Lubricating oil composition

A lubricating oil composition, the technology of the composition, applied in the directions of lubricating composition, petroleum industry, base material, etc., can solve the problems of low viscosity, shorten the life of equipment, increase the negative impact of corrosion of copper-containing components, and achieve excellent Durability, effect of saving fuel consumption

Active Publication Date: 2010-03-17

SHELL INT RES MAATSCHAPPIJ BV +1

View PDF1 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] But on the other hand, it is also necessary to save fuel consumption; in order to achieve this purpose, the stirring resistance must be reduced; and in order to achieve this purpose, it is necessary to obtain low viscosity

[0005] In order to meet these requirements at the same time, that is, to maintain the effect of forming an oil film on the gear tooth surface and to obtain low viscosity, if the conventional technique of increasing the amount of extreme pressure additive added to the low viscosity base oil is adopted, there is phosphorus used as an extreme pressure additive. or sulfur-based additives may increase the negative impact of corrosion of components containing copper components High risk of shortening equipment life

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1-2

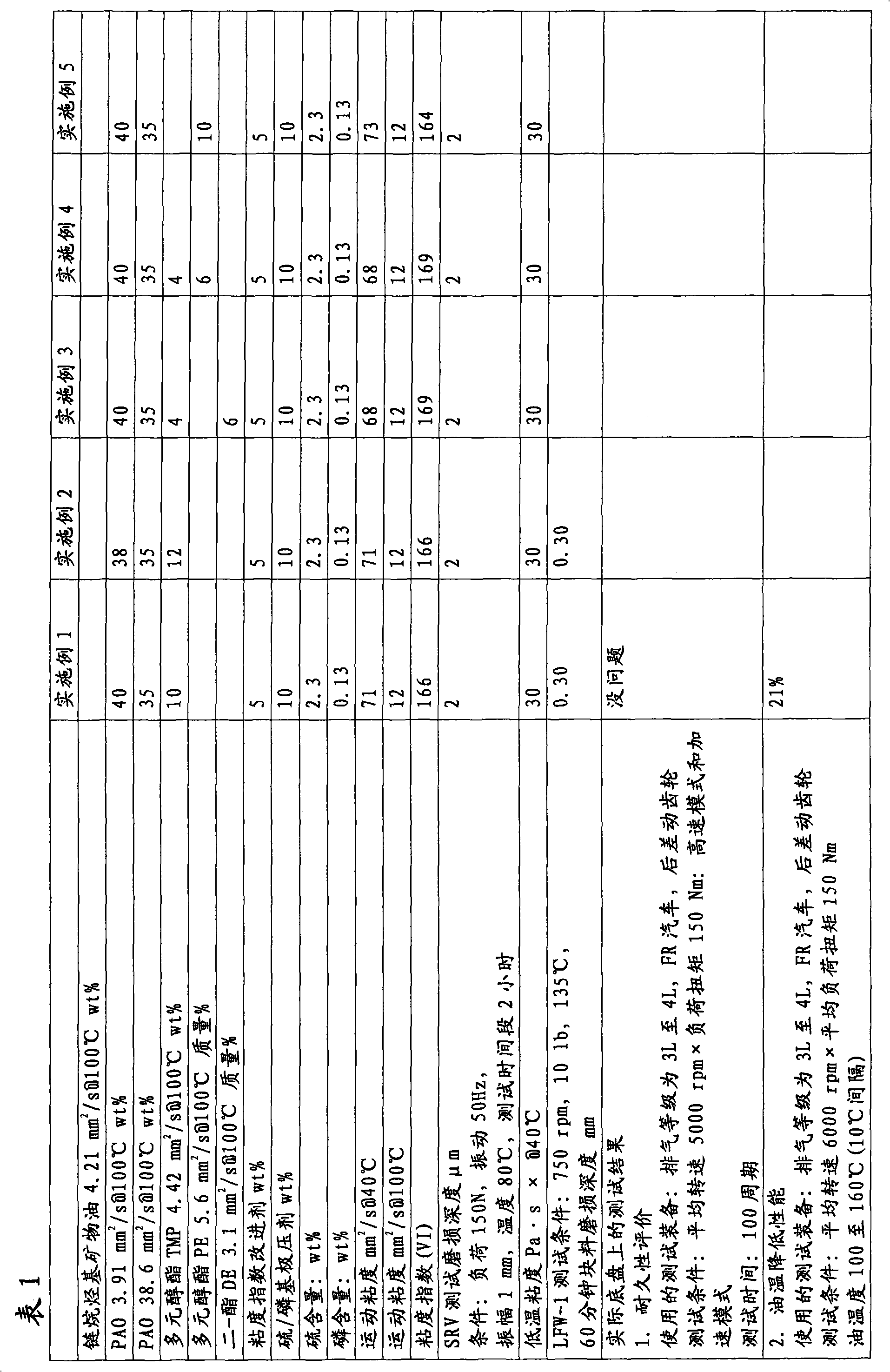

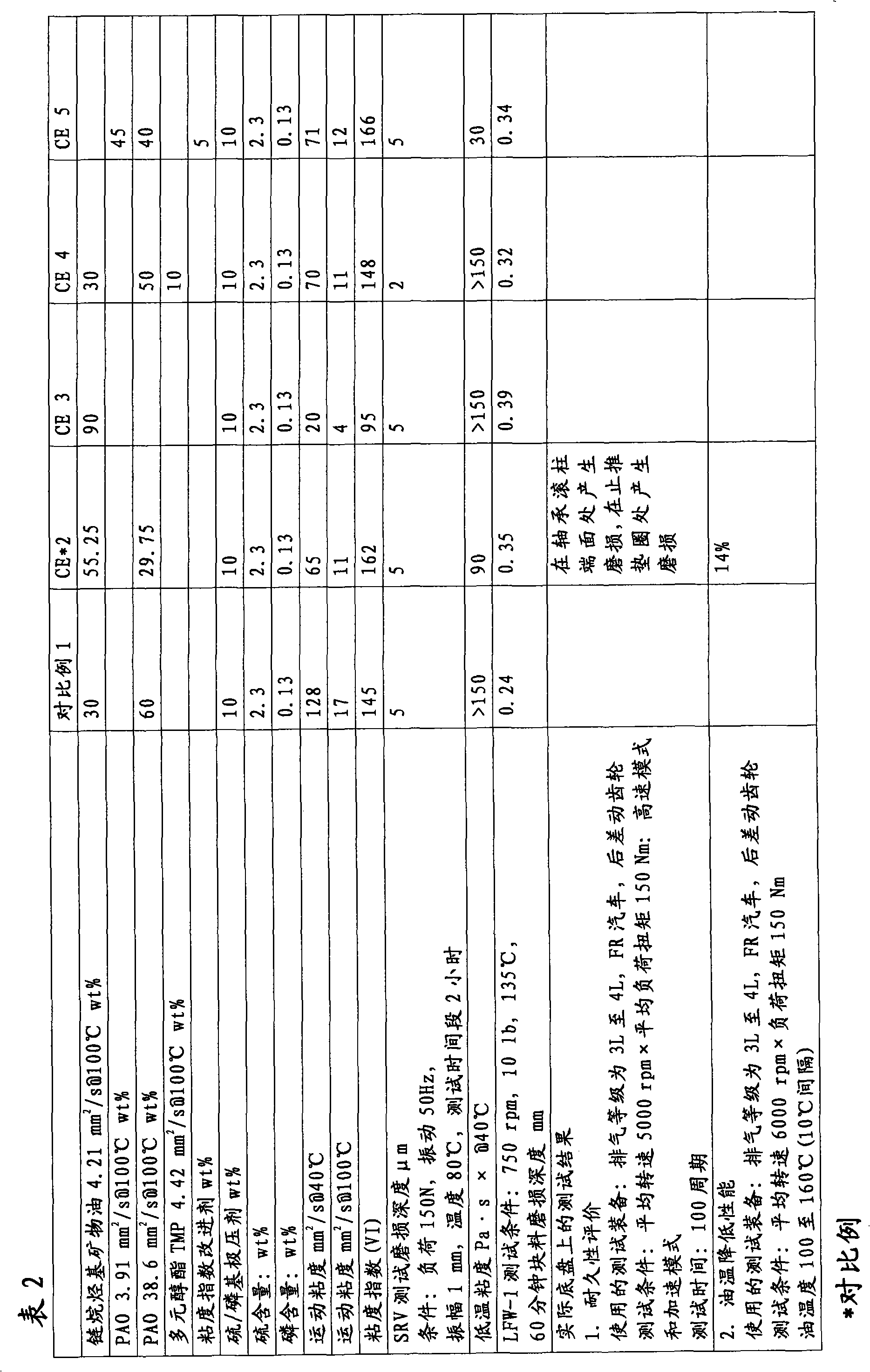

[0089] Embodiment 1-2, comparative example 1-5

[0090] Lubricating oil compositions of Examples 1-2 and Comparative Examples 1-5 were prepared according to the compositions shown in Table 1 and Table 2 using the above-mentioned component materials.

[0091] The following tests were performed to determine the performance of the examples and comparative examples.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity index | aaaaa | aaaaa |

Login to view more

Abstract

The present invention provides a lubricating oil composition comprising a mixture of both a poly-alpha-olefin and an ester compound, the lubricating oil composition having an SAE viscosity grade of 75W-85, satisfying GL- 5 in terms of API gear oil designation and having a viscosity index of 160 or more. The above mixture of the poly-alpha-olefin and ester compound is preferably contained in an amount of from 75 to 90 wt% with reference to the total amount of the lubricating oil composition. The poly-alpha-olefin is preferably a mixture of a poly-alpha-olefin having low viscosity of from about3 to 6 mm<2> / s at 100 DEG C and a poly-alpha-olefin having high viscosity of from about 35 to 45 mm<2> / s at 100 DEG C.

Description

technical field [0001] This invention relates to lubricating oil compositions, and in particular to lubricating oil compositions useful as automotive gear oils or automotive hypoid gear oils. Background technique [0002] In recent years, for the load-bearing performance required in automotive gear oils, as a result of increased automotive power, standards of GL-4 to GL-5 named by API (American Petroleum Institute) for gear oils are being demanded . [0003] In gear oils that are required to have such durability, for the purpose of maintaining an oil film on the gear tooth surface, viscosity No. 90 (13.5-24.0 mm) defined by SAE (Society of Automotive Engineers) is generally used. 2 / s(100℃)) oil. [0004] But on the other hand, it is also necessary to save fuel consumption; in order to achieve this, it is necessary to reduce the stirring resistance; and in order to achieve this, it is necessary to obtain low viscosity. [0005] In order to meet these requirements at the s...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Application Information

Patent Timeline

Login to view more

Login to view more Patent Type & Authority Applications(China)

IPC IPC(8): C10M105/38C10M107/10C10M111/02C10M111/04C10N20/02C10N40/04

CPCC10N2230/02C10N2240/04C10M2207/2825C10M2223/043C10N2230/06C10M2203/1025C10M2205/0285C10M111/04C10M2219/022C10M2207/2835C10N2220/022C10M2209/084C10N2020/02C10N2030/02C10N2030/06C10N2040/04

Inventor 森木惠一长富悦史植野贤治齐藤浩二石川清成藤户宏

Owner SHELL INT RES MAATSCHAPPIJ BV

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap