Flexible film transmission and guide device of film processor

A technology of guiding device and washing machine, which is applied in the direction of optics, instruments, photosensitive materials, etc. It can solve the problems of film scratches, grinding, and washing, etc., and achieve the effects of easy operation, increased working life, and reduced operating load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

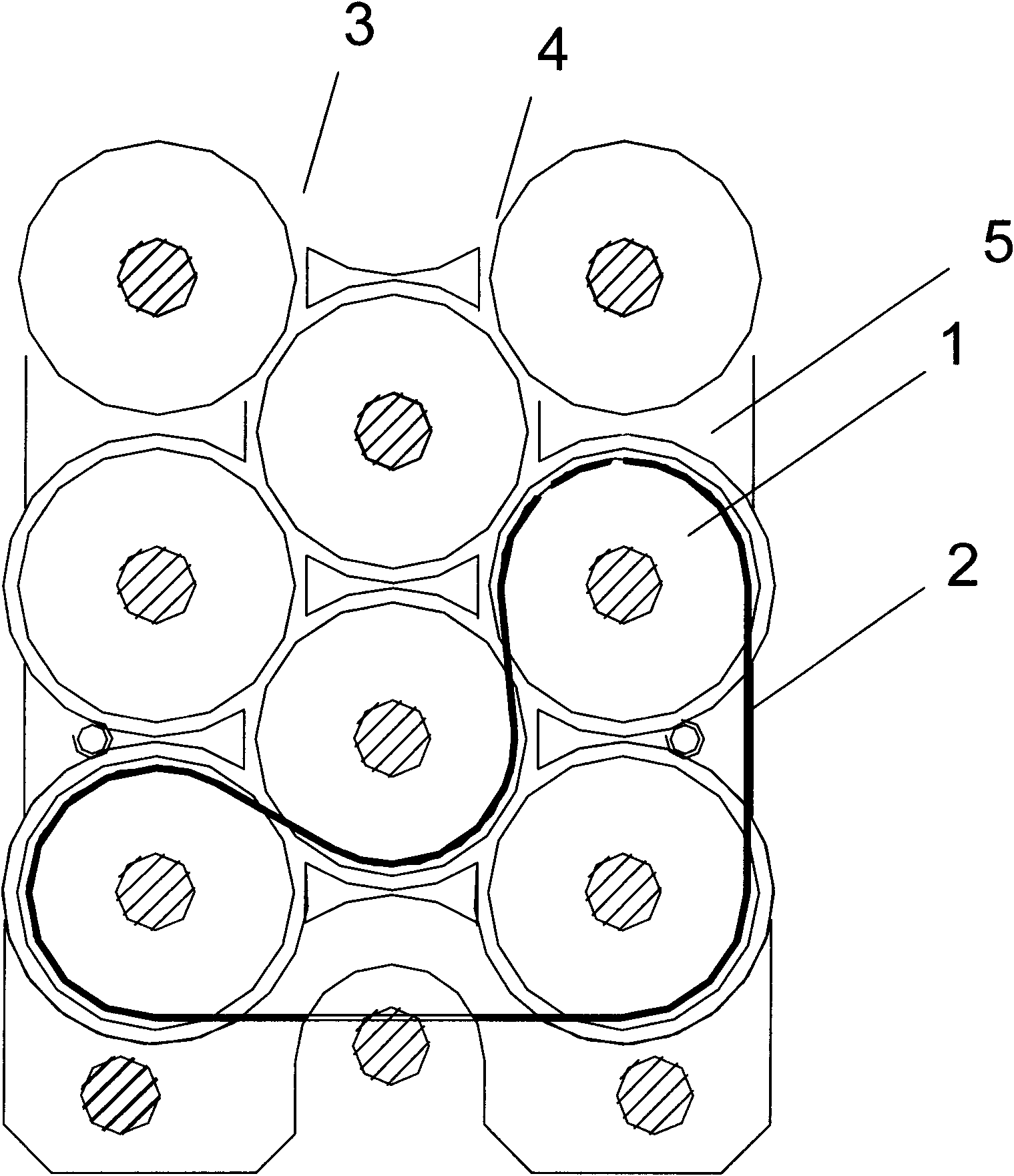

[0010] As shown in the attached figure, a soft film conveying guide device of a film developing machine is made of a special material sheet to make a ring-shaped circular soft guide belt 2, and the turning position under the soft guide belt roller shaft 1 driven by the film transmission sheet is guided by the circular soft guide belt. The belt 2 is connected, and the connection shape of the circular soft guide belt 2 is L-shaped. The film enters through the film inlet 3, and when turning through the bottom of the flushing spool 5, the film enters the direction of the film outlet 4 along the circular soft guide belt 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com