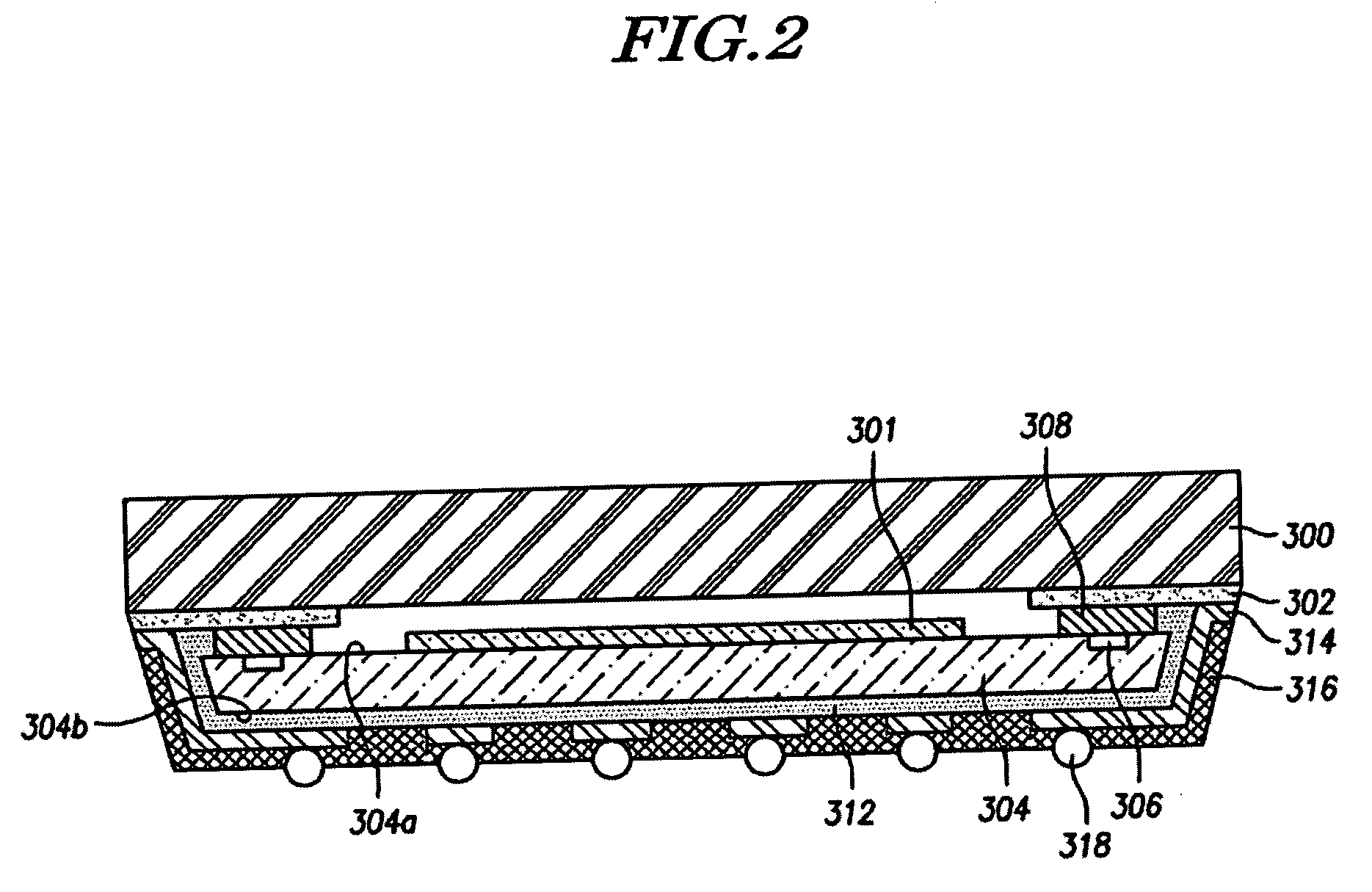

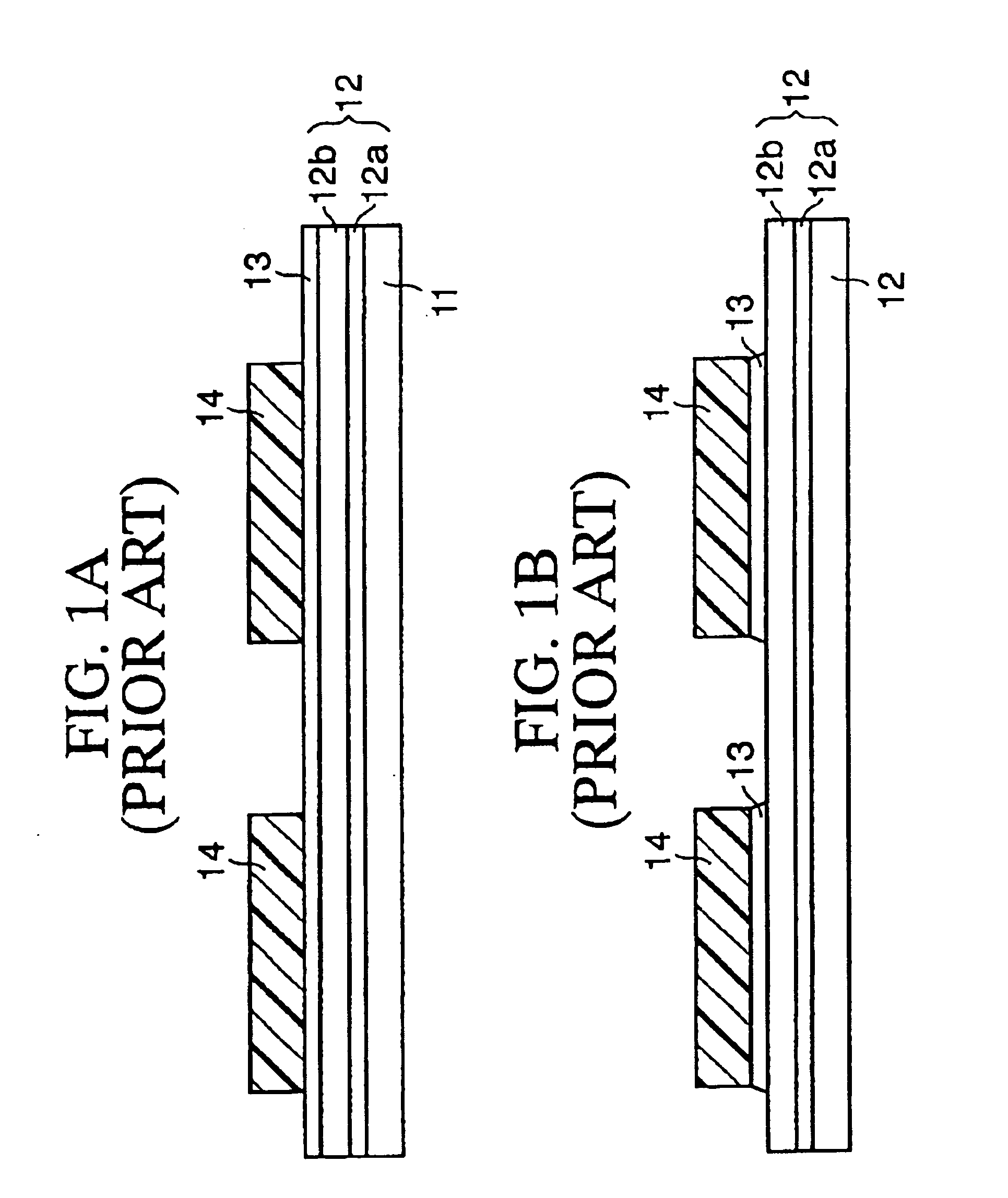

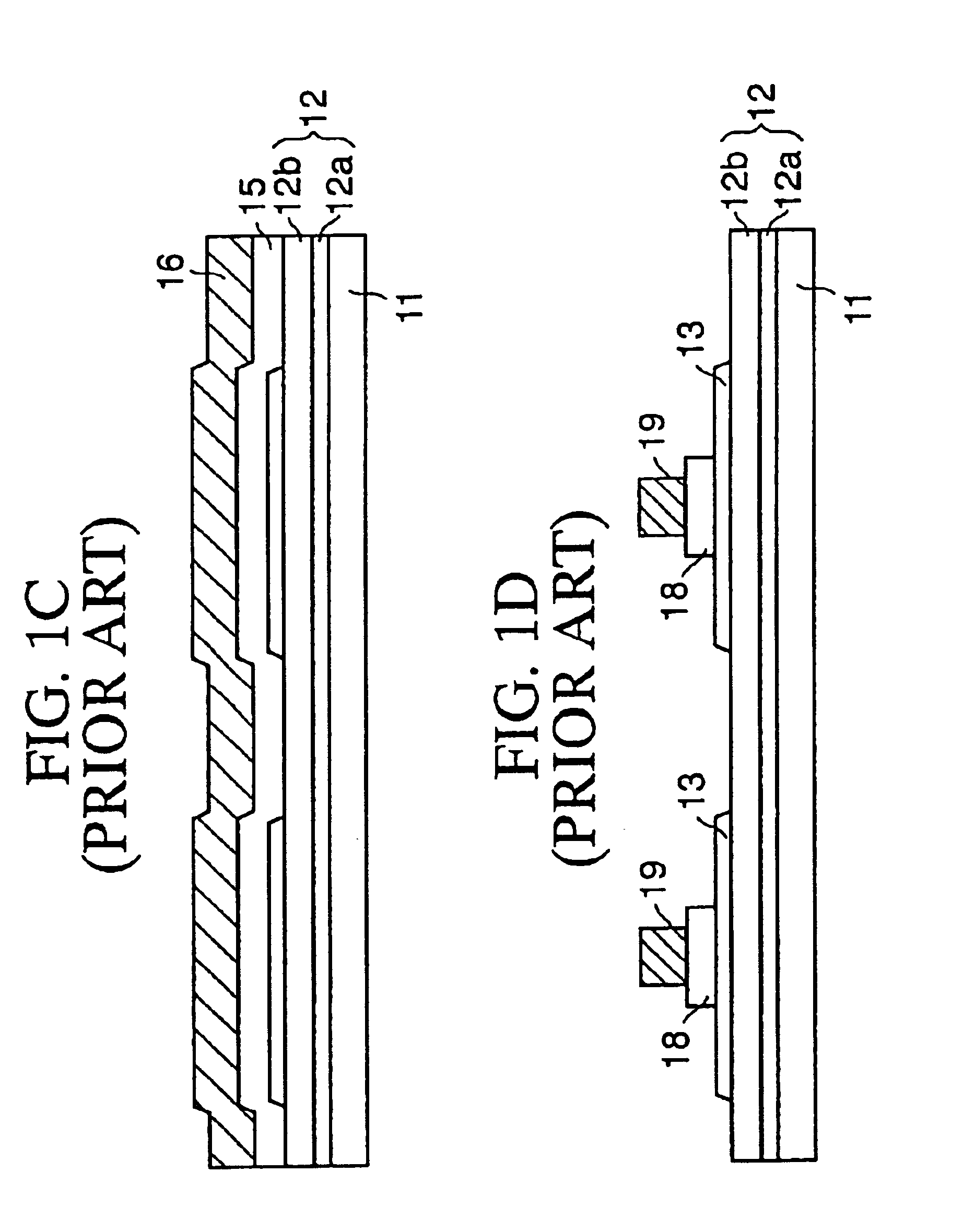

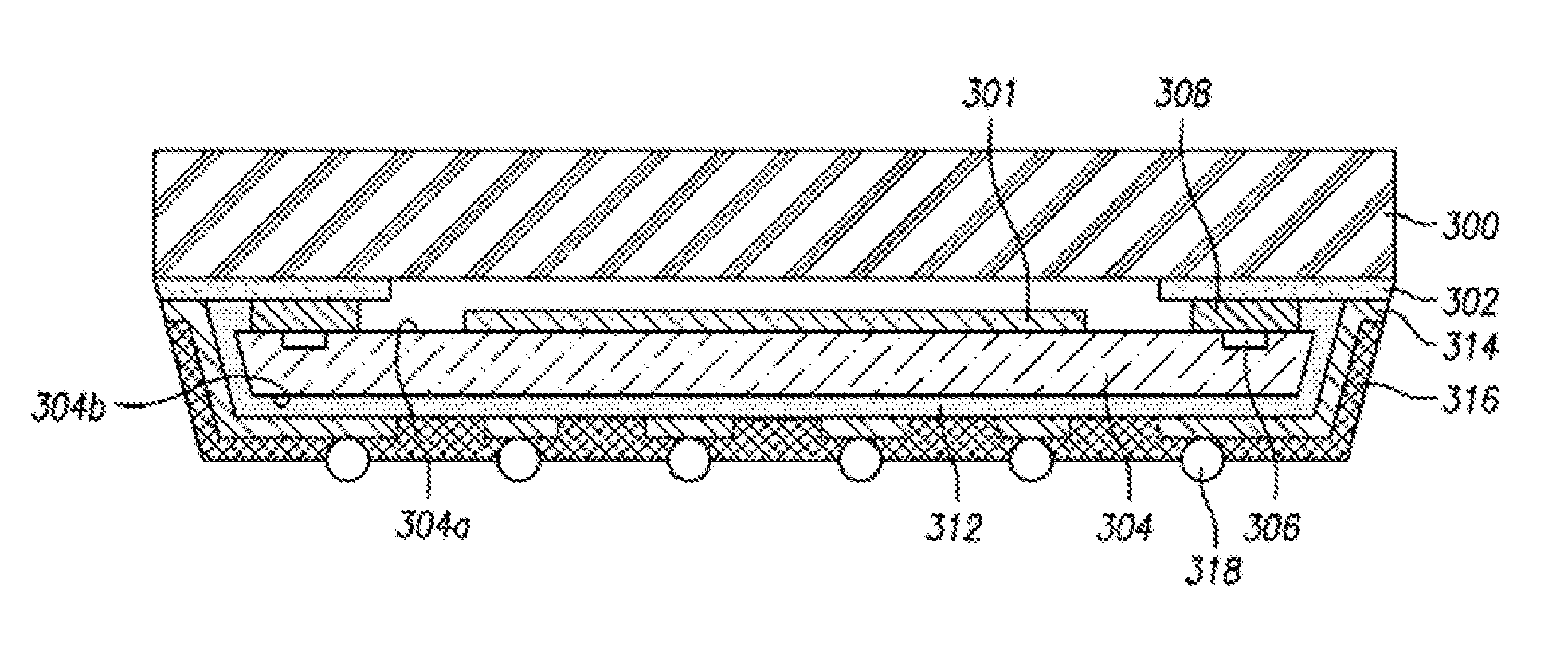

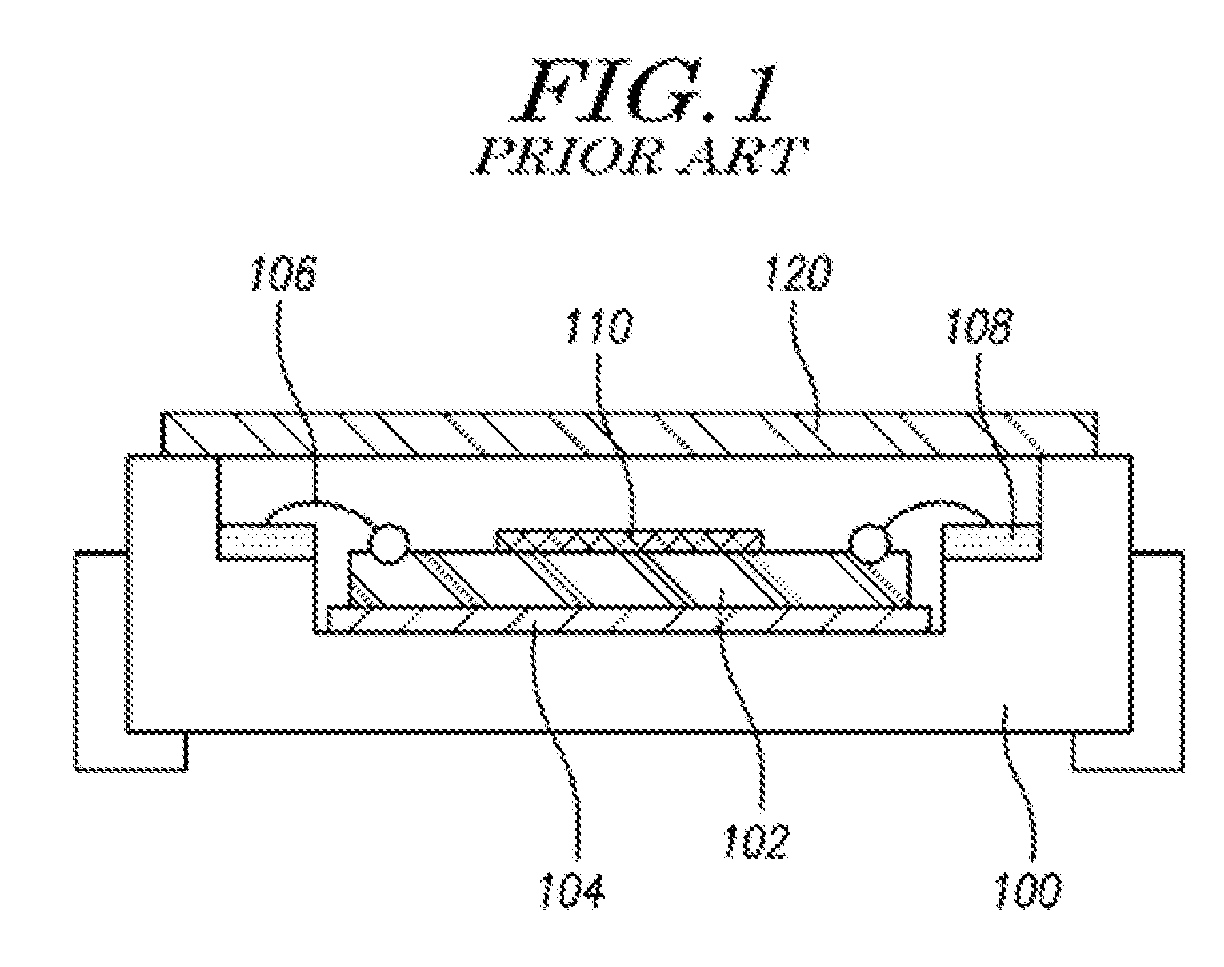

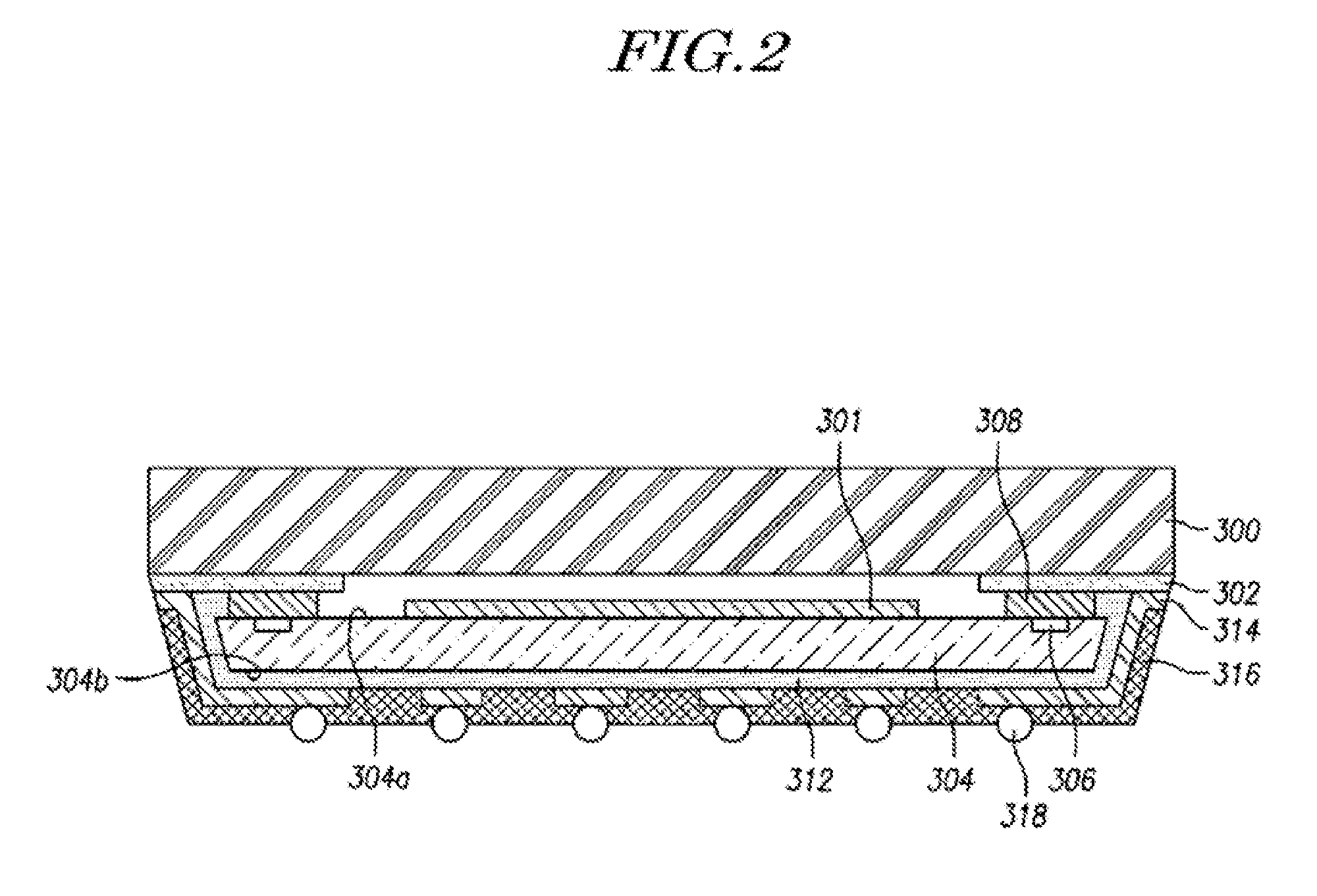

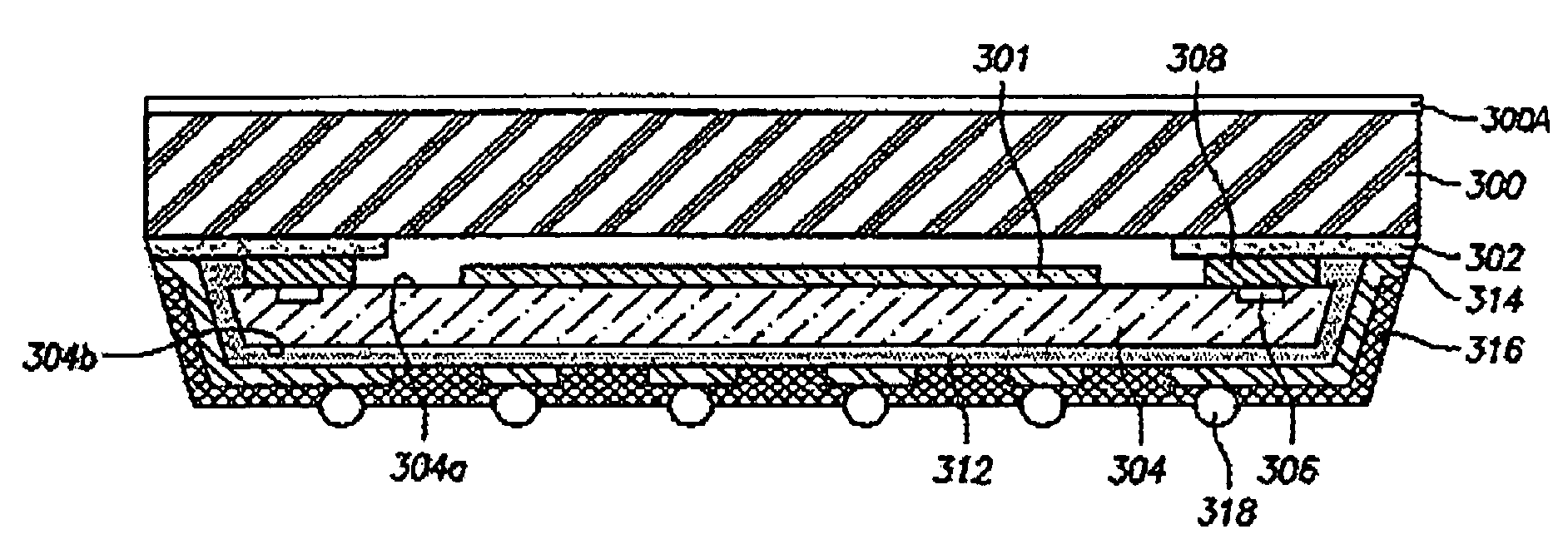

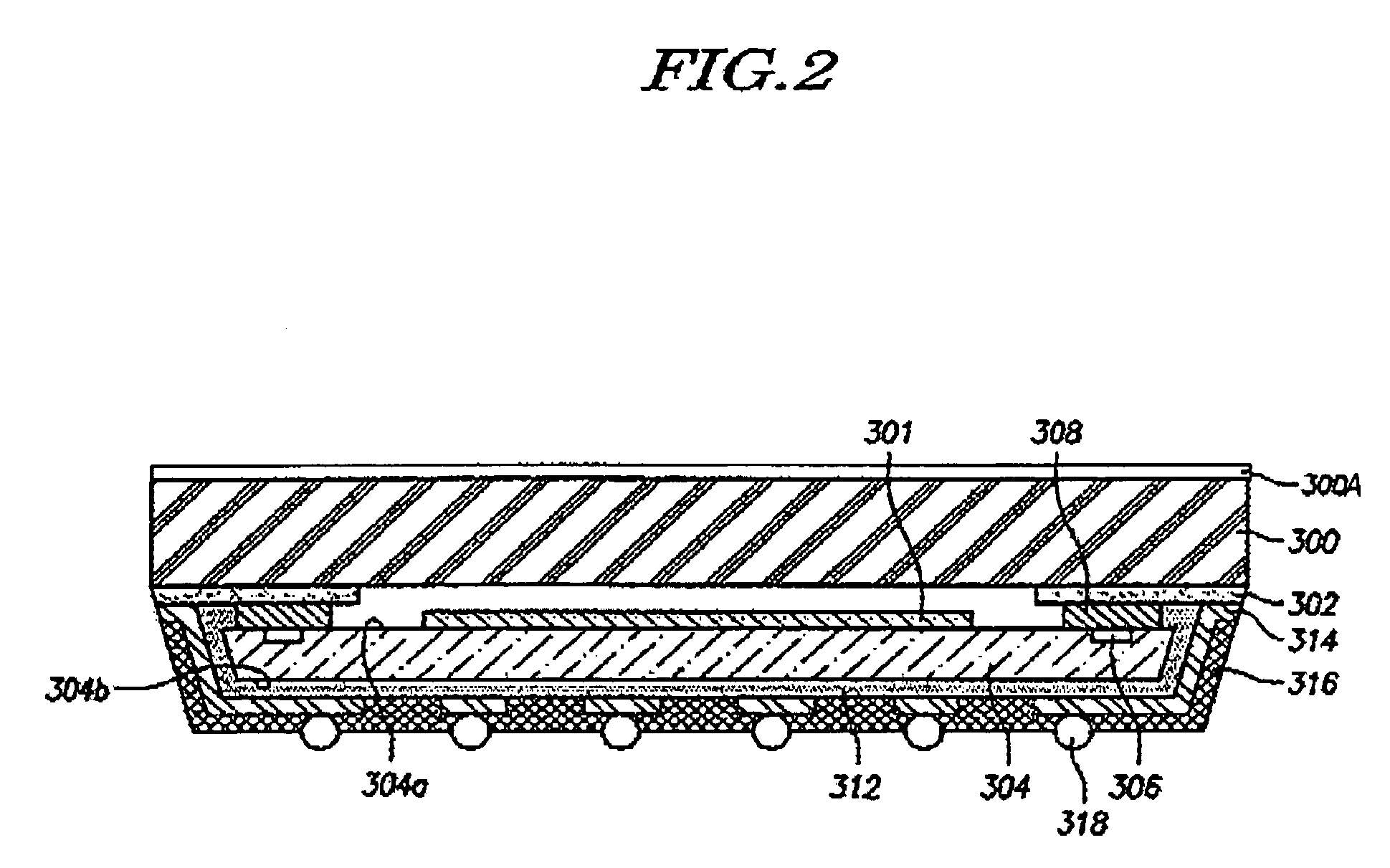

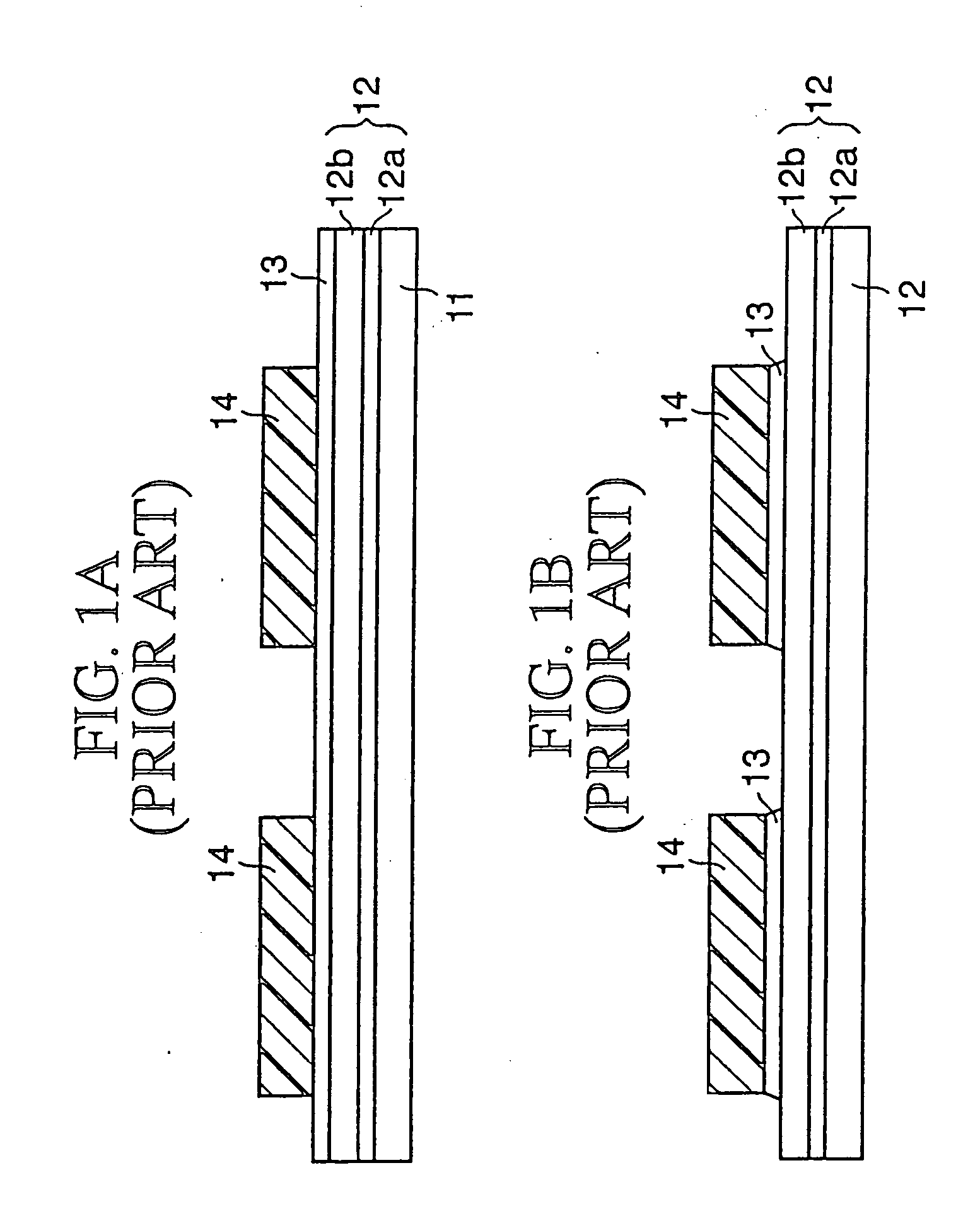

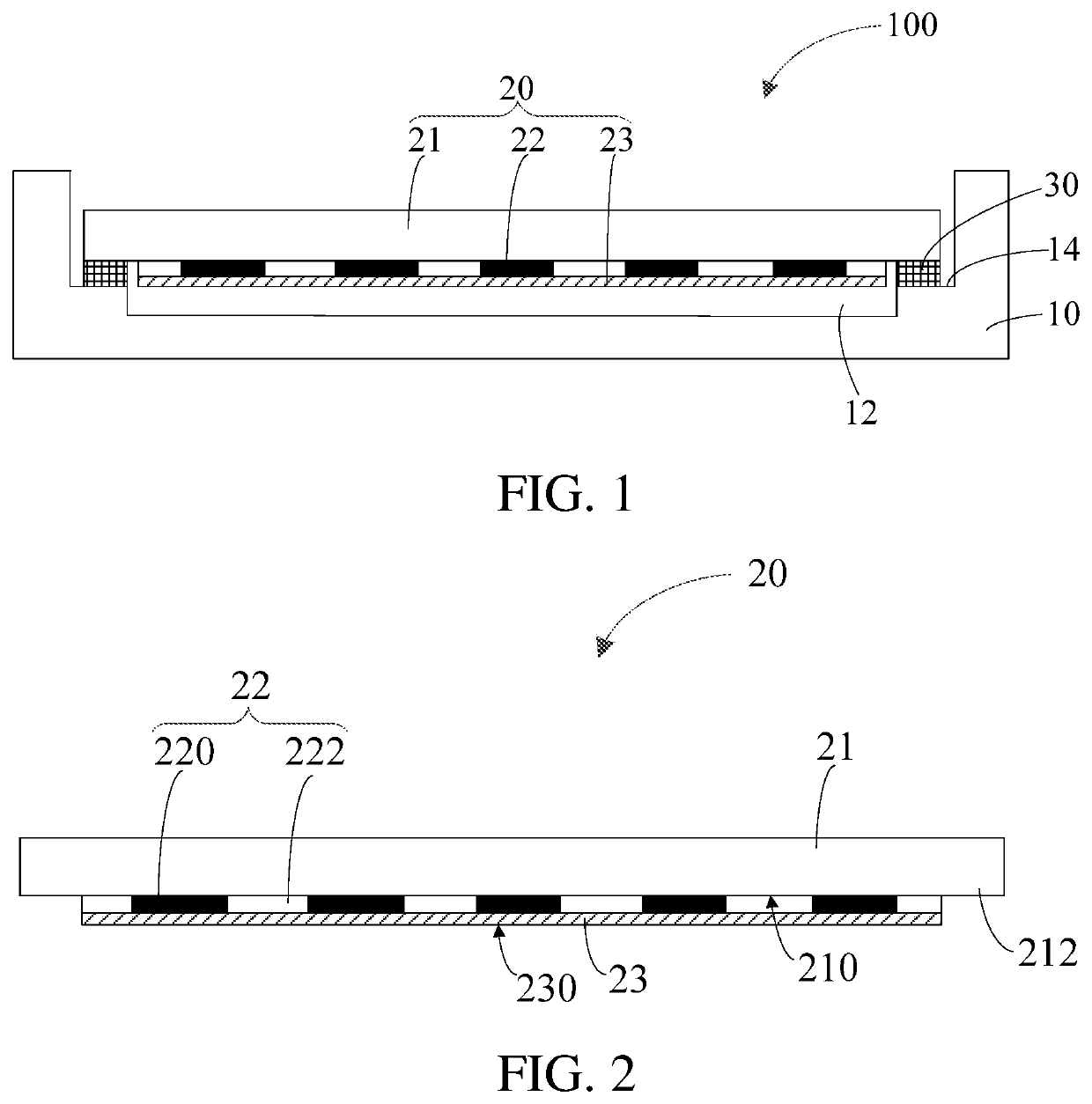

Image sensor chip package and method of fabricating the same

InactiveUS20060091488A1Simple processThinned imageSemiconductor/solid-state device detailsSolid-state devicesImage sensorSolder ball

The present invention relates to an image sensor chip package and a method for fabricating the same. In one embodiment of an image sensor chip package, chip pads on a first surface of an image sensor chip are attached to electrode pads of a glass substrate with conductive material. In addition, electrode pads are connected to solder balls via a metal wiring pattern arranged on a second surface of the image sensor chip. As a result, the present invention can provide further miniaturized and thinned image sensor chip packages, reduce fabricating processes, and improve device performance and reliability.

Owner:DONGBU ELECTRONICS CO LTD

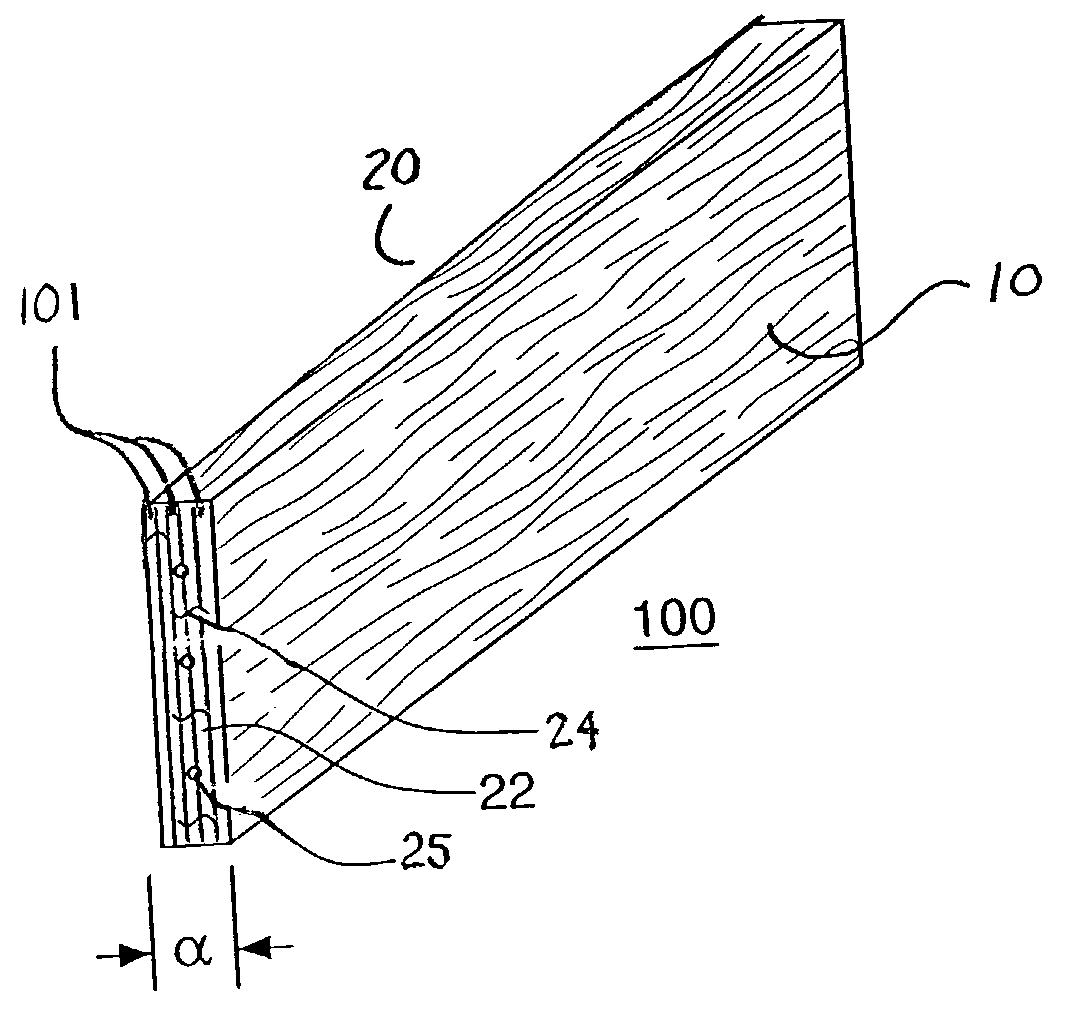

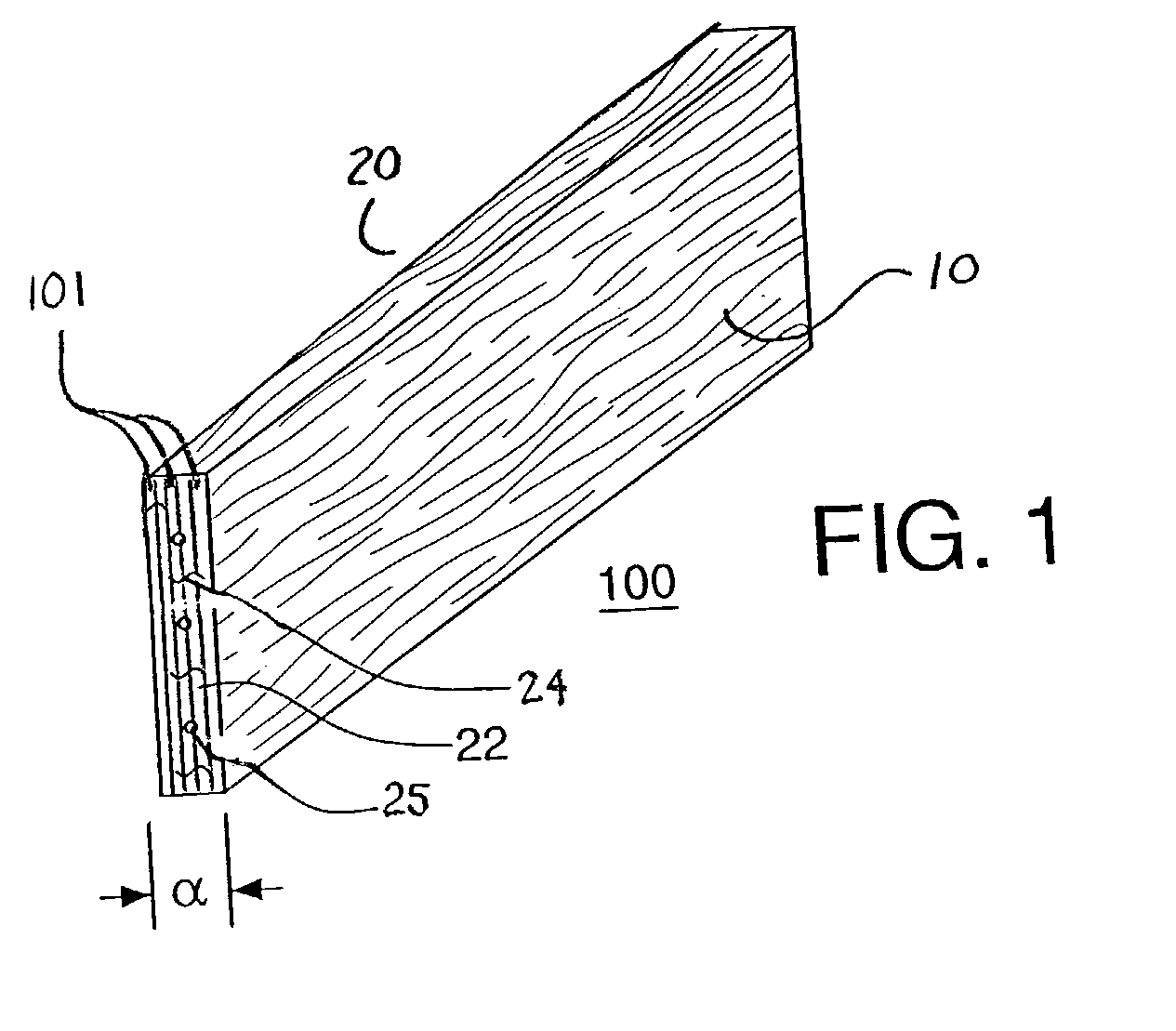

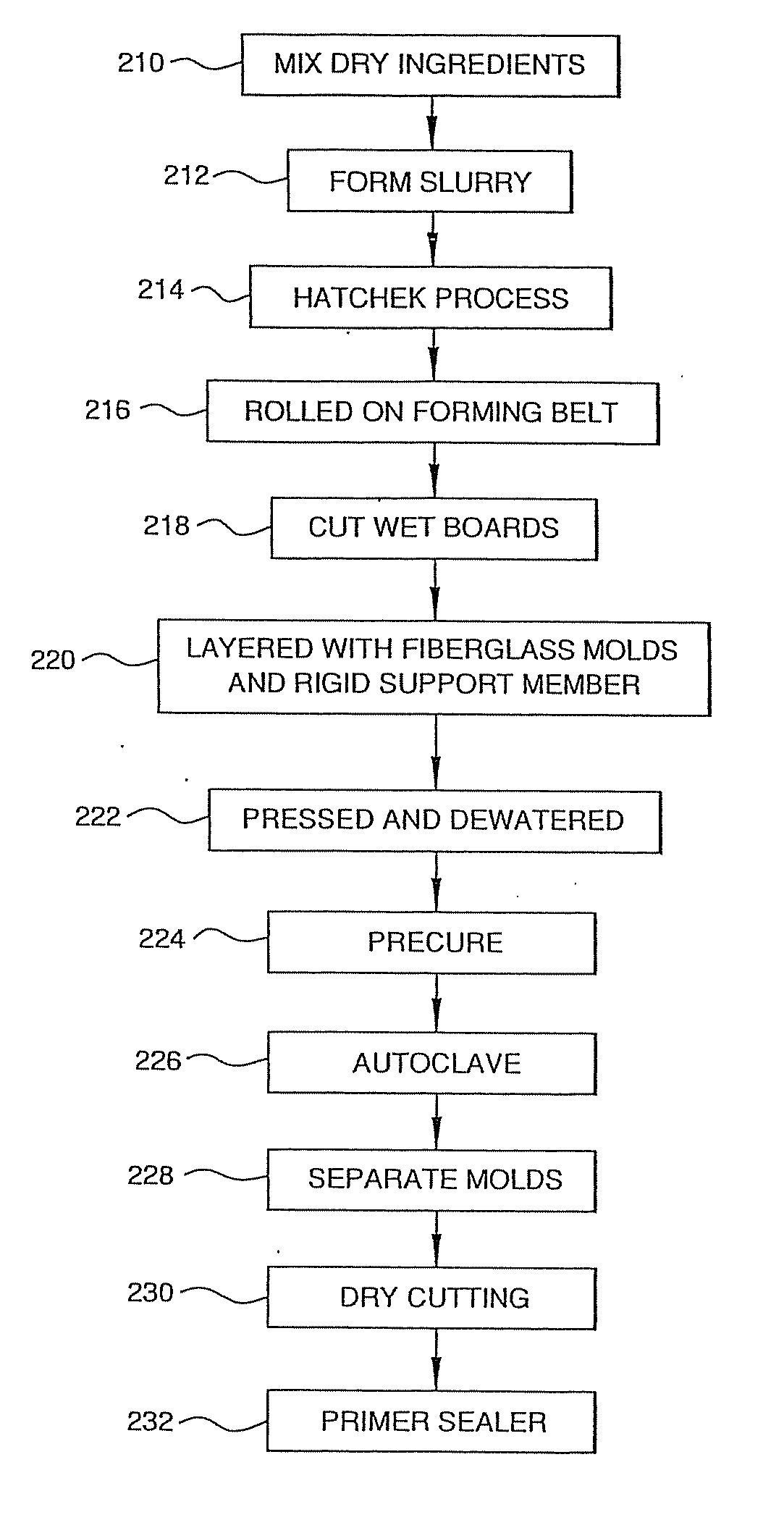

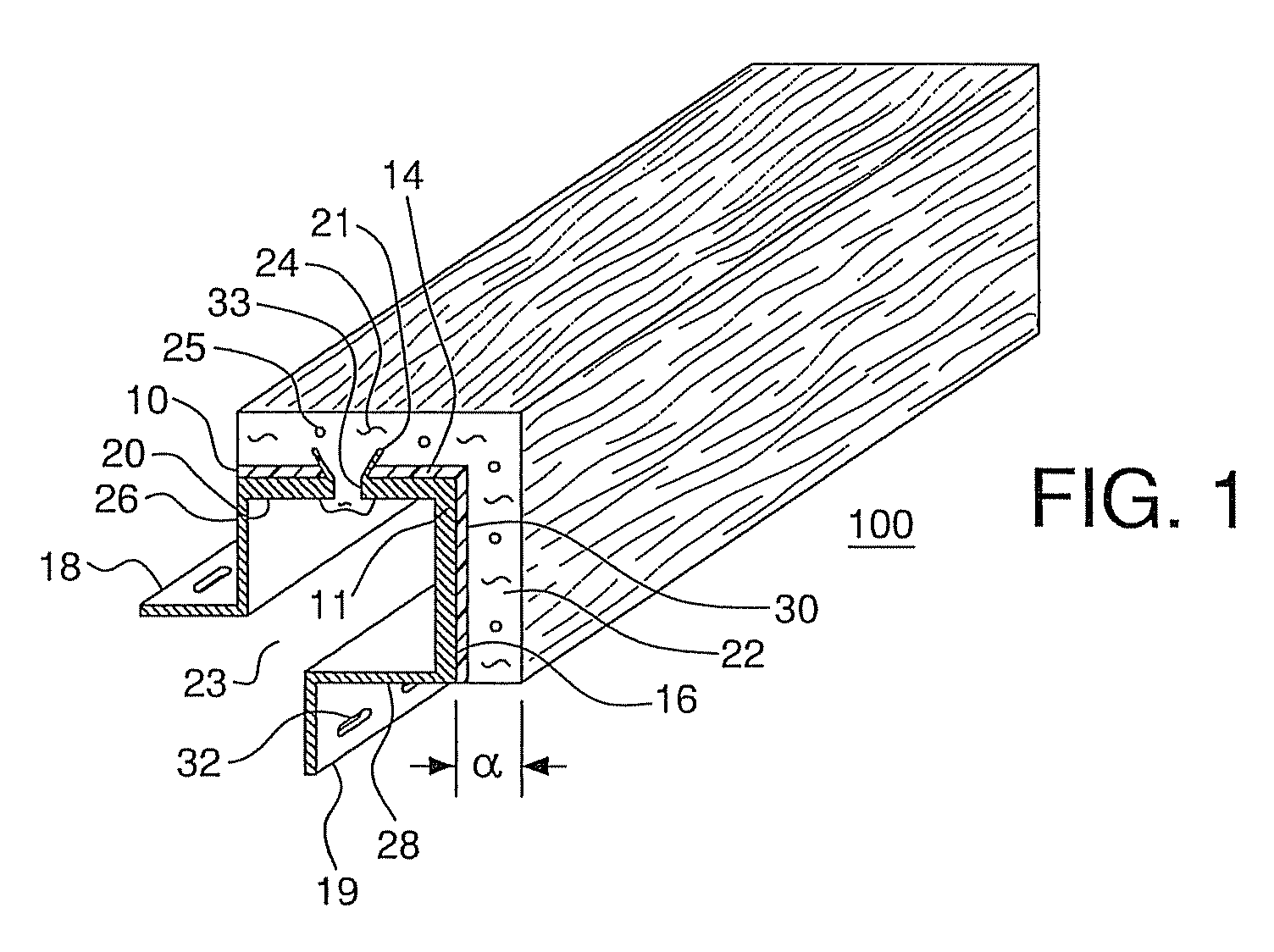

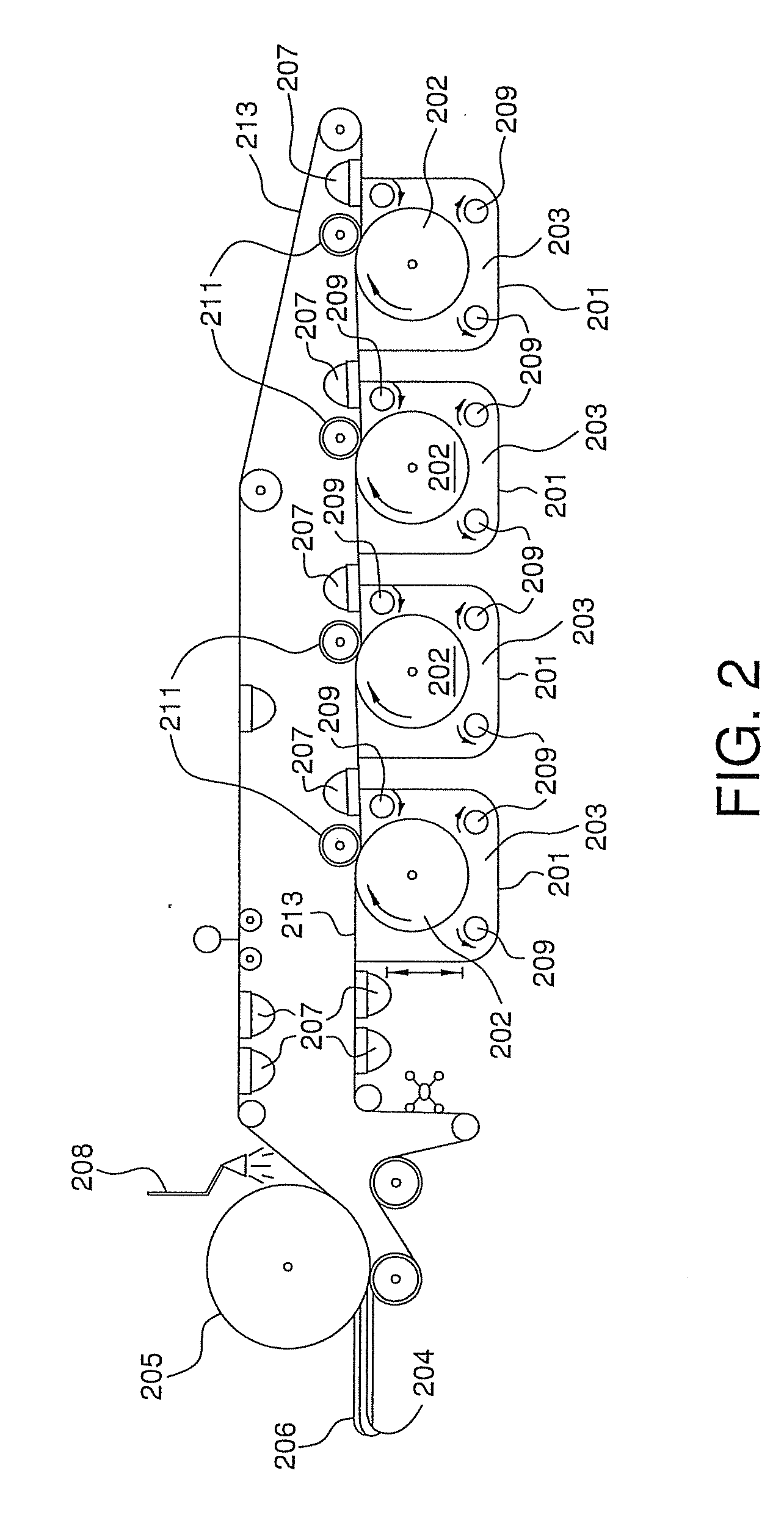

Cementitious exterior sheathing product having improved interlaminar bond strength

InactiveUS7155866B2High bonding strength between layersBeautiful appearanceRoof covering using tiles/slatesConstruction materialBuilding productFiber

The present invention provides exterior building products, such as roofing and siding, shake, shingles, siding, sheathing, panels, planks, vertical siding, soffit panels, fencing, decking, fascia, corner posts, column corners and trim boards in which a plurality of cementitious layers are provided with an improved interlaminar bond by employing a resinous bond promoter, a rheological agent, mechanical means to distribute fibers in a direction which is perpendicular to the machine direction so as to bridge between layers in the product, or a combination thereof. These techniques help to increase interlaminar bond strength to improve the mechanical properties of the product. When certain resinous bond promoters are used, the additional benefits of water absorption resistance and pigmentation throughout the product can be provided with minimal expense. Improvements in interlaminar bond strength of about 10–46% were observed with a percent elongation improvement of about 7%.

Owner:PLYCEM USA

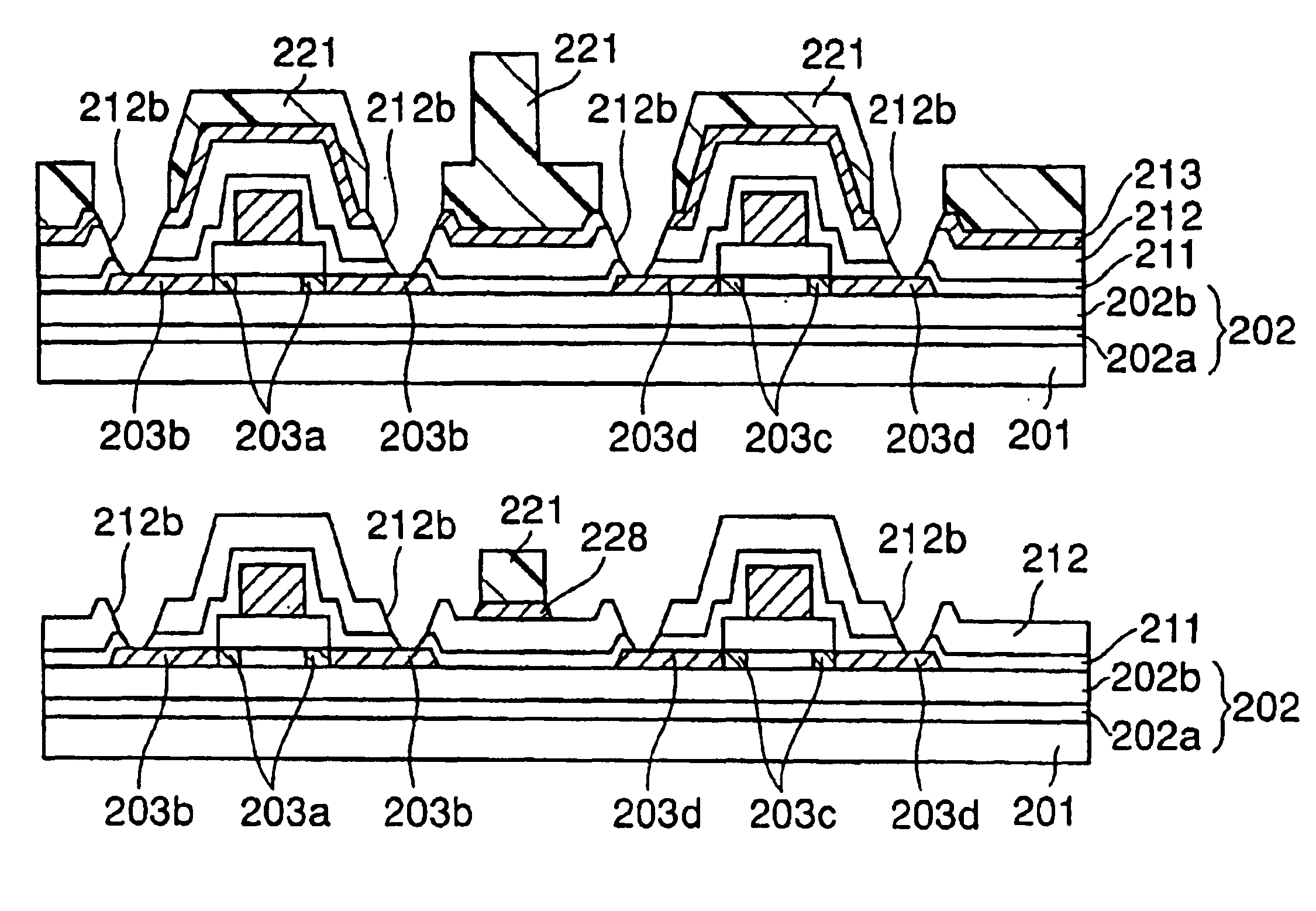

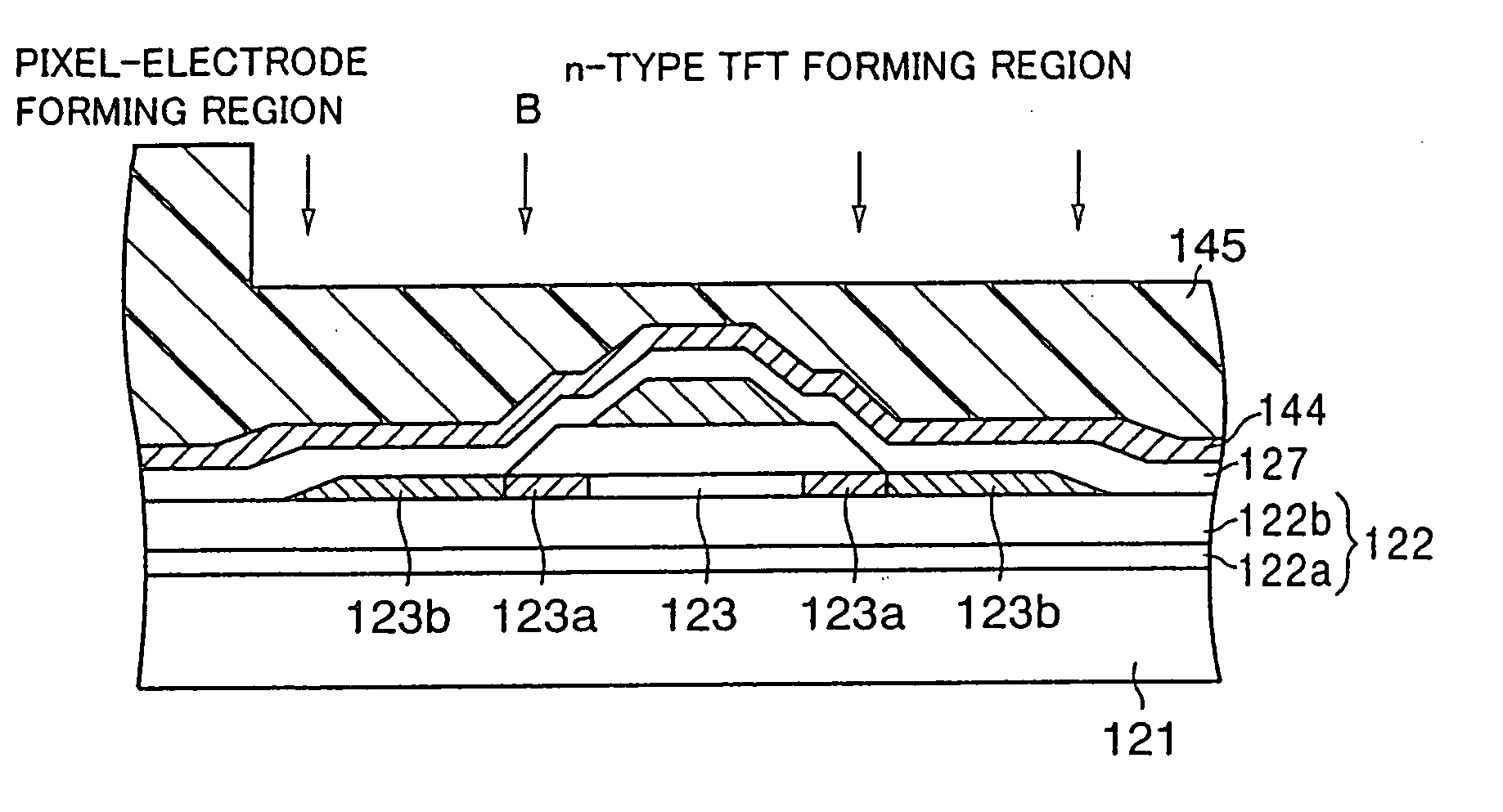

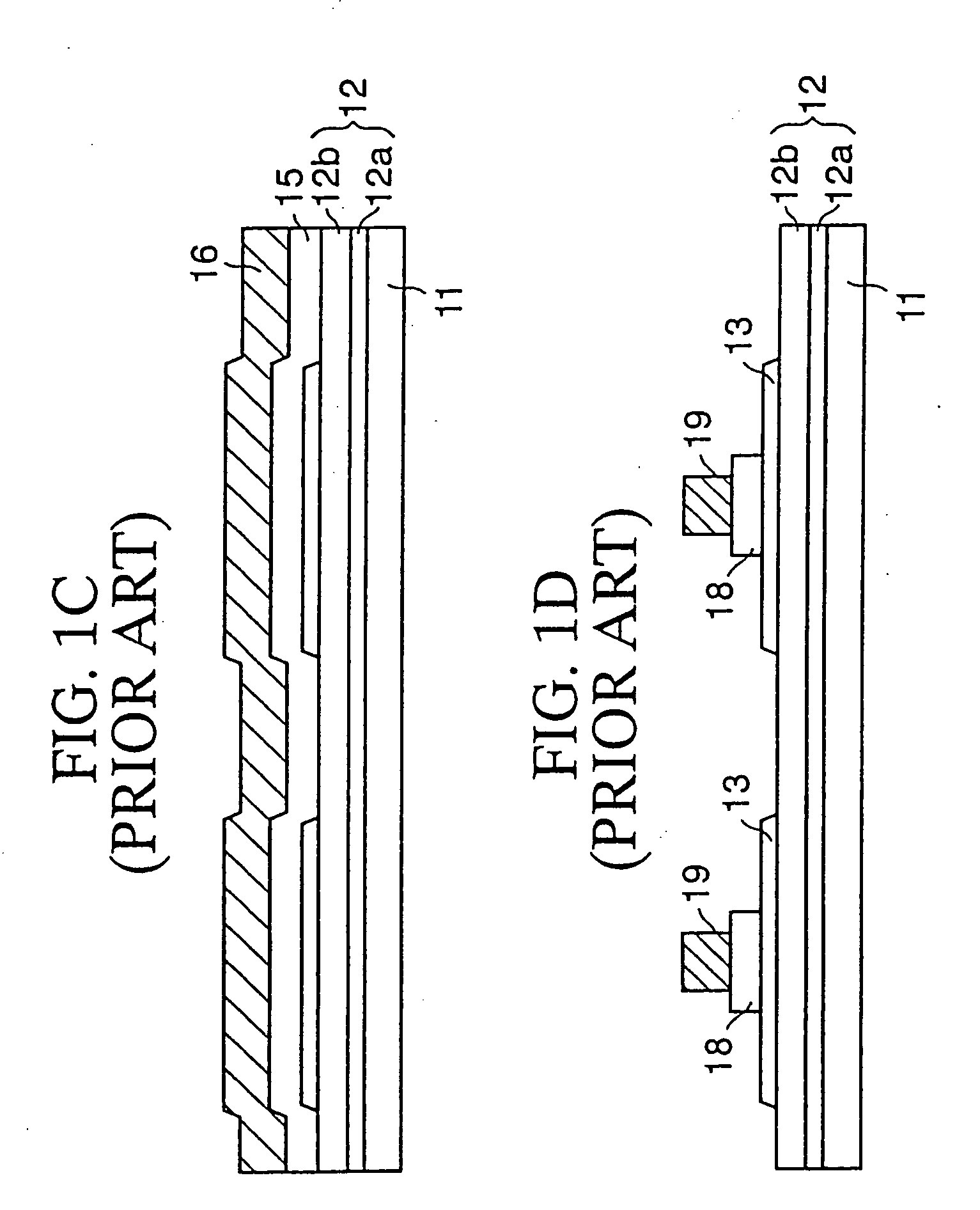

Thin film transistor device and method of manufacturing the same

A polysilicon film is formed in a predetermined region on a glass substrate, and then a gate insulating film and a gate electrode, whose width is narrower than the gate insulating film, are formed thereon. Then, an interlayer insulating film and an ITO film are formed on an overall surface. Then, n-type source / drain regions having an LDD structure are formed by implanting the n-type impurity into the polysilicon film. Then, an n-type TFT forming region and a pixel-electrode forming region are covered with a resist film, and then p-type source / drain regions are formed by implanting the p-type impurity into the polysilicon film in a p-type TFT forming region. Then, the resist film is left only in the pixel-electrode forming region and the resist film is removed from other regions. A pixel electrode is formed by etching the ITO film while using the remaining resist film as a mask.

Owner:UNIFIED INNOVATIVE TECH

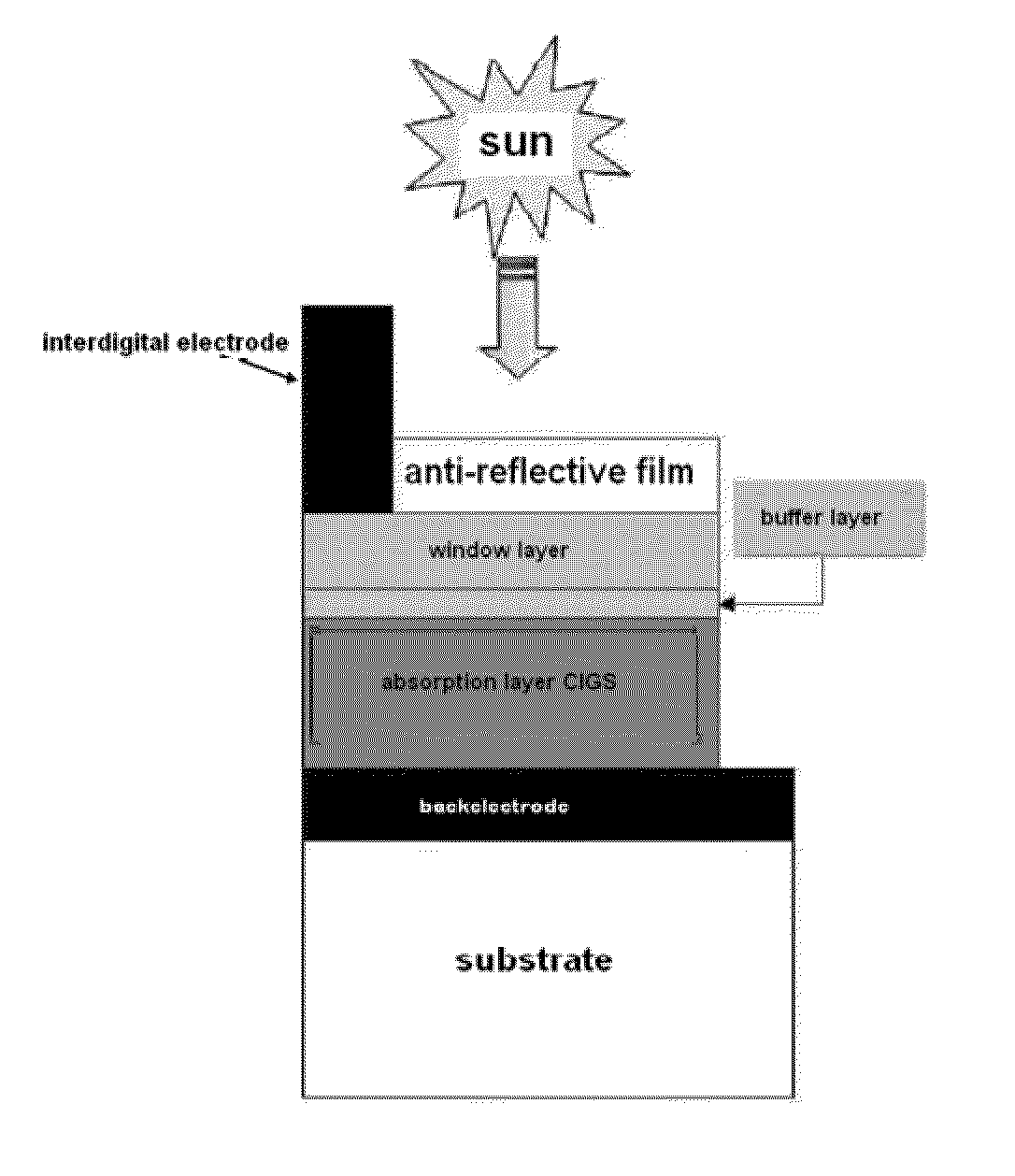

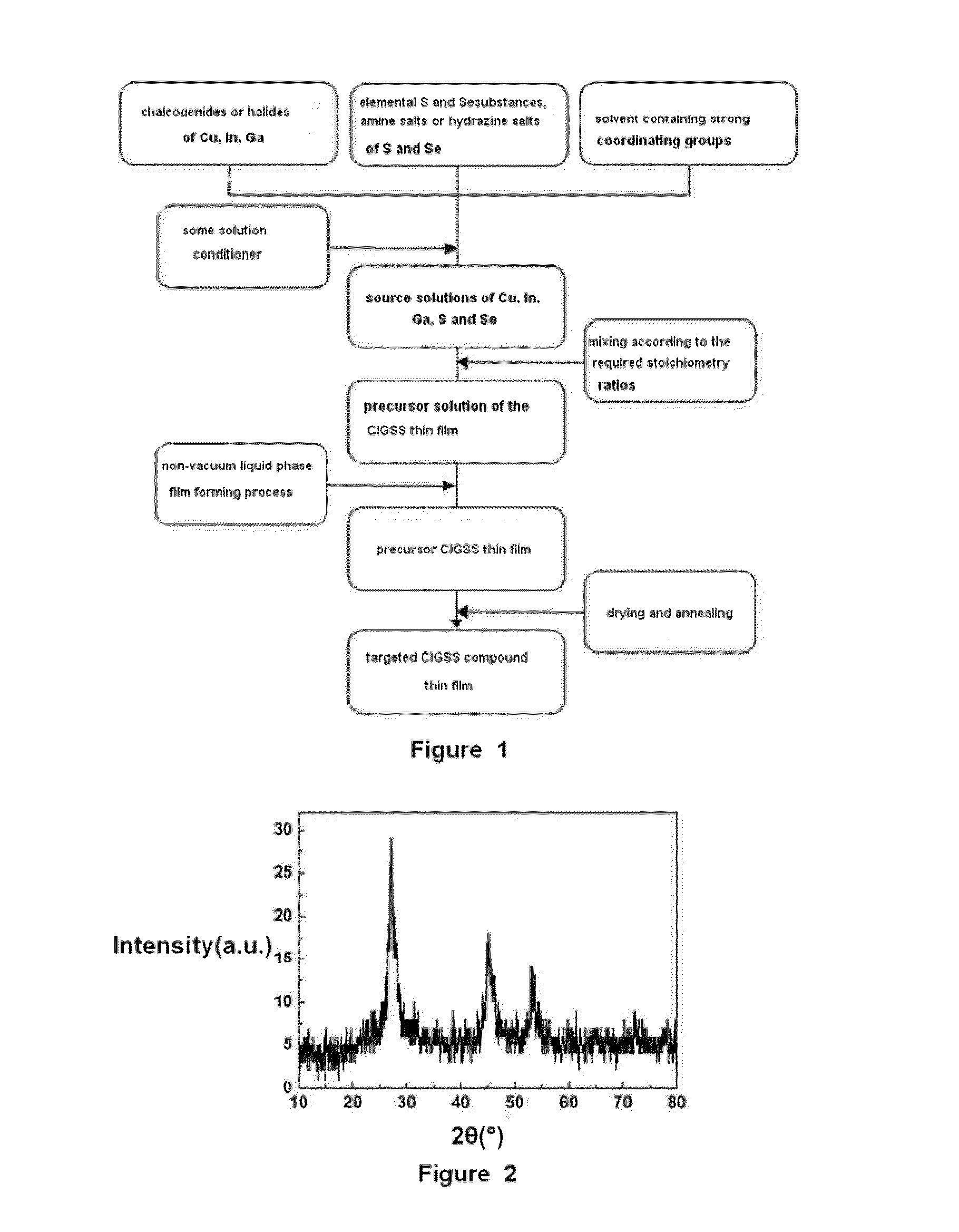

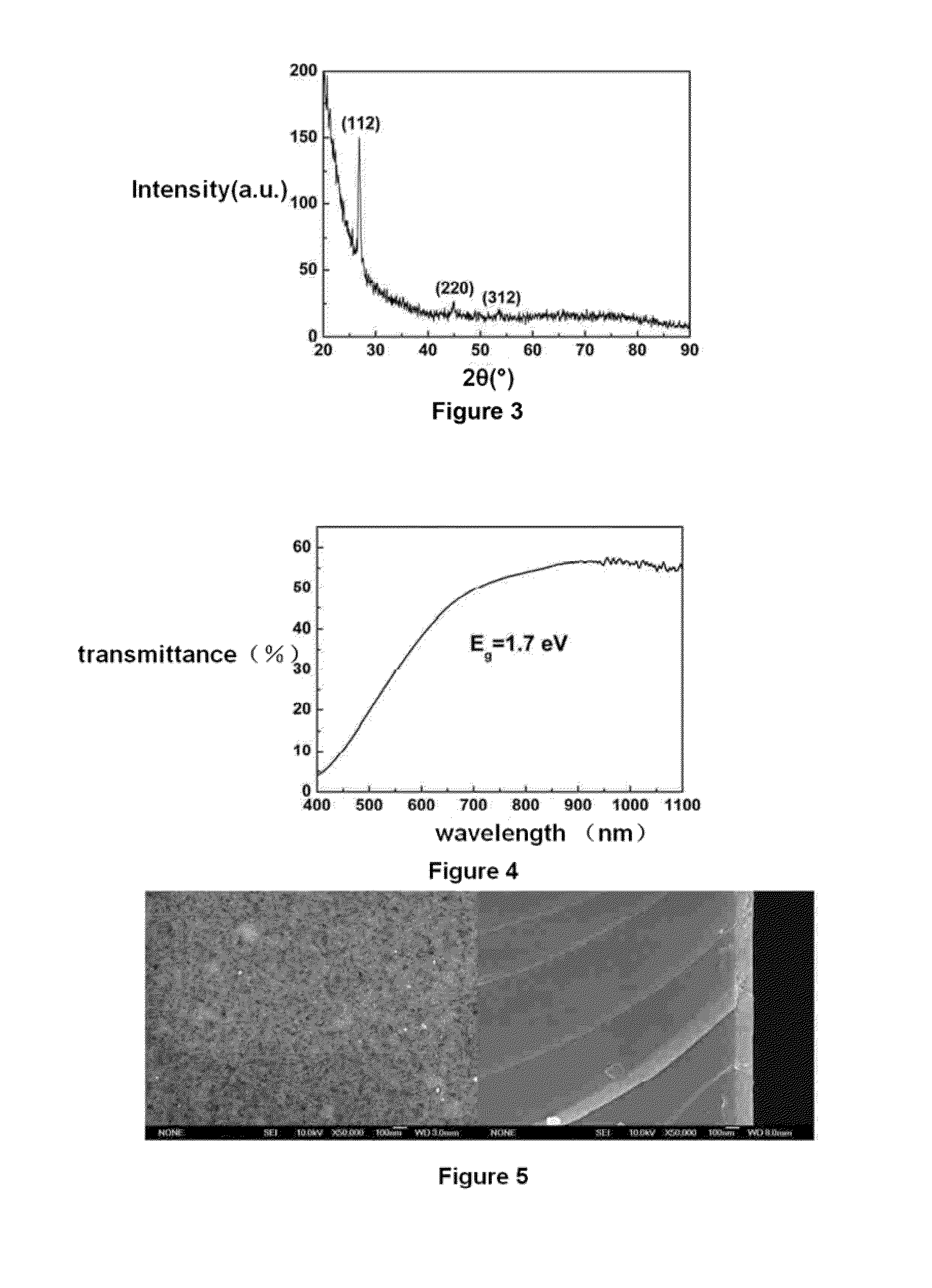

Method for preparing light absorption layer of copper-indium-gallium-sulfur-selenium thin film solar cells

ActiveUS20110008927A1Improve controllabilityLow production costSemiconductor/solid-state device manufacturingPhotovoltaic energy generationIndiumElectrical battery

A preparation method of the light absorption layer of a copper-indium-gallium-sulfur-selenium film solar cell is provided. The method employs a non-vacuum liquid-phase chemical technique, which comprises following steps: forming source solution containing copper, indium, gallium, sulfur and selenium; using the solution to form a precursor film on a substrate by a non-vacuum liquid-phase process; drying and annealing the precursor film. Thus, a compound film of copper-indium-gallium-sulfur-selenium is gained.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

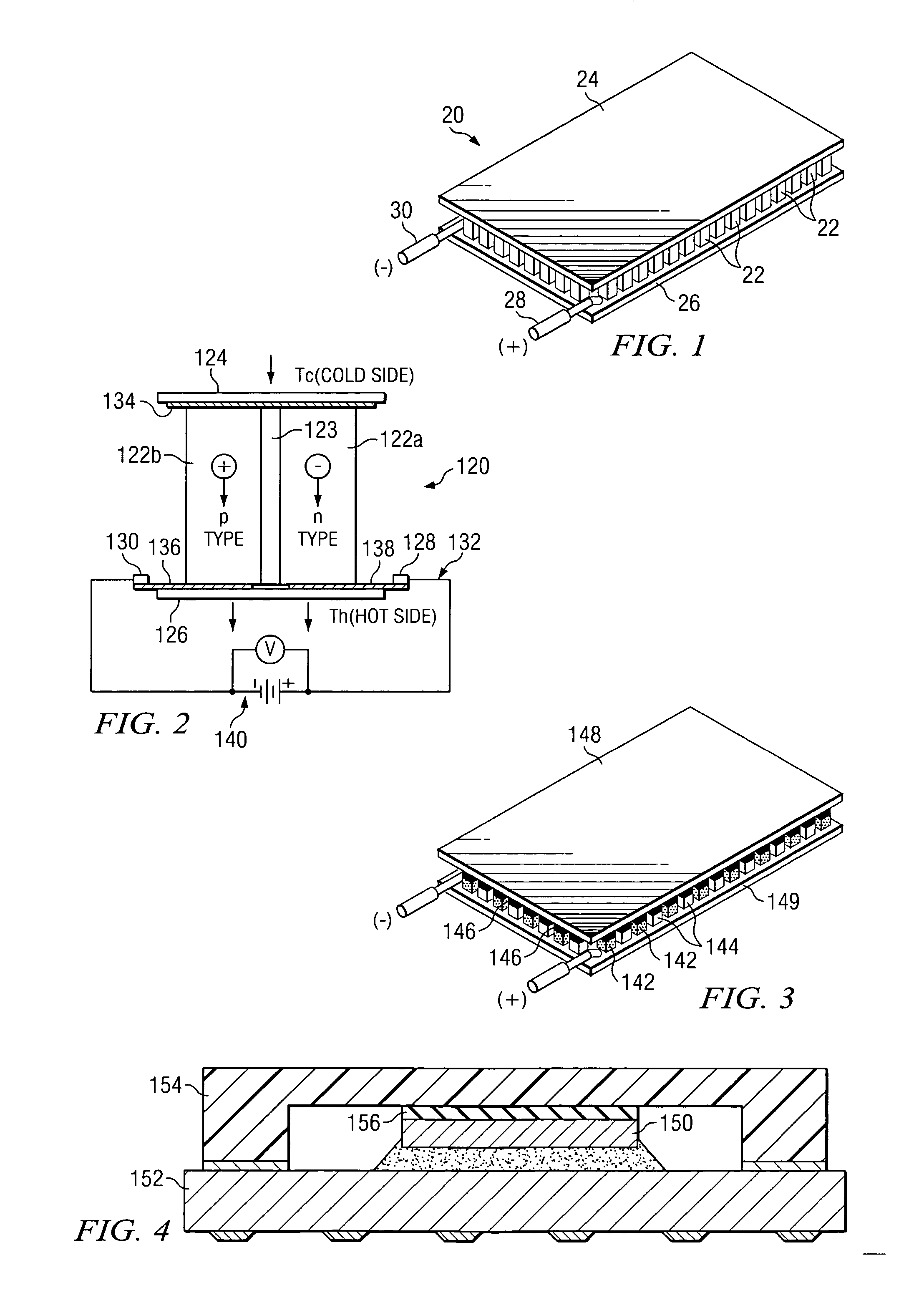

High watt density thermoelectrics

InactiveUS20060107989A1Easy to processDisadvantages problemsThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentThermoelectric materialsWafer dicing

In accordance with one embodiment of the present invention, a method of manufacturing a thermoelectric device is disclosed. The method includes forming a wafer of thermoelectric material and coupling the wafer to a stiff backing such that a bottom side of the wafer faces the stiff backing and a top side of the wafer faces away from the stiff backing. The method also includes reducing a thickness of the wafer by removing a portion of the wafer from the top side, and dicing the wafer into a plurality of blocks. At least a portion of the plurality of blocks are then coupled with a permanent substrate.

Owner:MARLOW INDUSTRIES

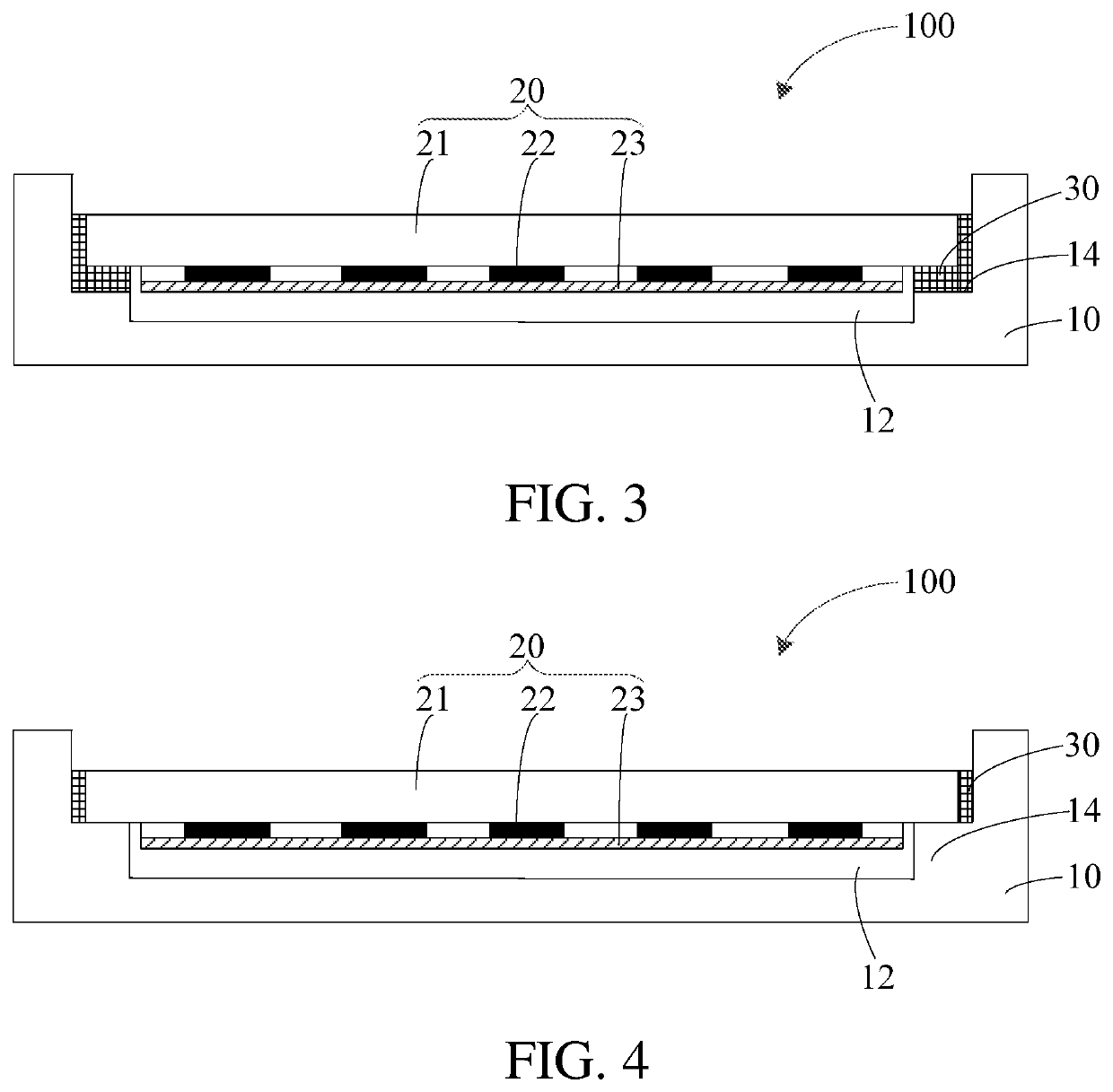

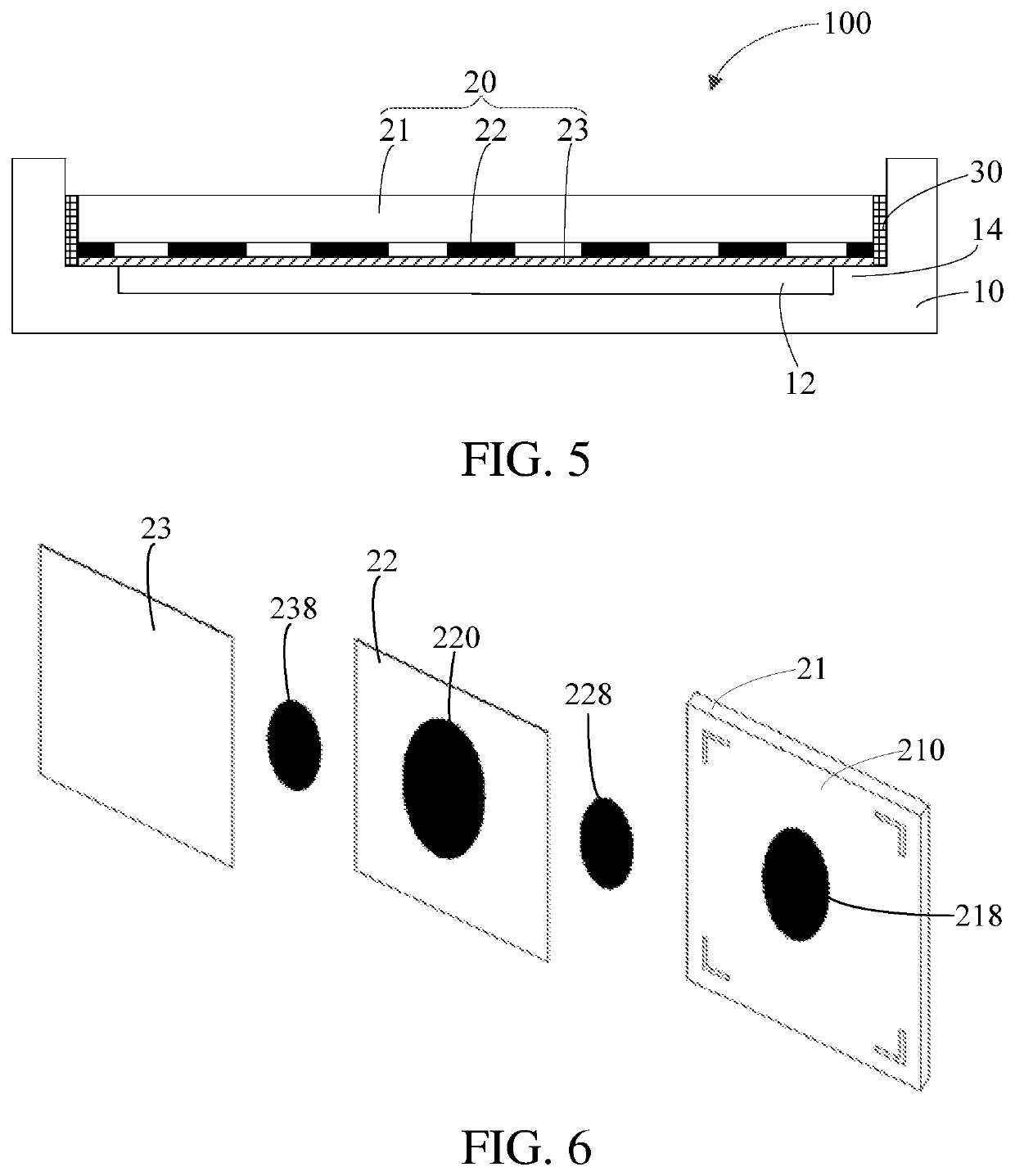

Image Sensor Chip Package and Method of Fabricating the Same

InactiveUS20080188030A1Thinned imageProduct thinSemiconductor/solid-state device detailsSolid-state devicesSolder ballMiniaturization

The present invention relates to an image sensor chip package and a method for fabricating the same. In one embodiment of an image sensor chip package, chip pads on a first surface of an image sensor chip are attached to electrode pads of a glass substrate with conductive material. In addition, electrode pads are connected to solder balls via a metal wiring pattern arranged on a second surface of the image sensor chip. As a result, the present invention can provide further miniaturized and thinned image sensor chip packages, reduce fabricating processes, and improve device performance and reliability.

Owner:DONGBU ELECTRONICS CO LTD

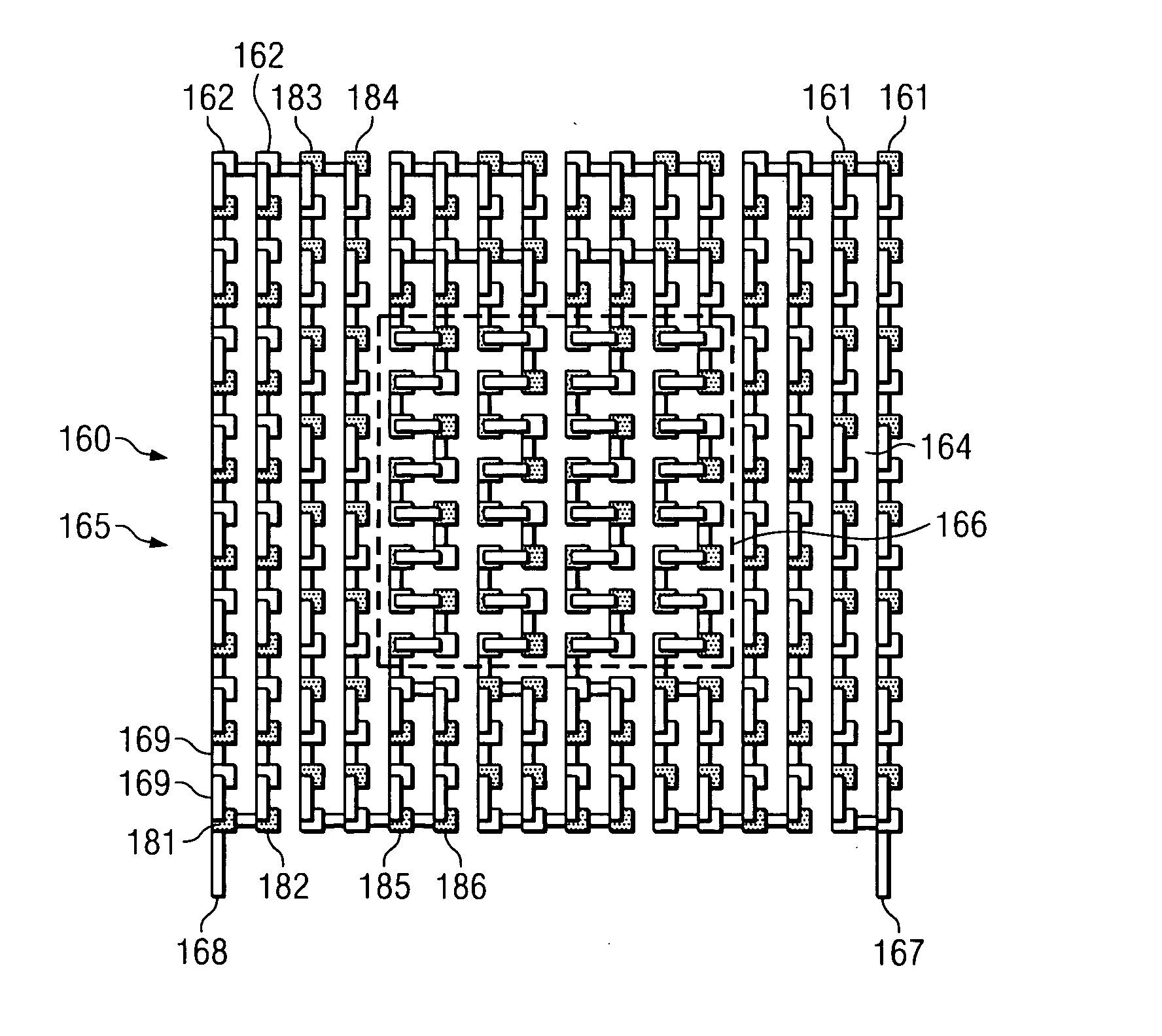

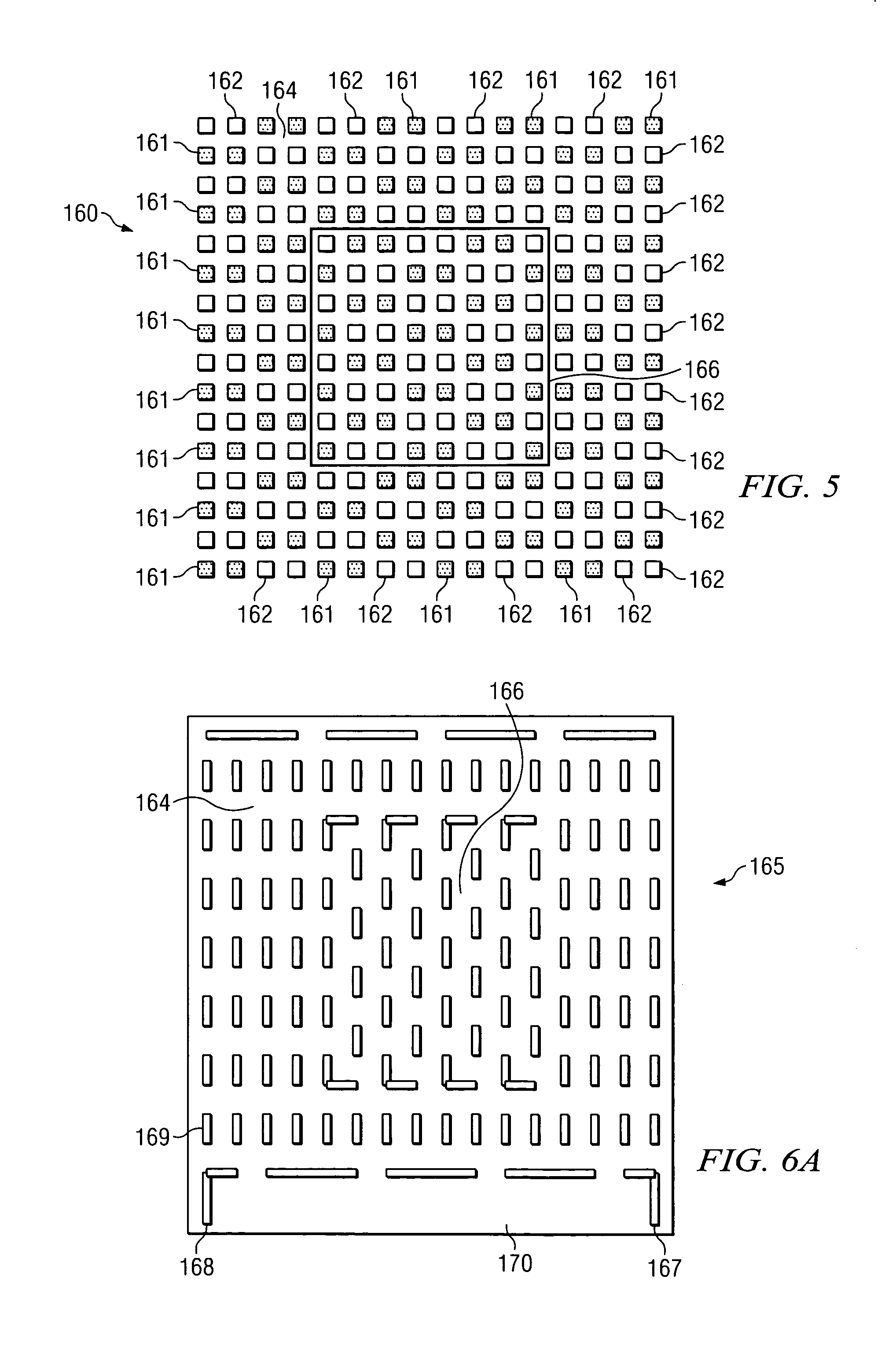

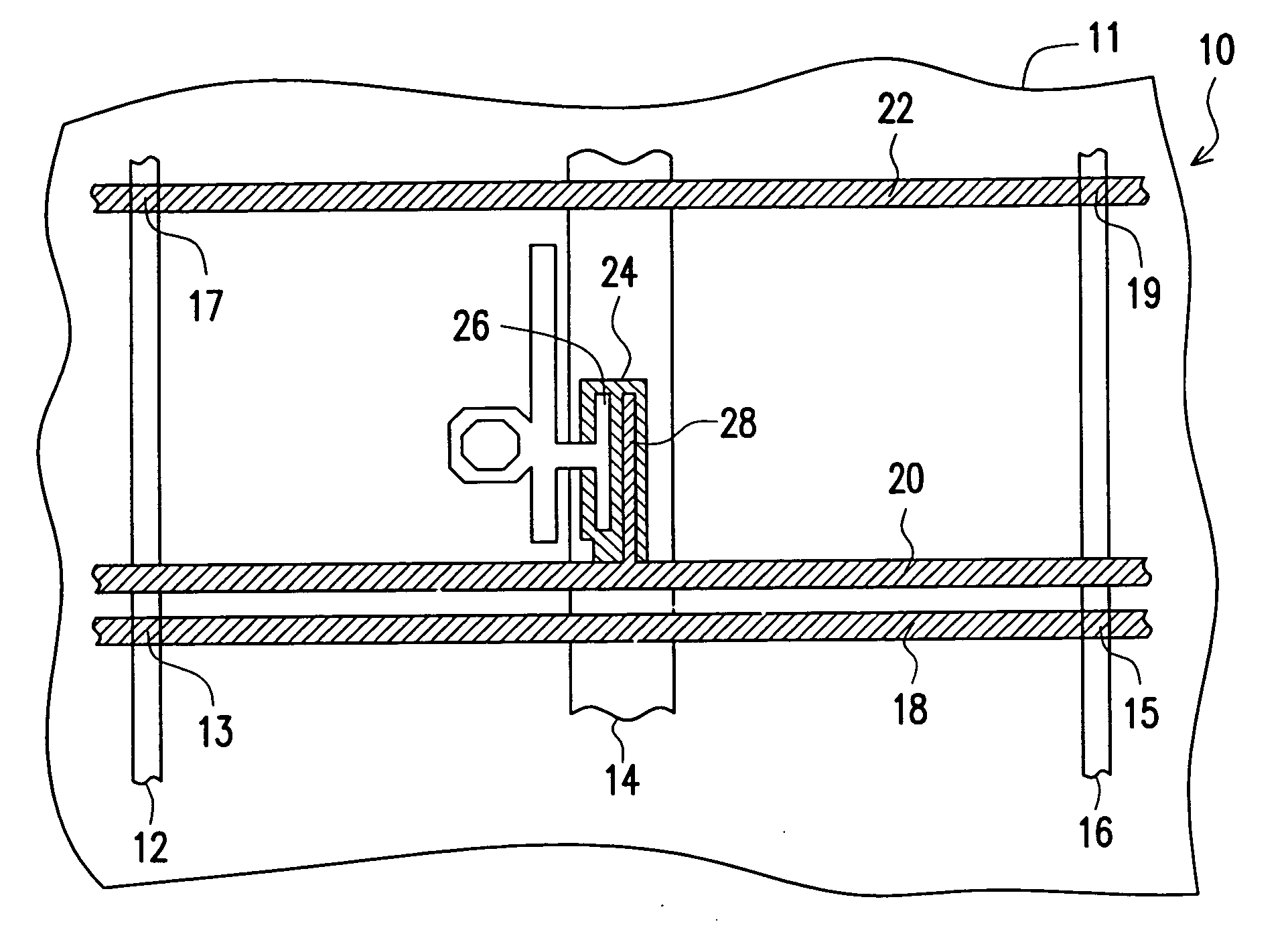

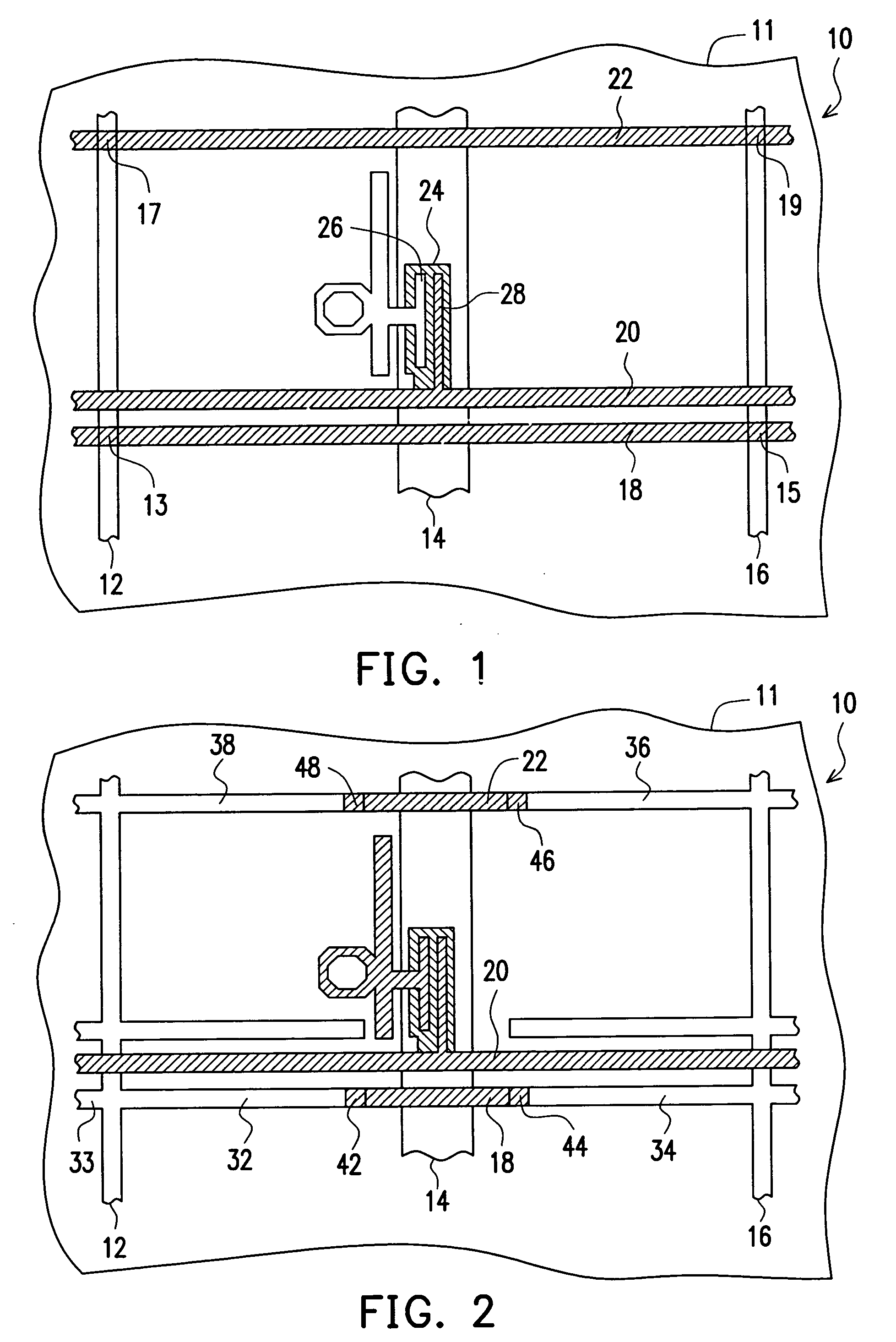

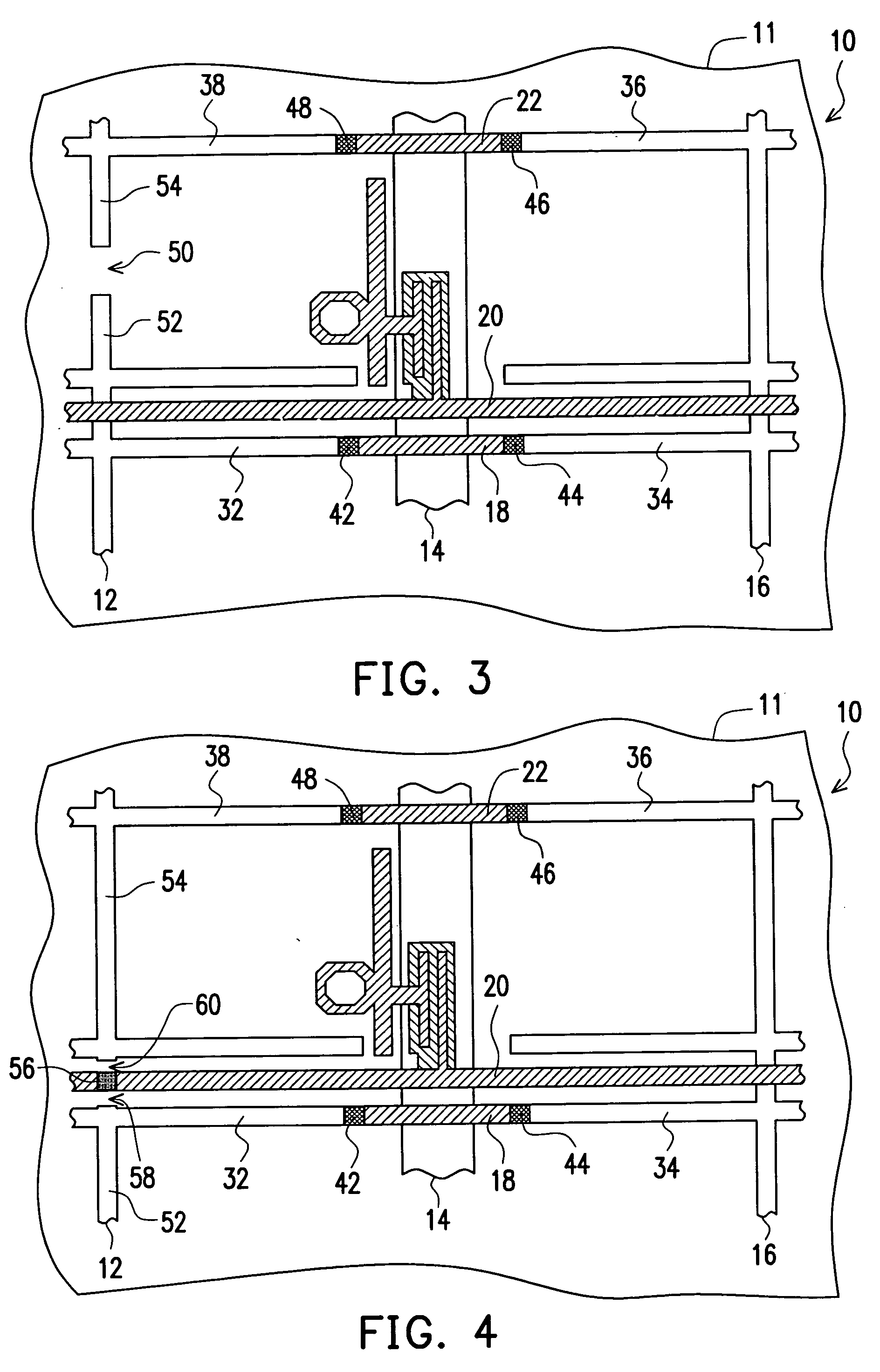

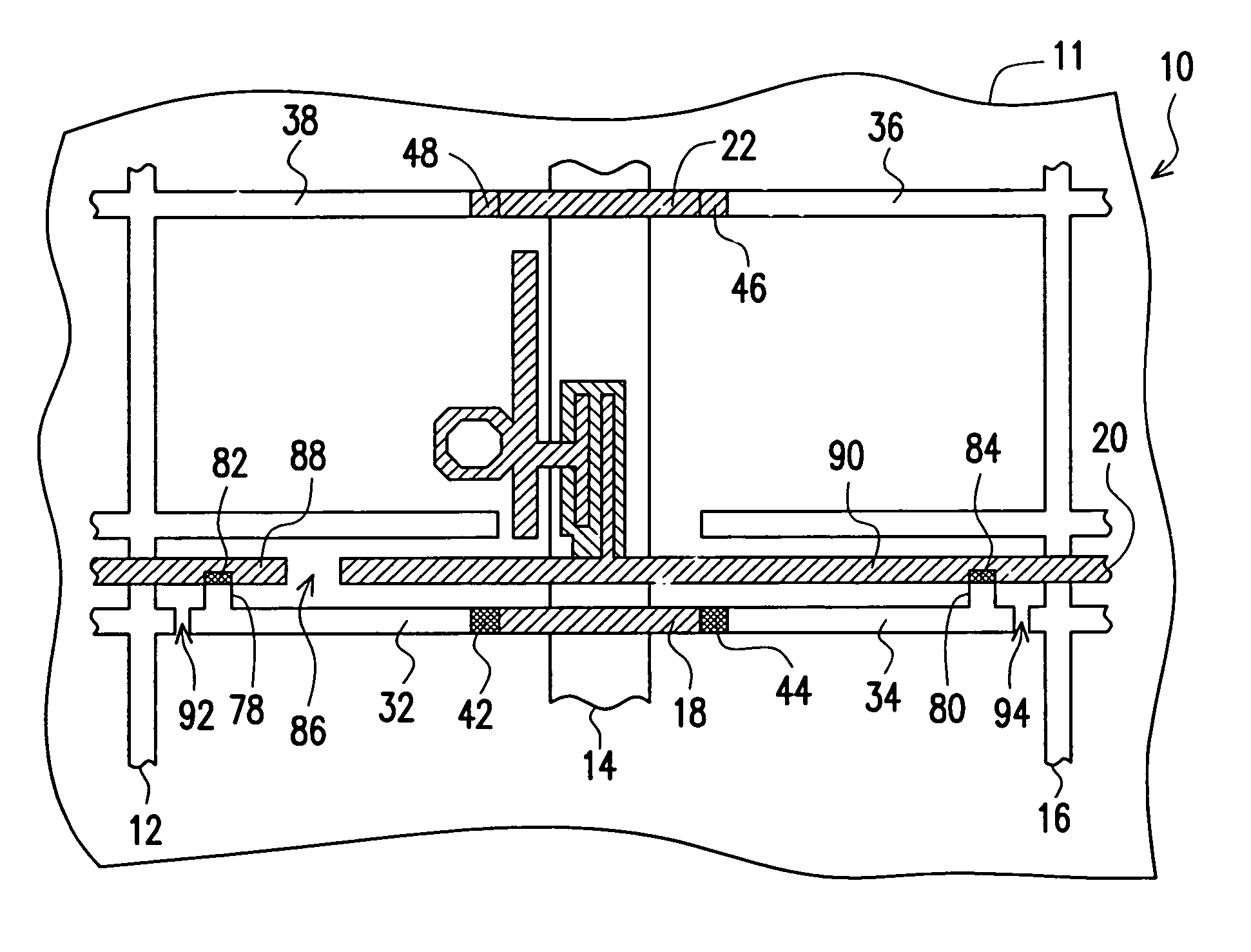

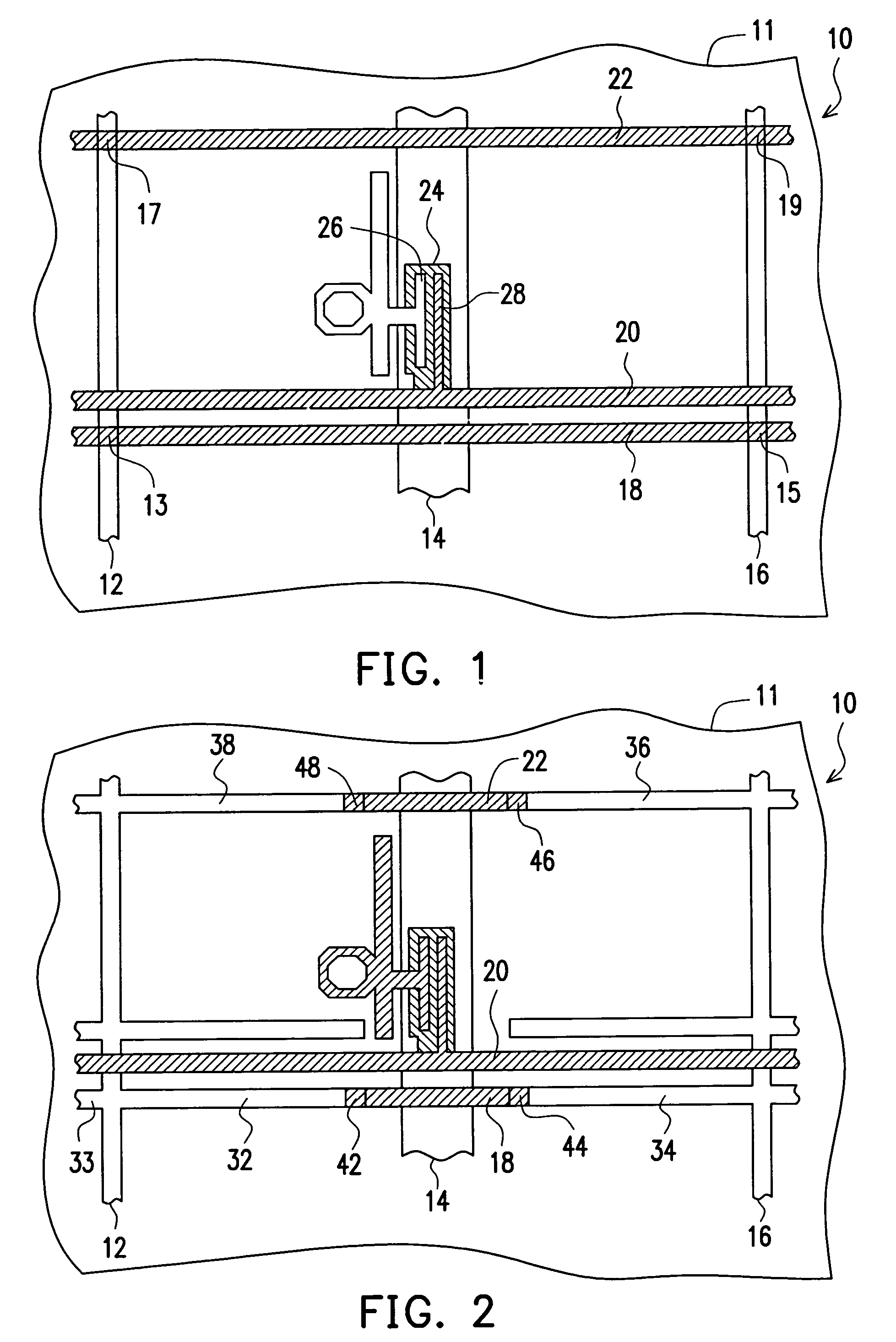

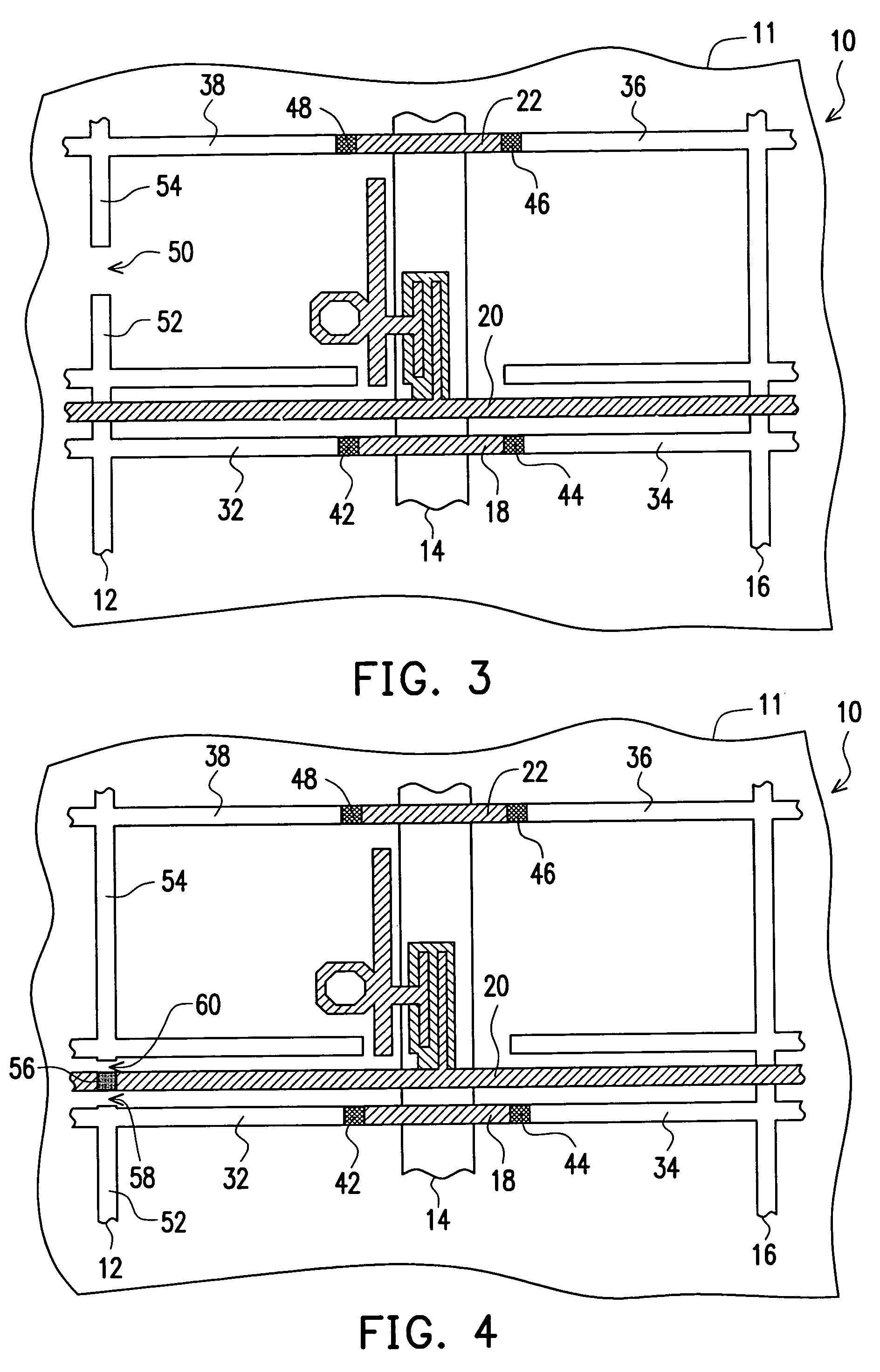

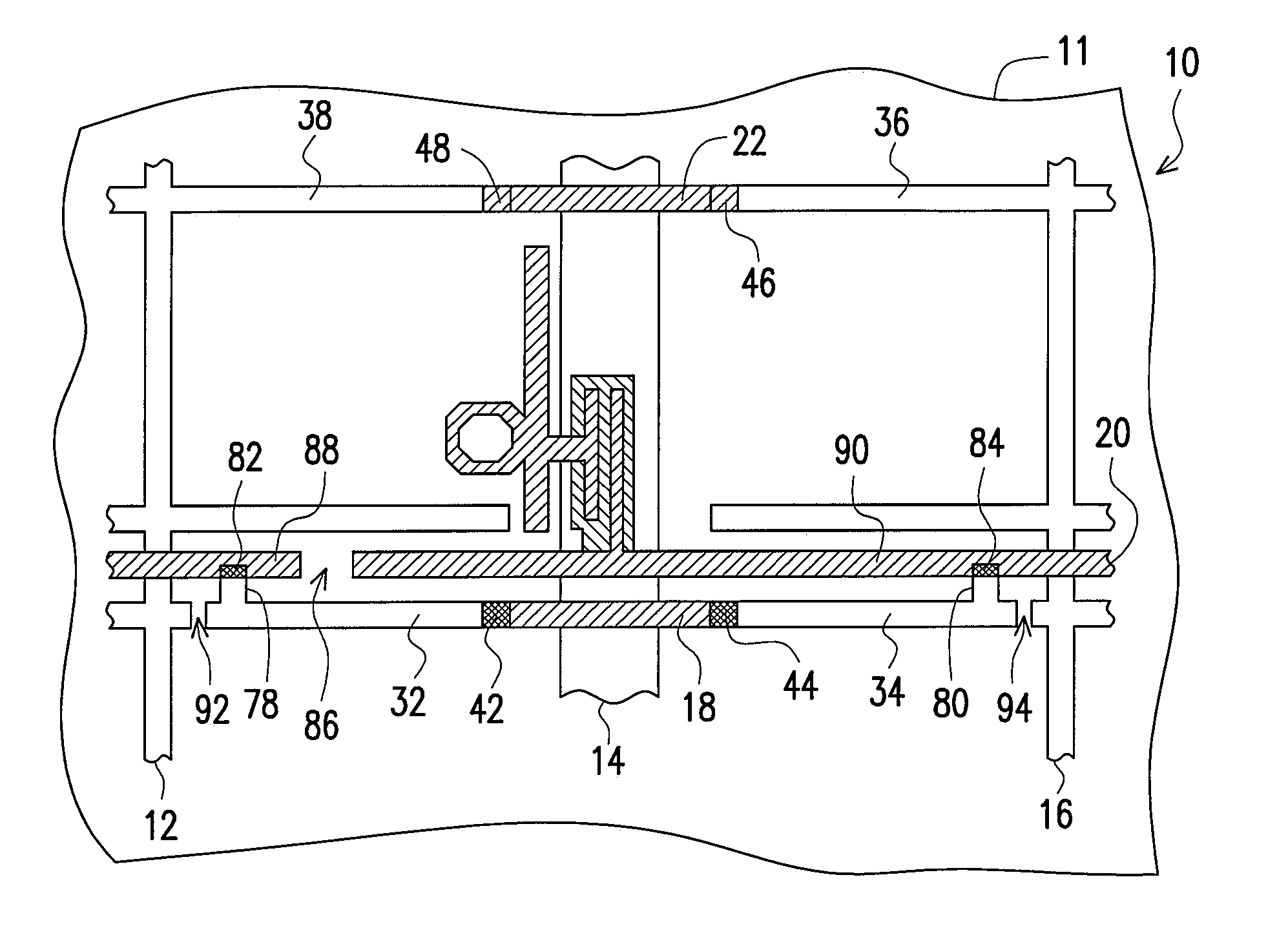

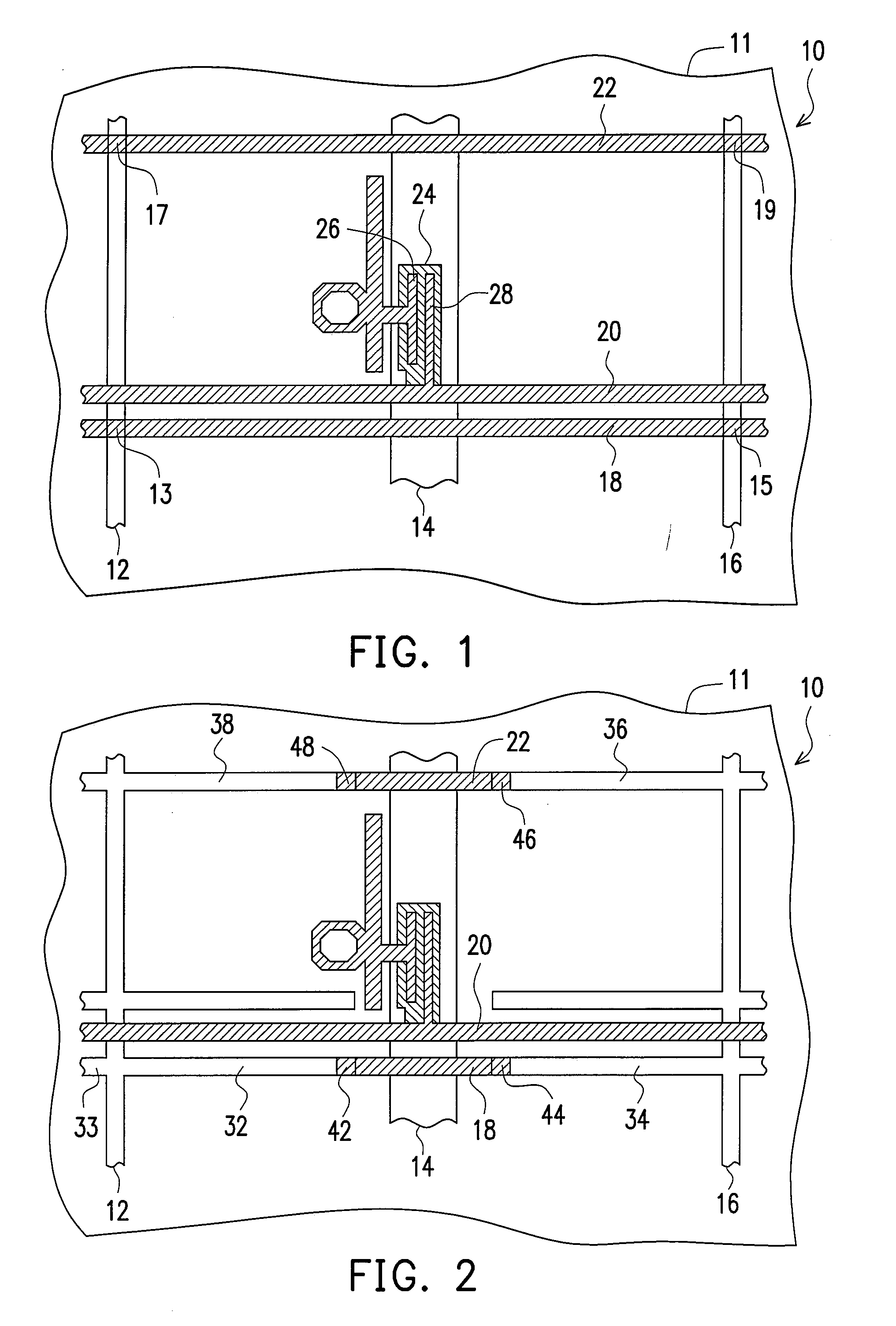

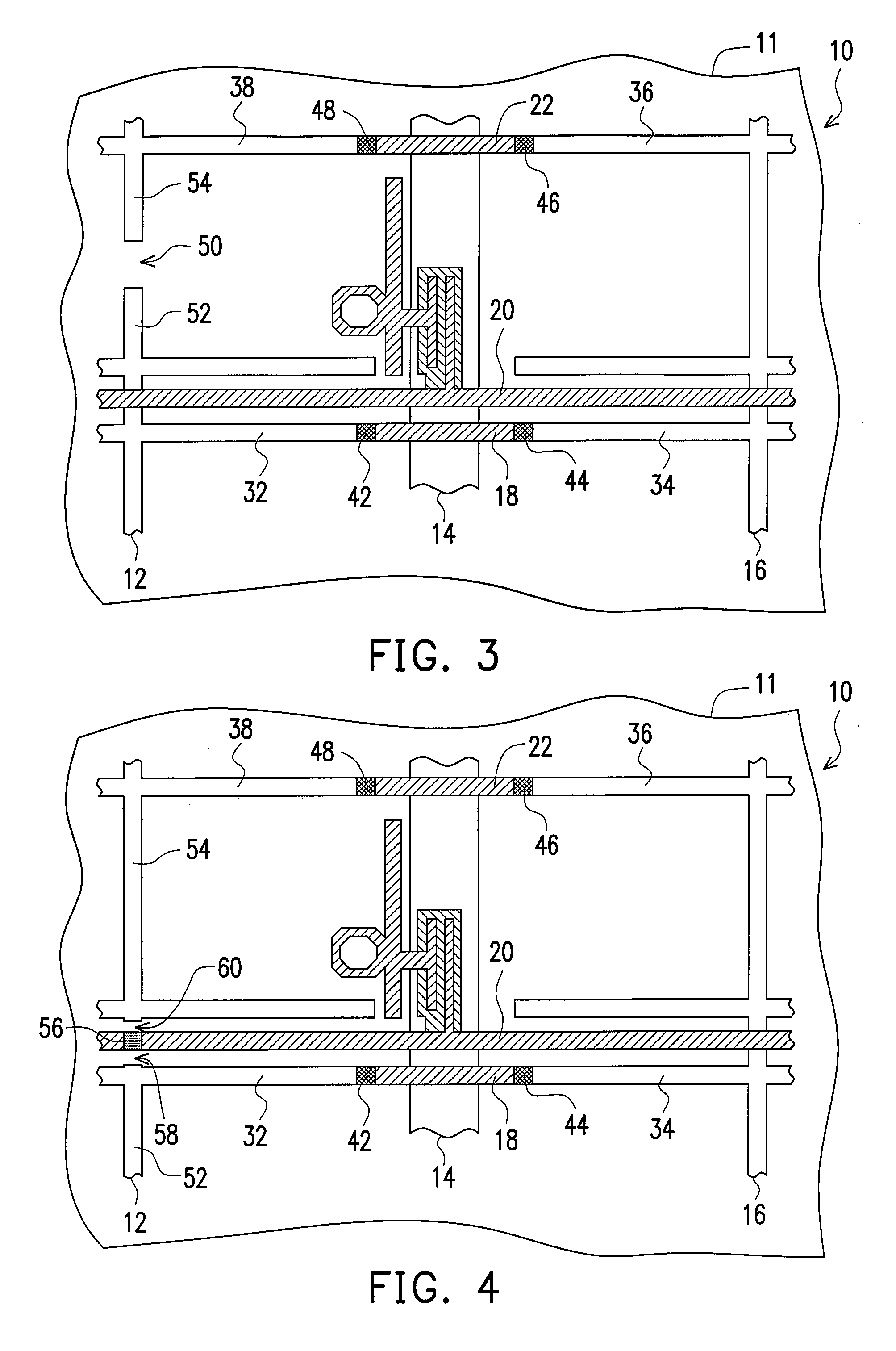

Thin film transistor array substrate and method for repairing the same

ActiveUS20070045625A1Improve production yieldProduct thinSolid-state devicesNon-linear opticsTransistor arrayScan line

A thin film transistor array substrate and method for repairing the same are provided. Repairing lines are formed when the data lines on the thin film transistor array substrate are defined. Furthermore, the protruding portions and branches of common lines overlap with the repairing lines and the data lines respectively. The repairing method includes performing a laser welding operation to connect the common line with the data line, the repairing line or a scan line as well as removing a portion of the lines by laser. Thus, the thin film transistor array substrate and repairing method thereof can repair line defects and increase the manufacturing yield.

Owner:CHUNGHWA PICTURE TUBES LTD

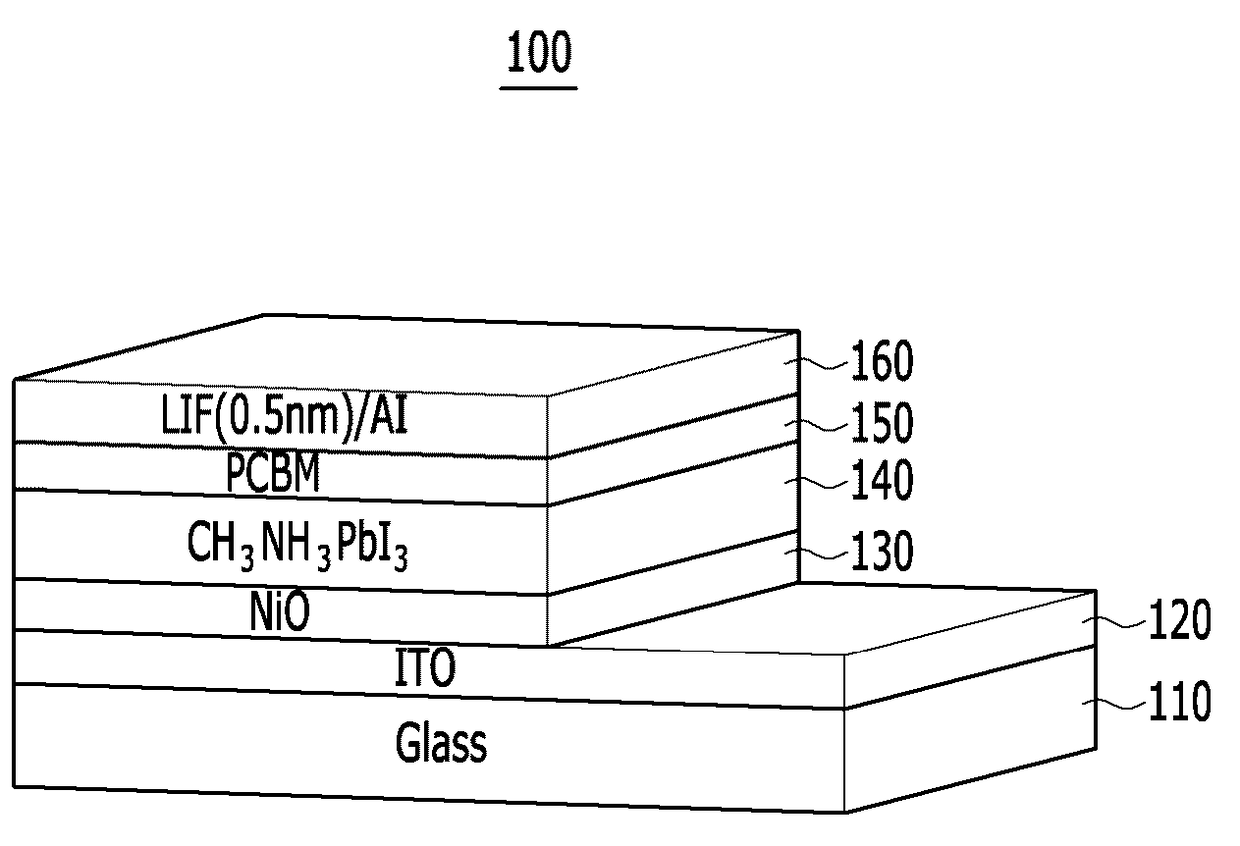

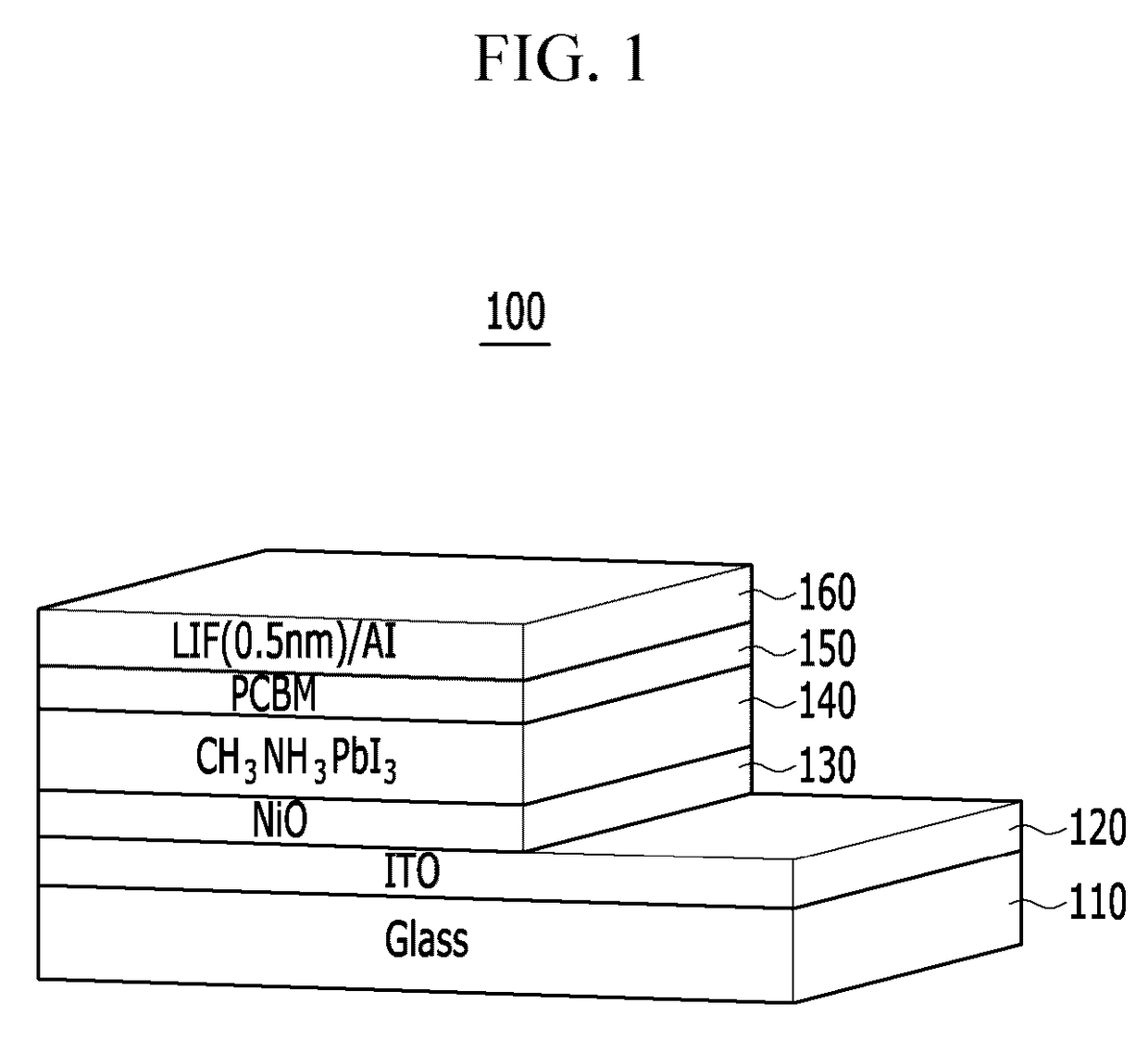

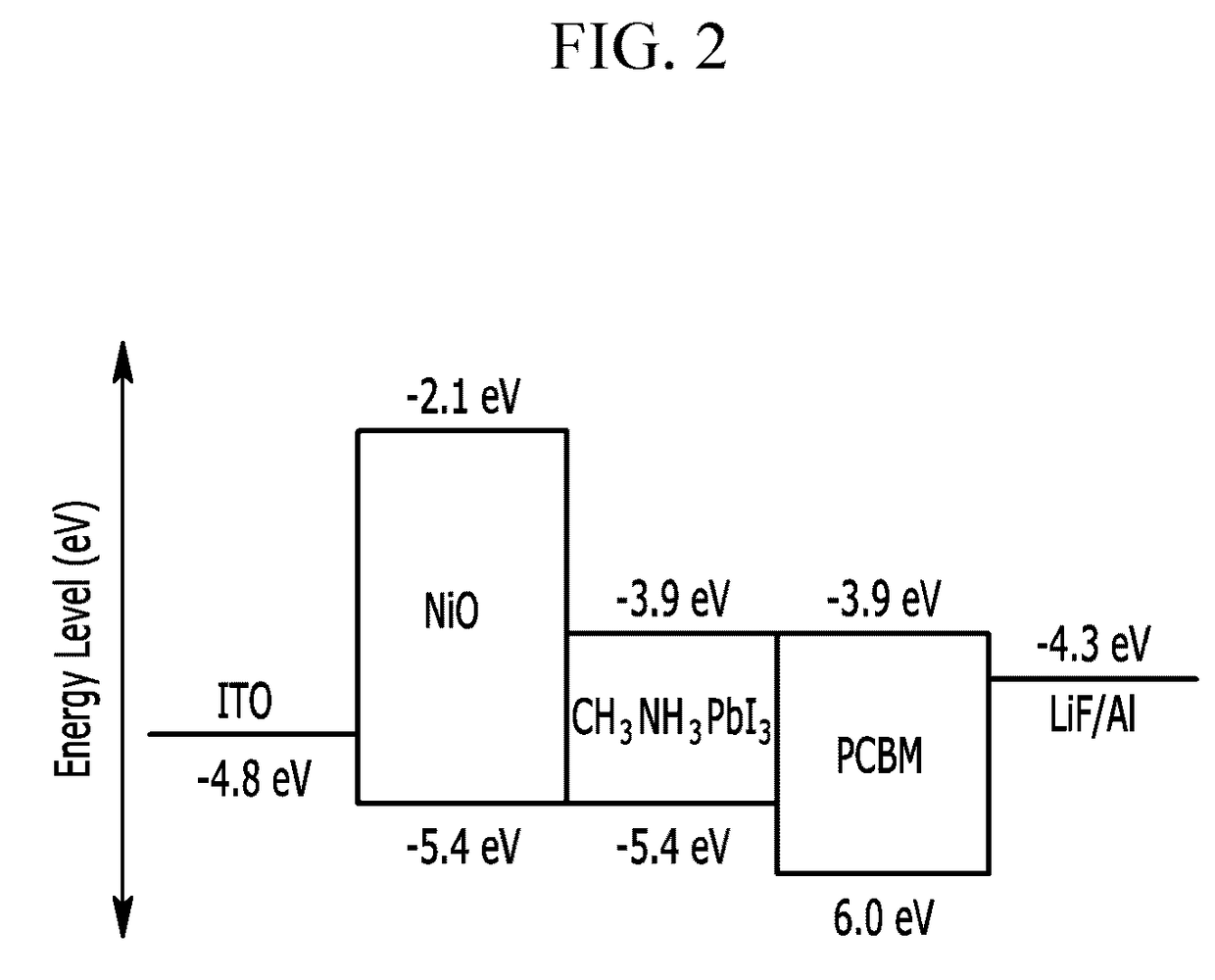

Method for manufacturing thin film including nickel oxide nanoparticle and solar cell having the same

InactiveUS20170149004A1Total current dropImprove power conversion efficiencyFinal product manufactureSolid-state devicesNanoparticleSolar cell

Owner:GACHON UNIV OF IND ACADEMIC COOPERATION FOUND +1

Thin film transistor array substrate and method for repairing the same

ActiveUS7265386B2Product thinImprove production yieldSolid-state devicesNon-linear opticsScan lineEngineering

A thin film transistor array substrate and method for repairing the same are provided. Repairing lines are formed when the data lines on the thin film transistor array substrate are defined. Furthermore, the protruding portions and branches of common lines overlap with the repairing lines and the data lines respectively. The repairing method includes performing a laser welding operation to connect the common line with the data line, the repairing line or a scan line as well as removing a portion of the lines by laser. Thus, the thin film transistor array substrate and repairing method thereof can repair line defects and increase the manufacturing yield.

Owner:CHUNGHWA PICTURE TUBES LTD

Image sensor chip package and method of fabricating the same

InactiveUS7372122B2Thinned imageProduct thinSemiconductor/solid-state device detailsSolid-state devicesSolder ballMiniaturization

Owner:DONGBU ELECTRONICS CO LTD

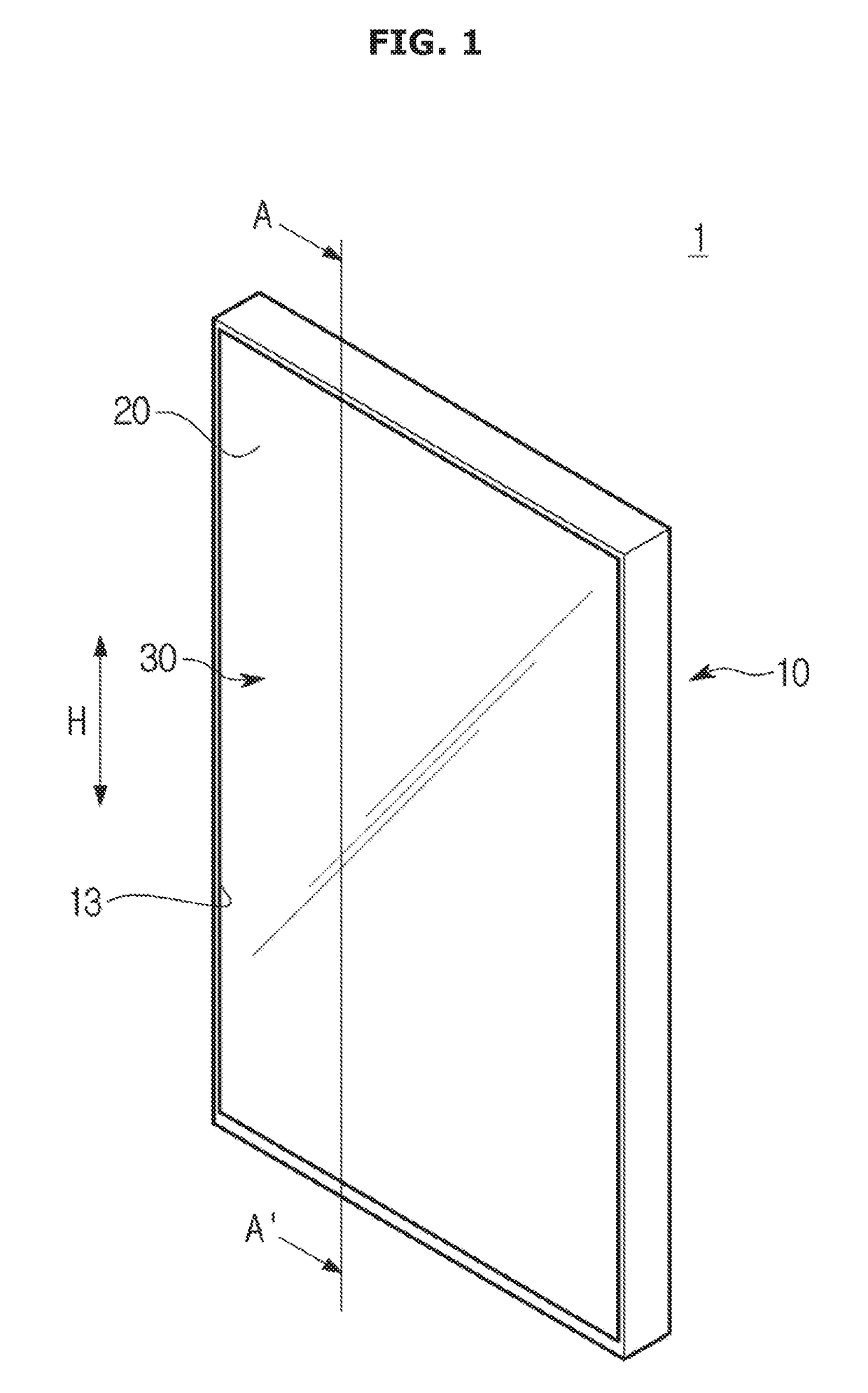

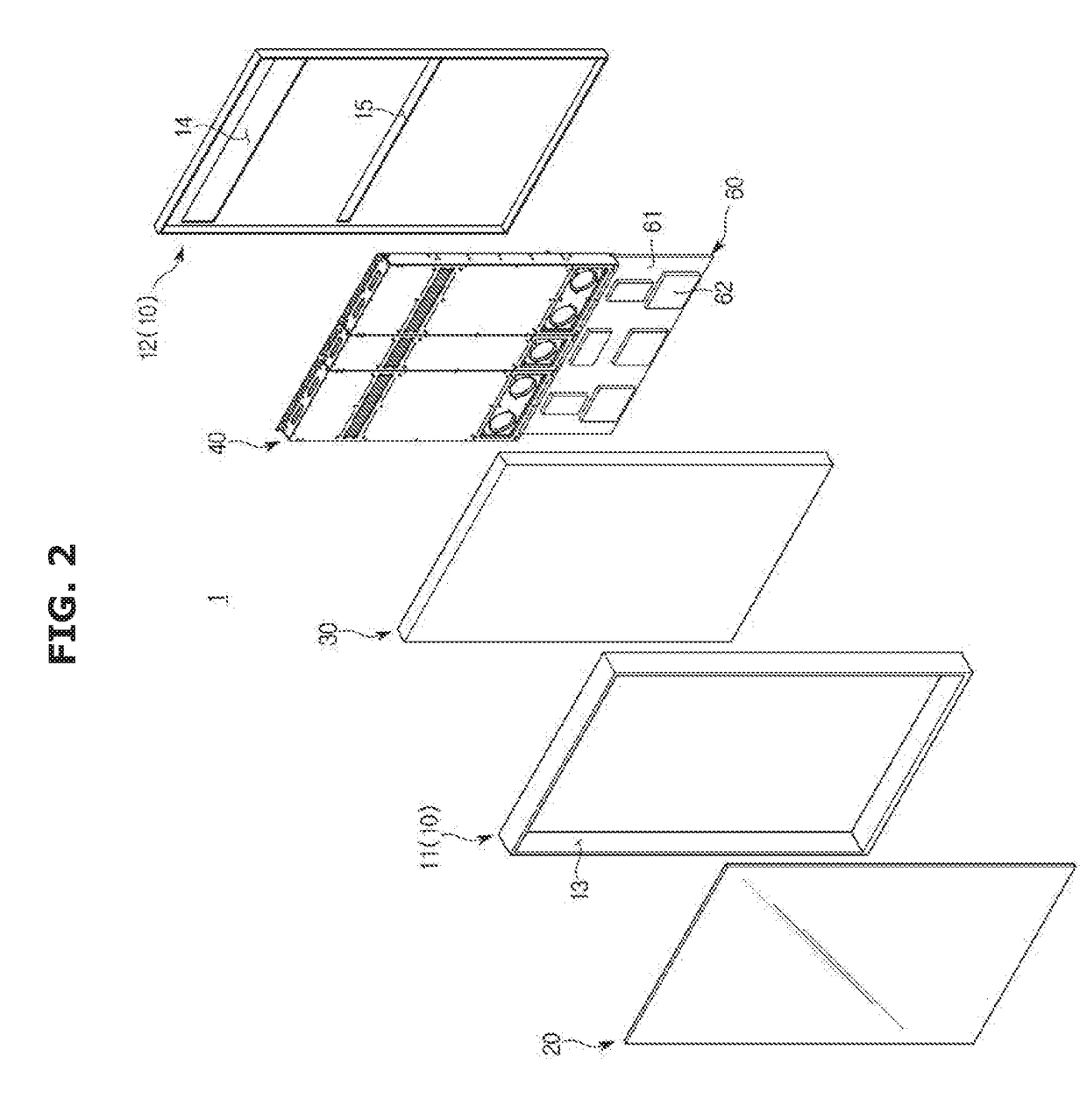

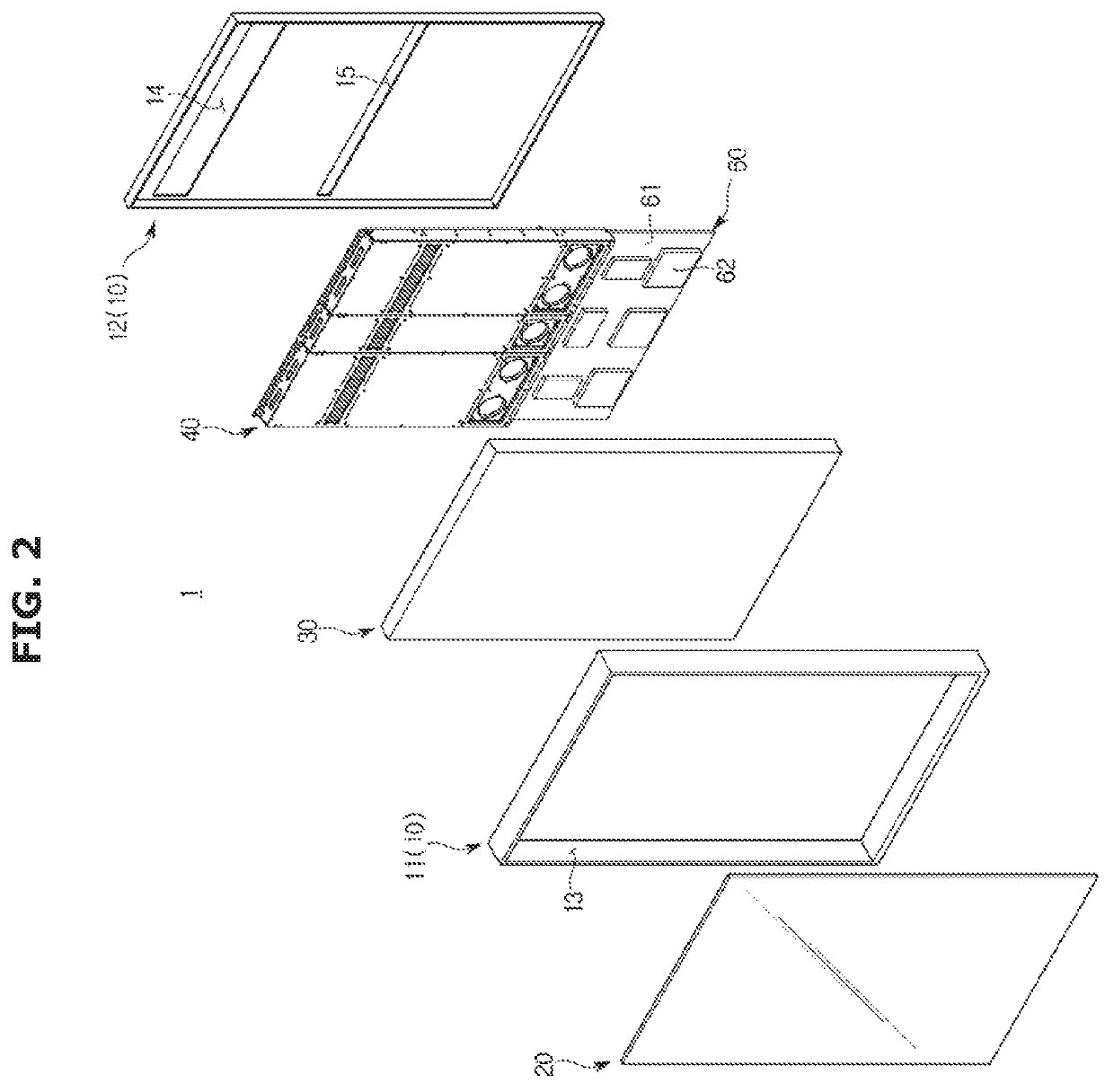

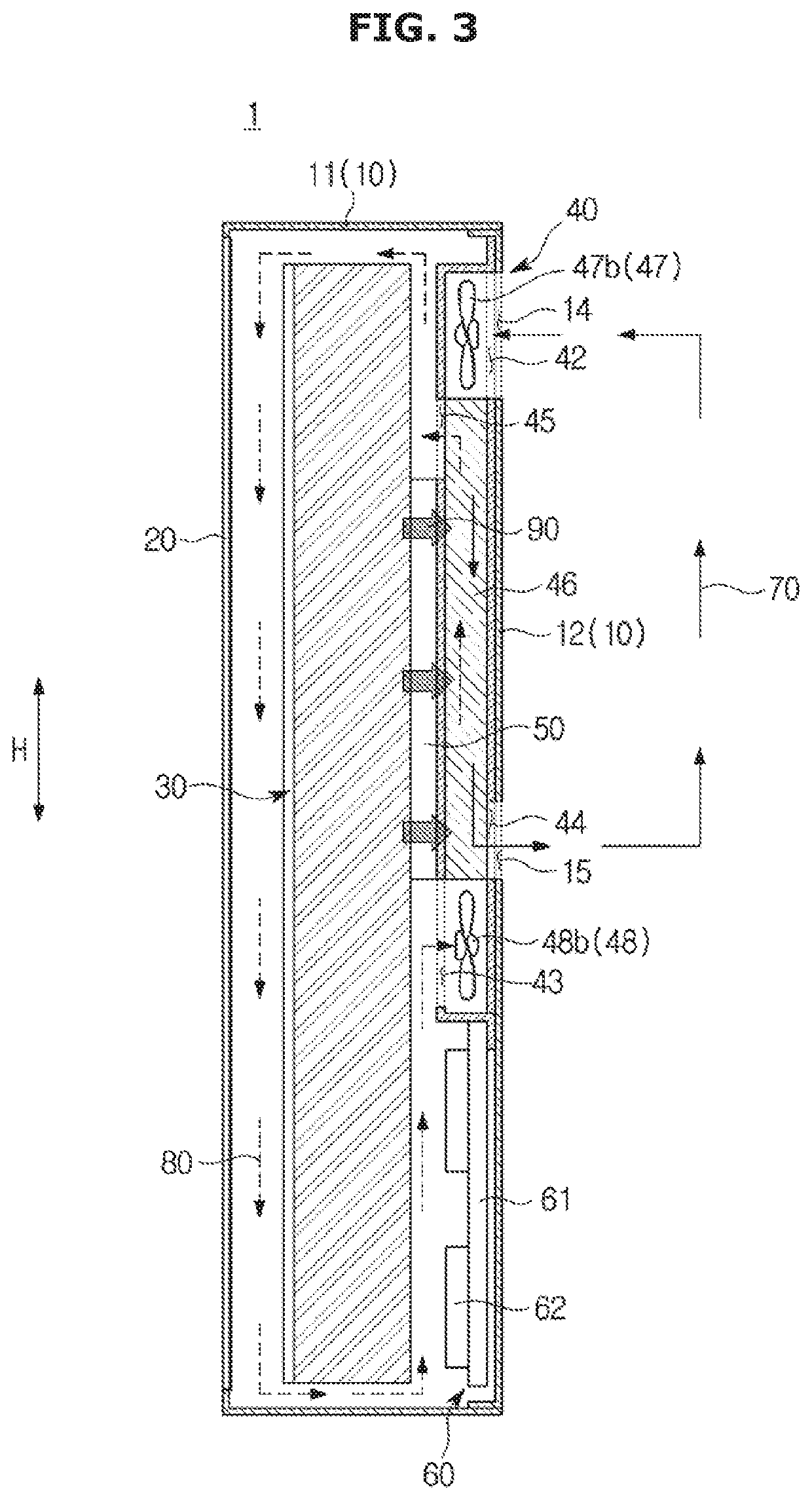

Outdoor display apparatus

ActiveUS20180160573A1Simple structureInhibit deteriorationTelevision system detailsDigital data processing detailsProtective glassesEngineering

Disclosed herein is an outdoor display apparatus having a heat-radiating structure. The outdoor display apparatus includes a housing; a display module disposed inside the housing, and including a display pan& on which an image is displayed; a heat-exchange module disposed on a rear surface of the display module, and configured to concentrate heat inside the housing on a rear surface of the display panel and discharge heat out of the housing; a protective glass disposed to correspond to a display area of the display panel, and configured to transmit infrared light; and a flow path formed inside the housing such that air flowing along the flow path transfers heat from the display panel to the heat-exchange module.

Owner:SAMSUNG ELECTRONICS CO LTD

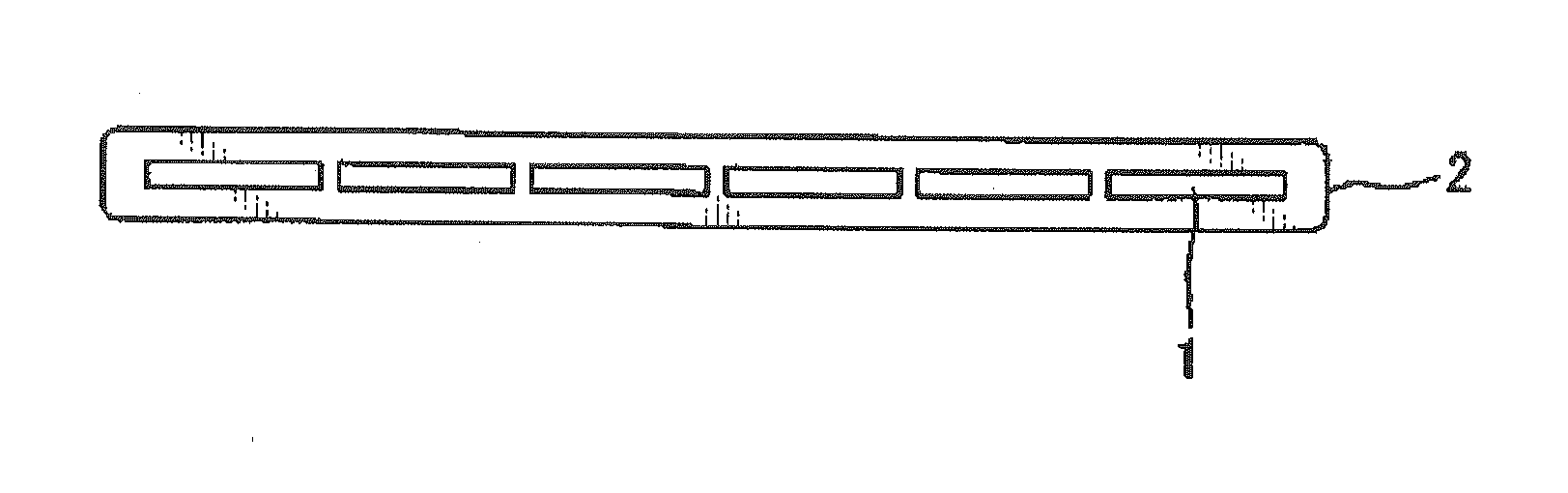

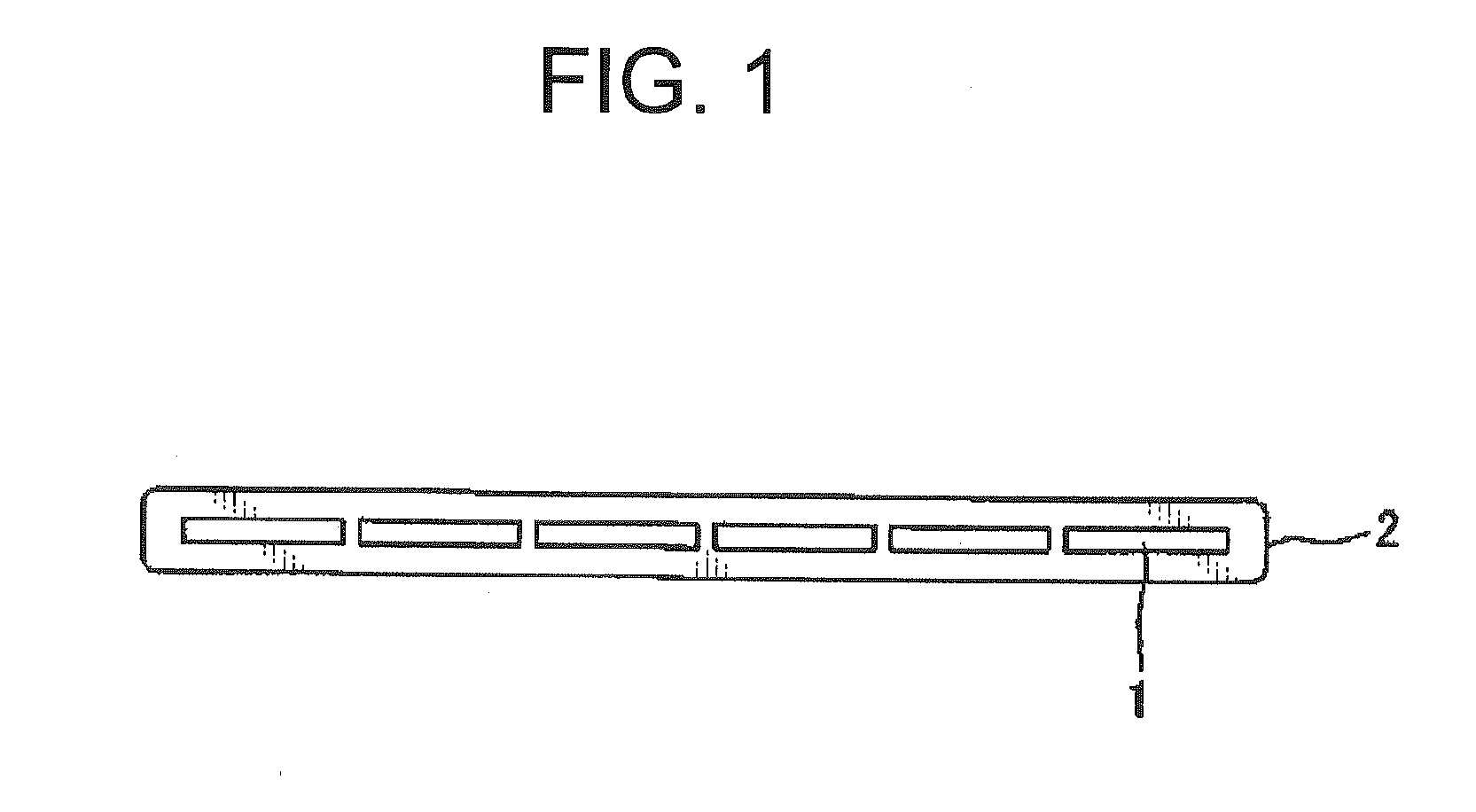

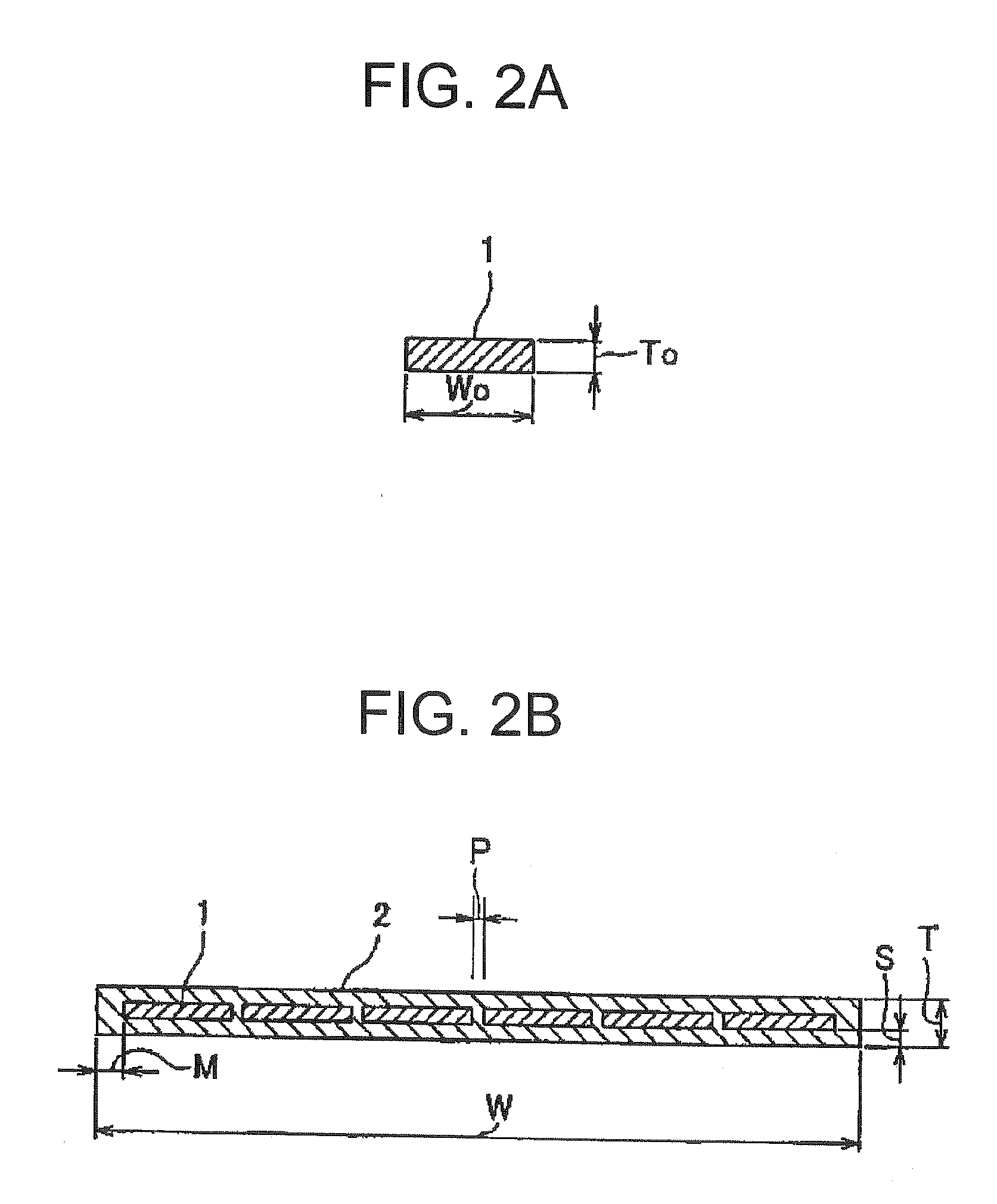

Flat cable and method for preparing the same

InactiveUS20140131064A1Stable productionLow costFlat/ribbon cablesInsulatorsPolyolefinElectrical conductor

The objective of the invention is to provide a thin and flexible flat cable suited for being arranged in a narrow space such as a vehicle, as well as, a method for stably preparing such a flat cable.To attain the objective, there is provided a flat cable which has a plurality of conductors which is arranged parallel to each other, and an insulating layer disposed over the plurality of conductors by extrusion molding. The insulating layer has Melt flow rate value of 2.0 g / 10 minutes or above at a molding temperature during the extrusion molding, and is formed of thermoplastic resin selected from the group consisting of polyolefin, polyphenylene ether, polyphenylene sulfide and a combination thereof.

Owner:YAZAKI CORP

Method for repairing thin film transistor array substrate

InactiveUS20070259455A1Product thinImprove production yieldSolid-state devicesSemiconductor/solid-state device manufacturingTransistor arrayScan line

A thin film transistor array substrate and method for repairing the same are provided. Repairing lines are formed when the data lines on the thin film transistor array substrate are defined. Furthermore, the protruding portions and branches of common lines overlap with the repairing lines and the data lines respectively. The repairing method includes performing a laser welding operation to connect the common line with the data line, the repairing line or a scan line as well as removing a portion of the lines by laser. Thus, the thin film transistor array substrate and repairing method thereof can repair line defects and increase the manufacturing yield.

Owner:CHUNGHWA PICTURE TUBES LTD

Laminate

ActiveUS20120107617A1Well formedLow costSynthetic resin layered productsFlexible pipesVulcanizationPolymer science

The present invention provides a vulcanized laminate in which a rubber layer and a fluororesin layer are firmly adhered to each other without using an adhesive or performing a surface treatment on the rubber layer and the fluororesin layer. The present invention relates to a laminate comprising a rubber layer (A) and a fluororesin layer (B) on the rubber layer (A), wherein the rubber layer (A) is a layer made of a rubber composition for vulcanization, the rubber composition for vulcanization contains an unvulcanized rubber (a1); at least one compound (a2) selected from the group consisting of a 1,8-diazabicyclo(5.4.0)undec-7-ene salt, a 1,5-diazabicyclo(4.3.0)-non-5-ene salt, 1,8-diazabicyclo(5.4.0)undec-7-ene, and 1,5-diazabicyclo(4.3.0)-non-5-ene; magnesium oxide (a3); and silica (a4), the amount of the compound (a2) is larger than 1.0 part by mass and not larger than 5.0 parts by mass, for each 100 parts by mass of the unvulcanized rubber (a1), the fluororesin layer (B) is a layer made of a fluoropolymer composition, and the fluoropolymer composition contains a fluoropolymer (b1) having a copolymer unit derived from chlorotrifluoroethylene.

Owner:DAIKIN IND LTD

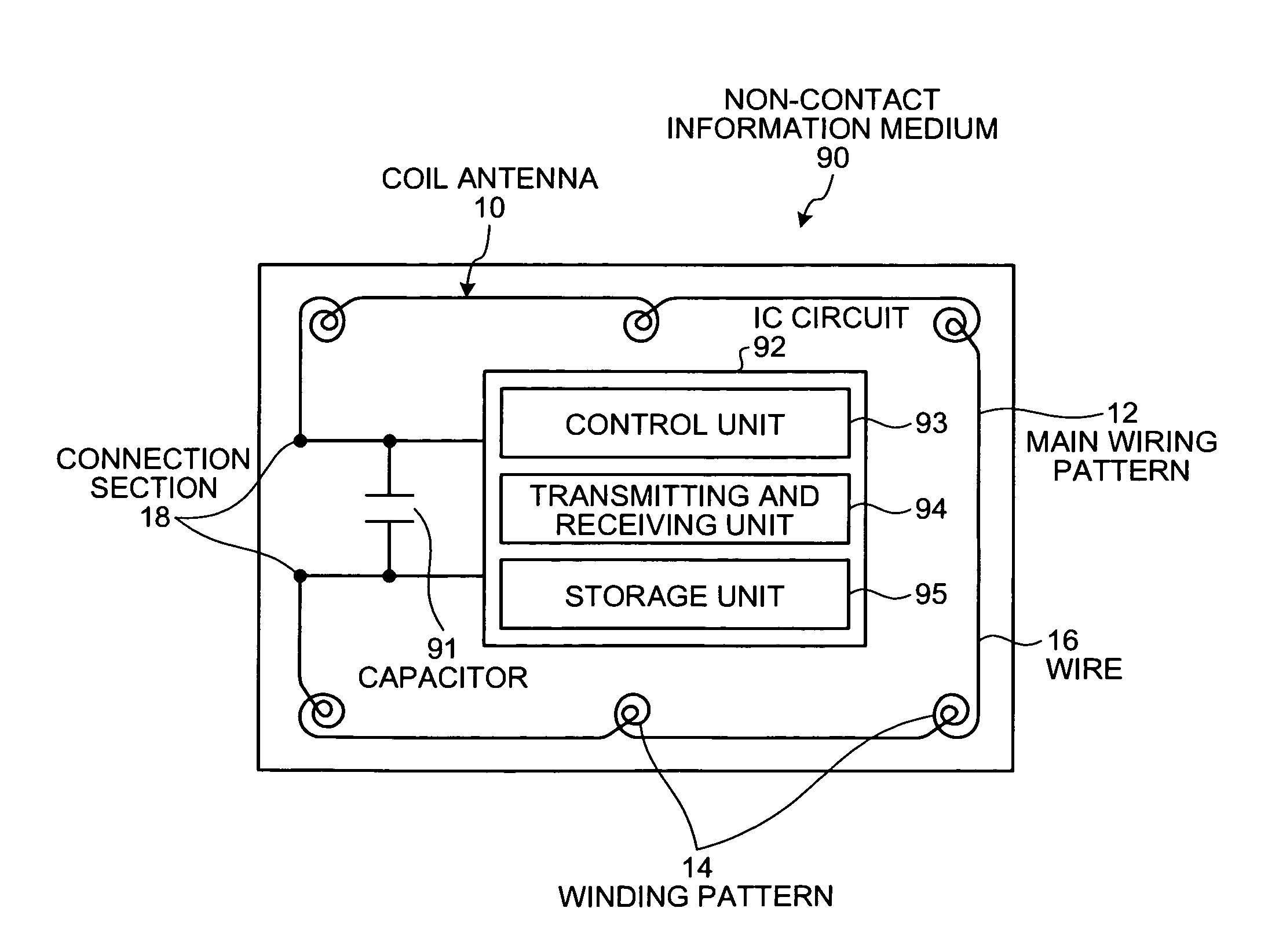

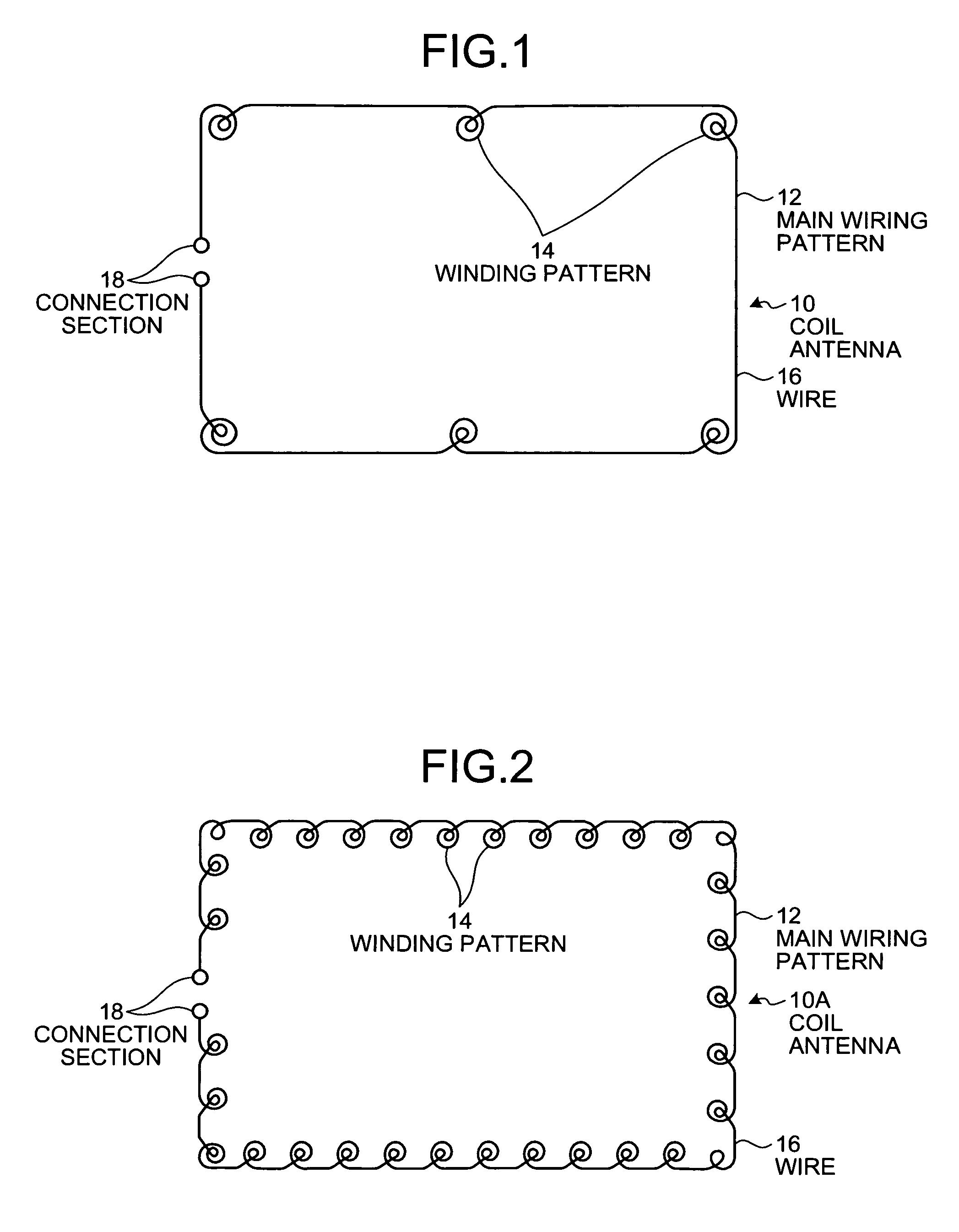

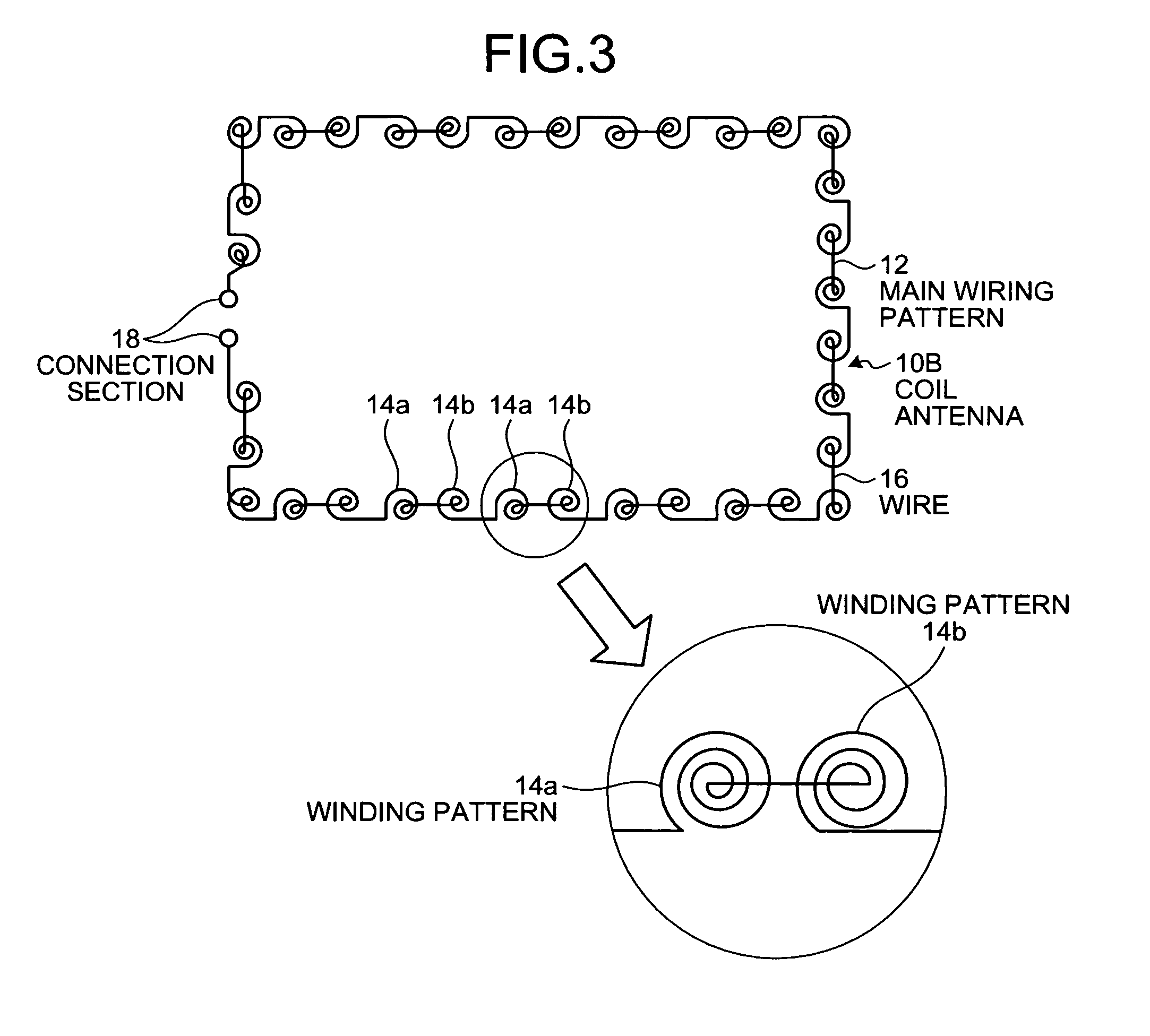

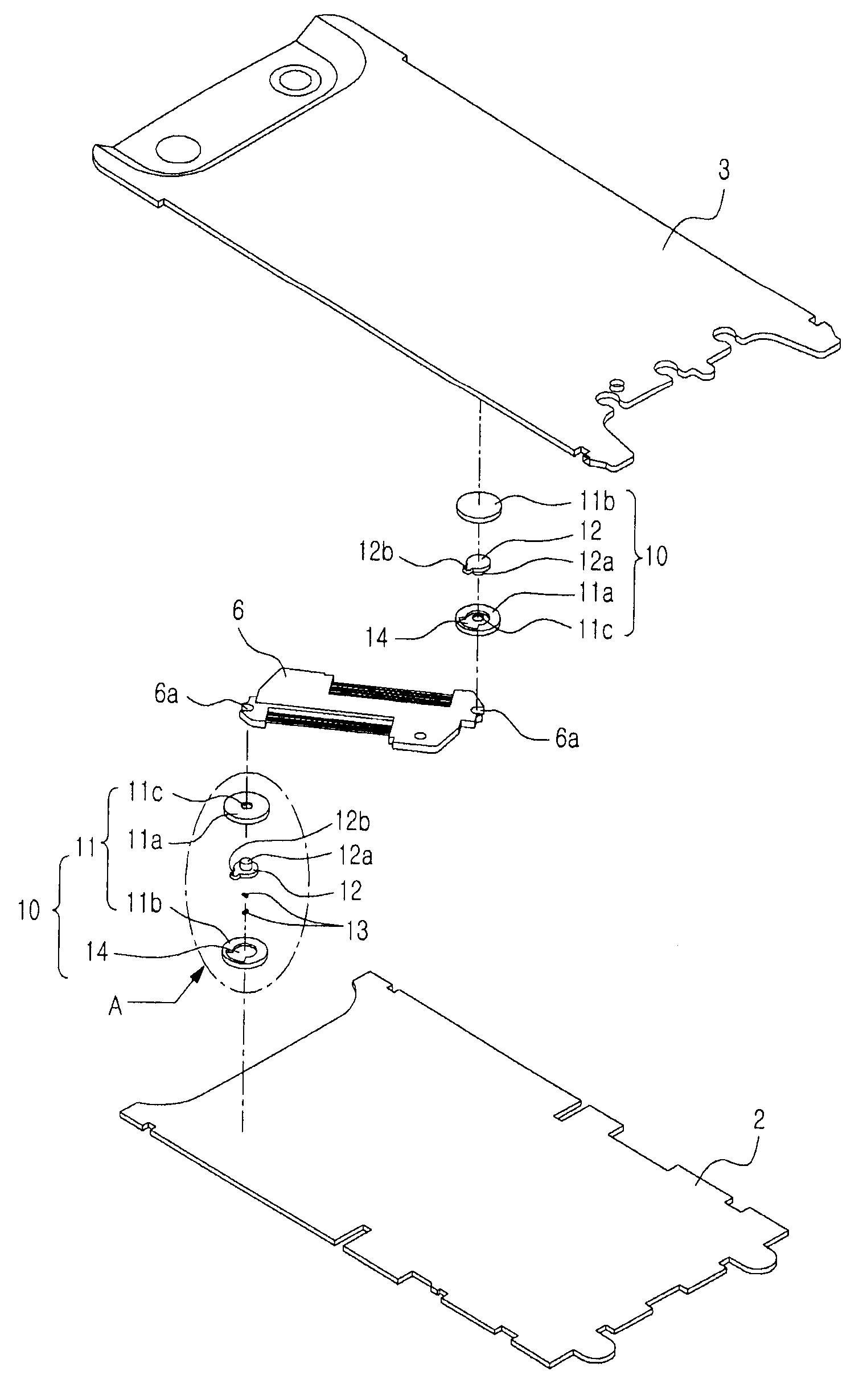

Coil antenna and non-contact information medium

ActiveUS8297516B2Product thinBig ratioLoop antennas with ferromagnetic coreRadiating elements structural formsEngineeringInductance

Without using a component such as a chip coil, a winding pattern is formed with a wire with which a main wiring pattern is formed. This enables to deal with the flexibility by realizing a thin product using a coil antenna. Further, the wiring pattern is designed such that the winding pattern is provided and distributed to the main wiring pattern forming a loop, and is formed with the wire so as to have a wound shape small enough compared with the main wiring pattern. In this way, the ratio of the self-inductance to the mutual inductance is appropriately made further large, so that the mutual inductance is made comparatively small.

Owner:NHK SPRING CO LTD

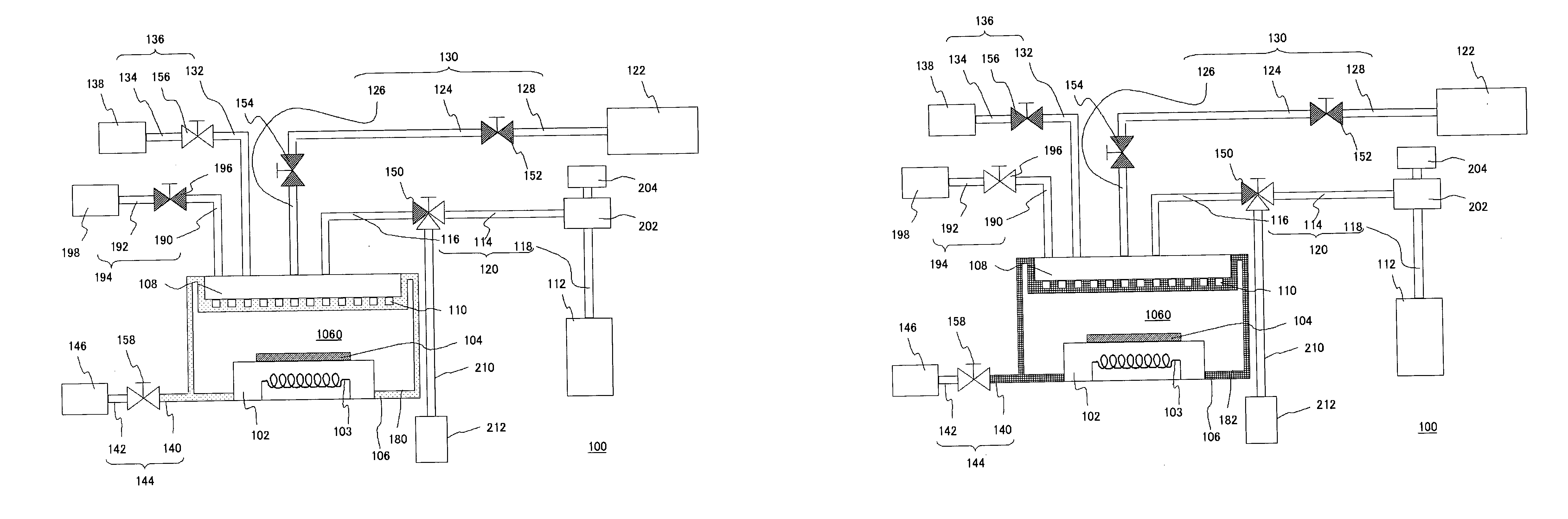

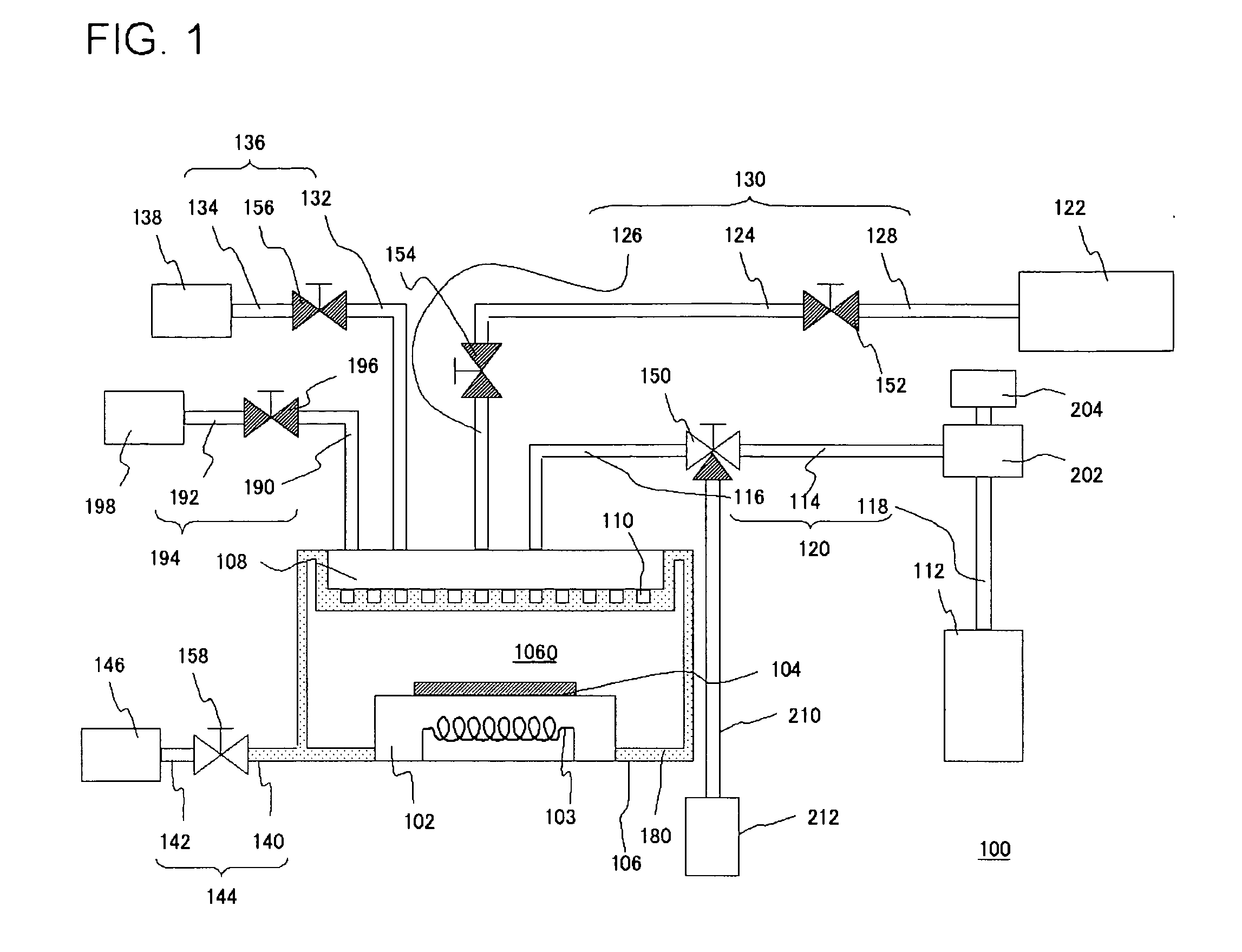

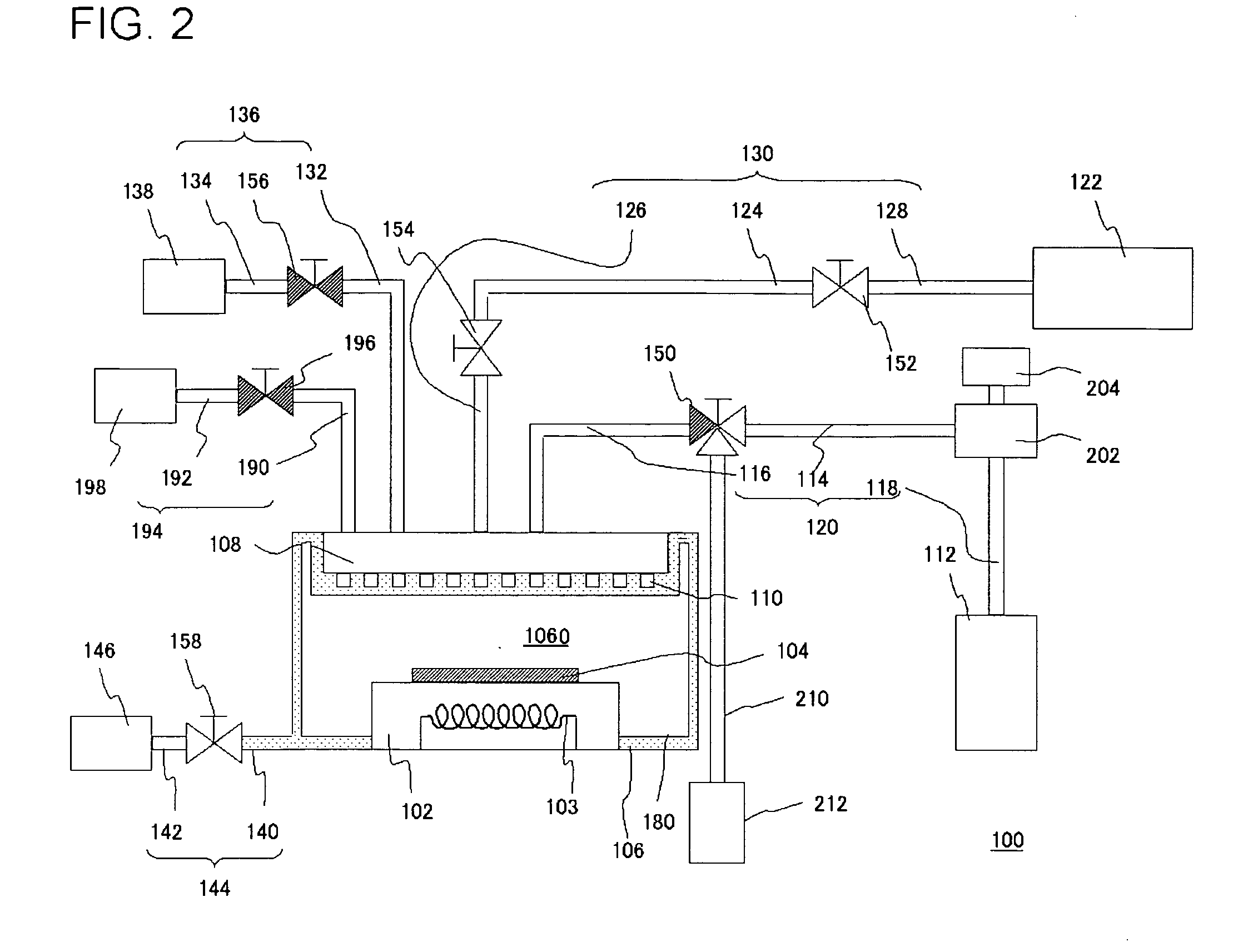

Method for processing interior of vapor phase deposition apparatus, method for depositing thin film and method for manufacturing semiconductor device

InactiveUS20050268851A1Product thinIncrease productivityTransistorSemiconductor/solid-state device manufacturingSimple Organic CompoundsGas phase

A method for depositing a metal compound film on the wafer by using a vapor phase deposition apparatus 100, comprising: forming a thin film on the wafer in an interior of the vapor phase deposition apparatus 100 by introducing a source gas for the metal compound film containing Hf or Zr; unloading the wafer having the metal compound film formed thereon from the interior of the vapor phase deposition apparatus 100; introducing a reactive gas in the interior of the vapor phase deposition apparatus 100 to immobilize the unreacted organic compound 180 derived from the source gas remained in the interior of the vapor phase deposition apparatus 100; loading another wafer in the interior of the vapor phase deposition apparatus 100; and depositing metal compound film on another wafer by further introducing the source gas in the interior of the vapor phase deposition apparatus 100, in the condition that the unreacted organic compound 180 exists therein as an immobilized form, is presented.

Owner:RENESAS ELECTRONICS CORP

Cementitious Exterior Sheathing Product Having Improved Interlaminar Bond Strength

InactiveUS20070098907A1High bonding strength between layersImprovement in ILB strengthLiquid surface applicatorsRoof covering using tiles/slatesBuilding productSlurry

A method of manufacturing a building product includes, forming a slurry of gypsum free cementitious material into successive fiber cement layers, and forming an interlayer in between the fiber cement layers, wherein the interlayer comprises a bond promoter of substantially gypsum free, acrylic based resin and water, and dewatering and curing the slurry while the bond promoter is between the fiber cement layers, such that the bond promoter bonds the fiber cement layers to one another with an increased interlaminar bond strength.

Owner:PLYCEM USA

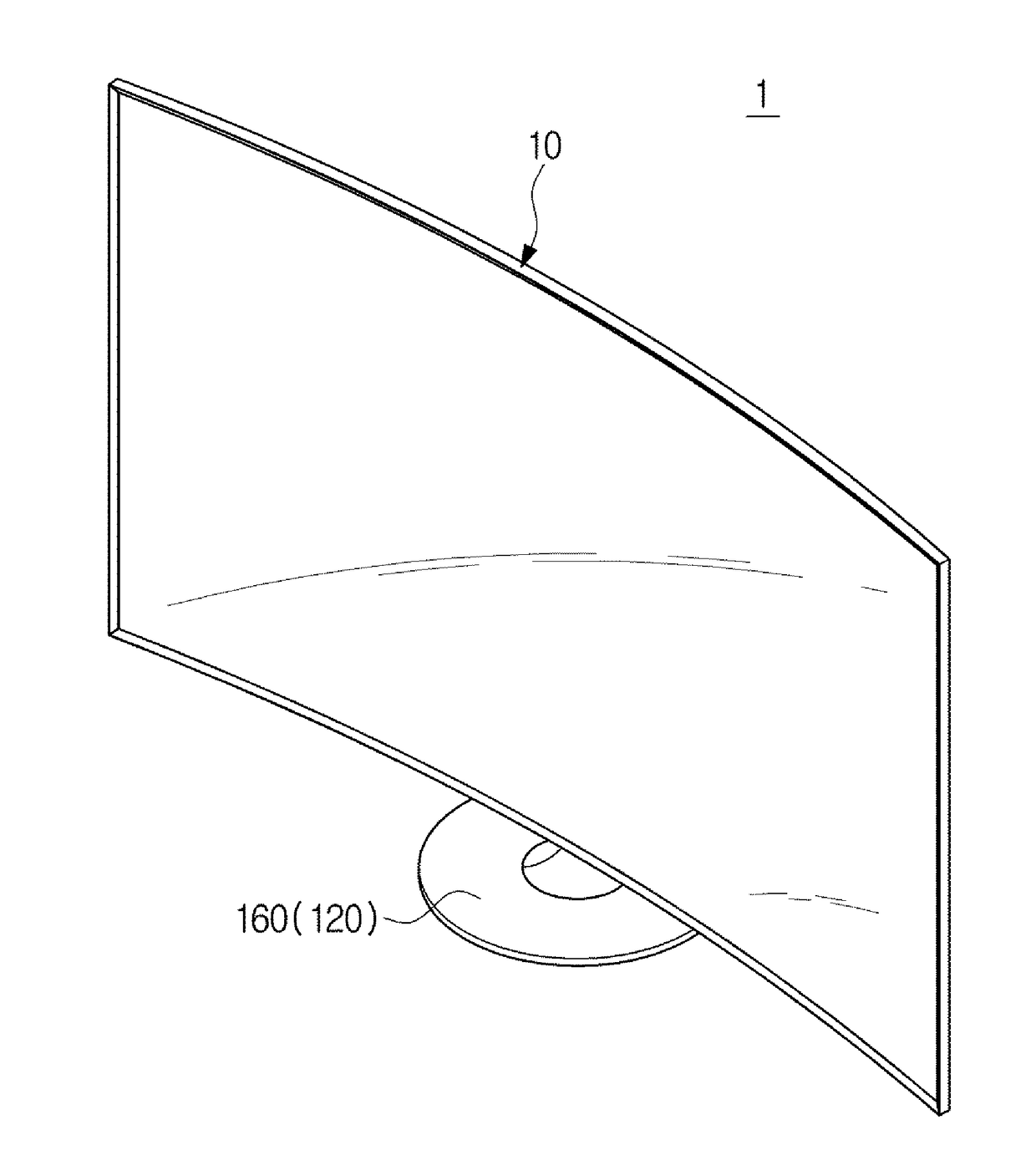

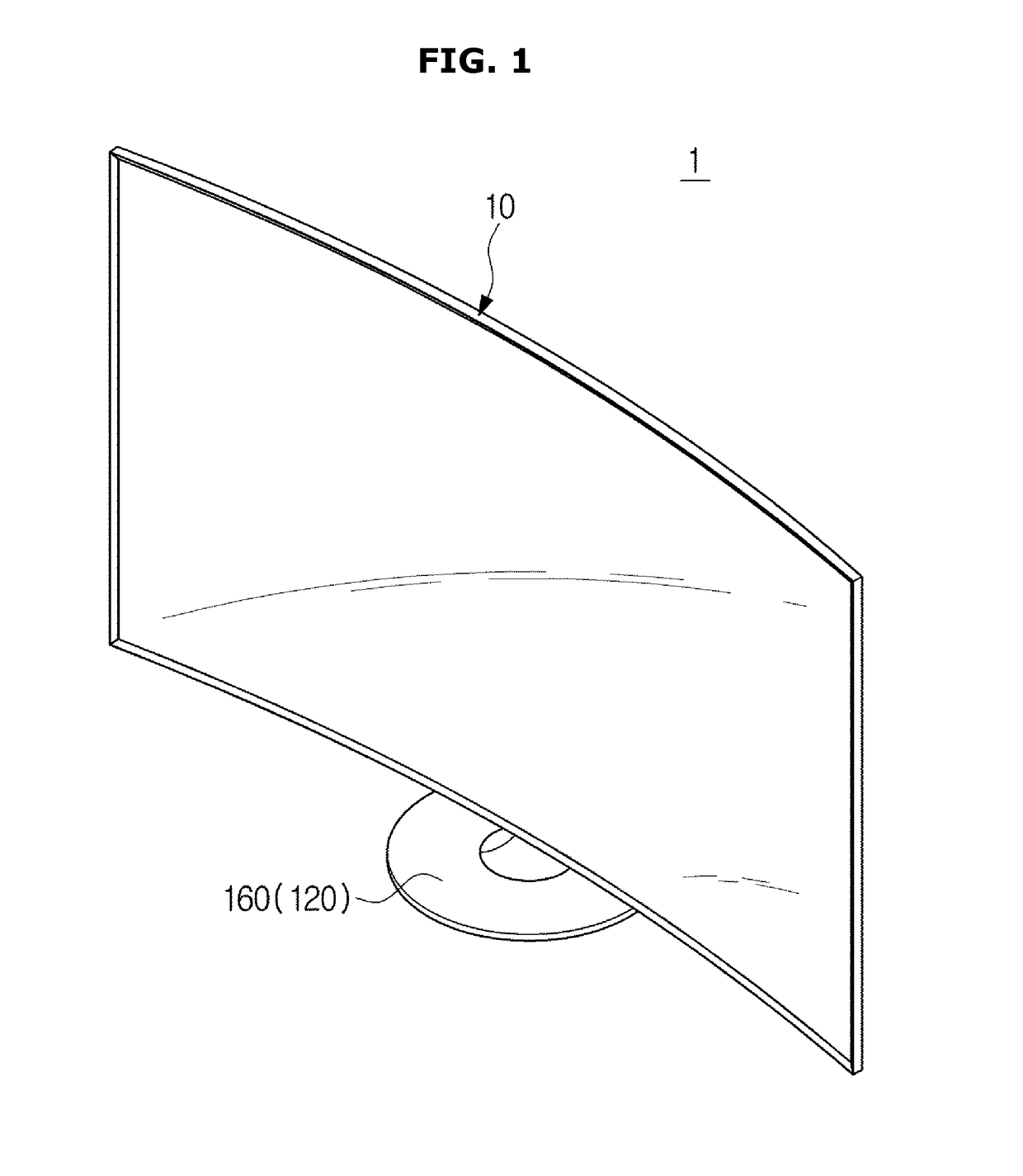

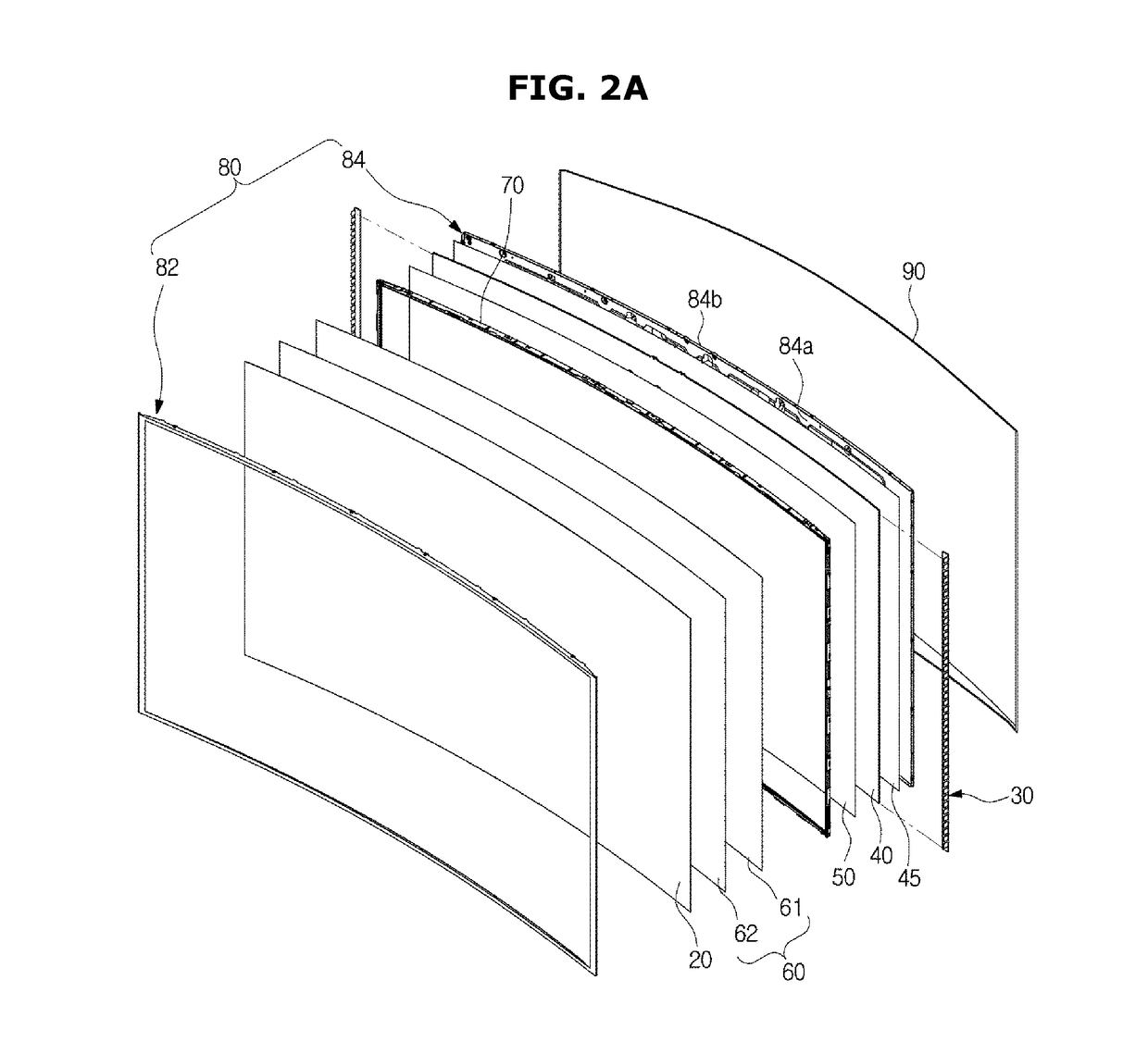

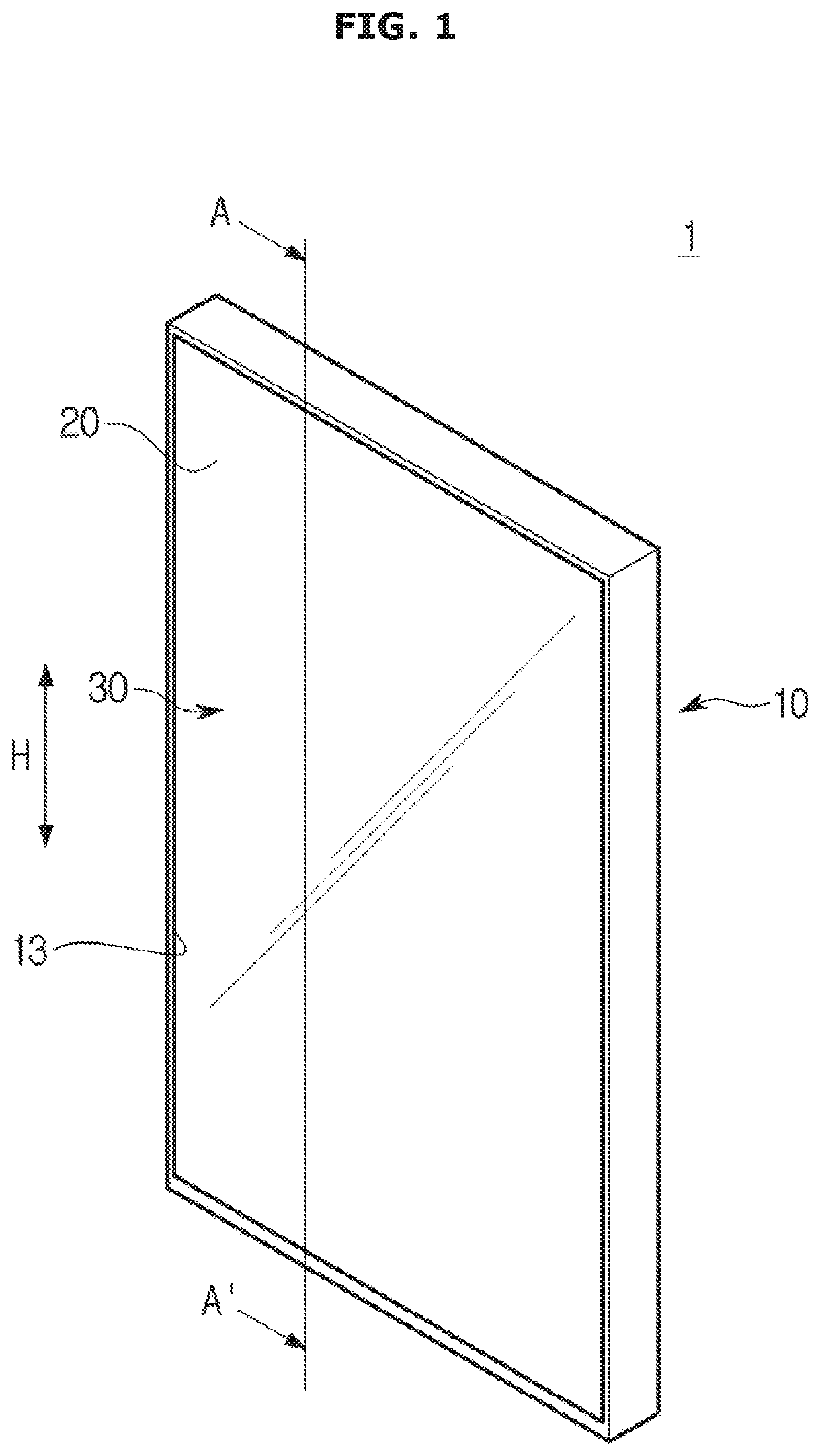

Display apparatus

ActiveUS9836080B2Improve AssemblabilitySimple structureSnap-action fastenersDigital data processing detailsCouplingEmbedded system

A display apparatus is provided. The display apparatus includes a display panel, a chassis disposed on at least one among a front side, a lateral side and a rear side of the display panel, and a cover removably coupled with the chassis in a snap button fashion. The display apparatus further includes a first coupling member disposed on one among the chassis and the cover, the first coupling member comprising a moving part that is movable, and a second coupling member disposed in a remaining one among the chassis and the cover, the moving part being removably coupled with the second coupling member.

Owner:SAMSUNG ELECTRONICS CO LTD

Thin film transistor device and method of manufacturing the same

A polysilicon film is formed in a predetermined region on a glass substrate, and then a gate insulating film and a gate electrode, whose width is narrower than the gate insulating film, are formed thereon. Then, an interlayer insulating film and an ITO film are formed on an overall surface. Then, n-type source / drain regions having an LDD structure are formed by implanting the n-type impurity into the polysilicon film. Then, an n-type TFT forming region and a pixel-electrode forming region are covered with a resist film, and then p-type source / drain regions are formed by implanting the p-type impurity into the polysilicon film in a p-type TFT forming region. Then, the resist film is left only in the pixel-electrode forming region and the resist film is removed from other regions. A pixel electrode is formed by etching the ITO film while using the remaining resist film as a mask.

Owner:UNIFIED INNOVATIVE TECH

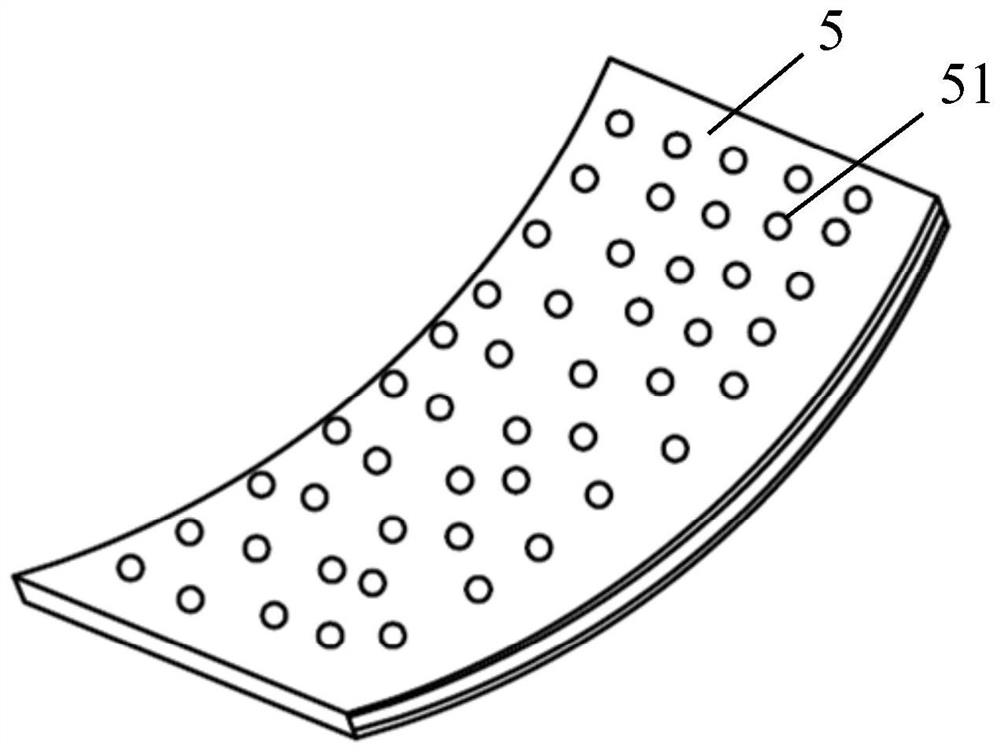

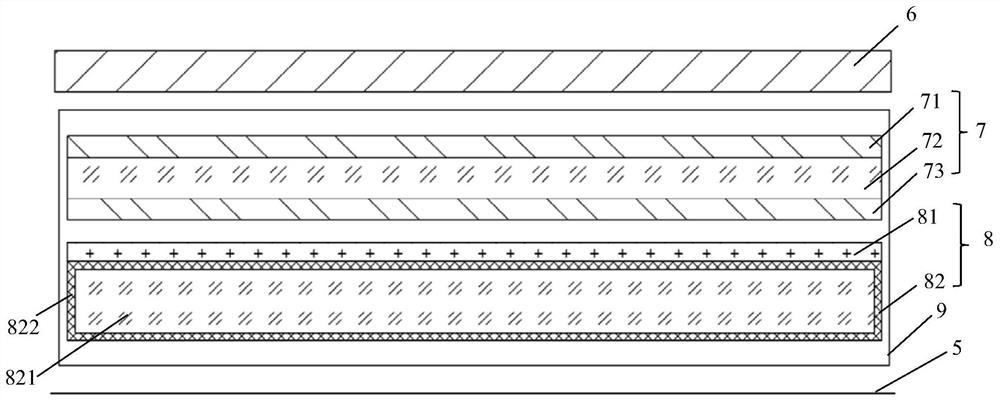

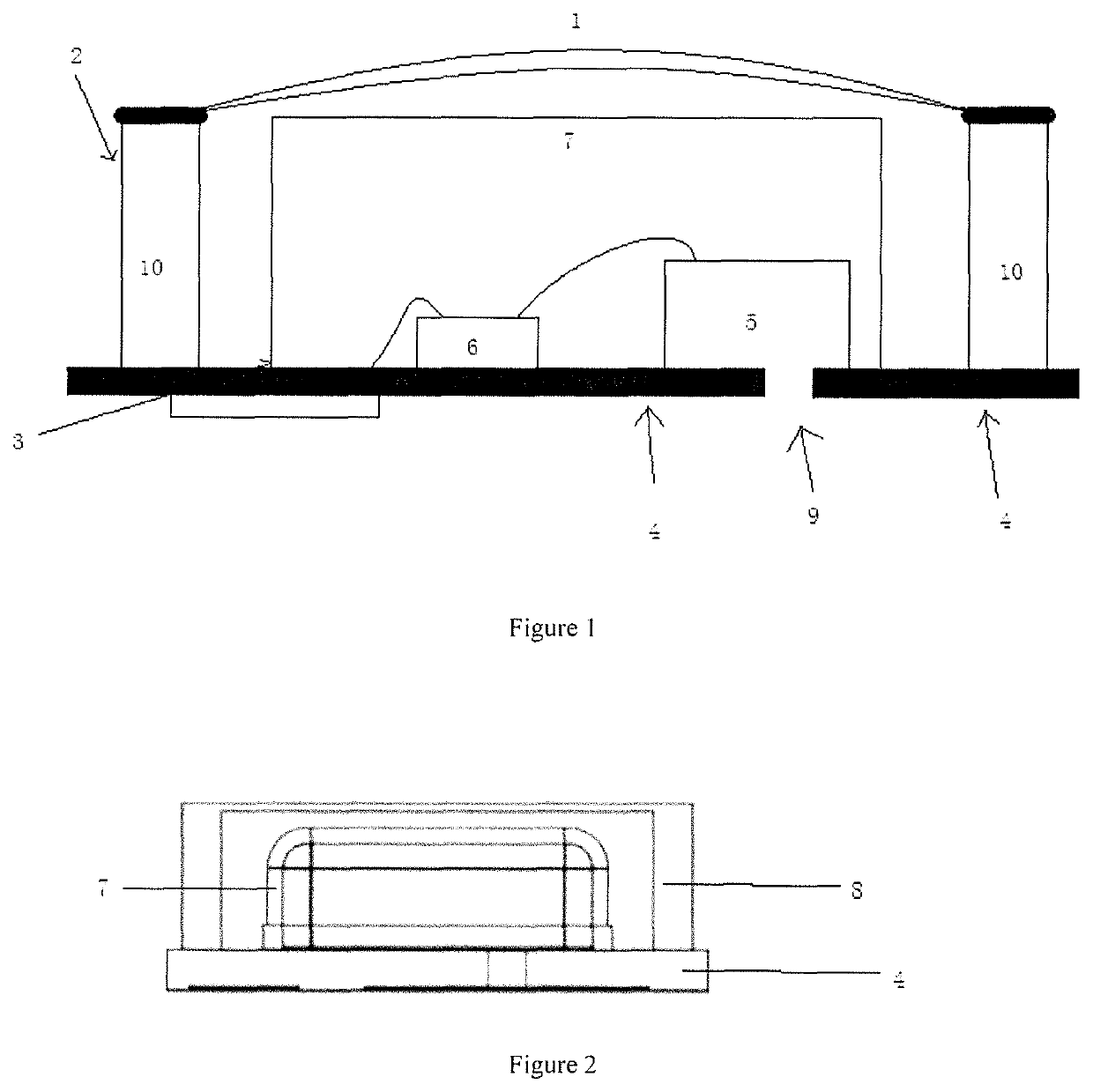

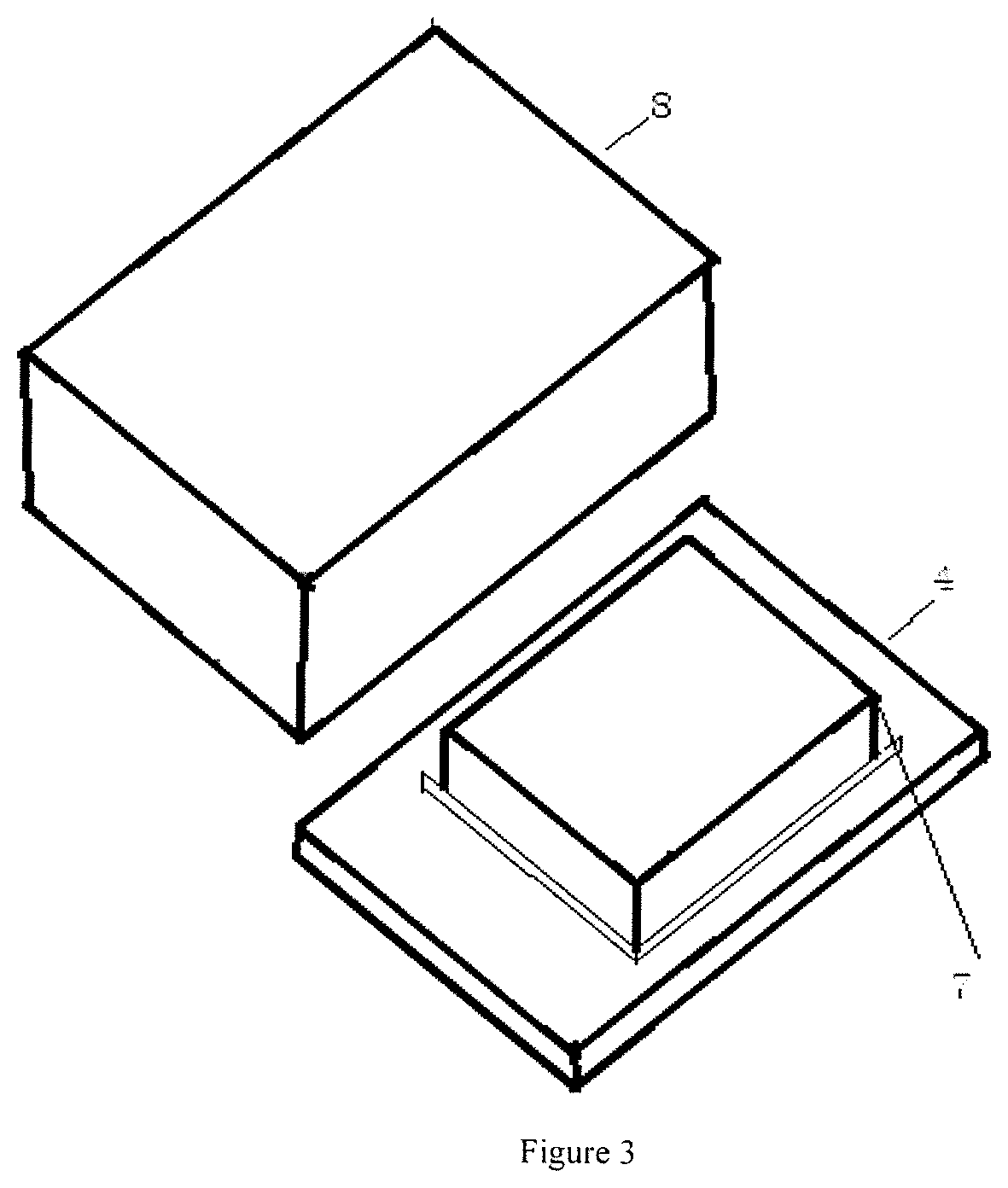

Target unit of machine vision system, target assembly and machine vision system

PendingUS20210156680A1ThinnerReduce weightImage enhancementImage analysisLight reflectionEngineering

The present invention belongs to the field of machine vision system technologies, and discloses a target unit of a machine vision system, a target assembly and a machine vision system, the target unit including a protective plate, a light absorbing layer and a light reflecting layer. The protective plate includes a connection surface. The light reflecting layer is connected to the light absorbing layer, one of the light absorbing layer and the light reflecting layer includes a preset pattern and is connected to the protective plate through the connection surface, and a surface that is of the other of the light absorbing layer and the light reflecting layer and that faces away from the protective plate is an outer surface of the target unit. In the target unit in the embodiments of the present invention, the protective plate can provide functions such as mechanical support, flatness and water resistance and scratch resistance, and a substrate in the prior art can be omitted, so that the weight of the target unit in this embodiment is reduced, and the thickness of a product is reduced, enabling that it is possible to make a thinner product. In addition, a product assembly process is simplified, and product costs are reduced.

Owner:AUTEL INTELLIGENT TECHNOLOGY CORP LTD

Laminate

ActiveUS9809008B2Well formedLow costSynthetic resin layered productsFlexible pipesPolymer scienceVulcanization

A laminate of a rubber layer (A) and a fluororesin layer (B) on the rubber layer (A), wherein the rubber layer (A) is a layer made of a rubber composition for vulcanization, the rubber composition for vulcanization contains an unvulcanized rubber (a1); at least one compound (a2) selected from the group consisting of a 1,8-diazabicyclo(5.4.0)undec-7-ene salt, a 1,5-diazabicyclo(4.3.0)-non-5-ene salt, 1,8-diazabicyclo(5.4.0)undec-7-ene, and 1,5-diazabicyclo(4.3.0)-non-5-ene; magnesium oxide (a3); and silica (a4), the amount of the compound (a2) is larger than 1.0 part by mass and not larger than 5.0 parts by mass, for each 100 parts by mass of the unvulcanized rubber (a1), the fluororesin layer (B) is a layer made of a fluoropolymer composition, and the fluoropolymer composition contains a fluoropolymer (b1) having a copolymer unit derived from chlorotrifluoroethylene.

Owner:DAIKIN IND LTD

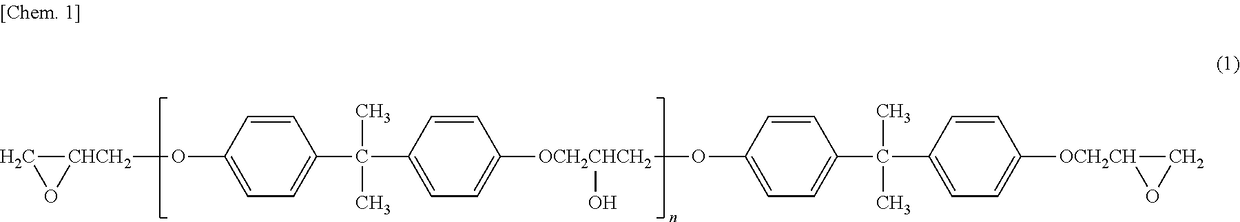

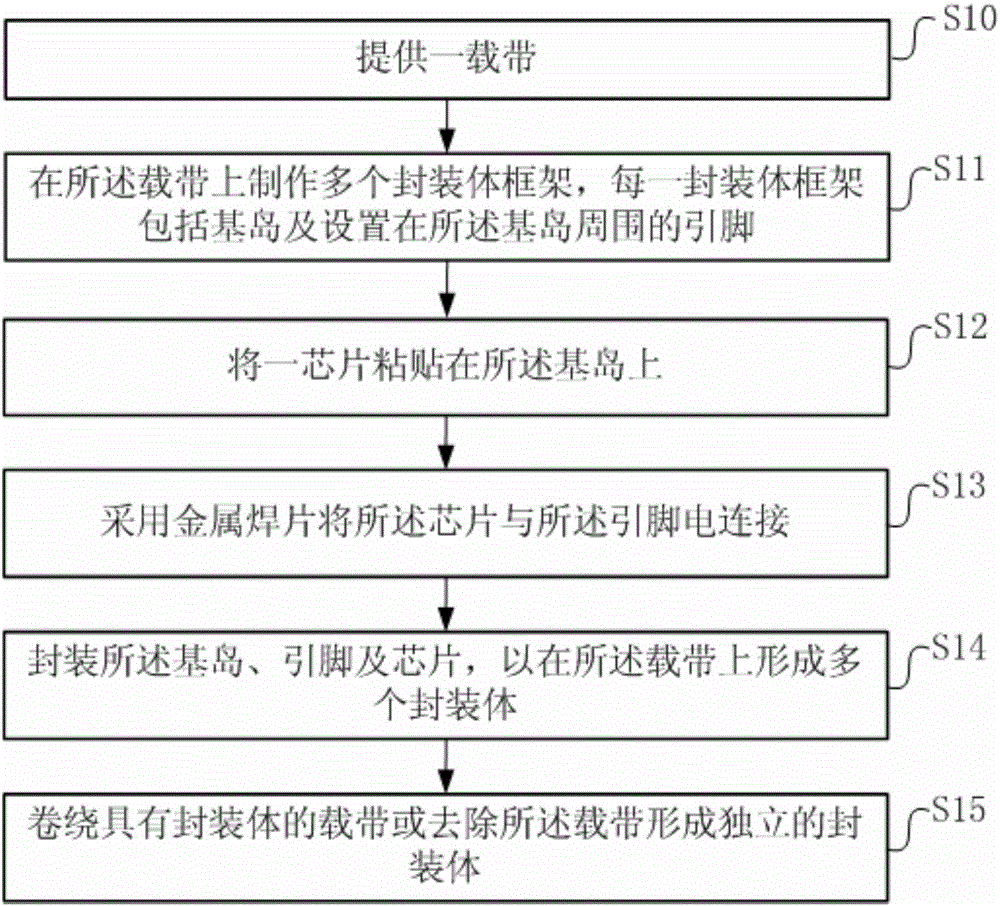

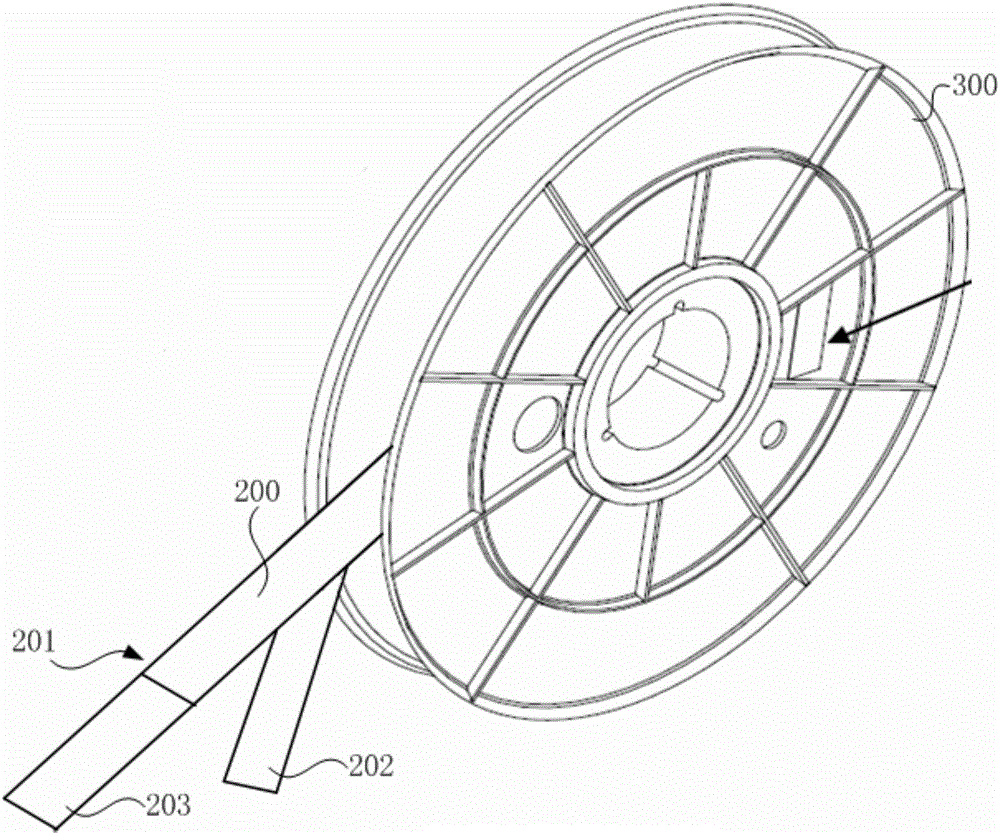

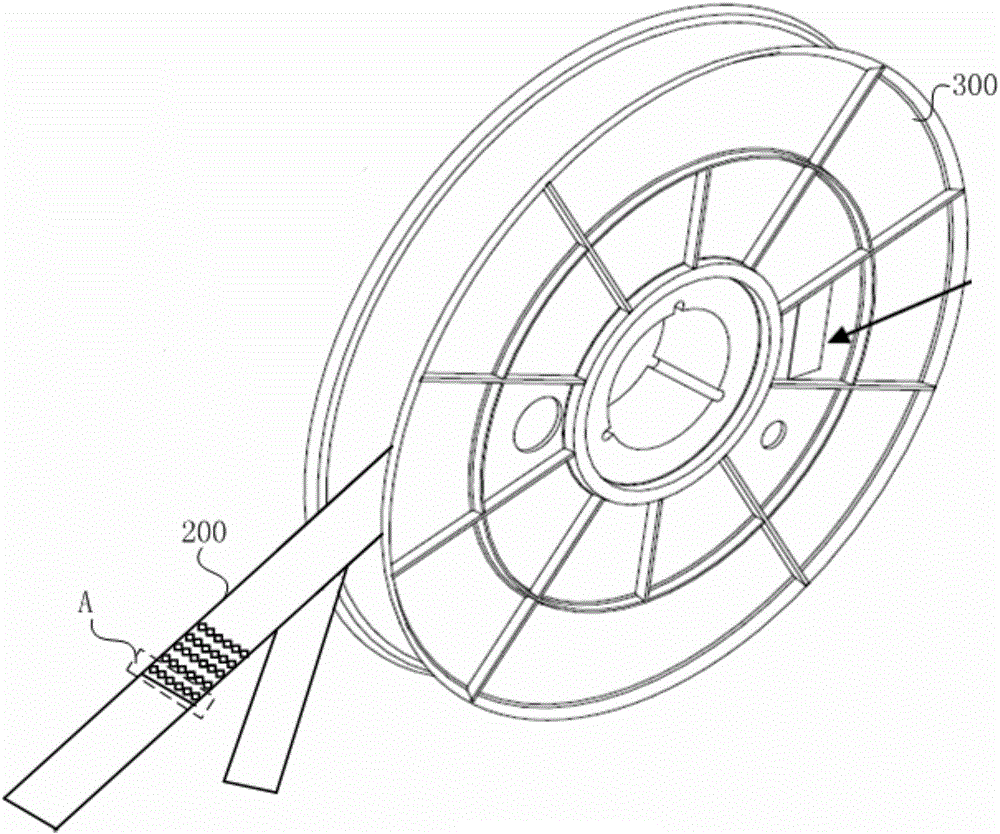

Tape coiling type intelligent card module SMD packaging structure and manufacturing method thereof

InactiveCN105845588AProduct thinGood heat dissipationSemiconductor/solid-state device detailsSolid-state devicesEngineeringMachine to machine

The invention provides a tape coiling type intelligent card module SMD packaging structure and a manufacturing method. The tape coiling type intelligent card module SMD packaging structure comprises a base island, pins arranged around the base island, and a chip arranged on the surface of the base island. The chip is electrically connected with the pins via a metal pad. The base island, the pins and the chip are packaged by a plastic package body to form a packaging body. The tape coiling type intelligent card module SMD packaging structure can meet the machine-to-machine communication requirement in the field of internet of things. Compared with the conventional chip packaging structure, the above structure is thinner and better in heat dissipation effect. Meanwhile, compared with the conventional SMD packaging process, the efficiency is higher.

Owner:SHANGHAI ETERNAL INFORMATION TECH

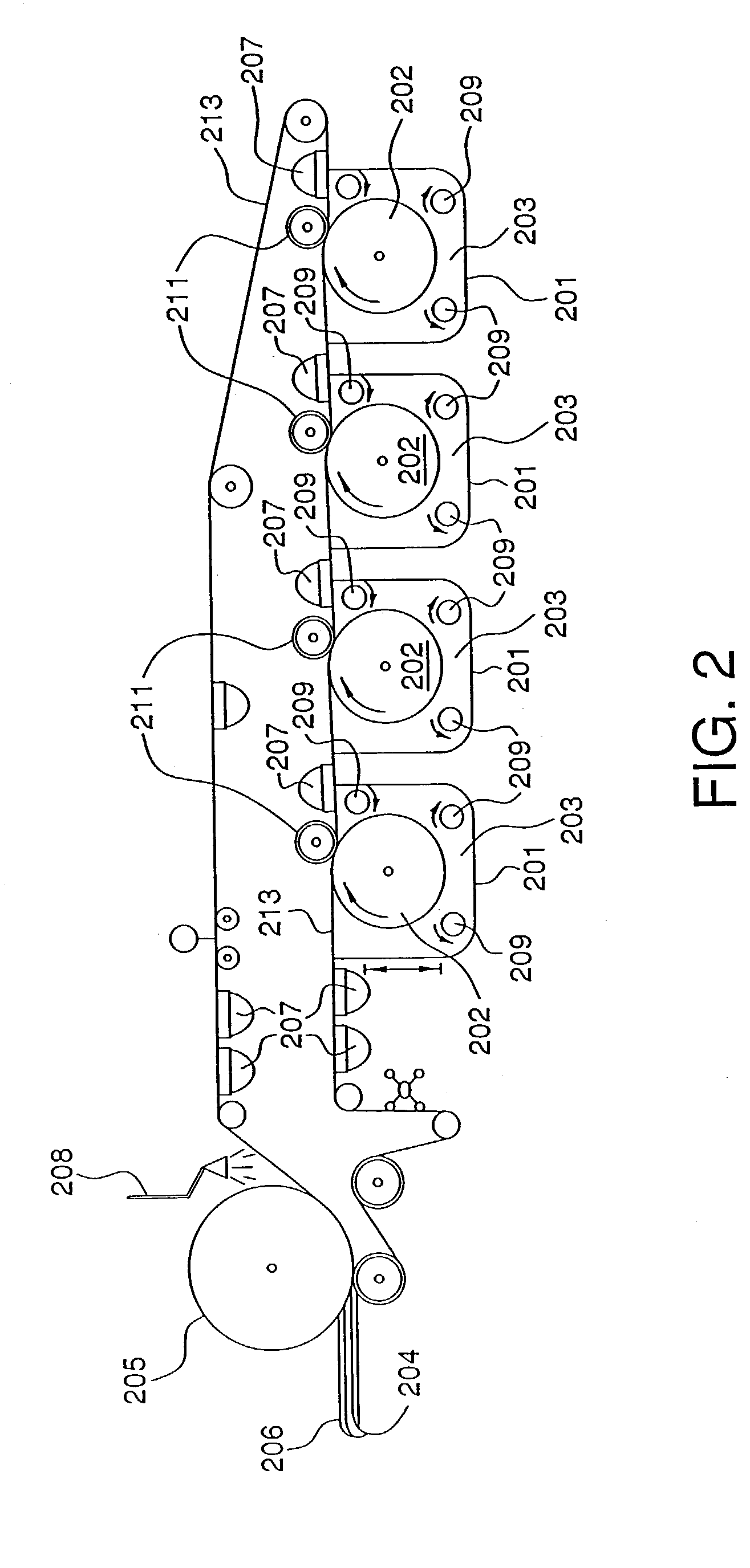

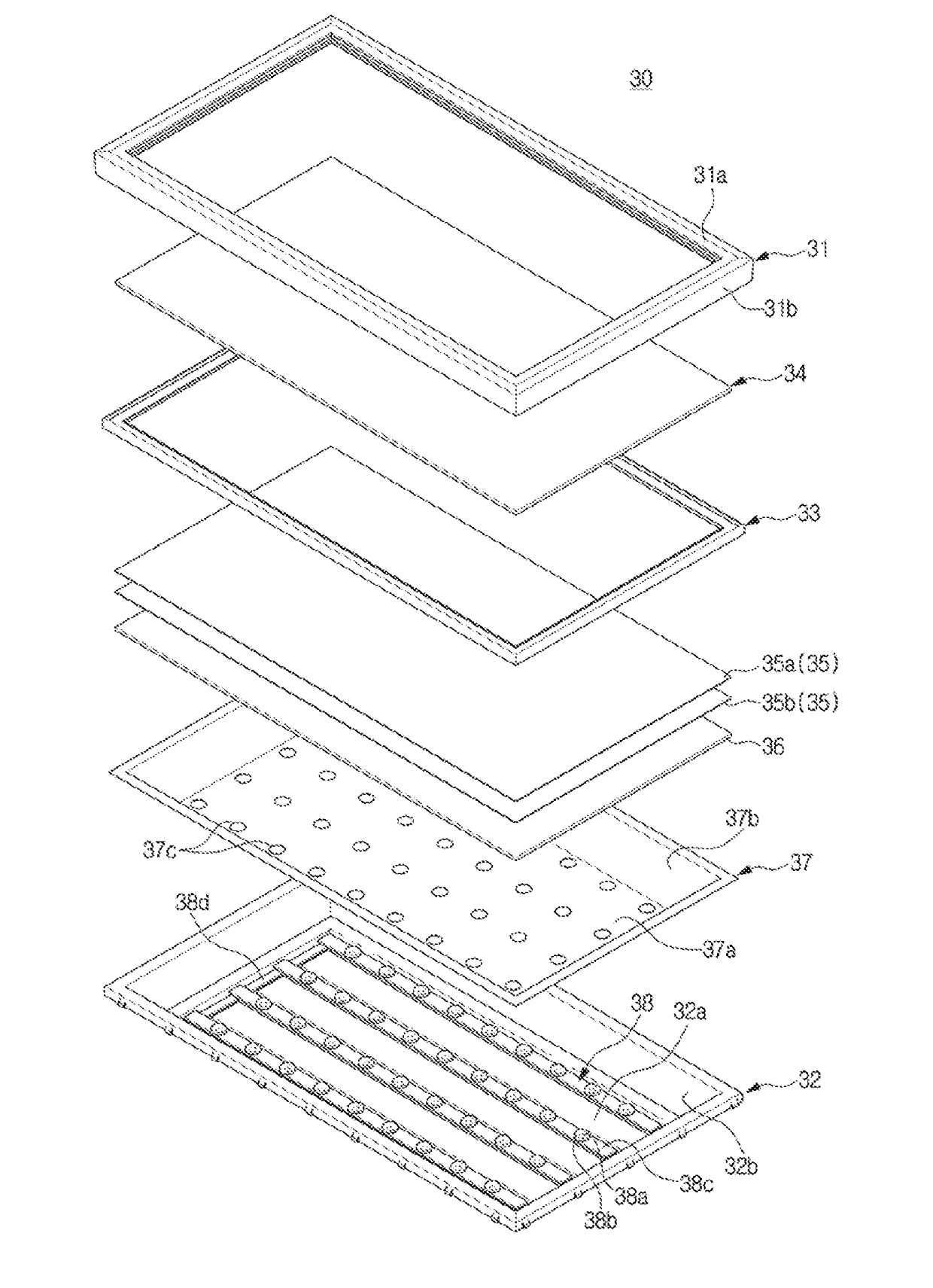

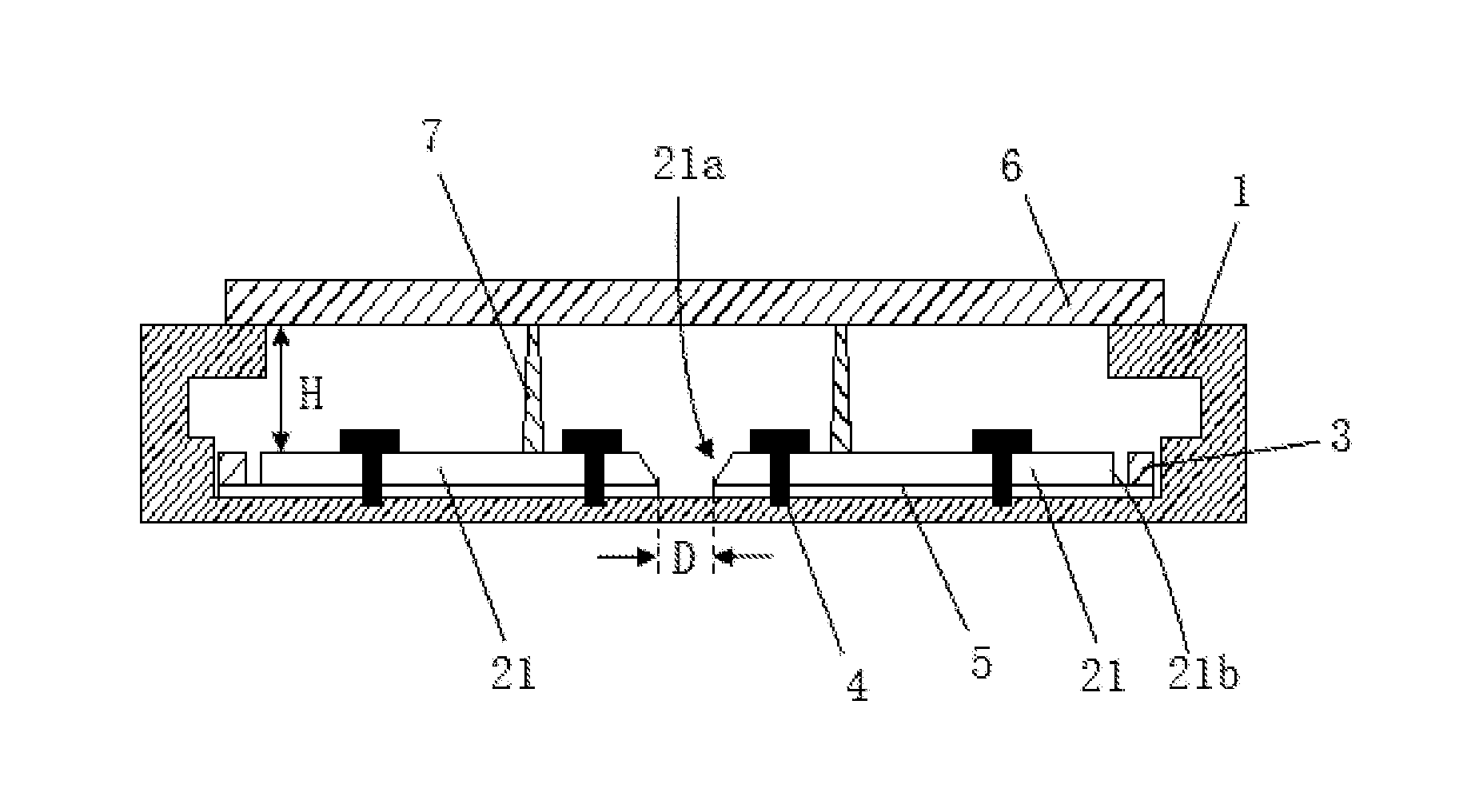

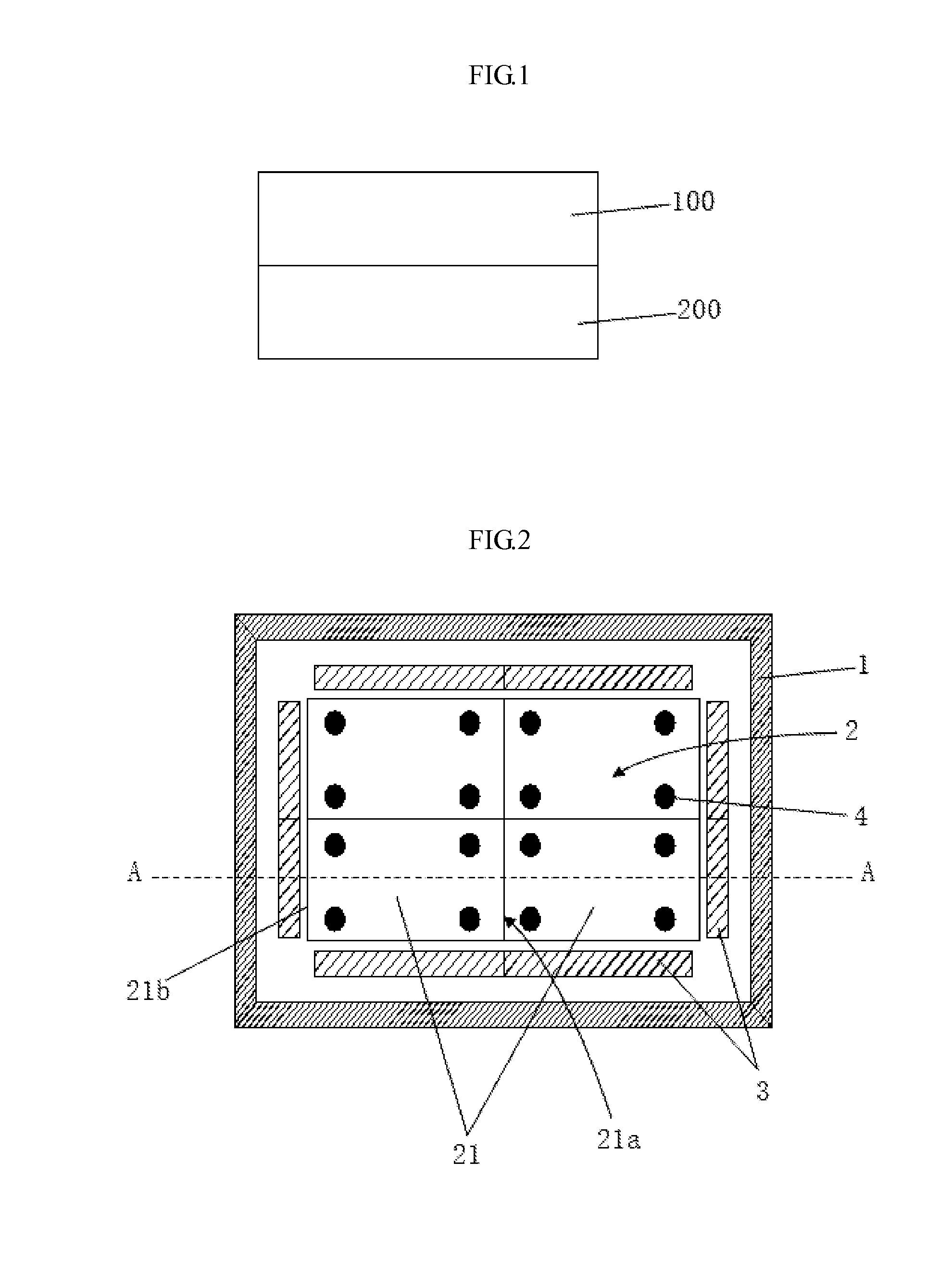

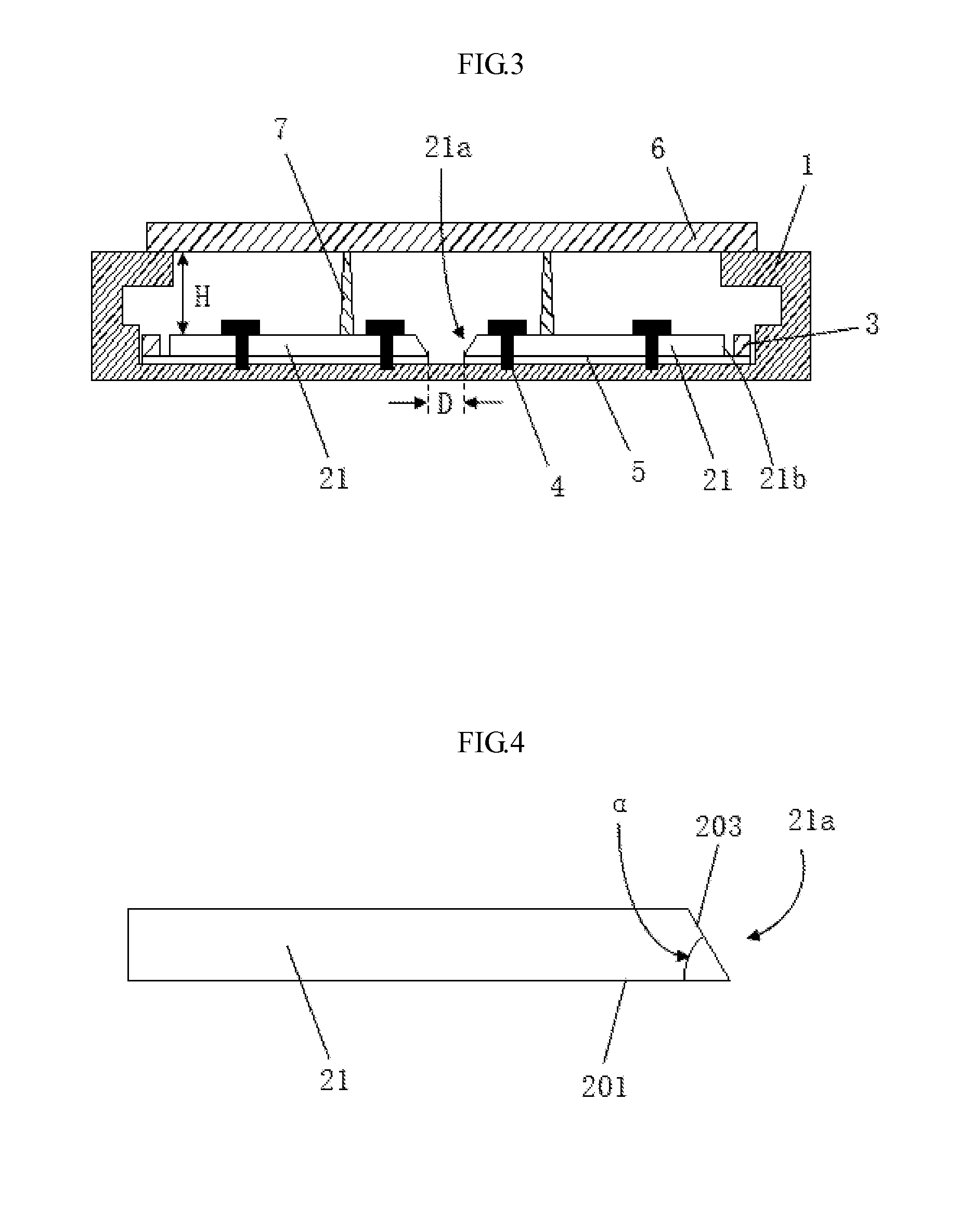

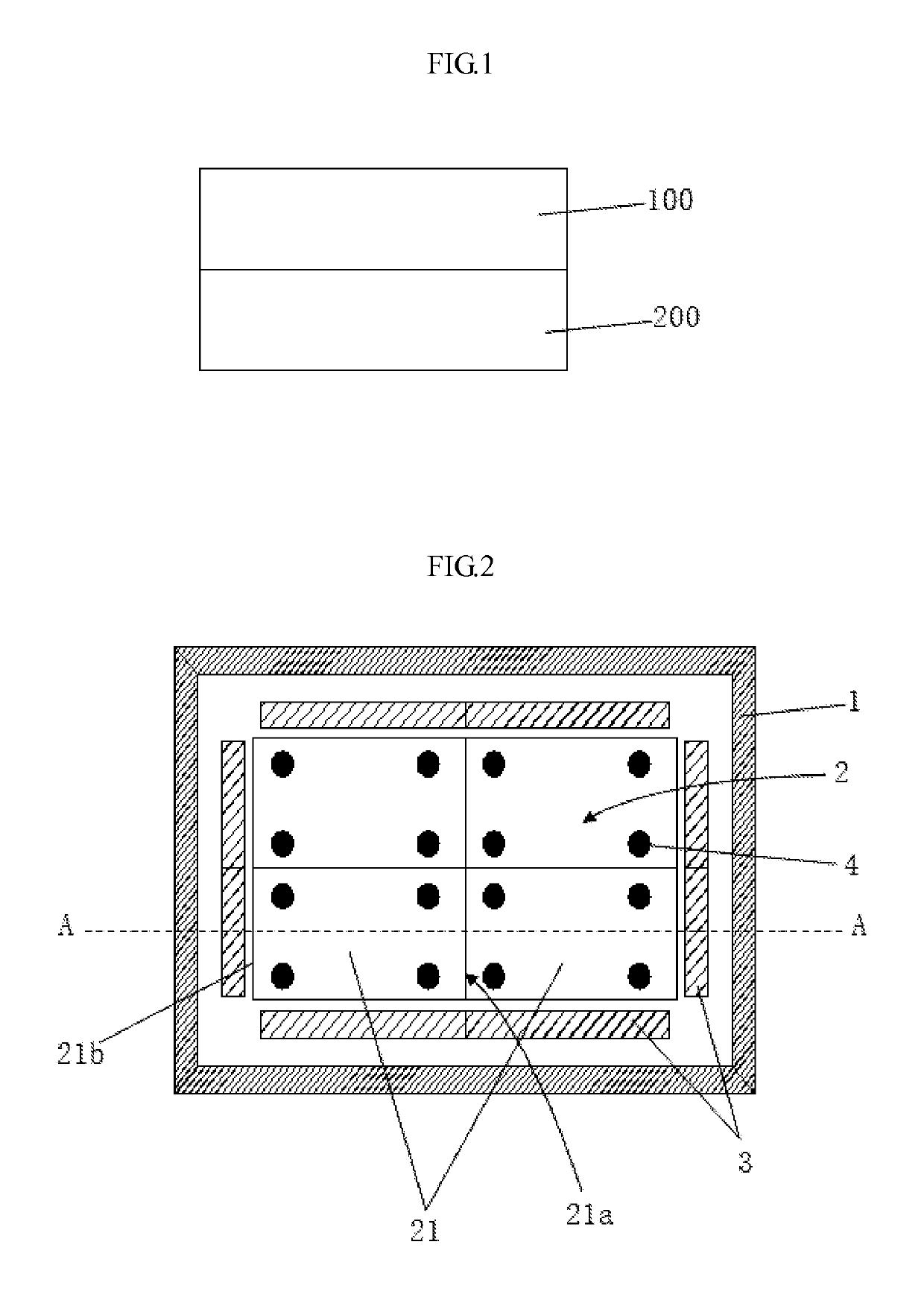

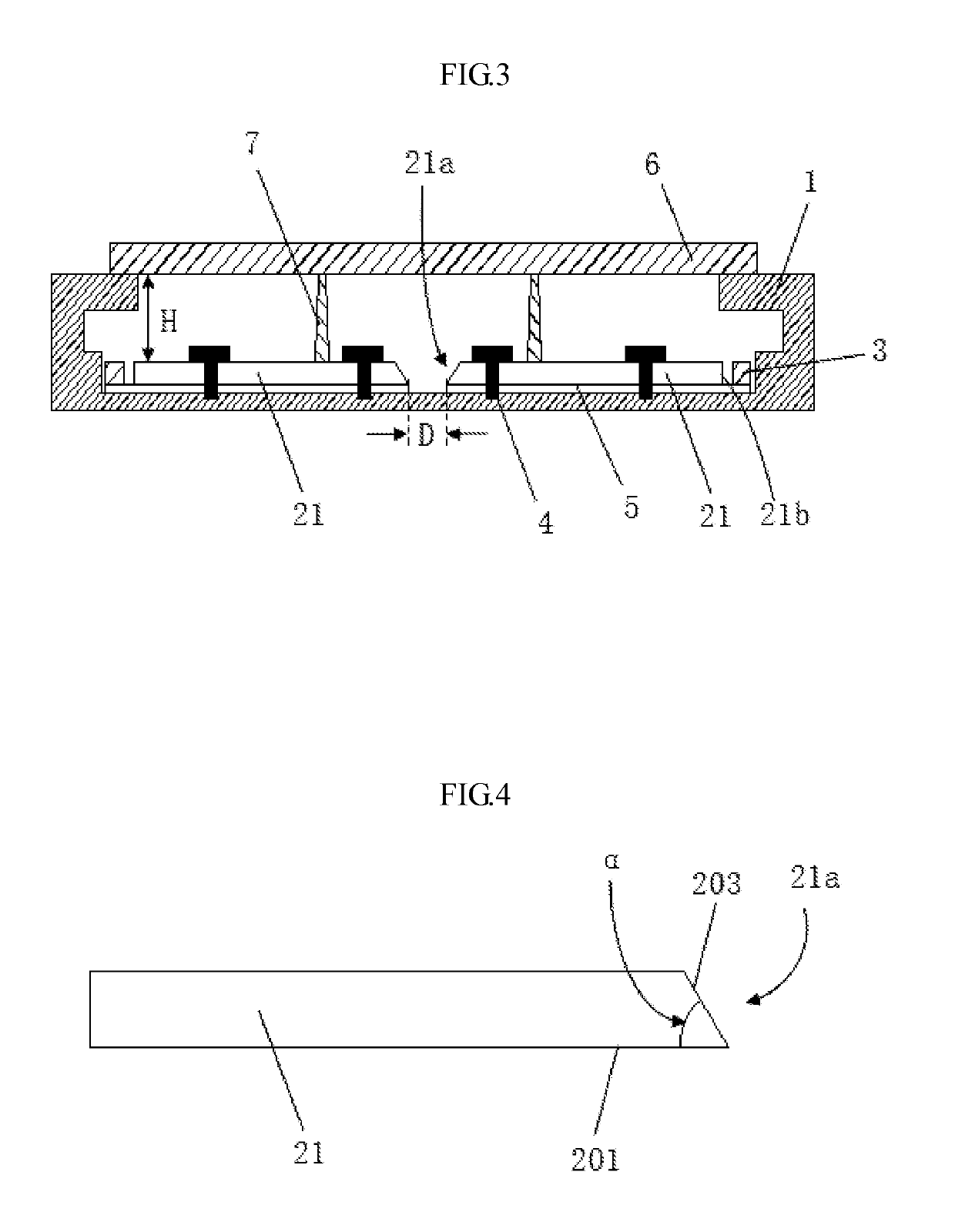

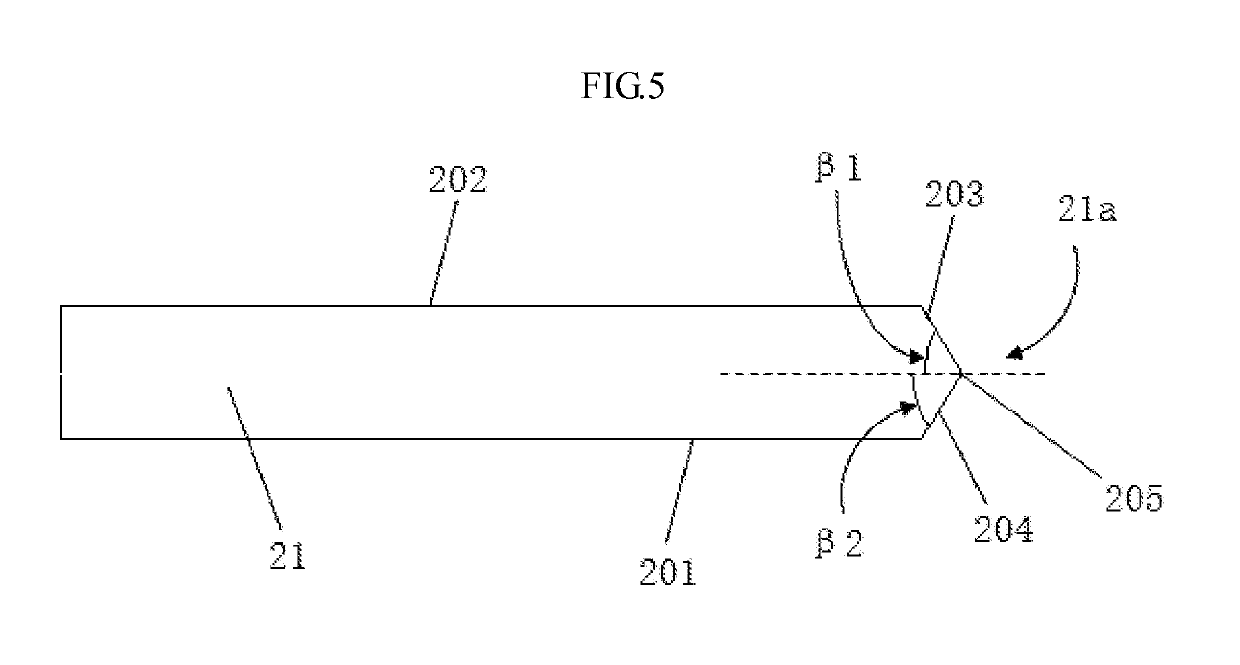

Backlight module and liquid crystal display device

InactiveUS20160363717A1Low costIncrease light mixing pathMechanical apparatusLight guides for lighting systemsLiquid-crystal displayLight guide

A backlight module including a back plate and a light guide plate structure and a light source assembly disposed on the back plate, wherein the light guide plate structure is mainly formed by splicing a plurality of light guide plate blocks, each of the plurality of light guide plate blocks includes a splicing end surface and at least one incident light end surface, and the light source assembly is disposed on at least one incident light end surface of the light guide plate blocks. Additionally, a liquid crystal display including the above backlight module is disclosed. The light guide plate structure in the backlight module may reduce a light mixing height of the backlight module and is advantageous to thinning the product; in addition, the structure of the light guide plate is simple and easy to be implemented, which is advantageous to lower the cost of the product.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

Outdoor display apparatus

ActiveUS10925195B2Simple structureInhibit deteriorationTelevision system detailsDigital data processing detailsProtective glassesEngineering

Disclosed herein is an outdoor display apparatus having a heat-radiating structure. The outdoor display apparatus includes a housing; a display module disposed inside the housing, and including a display panel on which an image is displayed; a heat-exchange module disposed on a rear surface of the display module, and configured to concentrate heat inside the housing on a rear surface of the display panel and discharge heat out of the housing; a protective glass disposed to correspond to a display area of the display panel, and configured to transmit infrared light; and a flow path formed inside the housing such that air flowing along the flow path transfers heat from the display panel to the heat-exchange module.

Owner:SAMSUNG ELECTRONICS CO LTD

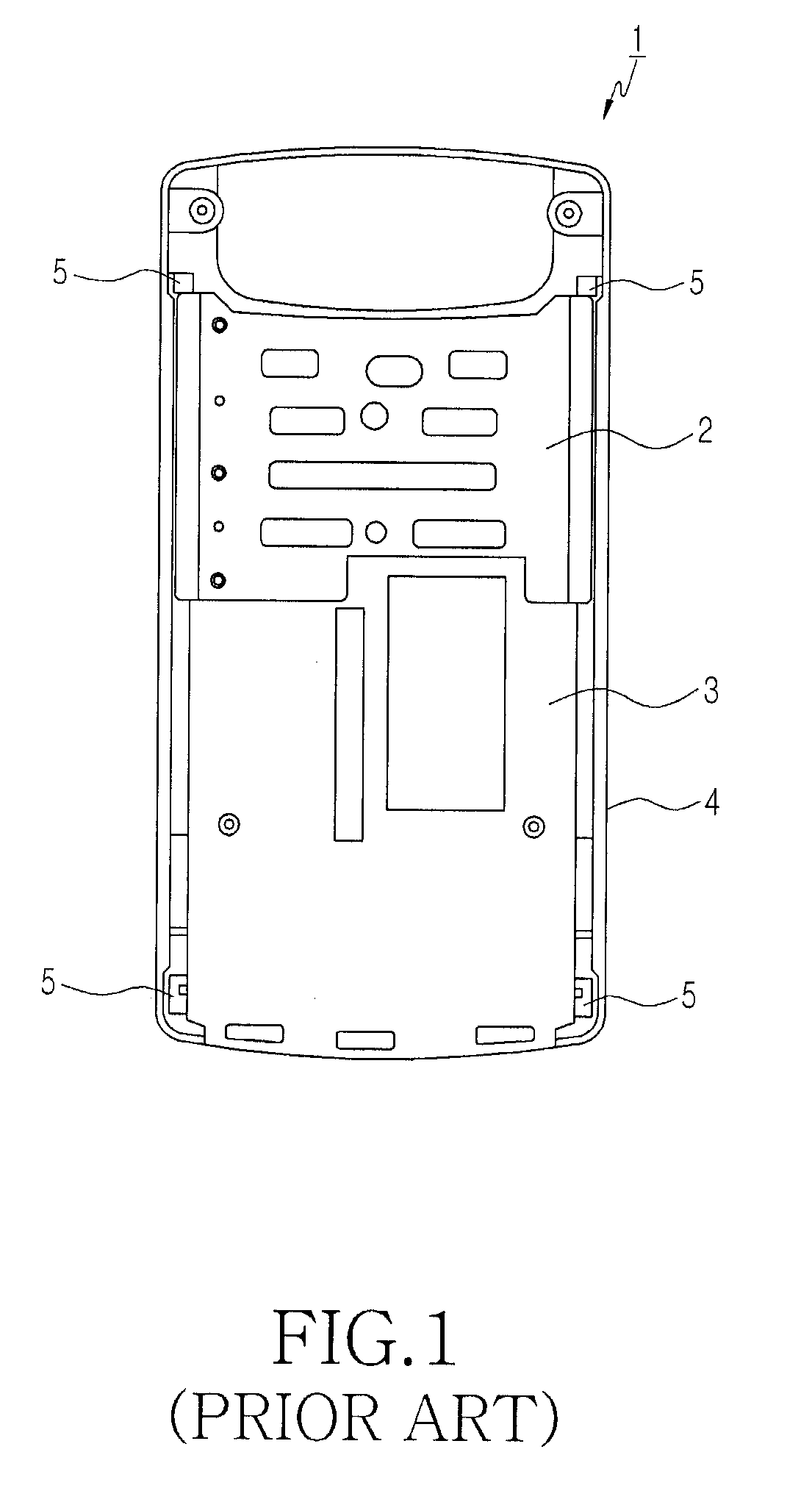

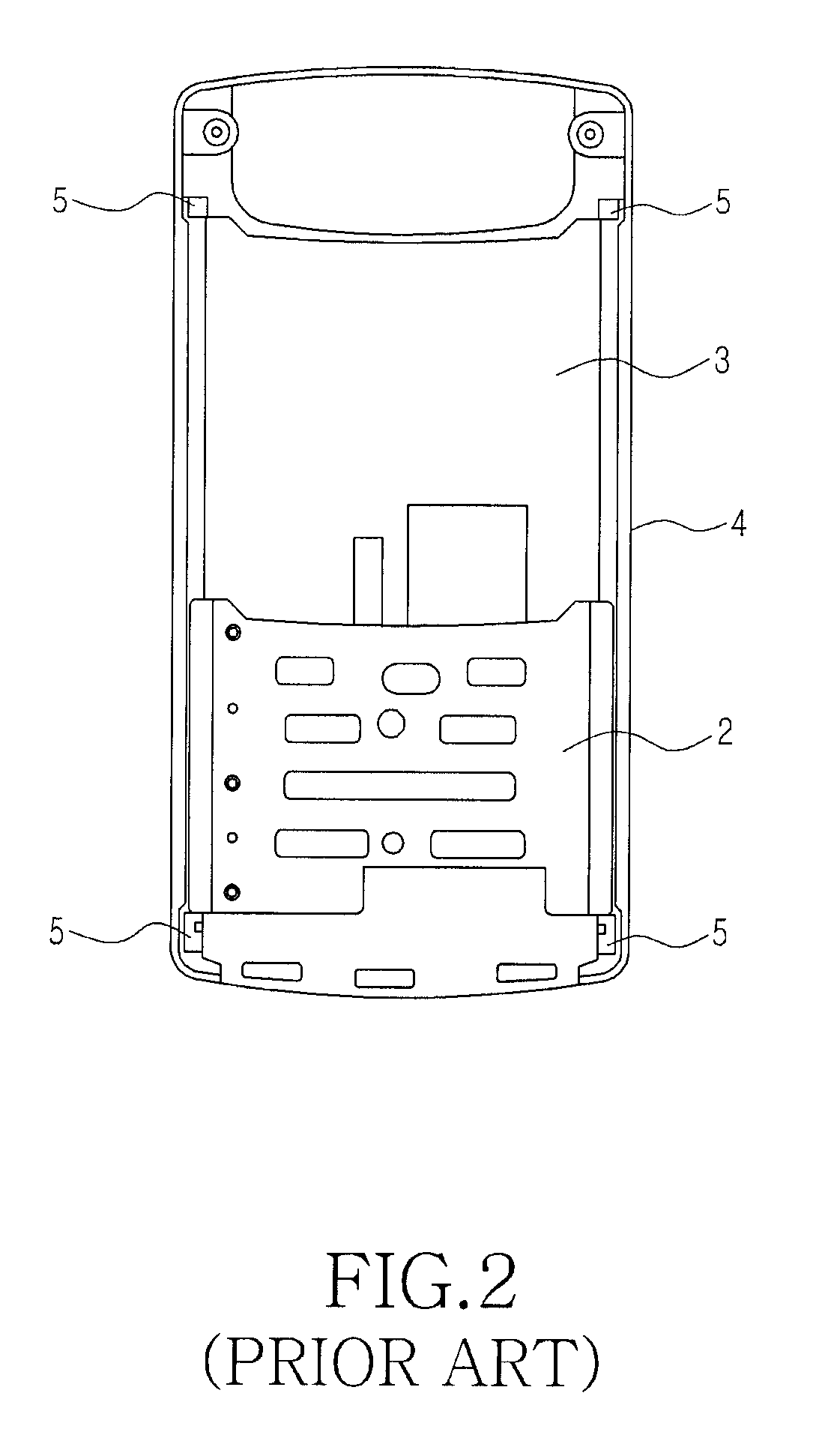

Sliding module for slide-type portable terminal having stopper device

InactiveUS20100192716A1Reduce manufacturing costProduct thinDigital data processing detailsGearingElastomerEngineering

A sliding module for a slide-type portable terminal with a stopper device, which includes a fixed plate, a moving plate slidable over the fixed plate, and an elastic body interposed between the fixed plate and the moving plate and providing an elastic force to slide the moving plate, in which a rivet stopper is formed on each of both ends of the elastic body so that during sliding movement of the moving plate, both ends of the elastic body also rotate and the sliding movement of the moving plate is restricted when rivets provided at both ends of the elastic body make contact.

Owner:SAMSUNG ELECTRONICS CO LTD

Backlight module and liquid crystal display device

InactiveUS10267978B2Reduce a light mixing height of the backlight moduleLow production costMechanical apparatusLight guides for lighting systemsLiquid-crystal displayLight guide

A backlight module including a back plate and a light guide plate structure and a light source assembly disposed on the back plate, wherein the light guide plate structure is mainly formed by splicing a plurality of light guide plate blocks, each of the plurality of light guide plate blocks includes a splicing end surface and at least one incident light end surface, and the light source assembly is disposed on at least one incident light end surface of the light guide plate blocks. Additionally, a liquid crystal display including the above backlight module is disclosed. The light guide plate structure in the backlight module may reduce a light mixing height of the backlight module and is advantageous to thinning the product; in addition, the structure of the light guide plate is simple and easy to be implemented, which is advantageous to lower the cost of the product.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

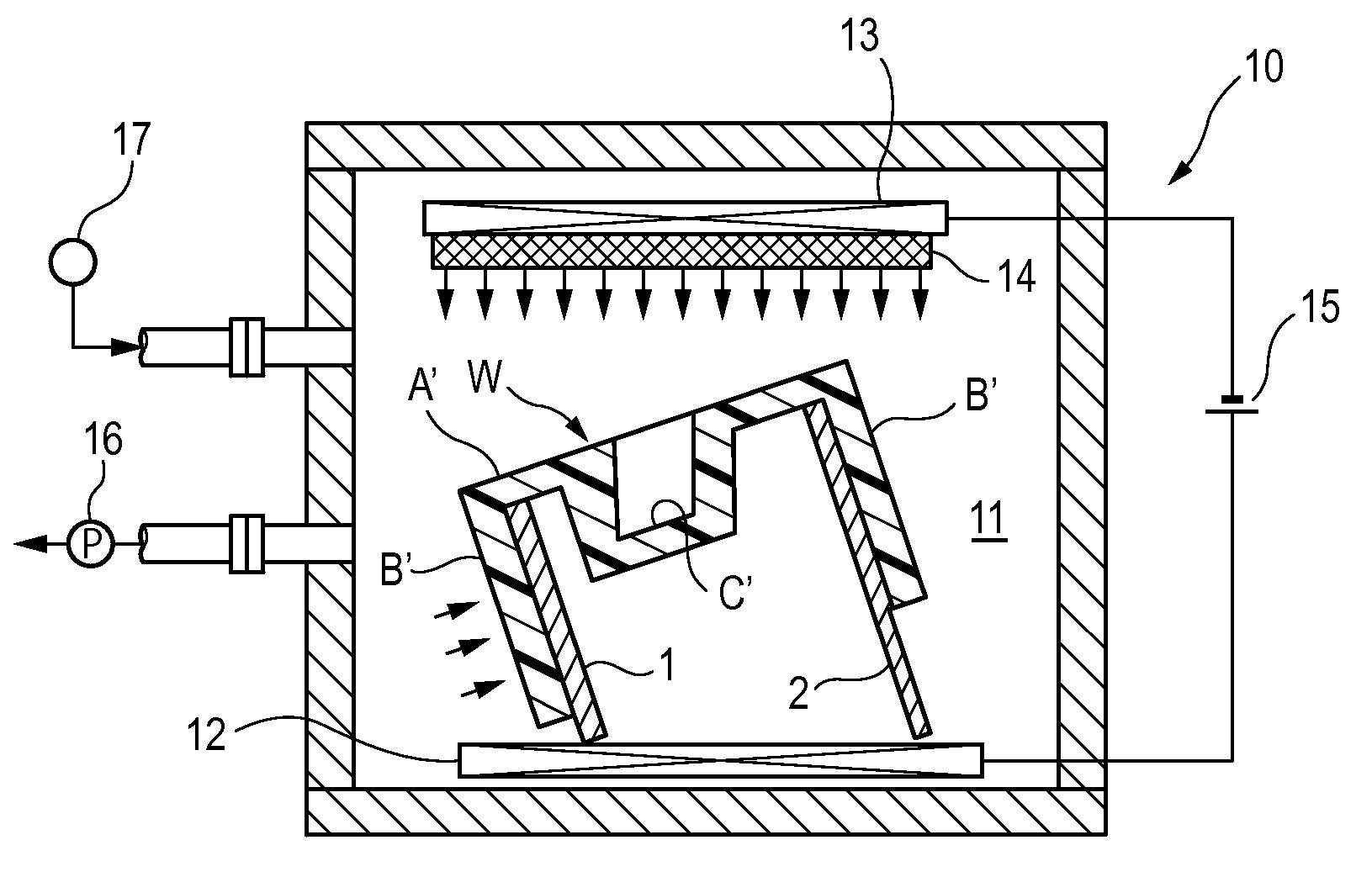

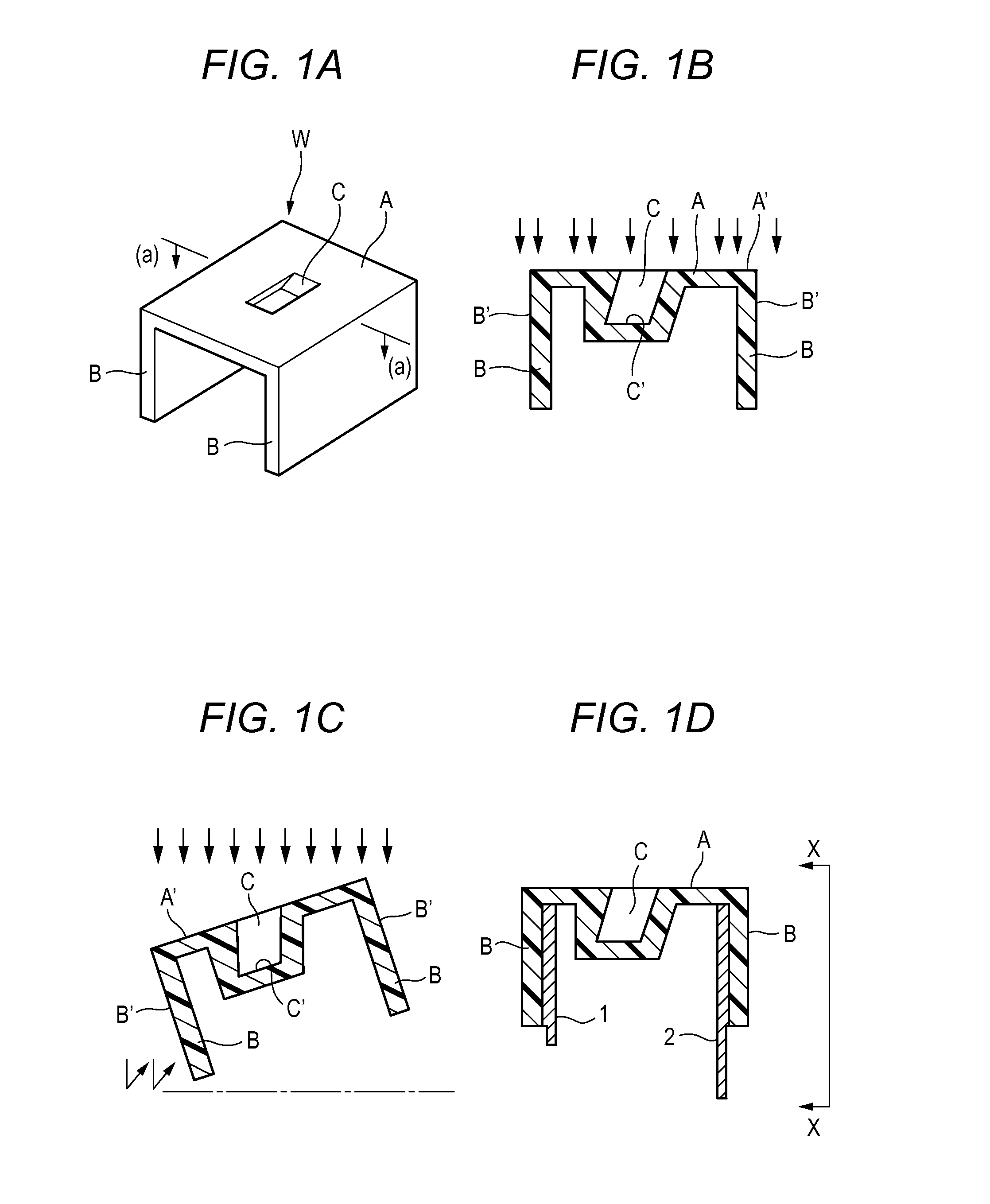

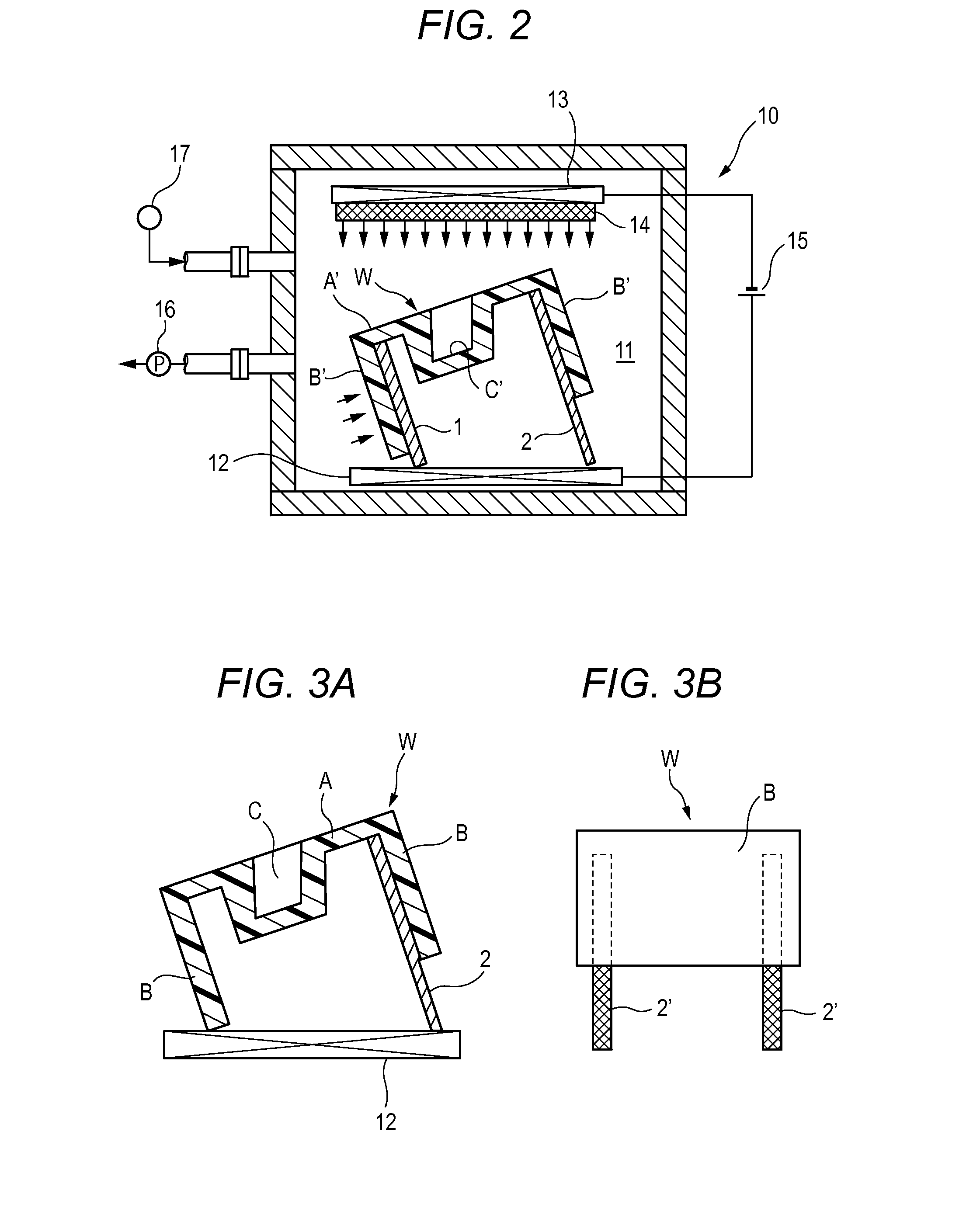

Method of deposition

InactiveUS9109282B2Easy to cutShorten the timeElectric discharge tubesVacuum evaporation coatingInjection mouldingMechanical engineering

A method of deposition is provided in which a deposition operation can be immediately performed when a workpiece for deposition is carried into a deposition chamber irrespective of a shape or a structure of the workpiece for deposition. The workpiece for deposition is integrally molded with an assisting member, which is configured to maintain the workpiece for deposition in a predetermined orientation such that a deposition surface or a deposition portion thereof faces a target material when the workpiece for deposition is carried into a deposition chamber and is placed on a deposition stand, when the workpiece for deposition is injection-molded; and the workpiece for deposition is carried into the deposition chamber and is deposited.

Owner:JAPAN STEEL WORKS LTD

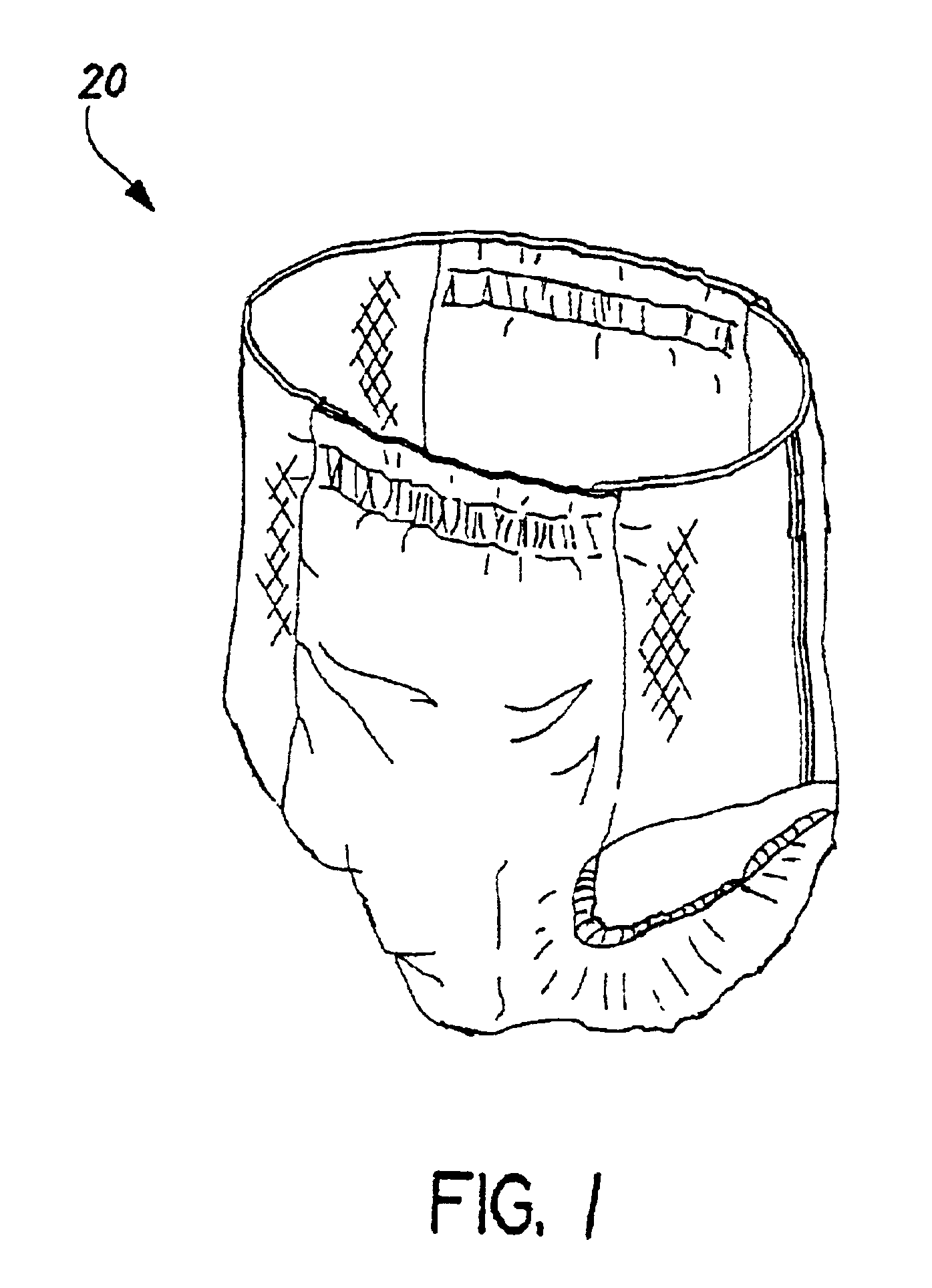

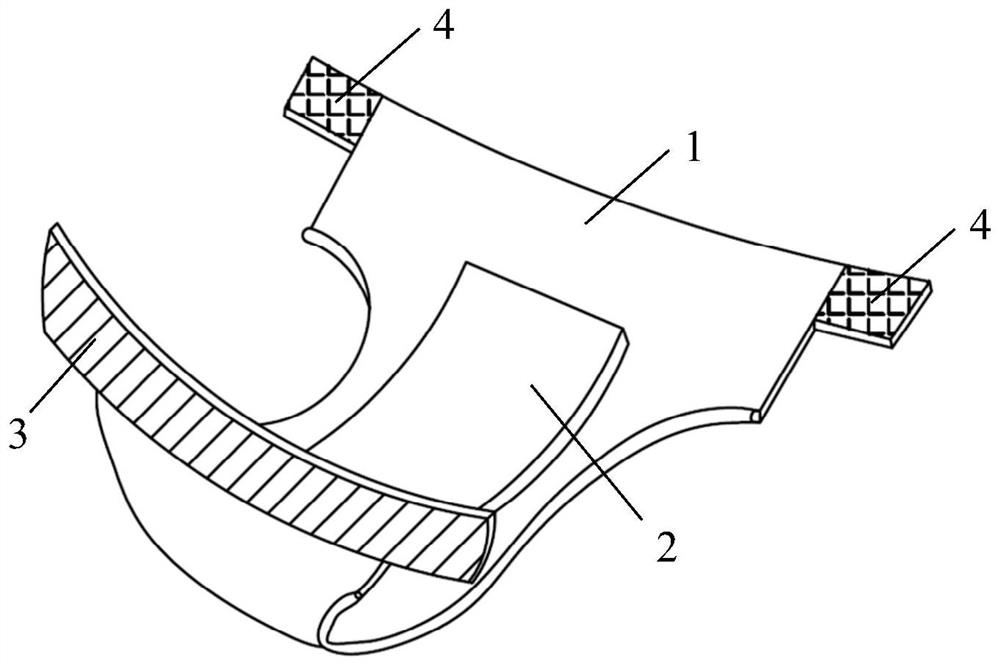

an adult diaper

ActiveCN113558871BEasy to replaceHigh liquid absorptionAbsorbent padsBandagesEczematous rashAdult diaper

The invention relates to an adult diaper, which comprises a diaper body and an auxiliary pad detachably arranged above the diaper body; the auxiliary pad sequentially includes a surface layer, an auxiliary pad absorber and a bottom film layer from top to bottom. There are liquid-permeable holes through the bottom film layer; the auxiliary pad absorbent body is composed of the auxiliary pad absorbent layer and the auxiliary pad wrapping layer that wraps the auxiliary pad absorbent layer; the diaper body includes the top layer, the main body absorbent body and the water-repellent layer in sequence from top to bottom ; The body absorber is composed of a body absorbing layer and a body wrapping layer wrapping the body absorbing layer. The adult diapers of the present invention can enhance the absorption capacity and absorption speed, keep the skin surface of the wearer dry, and effectively reduce the occurrence of skin diseases such as rashes, eczema, and diaper rash. The auxiliary pads included in the adult diapers of the present invention can be used after use. Replacement is performed, and the included diaper body can be selectively continued to be used, which can effectively save energy, protect the environment, and save costs.

Owner:诺宸股份有限公司

Microphone with mechanical switch function

Owner:ZILLTEK TECH SHANGHAI +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com