Industrialized process for preparing cerium oxide nano-rods doped with rare earth elements

A technology of rare earth elements and cerium oxide, which is applied in the direction of nanostructure manufacturing, nanotechnology, nanotechnology, etc., can solve the problems of difficult large-scale industrial production, difficult removal of product washing, limited application, etc., and achieve easy large-scale industrial production, Low cost and simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

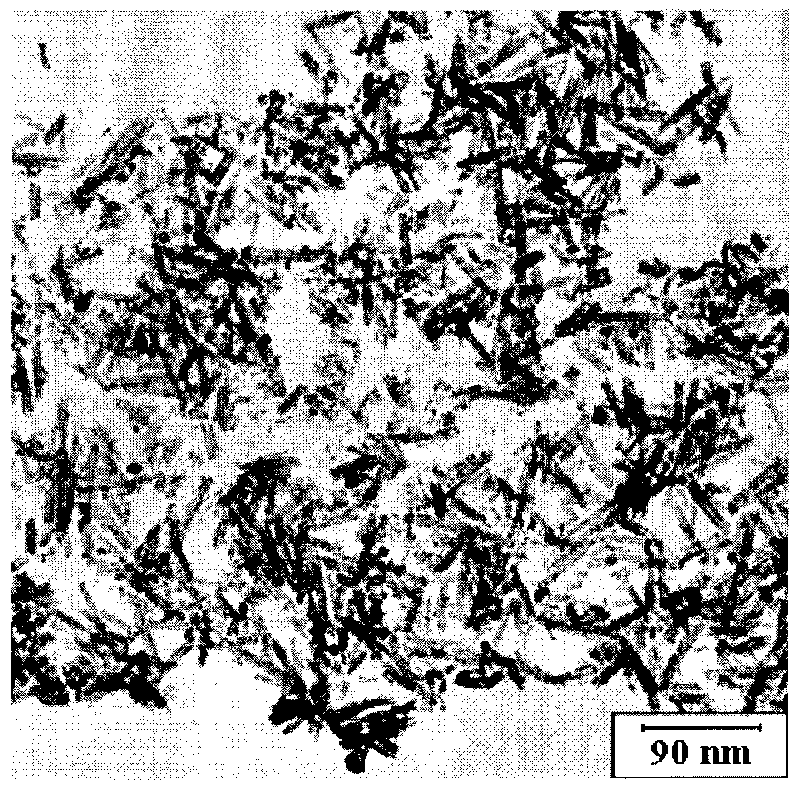

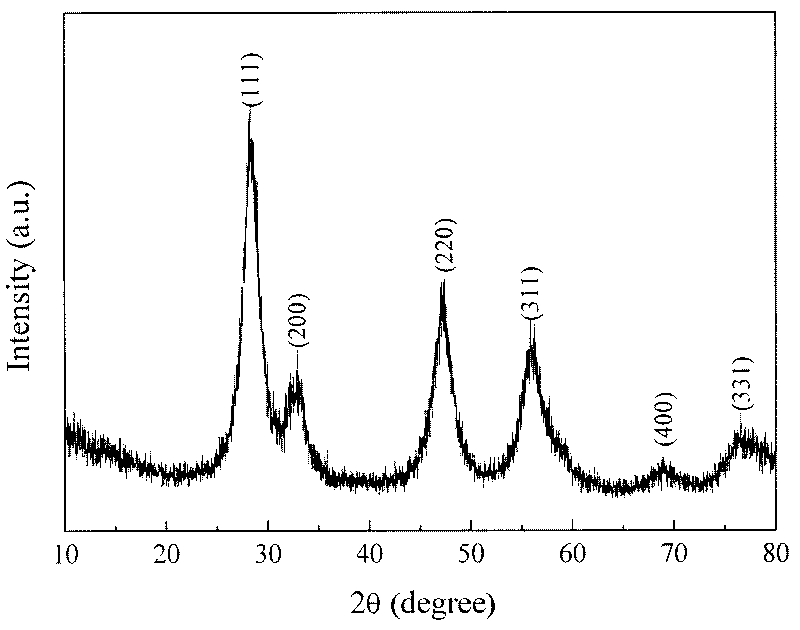

Embodiment 1

[0029] Weigh Ce(NO 3 ) 3 ·6H 2 O 7.82g was dissolved in 100ml deionized water, stirred and dissolved to obtain a clarified cerium nitrate solution, 150ml 25% ammonia water was taken, placed in a large beaker, at room temperature, the cerium nitrate solution was slowly added dropwise in excessive ammoniacal liquor, constantly stirred during the addition process, And control the pH > 10, after the dropwise addition, stop stirring, seal the large beaker containing the mixed solution, and statically age at room temperature for 48 hours, filter the obtained precipitate, wash several times with deionized water, and dry overnight at 100°C to obtain the long 50- Cerium oxide nanorods with a diameter of 100nm and a diameter of 10-20nm.

Embodiment 2

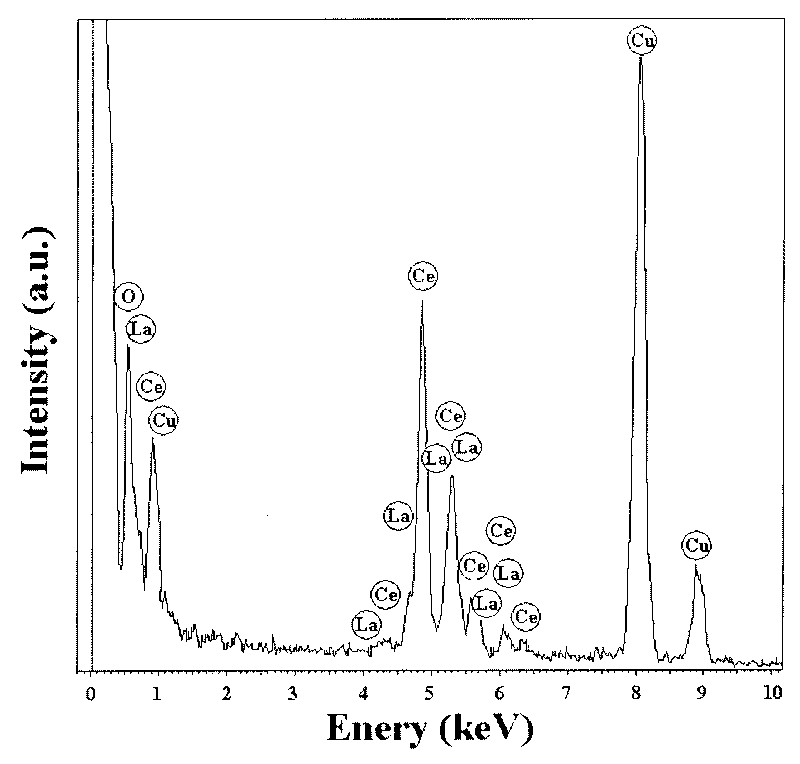

[0031] Weigh Ce(NO 3 ) 3 ·6H 2 O 6.33g and La(NO 3 ) 3 ·6H 2 O 0.60g was dissolved in 100ml of deionized water, stirred and dissolved to obtain a clear nitrate mixed solution, 150ml of 25% ammonia water was taken, placed in a large beaker, at room temperature, the nitrate mixed solution was slowly added dropwise to excess ammonia water, and the addition process continued Stir, and control the pH>10. After the dropwise addition, stop stirring, seal the large beaker containing the mixed solution, and statically age at room temperature for 48 hours. The resulting precipitate is filtered, washed with deionized water several times, and dried overnight at 100°C to obtain 50-100nm, diameter 10-20nm rare earth element La doped cerium oxide nanorods.

Embodiment 3

[0033] Weigh Ce(NO 3 ) 3 ·6H 2 O 13.03g and Pr(NO 3 ) 3 ·6H 2 O 1.45g was dissolved in 100ml deionized water, stirred and dissolved to obtain a clarified nitrate mixed solution, 150ml 25% ammonia water was taken, placed in a large beaker, at room temperature, the nitrate mixed solution was slowly added dropwise to excessive ammonia water, and the addition process continued Stir, and control the pH>10. After the dropwise addition, stop stirring, seal the large beaker containing the mixed solution, and statically age at room temperature for 48 hours. The resulting precipitate is filtered, washed with deionized water several times, and dried overnight at 100°C to obtain 50-100nm, diameter 10-20nm rare earth element Pr doped cerium oxide nanorods.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com