Electromagnetic ultrasonic excitation probe design method

An electromagnetic ultrasonic and excitation coil technology, which is used in the generation of ultrasonic/sonic/infrasonic waves, the use of sonic/ultrasonic/infrasonic waves for material analysis, measurement devices, etc., and can solve problems such as impure ultrasonic patterns.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to enable those skilled in the technical field to which the application belongs to understand the application more clearly, the technical solutions of the application will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

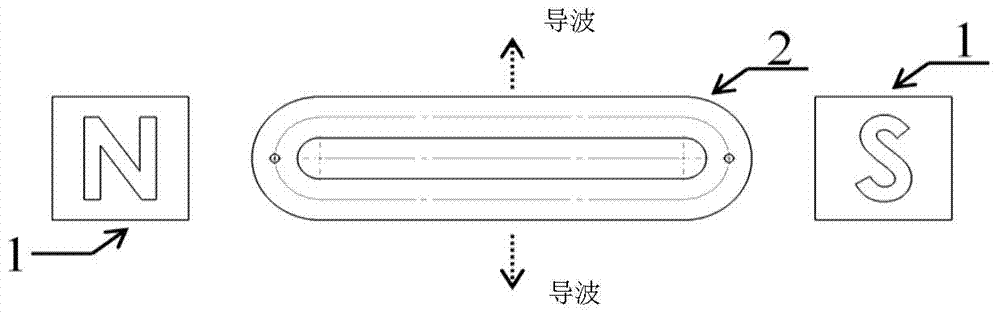

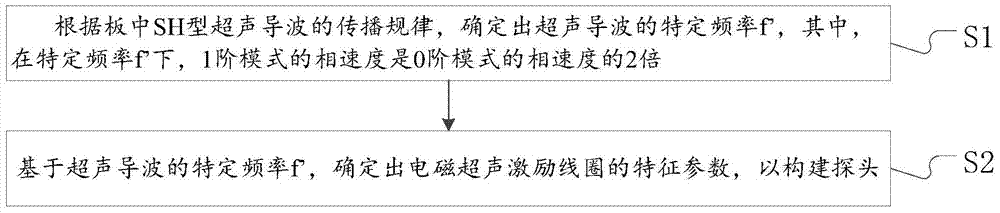

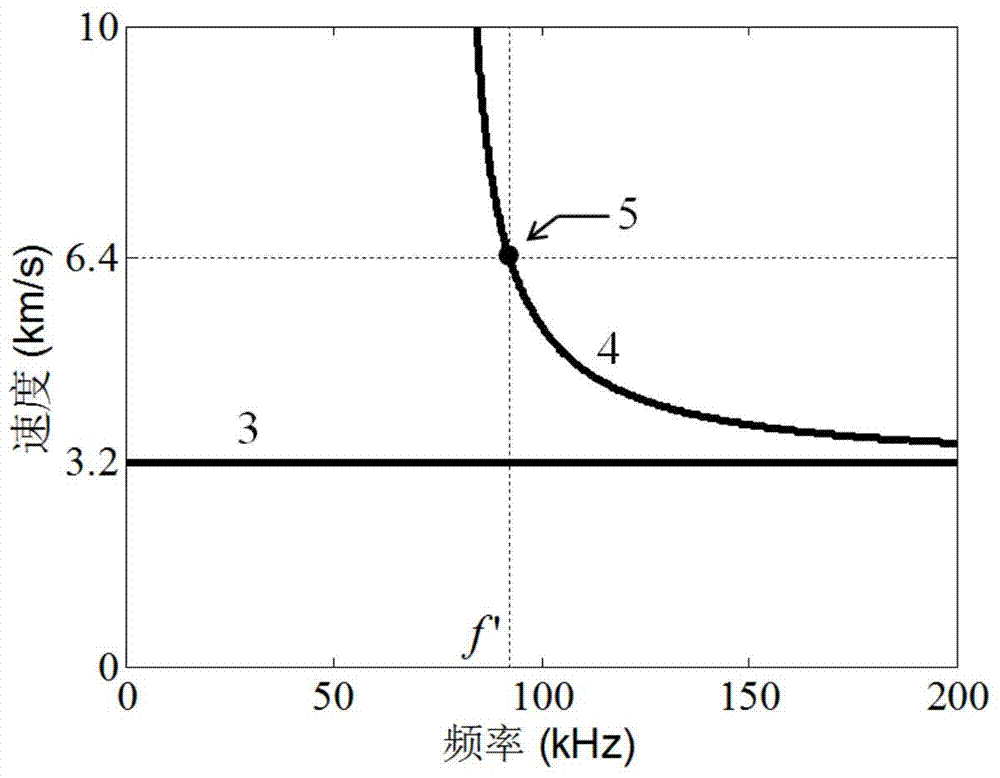

[0016] The main implementation principle of the present invention is: according to the sound propagation principle in the solid plate, i.e. the propagation law of the SH (Shear Horizontal, horizontal shear) type guided wave, determine a specific frequency, and then design the electromagnetic ultrasonic excitation probe according to the frequency. Wherein, the electromagnetic ultrasonic excitation probe is composed of a permanent magnet block 1 and an electromagnetic ultrasonic excitation coil 2, such as figure 1 As shown, the electromagnetic ultrasonic excitation coil 2 is placed between the N pole and the S pole of the permanent magnet block 1, and the permanent magnet block 1 generates ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com