Flame detector

A flame detector and flame technology, used in instruments, alarms, fire alarms that rely on radiation, etc., can solve the problems of increasing the number of parts and reducing the productivity of flame detectors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] (The overall structure of the flame detector)

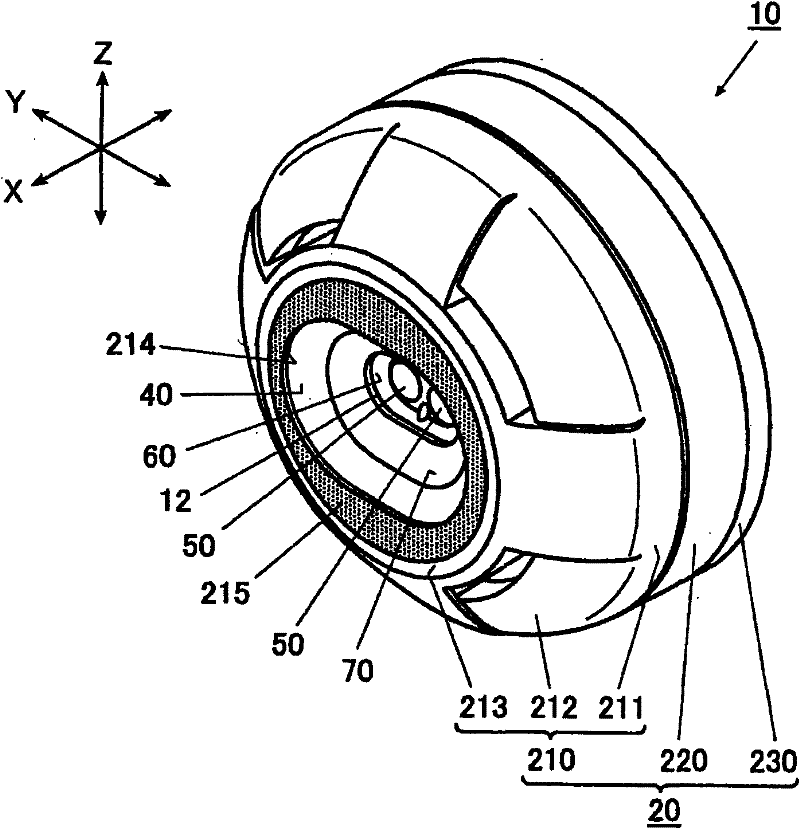

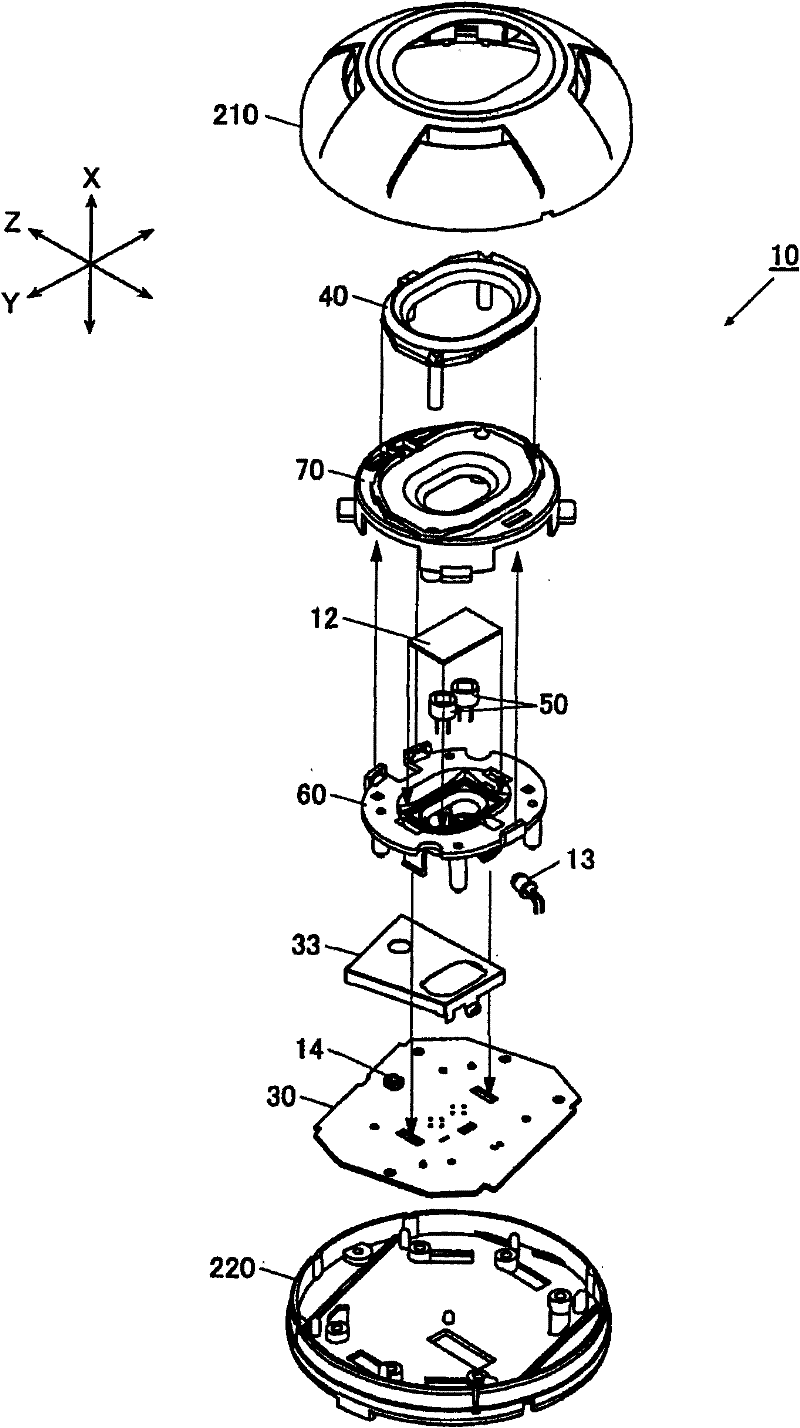

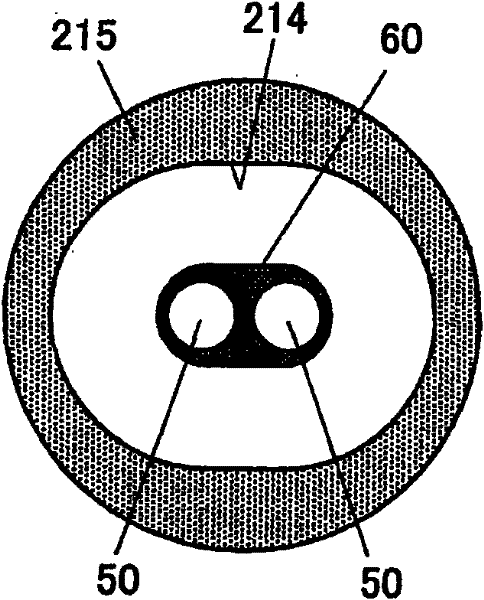

[0050] will refer to Figures 1 to 14B The flame detector 10 of the embodiment of the present invention is described. figure 1 is a perspective view of the flame detector 10, and figure 2 is its exploded perspective view.

[0051] Usually, the flame detector 10 is fixedly installed with its rear side upwards, and at the same time its front side remains downwards, for detecting fire in the area in front of its front side (that is, the lower area obtained in the installed state). flame. Such a flame detector 10 is connected to a receiver, not shown, which centrally handles a plurality of flame detectors arranged over the area to be monitored. At the time of flame detection, the flame detector sends a detection signal to the receiver.

[0052] In the following description, for the sake of convenience, the directions of the flame detector 10 are defined as follows. Specifically, the direction from the front side to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com