Component for a valve train of an internal combustion engine

A valve mechanism, internal combustion engine technology, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of drilling area deformation, falling off, connecting piston deformation, etc., to achieve the effect of reducing wear and reducing pulse force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

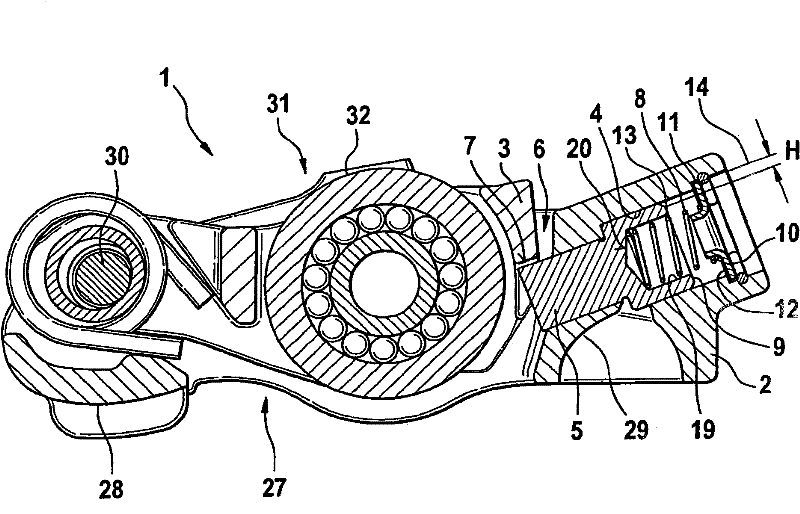

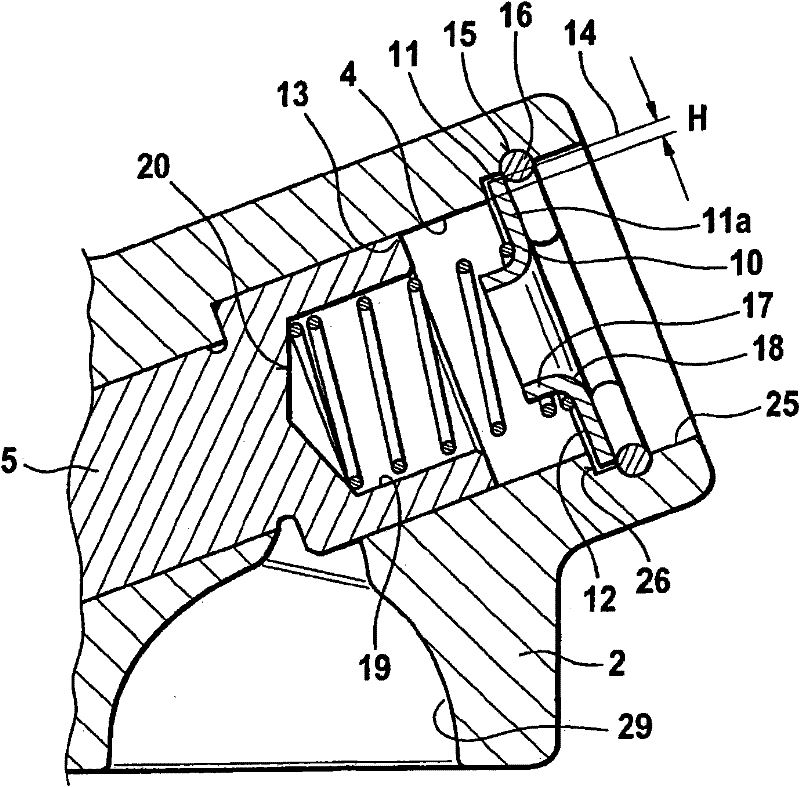

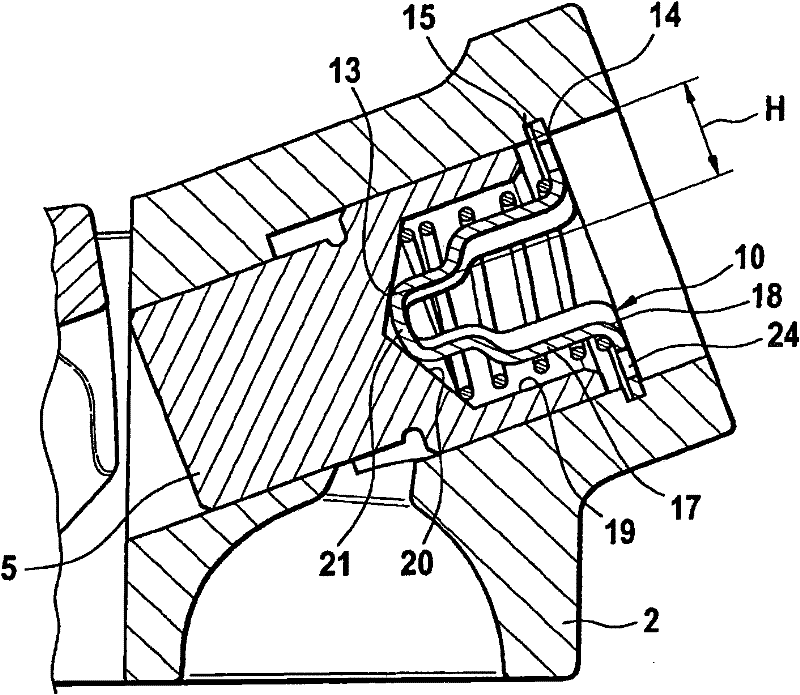

[0024] figure 1 and Figures 2 to 4 A component 1 of a valve train of an internal combustion engine is collectively disclosed, which component 1 can be switched to different strokes for at least one gas exchange valve. As can be easily seen by a person skilled in the art, the component 1 here is configured as a detachable rocker arm.

[0025] The component 1 is composed of a first element 2 and a second element 3 , which are present so as to be movable relative to one another. The first element 2 is designed as an outer rod, while the second element 3 is present as an opposite inner rod that is pivotable in the decoupled situation. The two elements 2 , 3 are distributed at one end on a common shaft 30 , wherein the second element 3 has a contact surface 32 designed as a rotatable roller for the stroke cam.

[0026] The element 2 has an abutment 28 for a gas exchange valve at one end on the underside 27 . At the other end, a cap-shaped abutment 29 for bearing on the top of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com