Big template combined by small steel templates

A technology of steel formwork and large formwork, applied in the field of combined large formwork, can solve the problems of high engineering cost, slow and cumbersome construction of small steel formwork, and easily damaged formwork

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

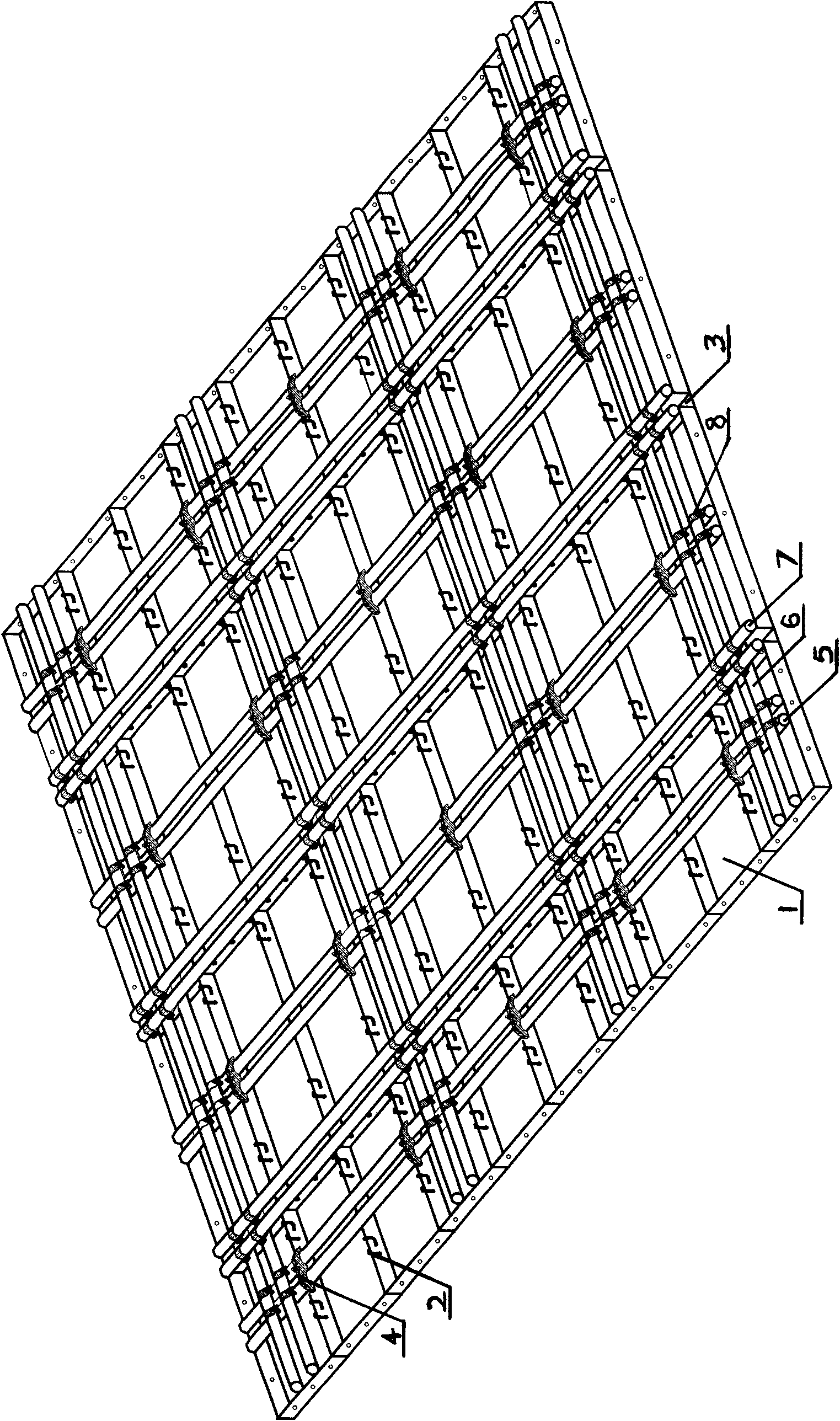

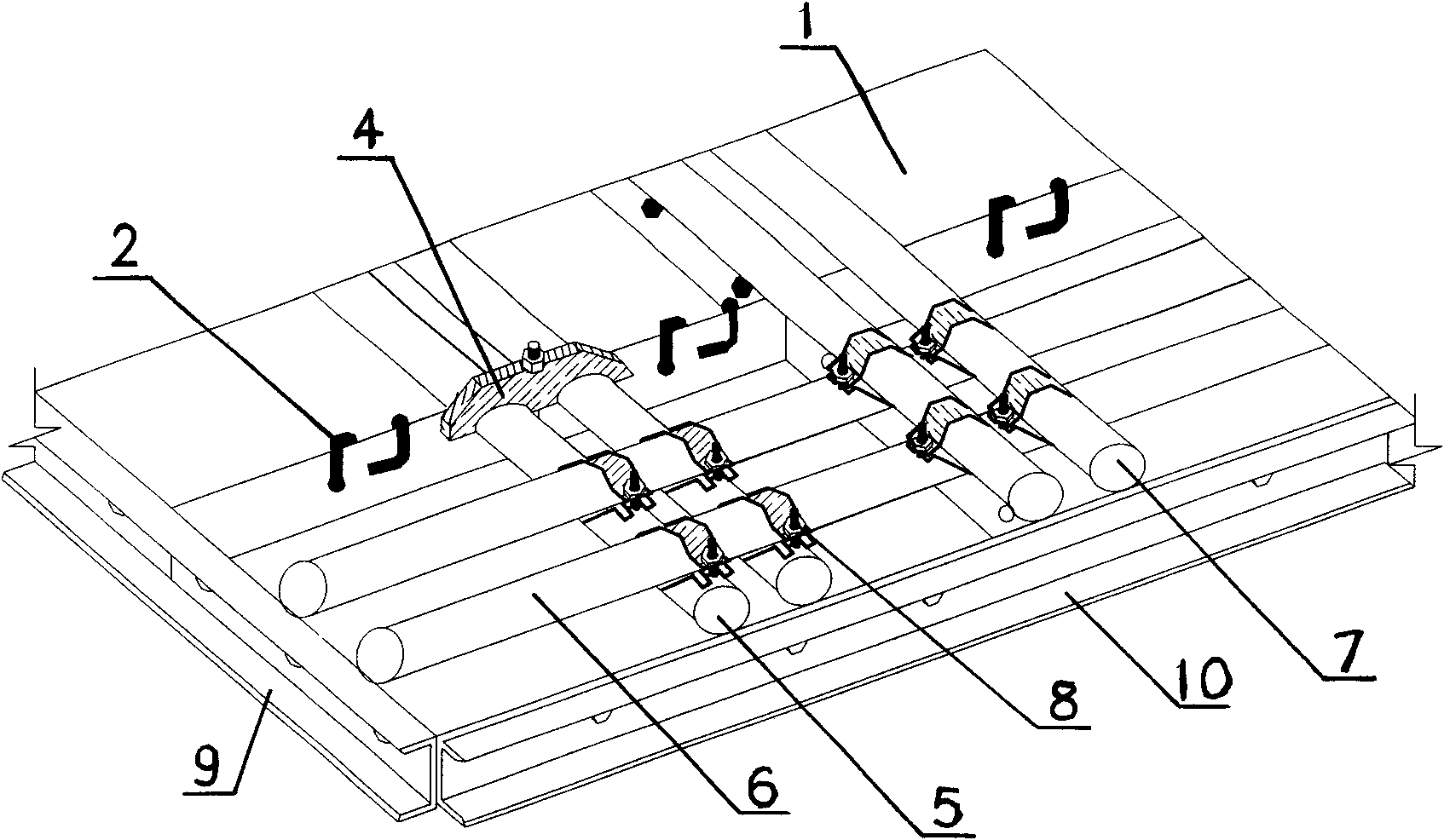

[0008] Embodiment 1: The present invention includes a small steel formwork 1, a connector, and a reinforcement device. The connector includes a small steel mold connector 2 and a channel steel connector 3. The small steel mold connector 2 is selected from a small steel mold buckle 2 for reinforcement. The device includes hook bolts 4, steel scaffolding rods, and steel scaffolding rod buckles 8. According to the required template width, a plurality of small steel formworks 1 are connected horizontally through small steel mold buckles 2 to form a group of small steel formworks. Each two groups of small steel formwork groups are connected and fixed together through the channel steel connector 3 along the longitudinal direction, and multiple groups of small steel formwork groups are connected and fixed together according to the required formwork height to form a large formwork bottom plate, which is inside the large formwork bottom plate It is connected with a reinforcement device ...

specific Embodiment approach 2

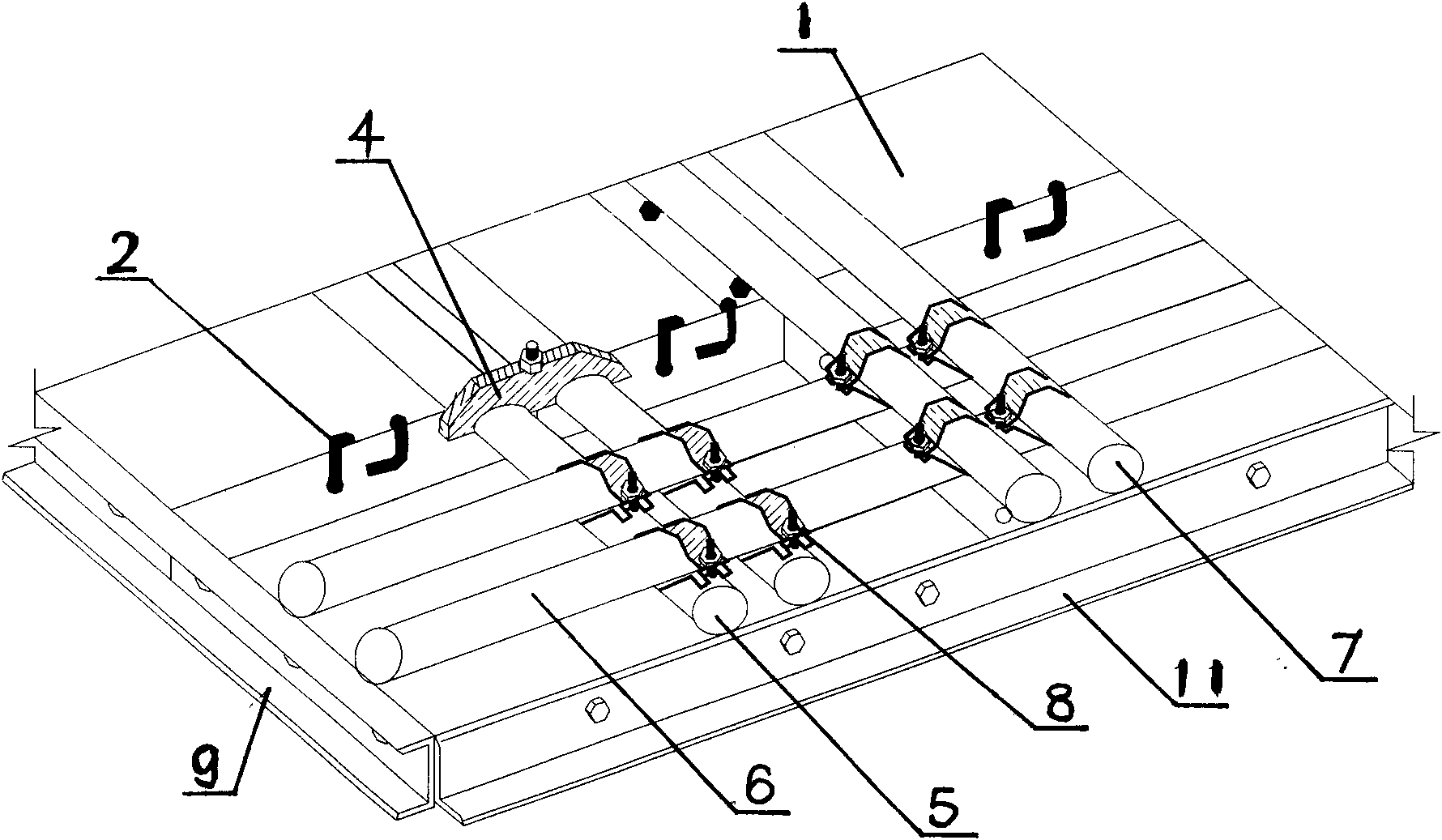

[0009] Specific embodiment 2: The present invention includes a small steel formwork 1, a connecting piece, and a reinforcement device. The connecting piece includes a small steel mold connecting piece 2 and a channel steel connecting piece 3. The small steel mold connecting piece 2 is selected from a small steel mold buckle 2, The reinforcement device includes hook bolts 4, steel scaffolding rods, steel scaffolding rod buckles 8, two channel steels 9, sub-ports 11, and female ports 10. The sub-ports 11 can be angle steel, and the female port 10 can be channel steel. According to the required formwork width, multiple small steel formworks 1 are horizontally connected together through small steel formwork buckles 2 to form a group of small steel formwork groups, and each two groups of small steel formwork groups are connected vertically through channel steel connectors 3 Fix together, according to the required formwork height, connect and fix multiple groups of small steel formwo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com