Adhesive transfer device

An appliance, transfer technology, applied in the directions of printing, eraser, adhesive, etc., can solve the problem of insufficient transfer of adhesive, and achieve the effect of smooth movement, high-efficiency transfer operation, and reduction of contact friction resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

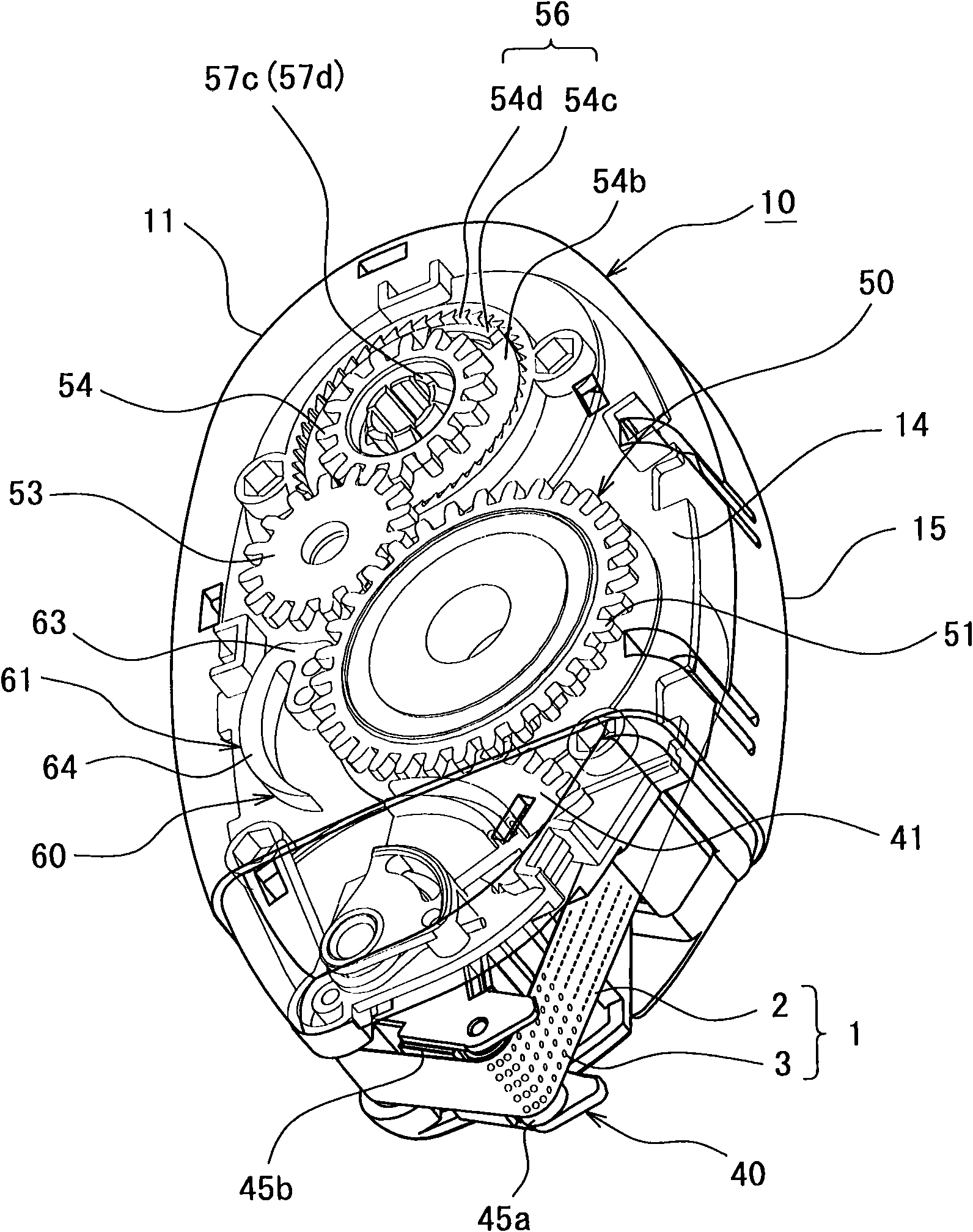

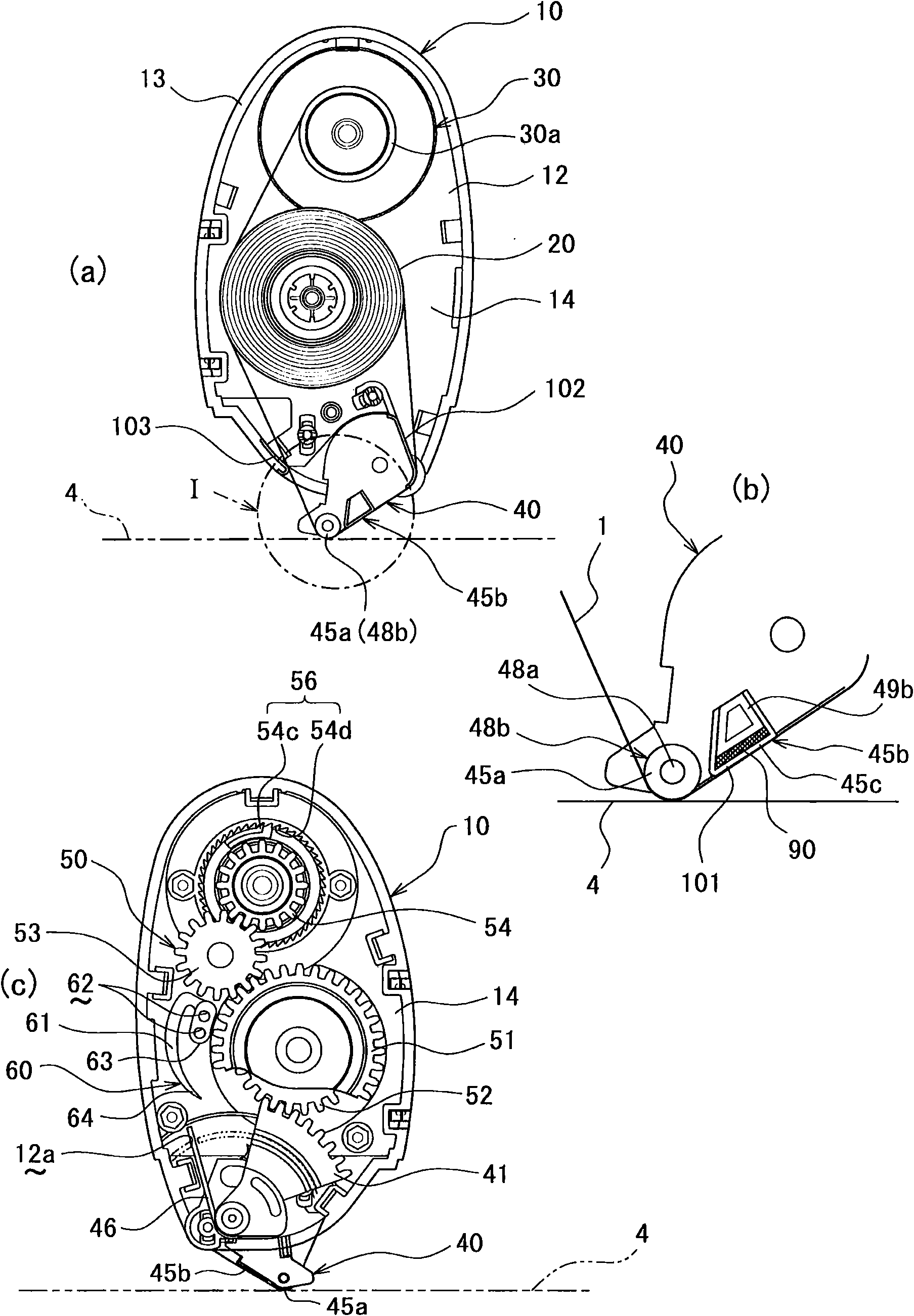

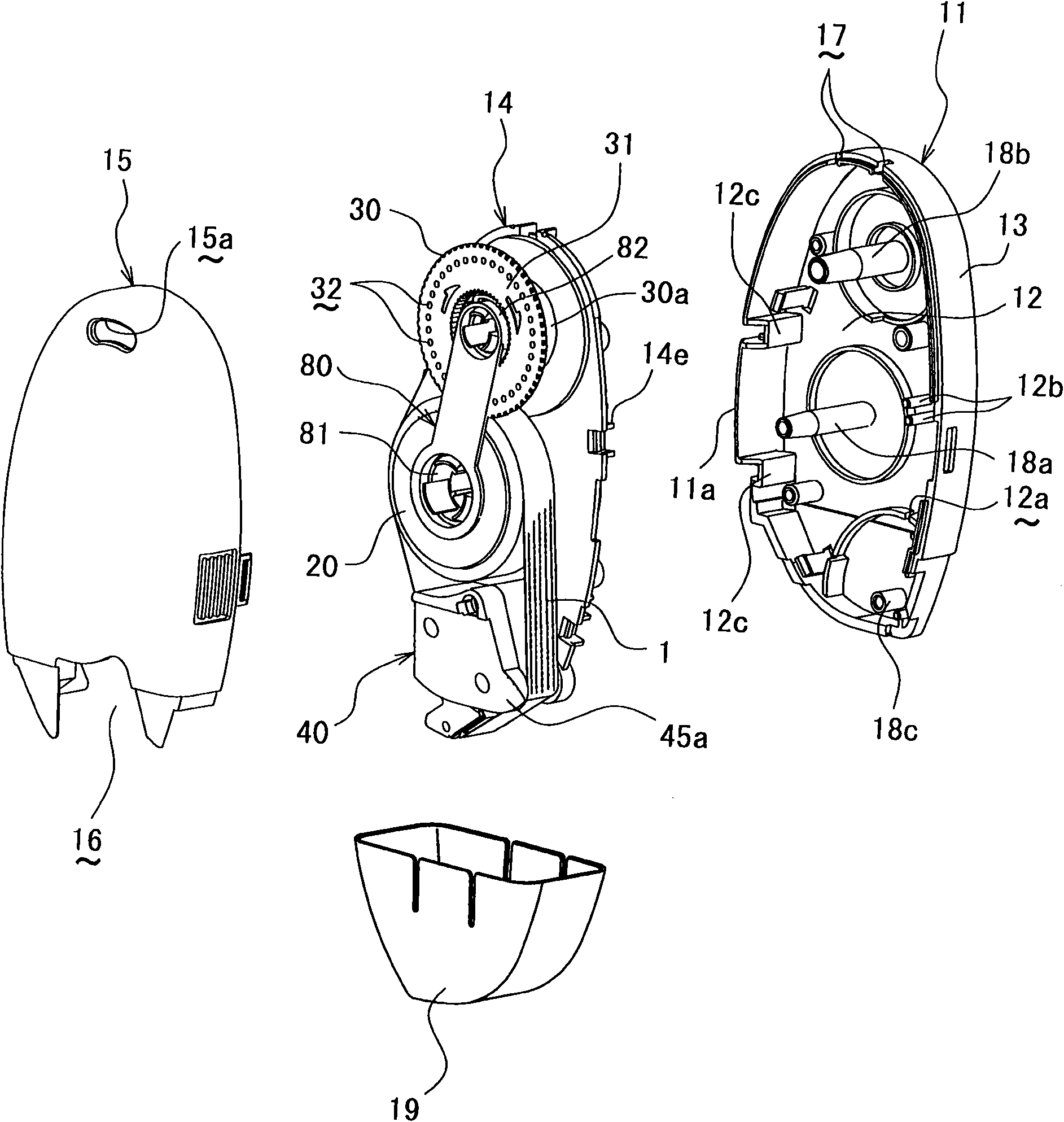

[0042] Such as Figure 1 to Figure 3 As shown, the adhesive transfer device of the present invention has: a housing 10; a rotatable supply reel 20 on which a transfer belt 1 is wound; Mixture 3; rotatable winding reel 30, which is used to wind the tape substrate 2 of the transfer tape 1 pulled out from the supply reel 20; transfer head 40, which will be pulled out from the supply reel 20 The adhesive 3 of the transfer tape 1 is transferred to the transferred surface 4; the winding mechanism 50 winds the transfer tape 1 on the winding reel 30; the confirmation sound generating mechanism 60, which is at the point of Make a confirmation sound when the status is transferred.

[0043] The above-mentioned transfer belt 1 is formed of a pressure-sensitive belt made, for example, on one side of the belt base 2 formed of a release paper, for example, in a staggered shape or the like along the length direction and the width direction of the belt base 2 . Adhesives 3 made of, for examp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com