Metal coiled pipe fan assembly machine

A duct fan, assembly machine technology, applied in the direction of machine/engine, mechanical equipment, liquid fuel engine, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

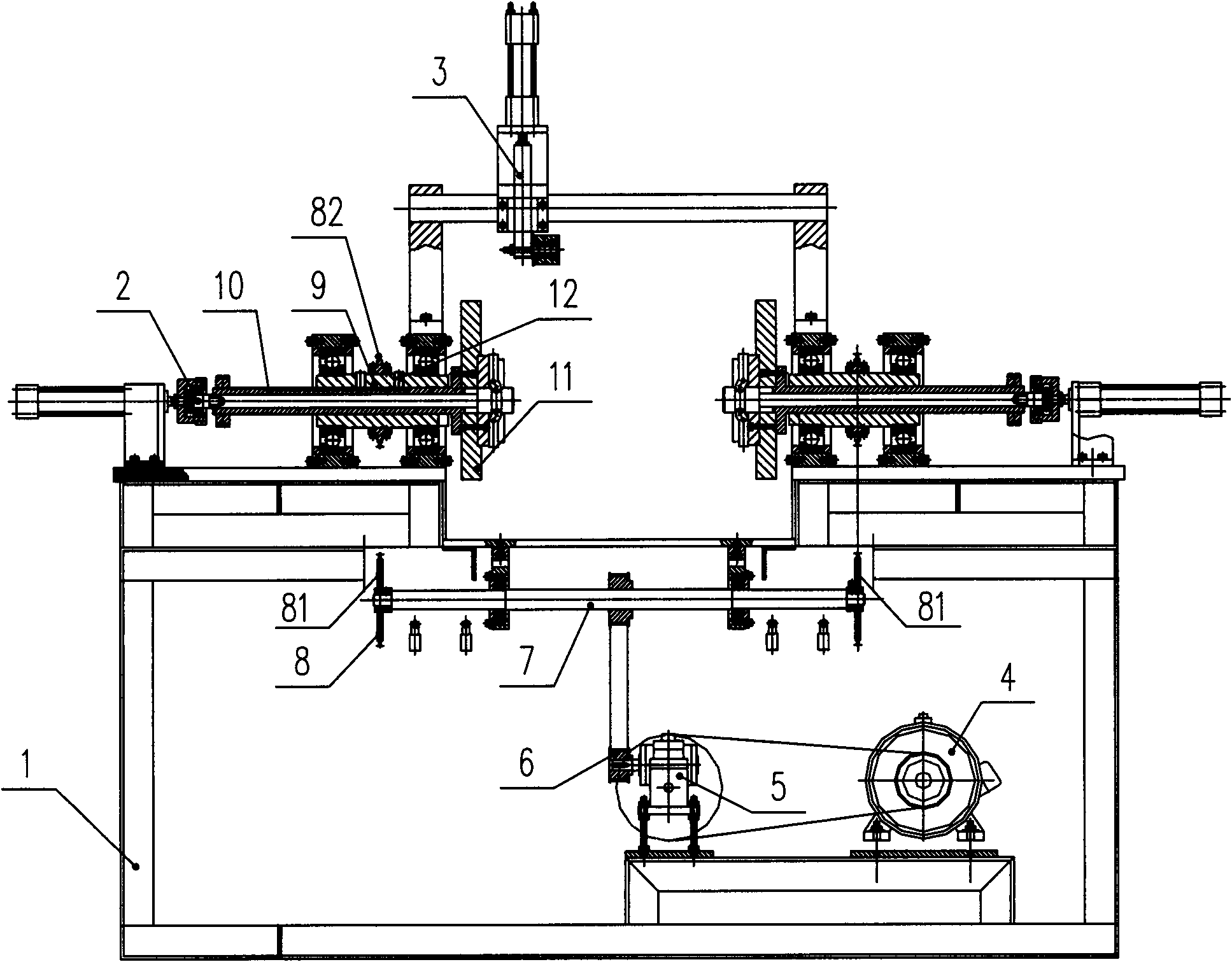

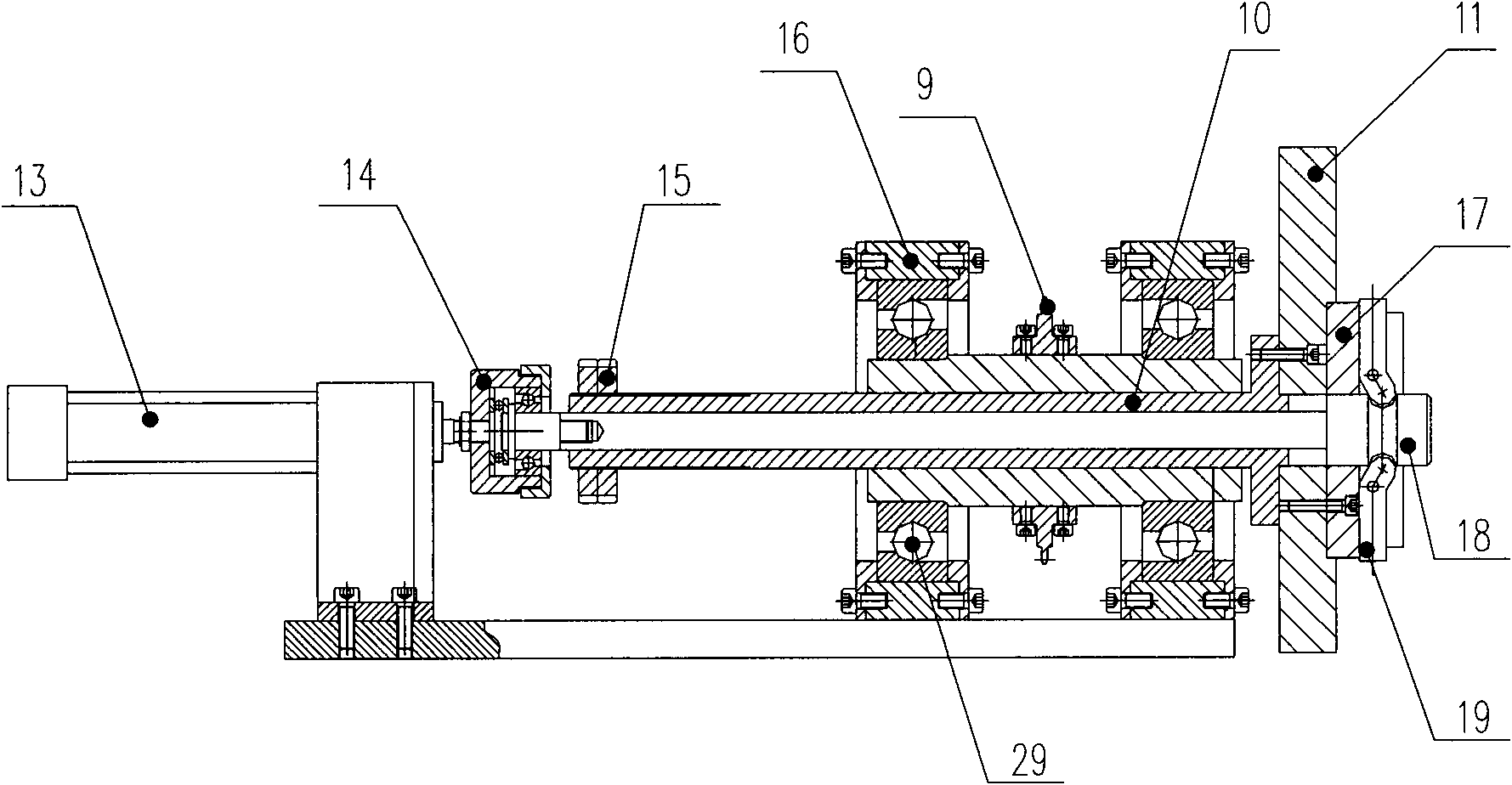

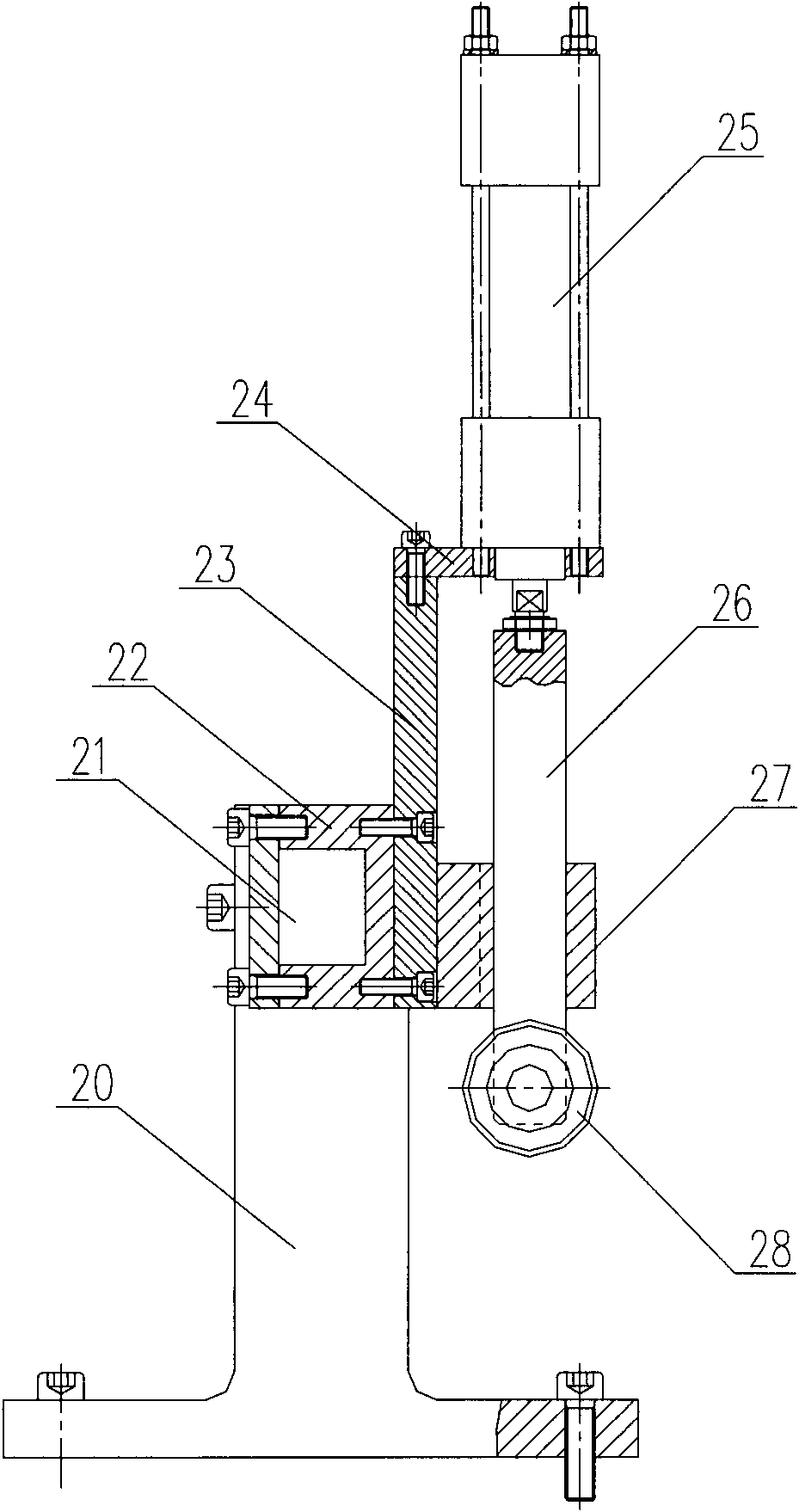

[0026] Such as Figure 1~3 The metal coil fan assembly machine shown is composed of a frame 1 , a bracket 20 installed on the frame, a transverse guide rail 21 , a power transmission mechanism, a side plate locking mechanism 2 and a shroud pressing mechanism 3 . The transverse guide rail 21 is mounted on the bracket 20 .

[0027] The power transmission mechanism consists of a motor 4, a reducer 5, a synchronous gear train 6, a transmission shaft 7 and a transmission device 8; the motor 4 is connected to the transmission shaft 7 through a reducer 5, and the output end of the reducer 5 to the transmission shaft 7 adopts a synchronous gear train 6 transmission, to achieve the relative accuracy of the halfway stop assembly position during operation, and the installation position will not change for a long time. The motor 4 and the reducer 5 are connected by a V-belt transmission, which acts as a shock absorber. The transmission device 8 is mounted on the transmission shaft 7 . ...

Embodiment 2

[0035] Such as Figure 2~4 The metal coil fan assembly machine shown is composed of a frame 1 , a bracket 20 installed on the frame, a transverse guide rail 21 , a power transmission mechanism, a side plate locking mechanism 2 and a shroud pressing mechanism 3 . The transverse guide rail 21 is mounted on the bracket 20 . The structures of the power transmission mechanism and the side plate locking mechanism 2 are the same as those described in Embodiment 1.

[0036] The coaming pressing mechanism 2 is left and right 2 groups, is all installed on the guide rail 21 and can move left and right, and the structure of each group is identical with that described in embodiment 1.

[0037] When in use, two groups of coaming pressing mechanisms on the left and right are used to respectively compress the two sides of the coaming. If there is a difference in height between the two sides of the coaming, one side can be compressed but the other cannot be pressed tightly. The pressing forc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com