Compound for photoresist, photoresist solution, and etching method using the photoresist solution

A photoresist and compound technology, applied in chemical instruments and methods, complex metal compounds of azo dyes, photosensitive materials used in optomechanical equipment, etc., can solve problems such as increasing processes

- Summary

- Abstract

- Description

- Claims

- Application Information

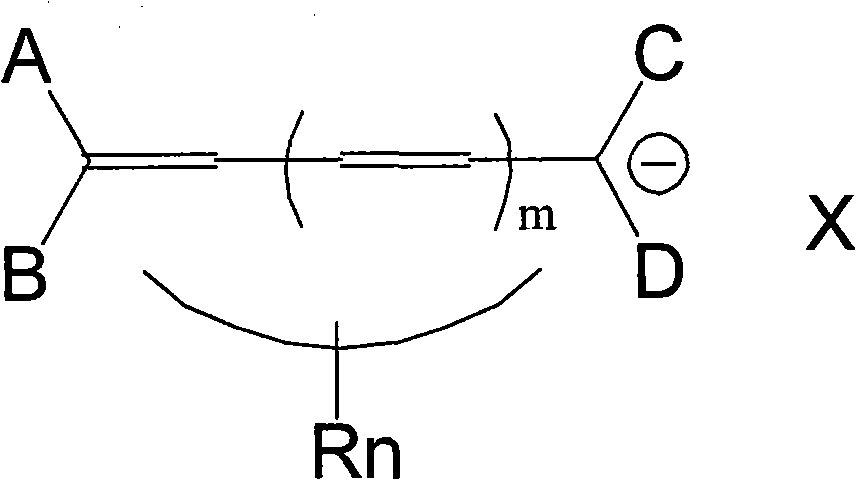

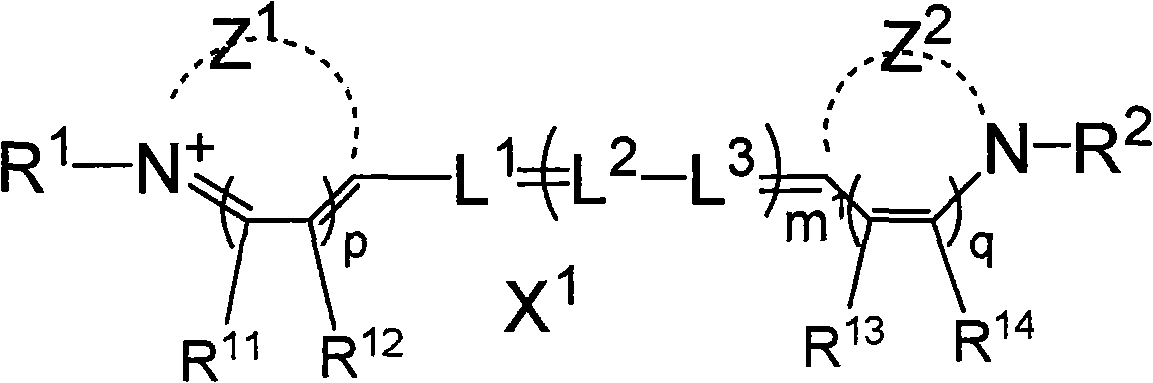

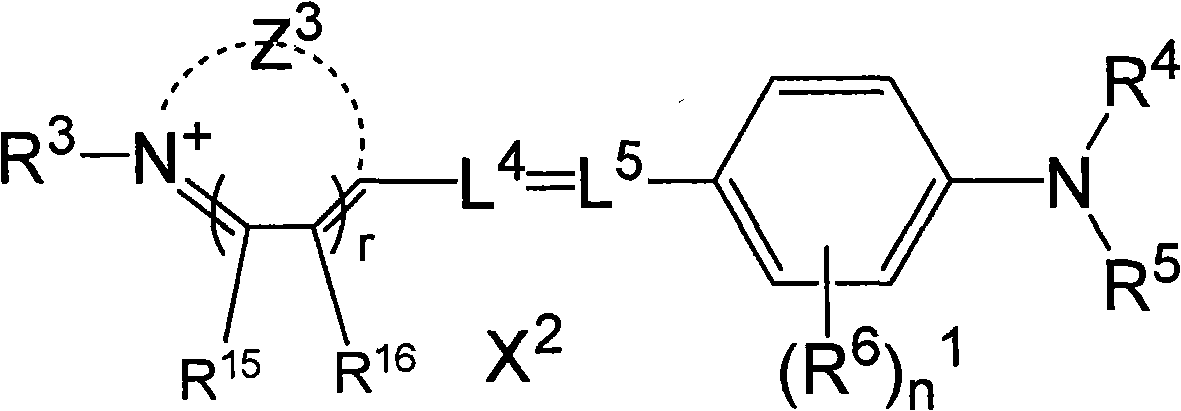

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0310] Formation of photoresist film

[0311] Dissolve 2 g of oxonol dye (example compound (II)-5, λmax of film: 378 nm, thermal decomposition temperature: 216° C.) in 100 ml of tetrafluoropropanol (TFP), and spin-coat it on a disk-shaped silicon substrate ( A coating film was formed on a thickness of 0.6 mm, an outer diameter of 120 mm, and an inner diameter of 15 mm. Spin coating is carried out as follows: the coating liquid is dispersed on the inner periphery of the substrate with the rotation speed of 500 rpm at the start of coating and 100 rpm at the end of coating, and the spin coating speed is gradually increased to 2200 rpm to make the coating film dry. The thickness of the formed coating film was 100 nm.

[0312] The silicon substrate on which the coating film was formed was set in NEO500 (wavelength: 405 nm, NA: 0.65) manufactured by Palos Technology Co., Ltd., and laser light was irradiated toward the coating film surface. The laser irradiation conditions are as ...

Embodiment 2

[0317] Bump formation

[0318] The silicon substrate treated in Example 1 was subjected to RIE etching from the side where the coating film was formed under the following conditions, and then the coating film was removed using ethanol as a stripping solution. It was confirmed with the naked eye that fine unevenness was formed on the coating film-removed surface of the silicon substrate surface. From this result, it is clear that the coating film treated in Example 1 functions as an etching mask.

[0319] Etching gas: SF 6 +CHF 3 (1:1)

[0320] Etching depth: 50nm

Embodiment 3~14

[0322] Except for using the exemplary compounds shown in Table 2 below as oxonol dyes, the same procedure as in Example 1 was carried out, and laser light was irradiated on the surface of the coating film. pit.

[0323] 【table 3】

[0324]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com