Light source of projector

A projector and light source technology, which is applied in the field of projector light sources, can solve problems such as brightness drop, screen shaking, and reduced service life, and achieve the effects of not being easy to attenuate brightness, improve output quality, and reduce use costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

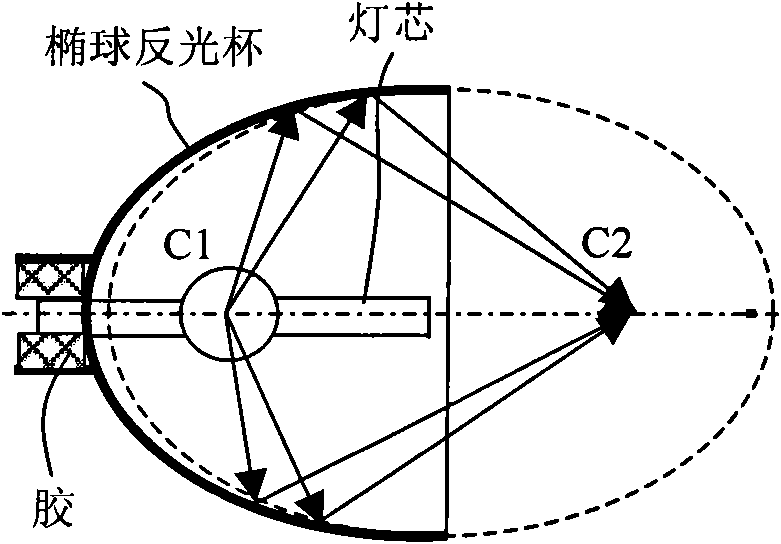

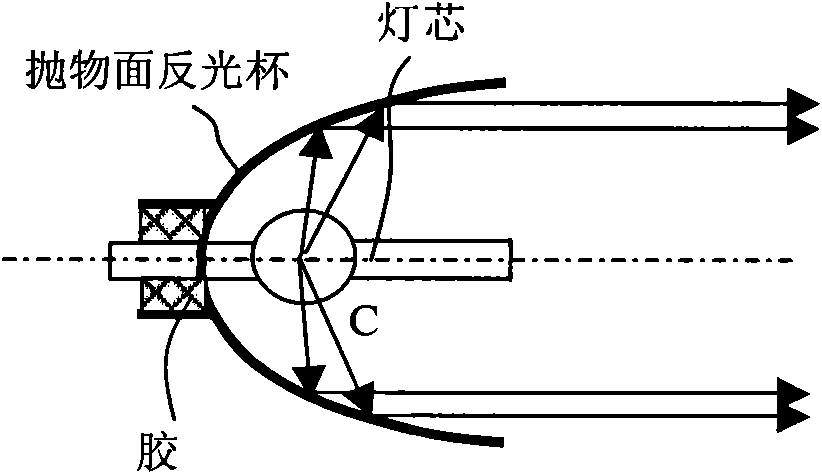

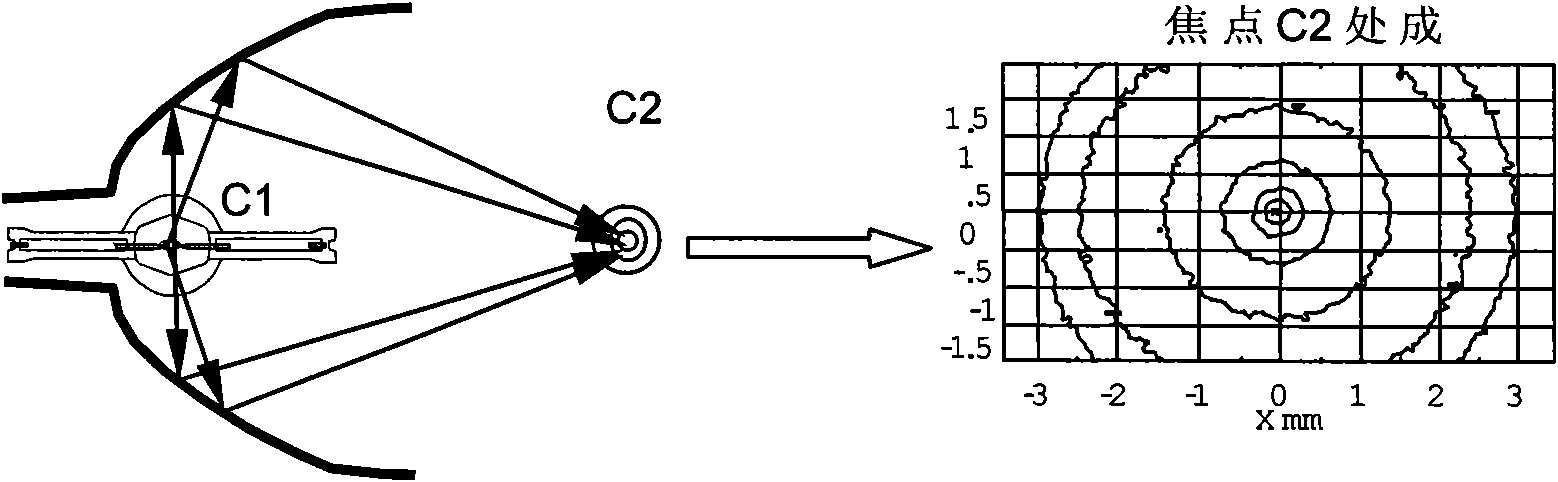

[0018] Such as Figure 6 As shown, a projector light source includes two reflectors, wherein the primary reflector 1 is a spherical or approximately spherical reflector, the secondary reflector 2 is an ellipsoidal reflector, and the front end of the primary reflector has an opening 3 . A wick 4 is also included, the axis of the wick 4 is not perpendicular to the optical axis of the reflective cup, and the light-emitting area between the electrodes of the wick is located on the focal point F1 of the secondary reflective cup 2 . The axis of the wick can form an included angle within ±20° with the horizontal plane. The wick 4 is detachably installed on the wick support 5 such that the wick 4 is located between the primary reflector 1 and the secondary reflector 2 , and the wick 4 is installed symmetrically with respect to the optical axis of the reflector. Reflector material can be metal, boride glass or ceramic material.

[0019] Such as Figure 7 As shown, when the wick 4 o...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap