Automatic overhead door

An automatic lift door and door panel technology, applied in the direction of windows/doors, door/window applications, door/window accessories, etc., can solve the problems of user safety hazards, poor sealing, easy wear and tear of the side lifting belts on both sides, etc. To achieve the effect of ensuring sealing and reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to understand the present invention and enable those skilled in the art to realize the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings.

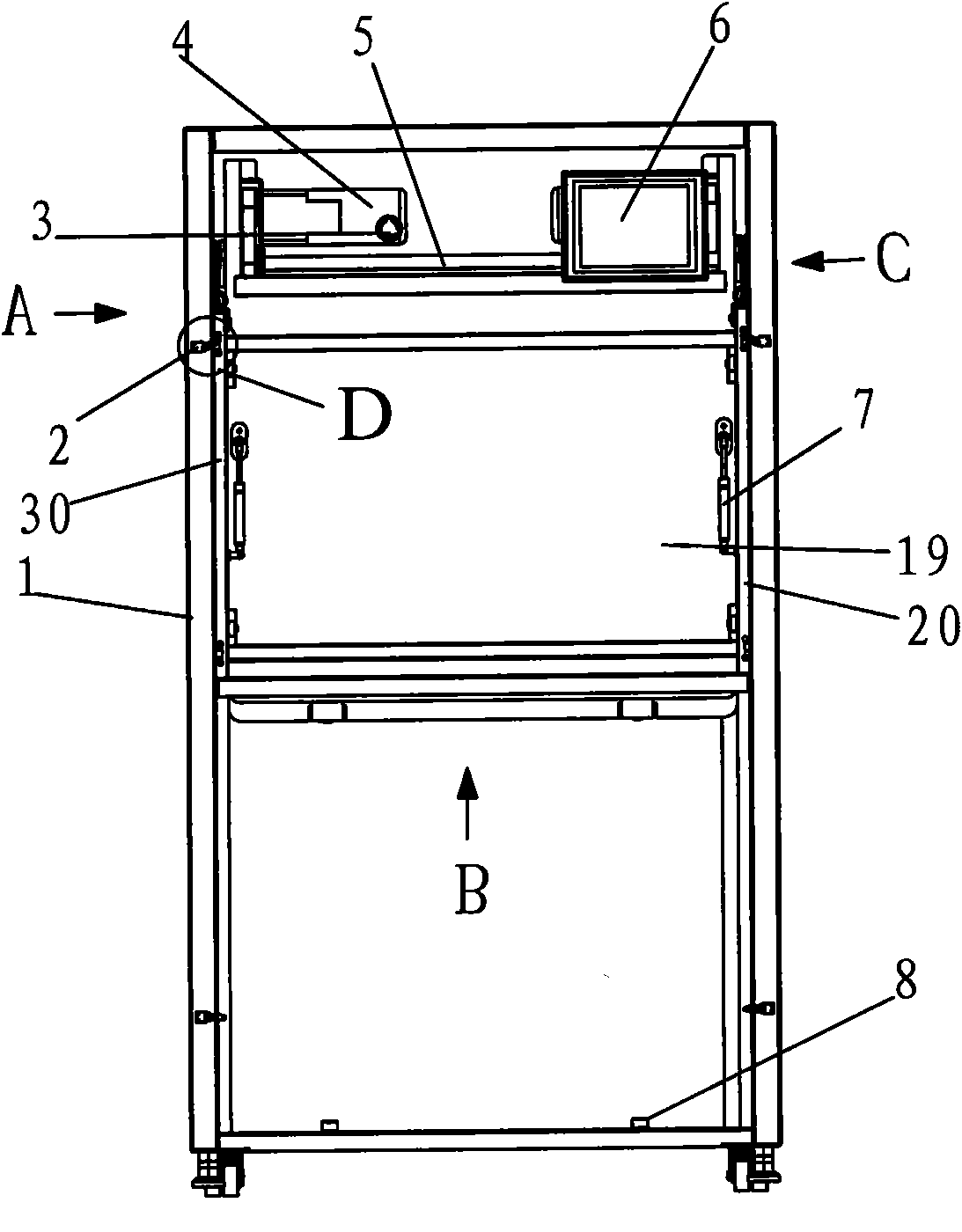

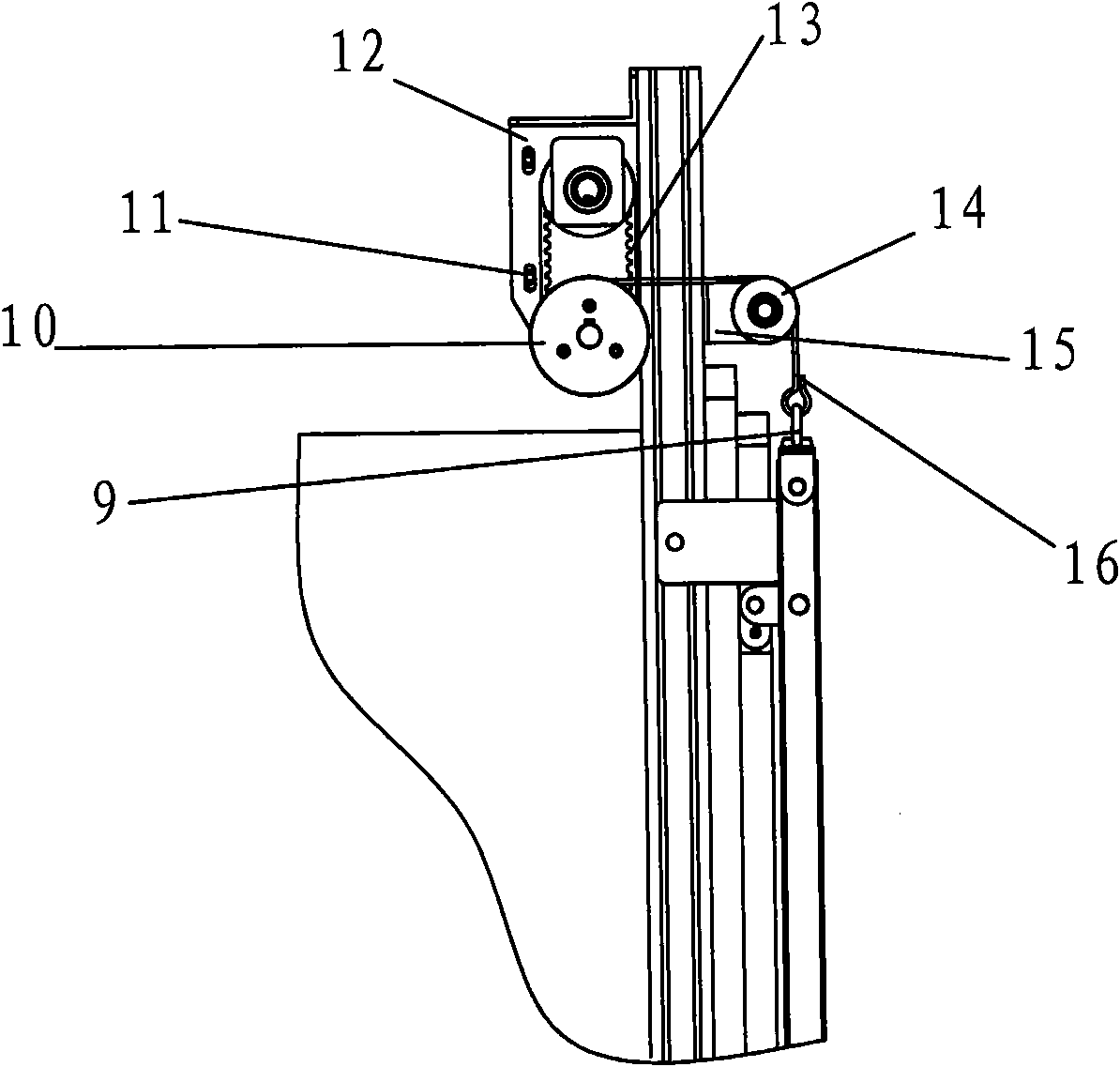

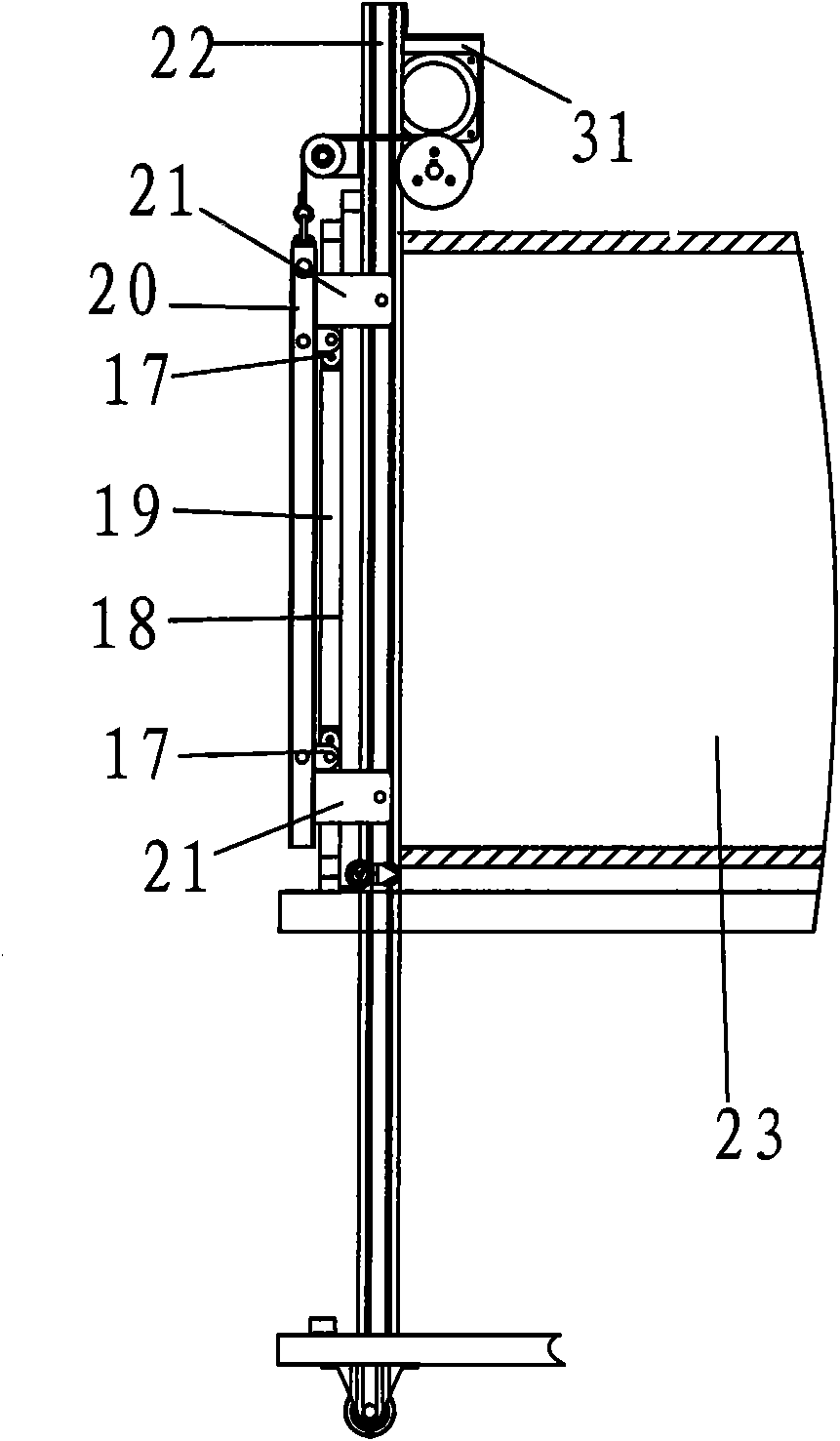

[0020] refer to Figure 1-Figure 5 , an automatic lifting door is composed of a door panel 19, a door panel fixing frame assembly 30, a gas spring 7, a connecting piece 17, a lifting ring 9, a limit block 26, a limit wheel 28, a door panel fixing frame 20, a door panel fixing frame connecting block 21, etc. , refer to figure 1 and Figure 5 , four door panel holders 20 are welded into a door panel holder assembly 30, the connecting piece 17 and the gas spring 7 connect each door panel holder 20 of the door panel 19 with the door panel holder assembly 30 around the door panel 19, see in conjunction with figure 2 and image 3 , the two ends of the connecting piece 17 are respectively connected with the door panel fixing frame 20 and the door panel 19 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com