Laser scanning sensor test system and test method

A laser scanning and testing system technology, applied in electronic circuit testing, printed circuit testing, instruments, etc., can solve the problems of inhibiting production speed, time-consuming and laborious, false detection, etc., and achieve the effect of improving production speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

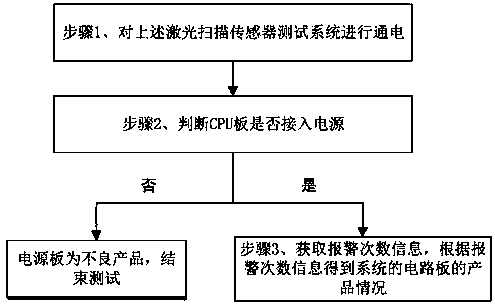

[0068] As a preferred embodiment of the present invention, the test method also includes:

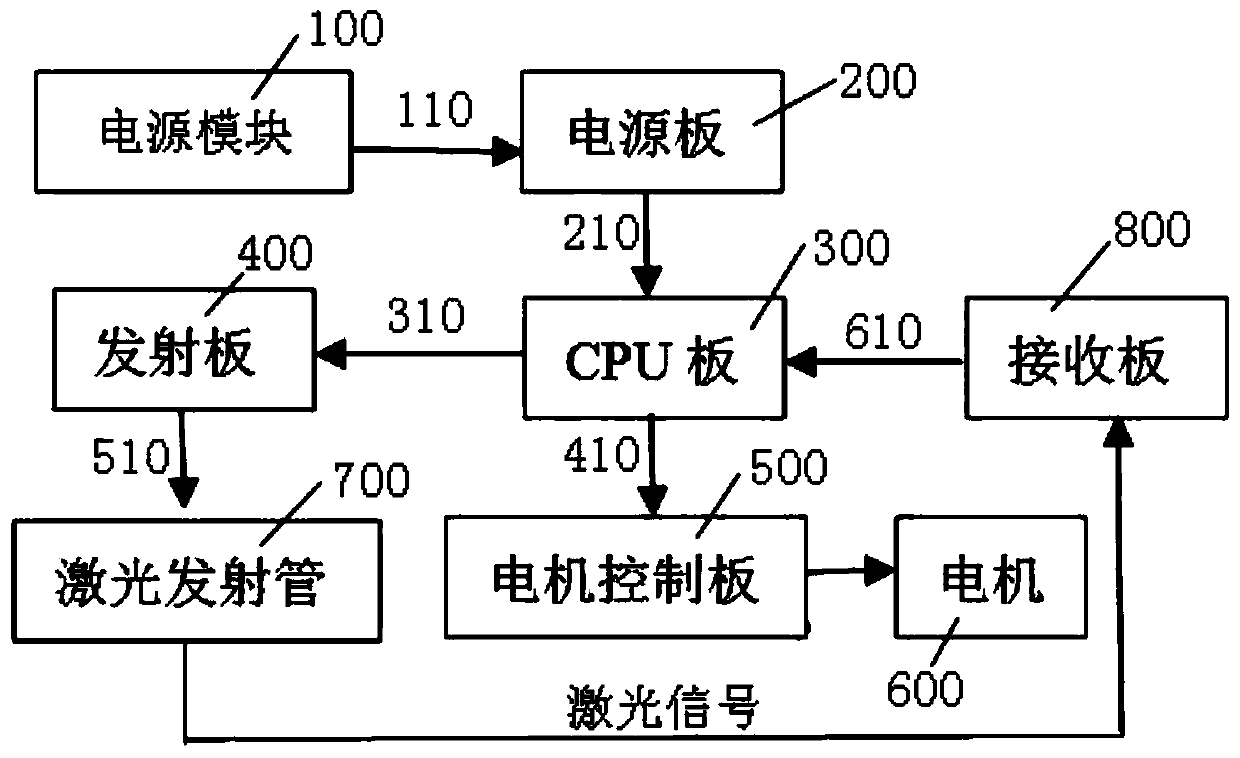

[0069] After judging that the circuit boards of the system are all normal products, the communication function of the laser scanning sensor is detected through the configuration software on the PC side, and the abnormal communication function of the laser scanning sensor is displayed through the configuration software. The communication function includes RS232 communication module, Running information of RS485 communication module and Can communication module.

[0070] When working, first connect the above-mentioned circuit board and fix it on the test frame through connecting wires and probes, and then power on to simulate laser operation. As long as there is an error in one step during the power-on test, the entire laser system will not operate normally, the motor 600 will stop running, and the indicator light of the CPU board 300 will report a corresponding error. Specifically, when...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com