Hydraulic sealing pressure buffer filter

A hydraulic sealing and filter technology, applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems affecting the quality and clean appearance of the oil cylinder, unable to seal and scrape oil, and not completely solving the sealing ring, etc. Excellent filtering and anti-fouling, excellent sealing performance, not easy to stick to oil and foreign matter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

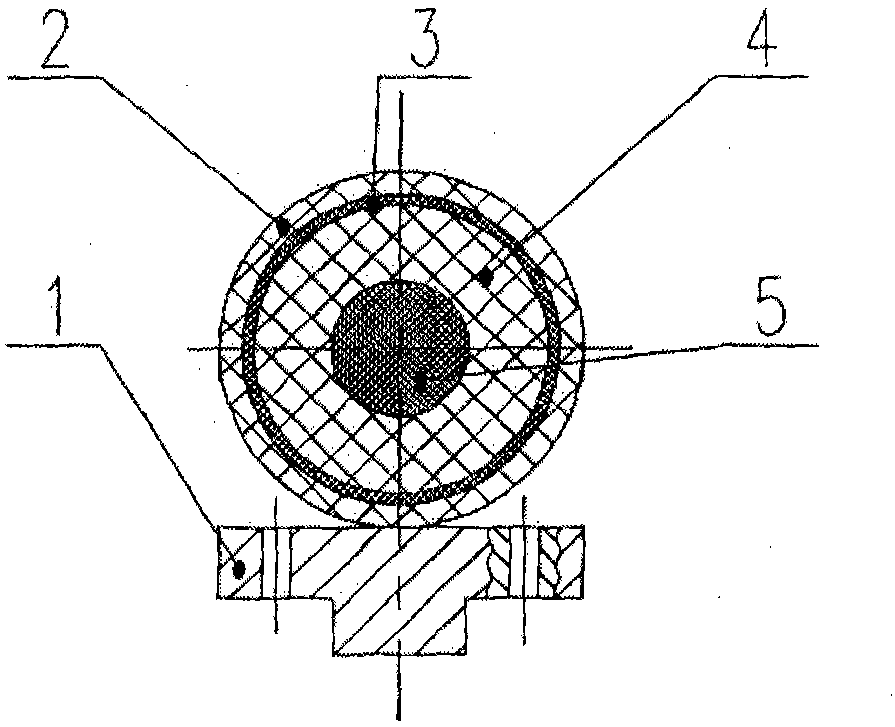

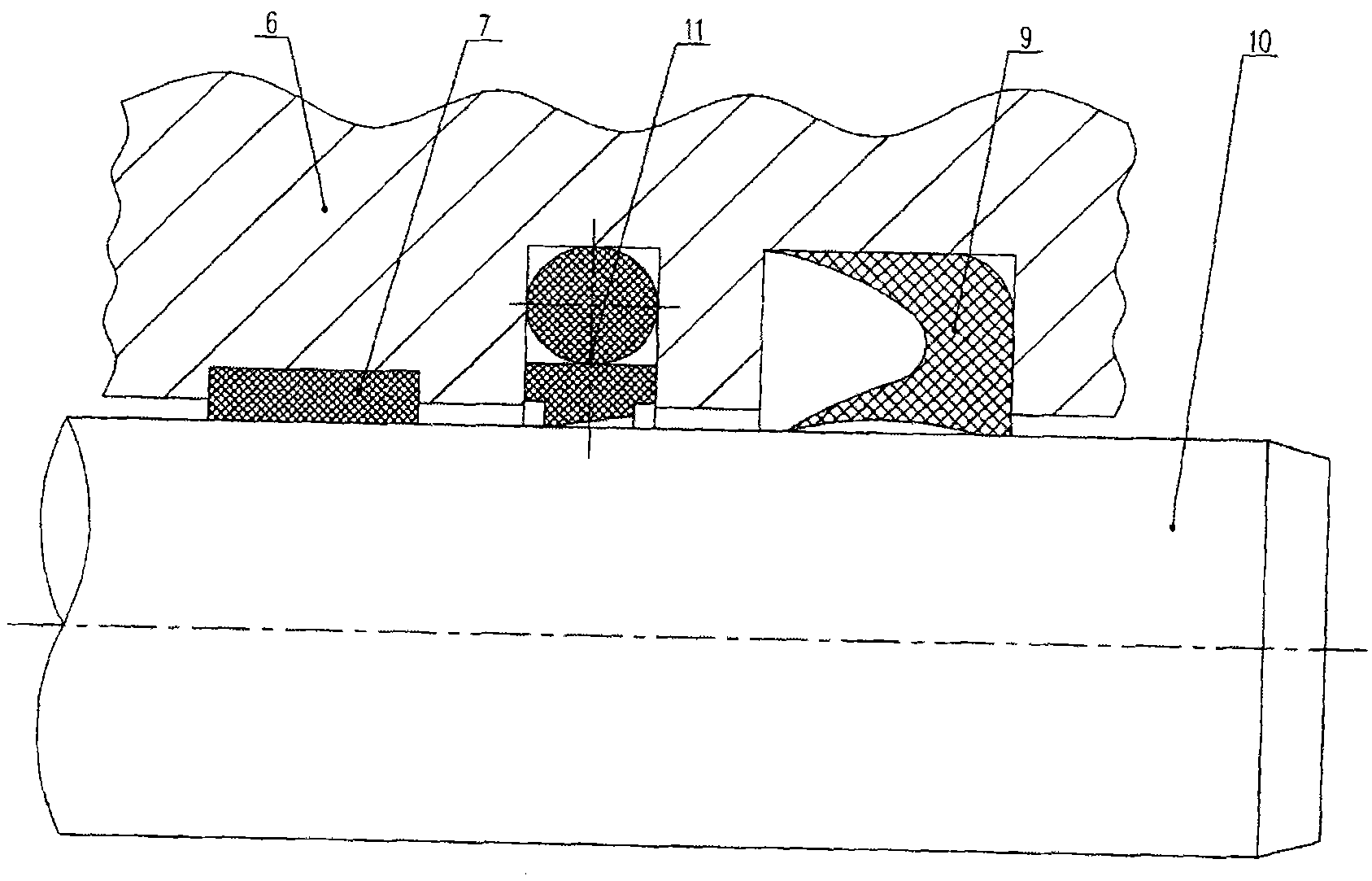

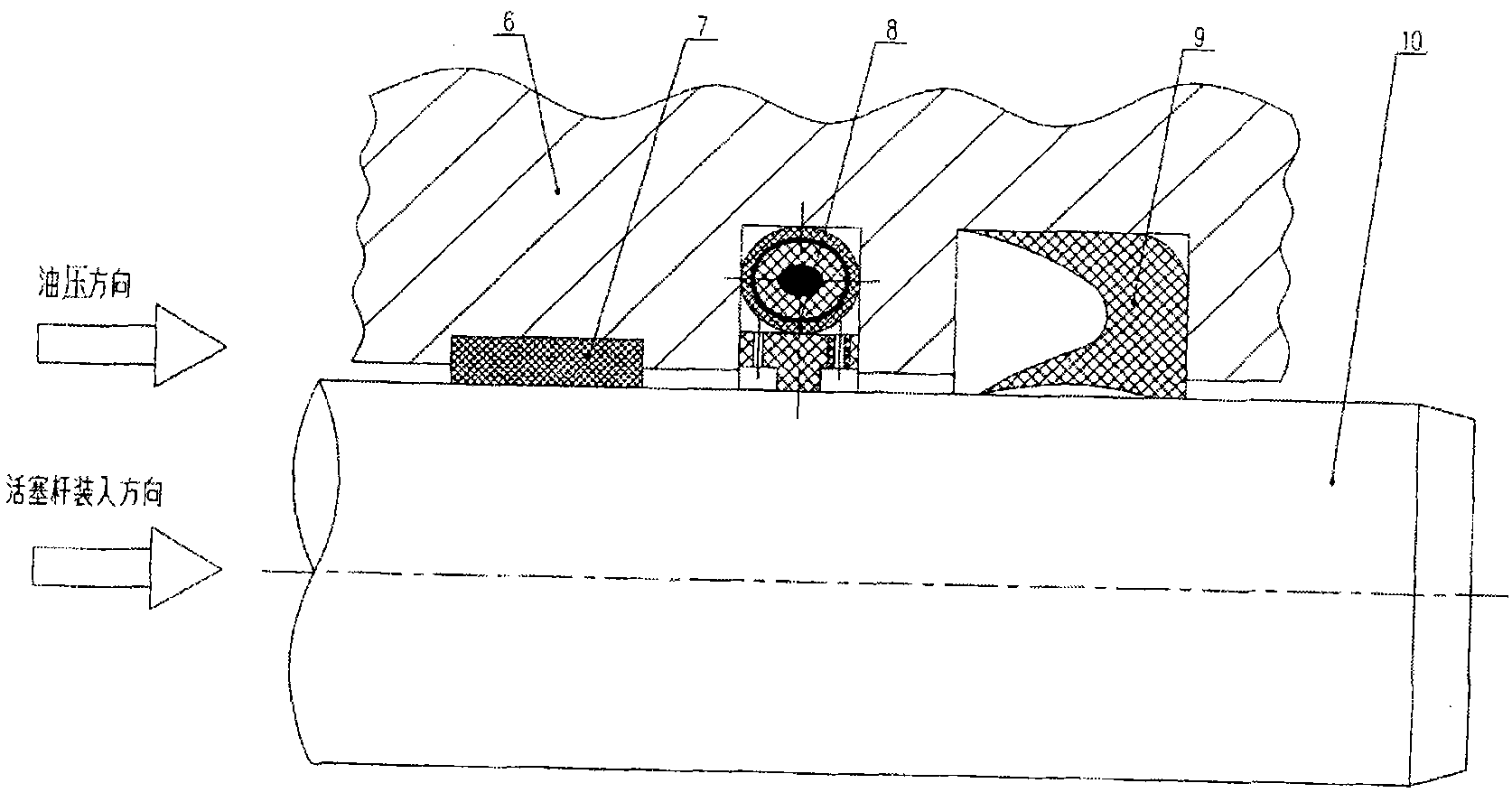

[0031] figure 1 Shown is an embodiment of the hydraulic seal pressure buffer filter of the present invention, which includes a filter body ring and a support body ring 1. The filter body ring is composed of a multi-layer composite mesh ring set outside the matrix, and the matrix is PTFE. Type ring 5, the peripheral multi-layer composite mesh ring is a nylon mesh mesh ring 4 that is set outside the rubber O-ring 5, a metal mesh mesh ring 3 that is set outside the nylon mesh mesh ring 4, and a suit The protective nylon mesh mesh ring 2 outside the metal mesh mesh ring 3; the three mesh rings are all bent into rings by plane mesh, and bonded or welded at the joints. The support body ring 1 is a circular body of composite material, and this embodiment is a polytetrafluoroethylene composite material ring. The filter ring is placed on the support ring 1 . The hydraulic seal pressure buffer filter of the present invention is installed in the groove opened on the guide sleeve 6 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com