Composite reinforced discharge hose

A technology of reinforcing ribs and pipe walls, applied in the direction of hoses, pipes, pipes/pipe joints/pipe fittings, etc., can solve the problems of complex manufacturing process, low production efficiency, unacceptable and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

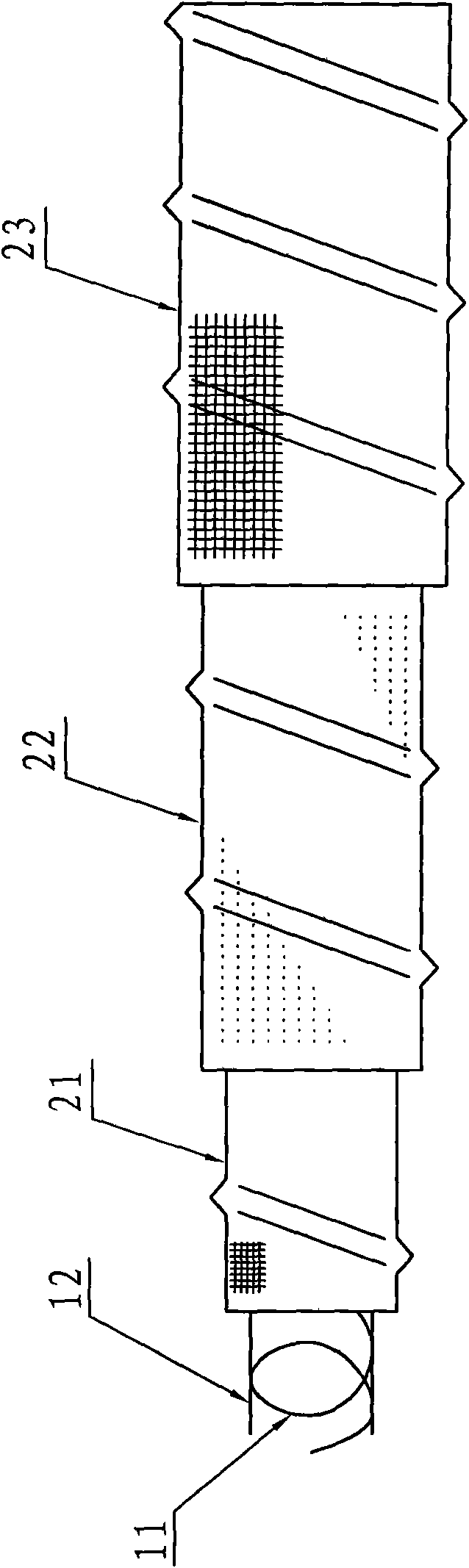

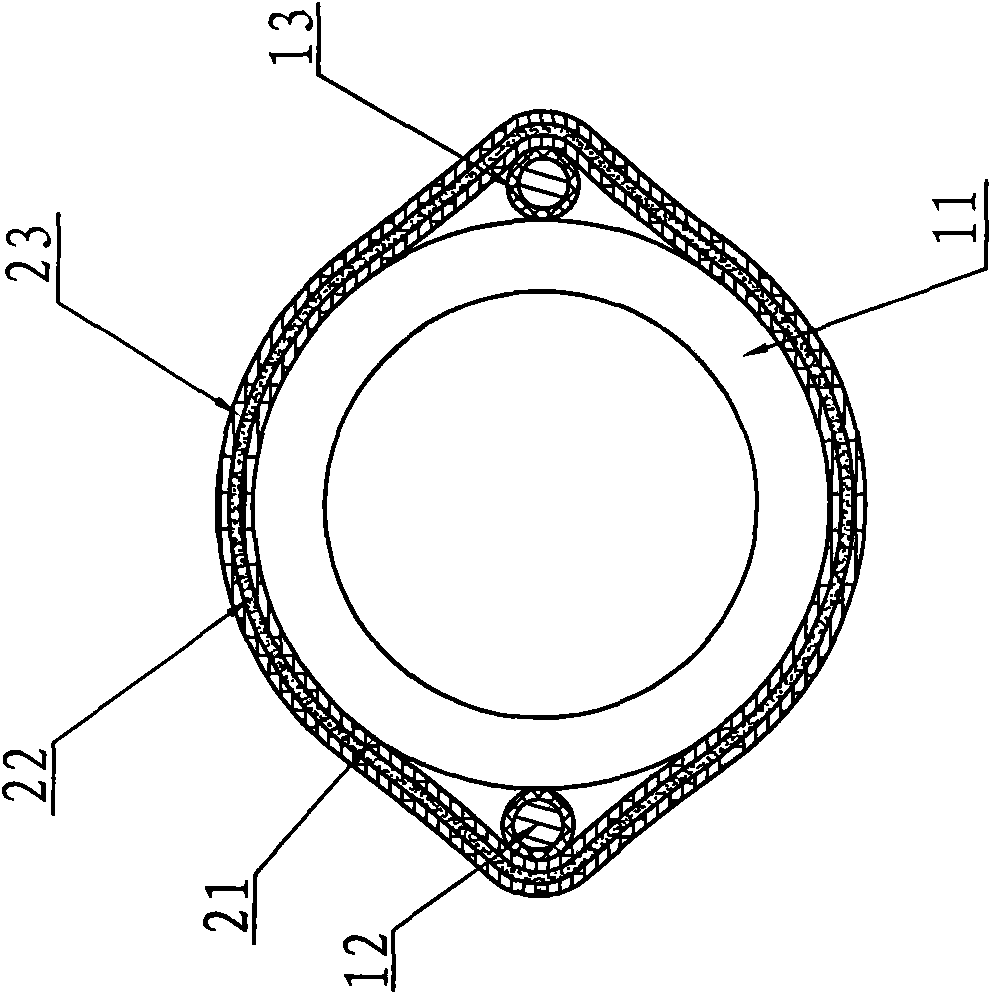

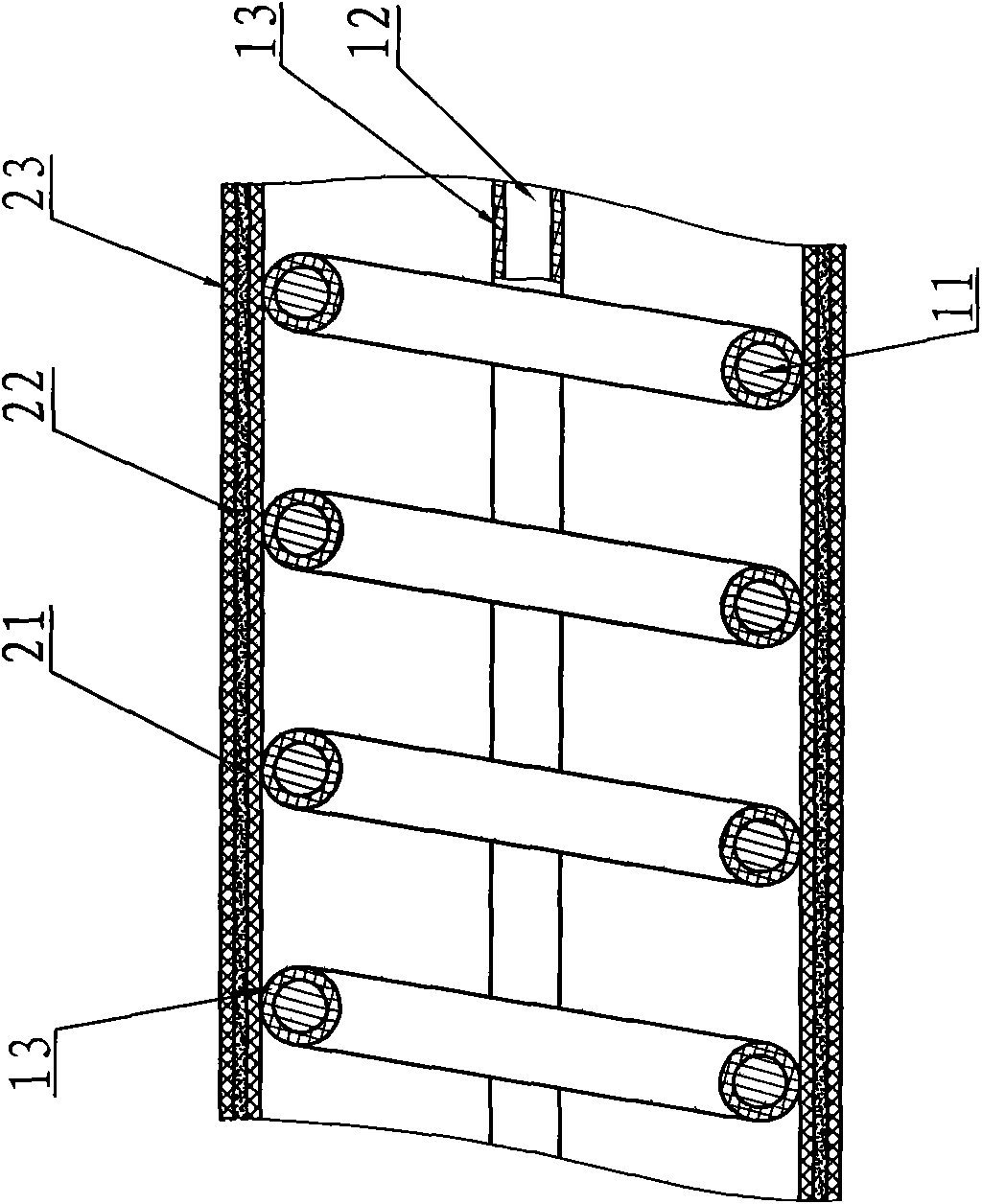

[0012] A composite reinforced drainage hose, which is composed of a pipe wall support body and a drainage sleeve. The pipe wall support body is composed of a cylindrical helical spring 11 and two reinforcement ribs 12 fixed on the spring coil. The two reinforcement ribs 12 are symmetrical Fixed on the outer circle of the cylindrical coil spring 11, a layer of plastic protection layer 13 is arranged on the outer surface of the cylindrical coil spring 11 and the two reinforcing ribs 12 fixed on the spring coil; layer 22 and protective layer 23, the inner lining layer 21 is a polyester knitted mesh sleeve, the filter layer 22 is a non-proof geotechnical filter cloth wrapped on the outer surface of the inner lining layer 21, and the protective layer 23 is also a polyester knitted mesh sleeve; The liner 21 is set on the pipe wall support, the filter layer 22 is wrapped on the outer surface of the inner liner 21 , and the protective layer 23 is set on the outer surface of the filter ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap