Perfected flotation cell for purifying fibrous suspensions

A flotation machine and suspension technology, applied in fiber raw material processing, flotation, fiber raw materials, etc., can solve the problems of pump suction device consumption, high power, complicated maintenance time and other problems, and achieve low implementation cost, overall simplicity, The effect of great flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

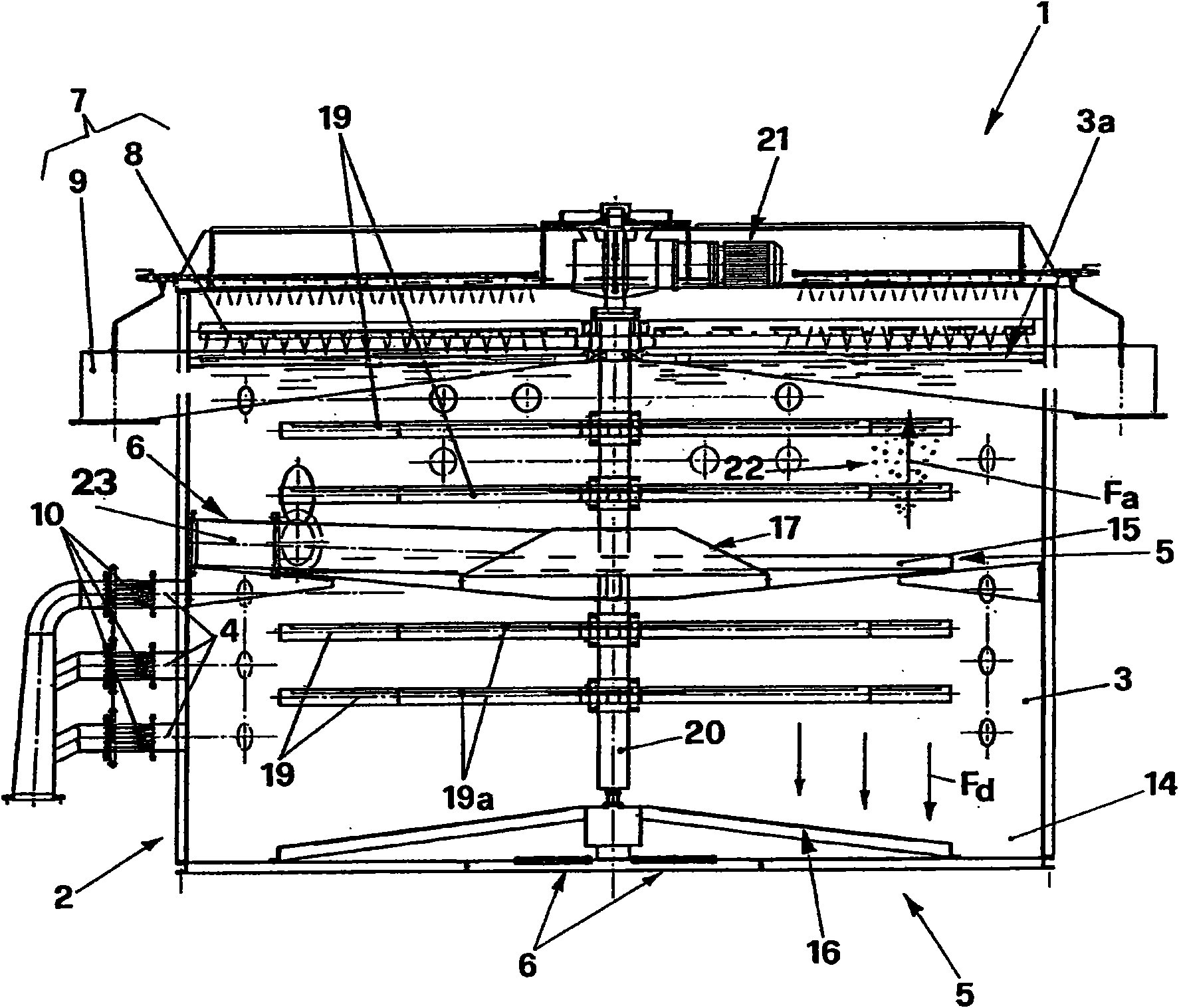

[0040] figure 1 The flotation machine that is the subject of the invention is illustrated in , where the reference number 1 indicates the flotation machine as a whole, in figure 1 As can be seen in , the flotation machine comprises a container 2 for the suspension 3 to be purified, said container 2 being preferably but not necessarily cylindrical.

[0041] The suspension 3 is introduced into the container 2 through supply pipes 4 , the number and outlet positions of which can vary in different embodiments of the invention according to the flow generated in the container 2 .

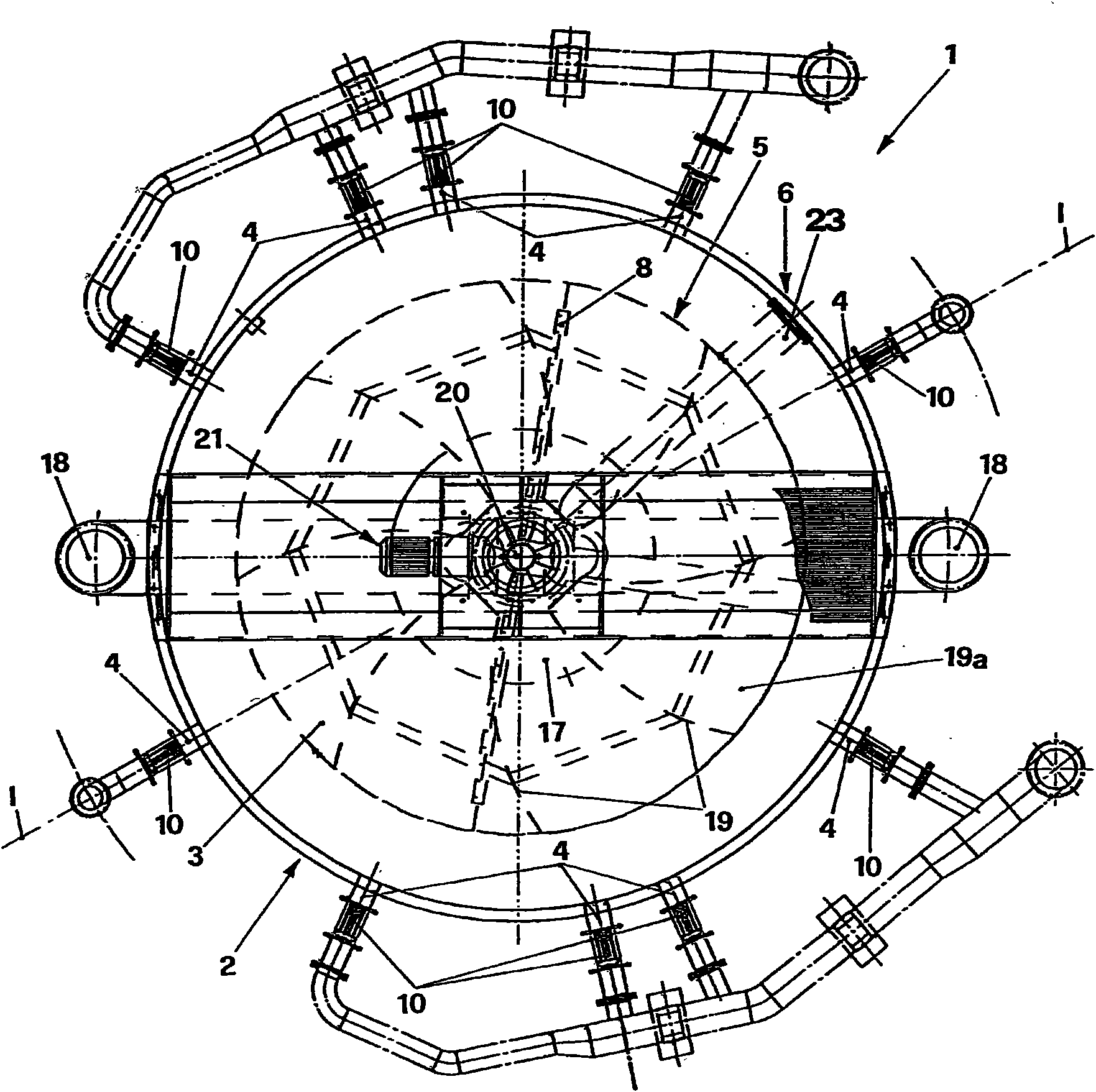

[0042] For simplicity, figure 1 Only three supply pipes 4 on the left are shown, however, as image 3 As shown in the plan view of , the supply pipe 4 is arranged on the entire periphery of the container 2 .

[0043] The flotation machine 1 of the invention also comprises means 5 for intercepting the purified suspension flowing downwards towards the bottom of the vessel 2 due to gravity, said means 5 b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com