Gas combustion type driving tool

A technology for driving tools and gas, which is applied in the direction of nailing tools and manufacturing tools, and can solve the problems of increasing the overall weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

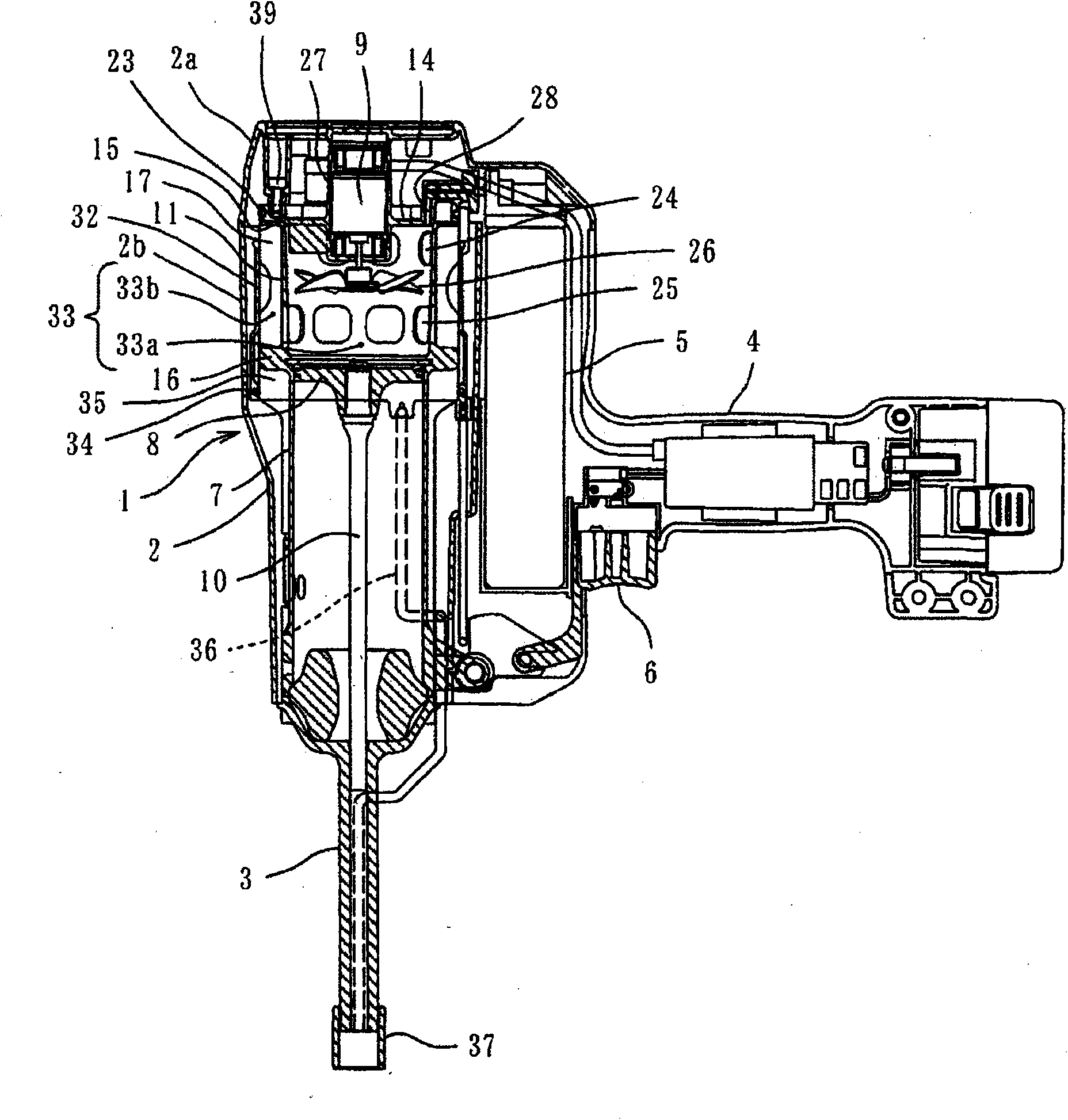

[0041] Hereinafter, a nail driver will be described as a gas combustion chamber driving tool according to the present invention.

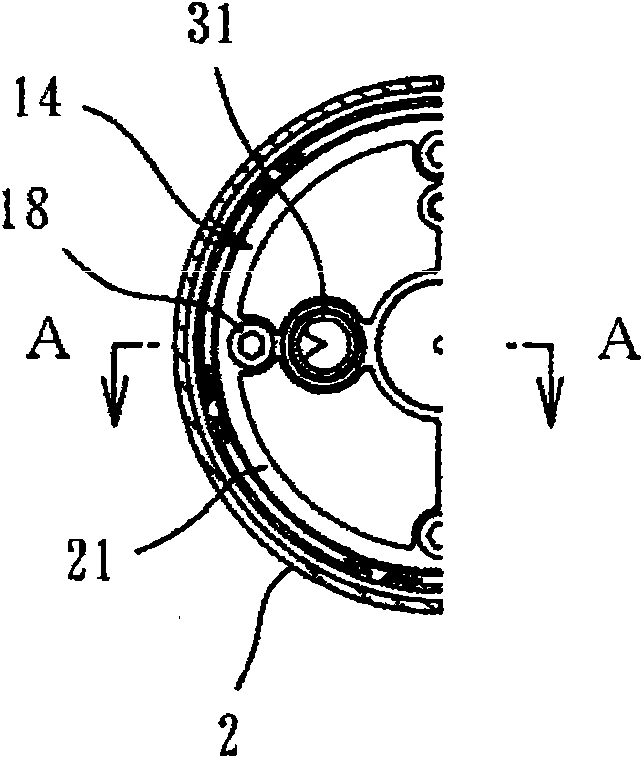

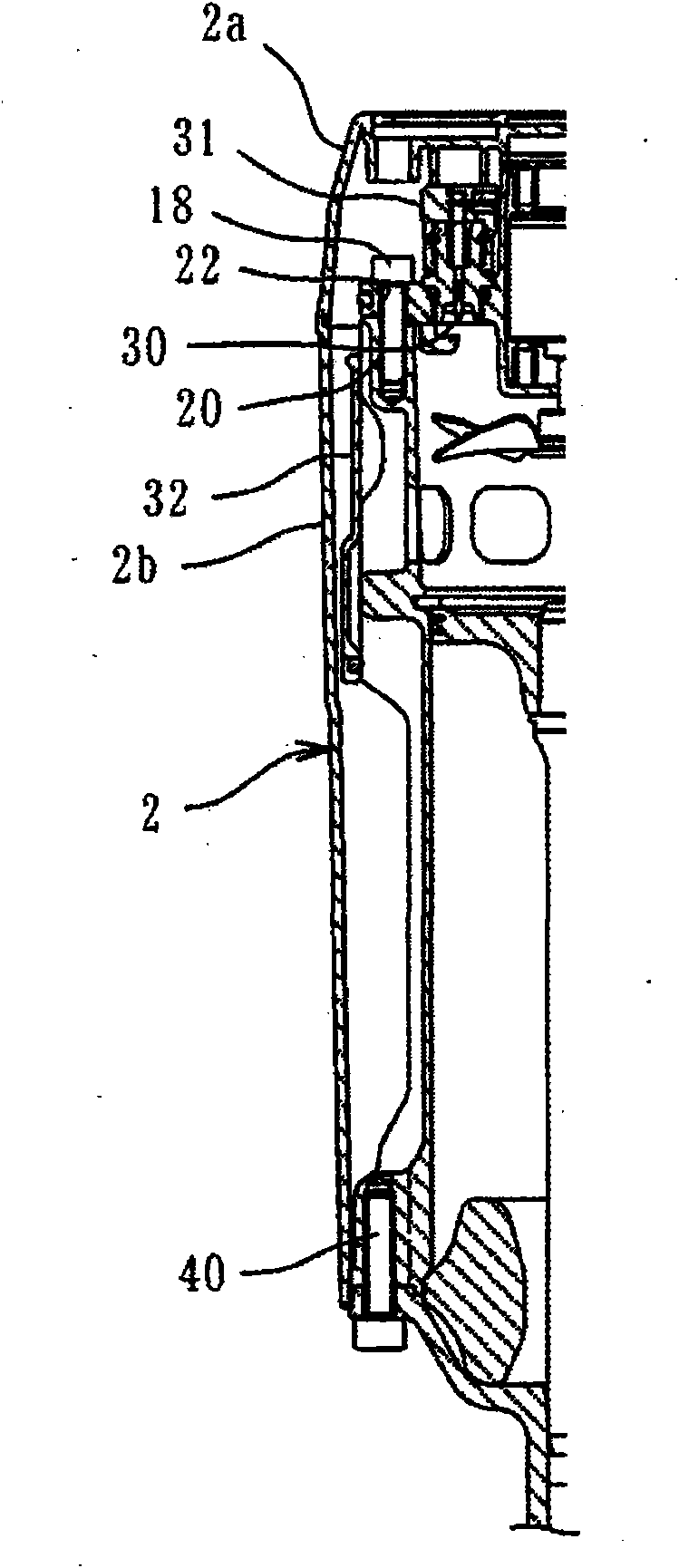

[0042] exist Figure 1 to Figure 4 In , reference numeral 1 denotes a tool body of a gas combustion driving tool (nail driver). This tool main body 1 is provided with combustion chamber and piston-cylinder mechanism in the inside of main body cover 2, is provided with the machine head 3 that is used for driving nail under the tool main body 1, is connected with handle 4 on the tool main body 1, on the machine head A staple cartridge (not shown) is connected to the part 3 , and a gas container 5 is detachably provided on the handle 4 side of the tool body 1 . Reference numeral 6 denotes a trigger.

[0043] In the piston-cylinder mechanism, a piston 8 is slidably accommodated in a cylinder 7 , and a driver 10 is integrally coupled below the piston 8 .

[0044] A cylindrical connecting wall 11 is provided as a connecting portion on the upper extens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com