Volume high-pressure water pump with slide block structure

A high-pressure water pump, positive displacement technology, applied in rotary piston pumps, rotary piston/swing piston pump components, pumps, etc., can solve the problems of short service life, large vibration of positive displacement pumps, low lift, etc. The effect of volume and weight, improved work efficiency, and convenient mobile use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to make the object and technical solutions of the present invention clearer, the present invention will be further described below in conjunction with the accompanying drawings and embodiments:

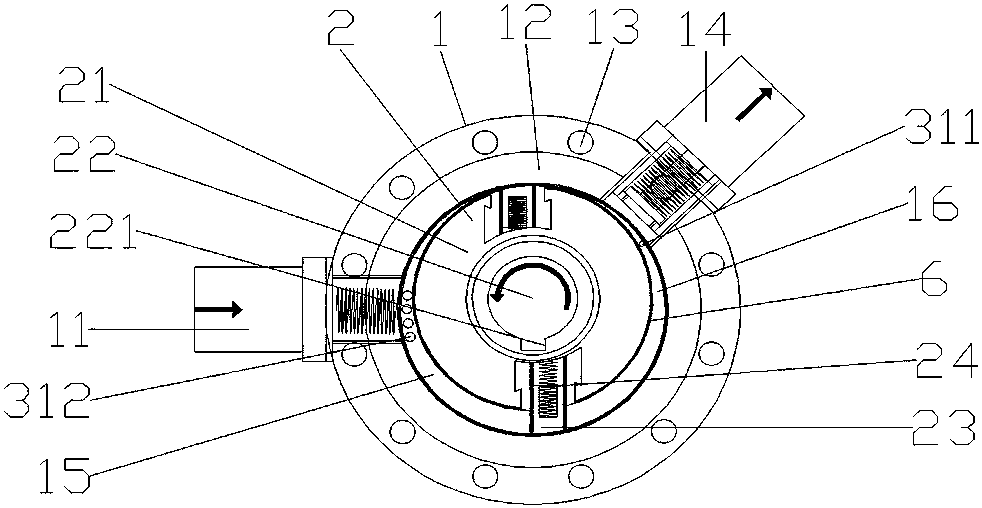

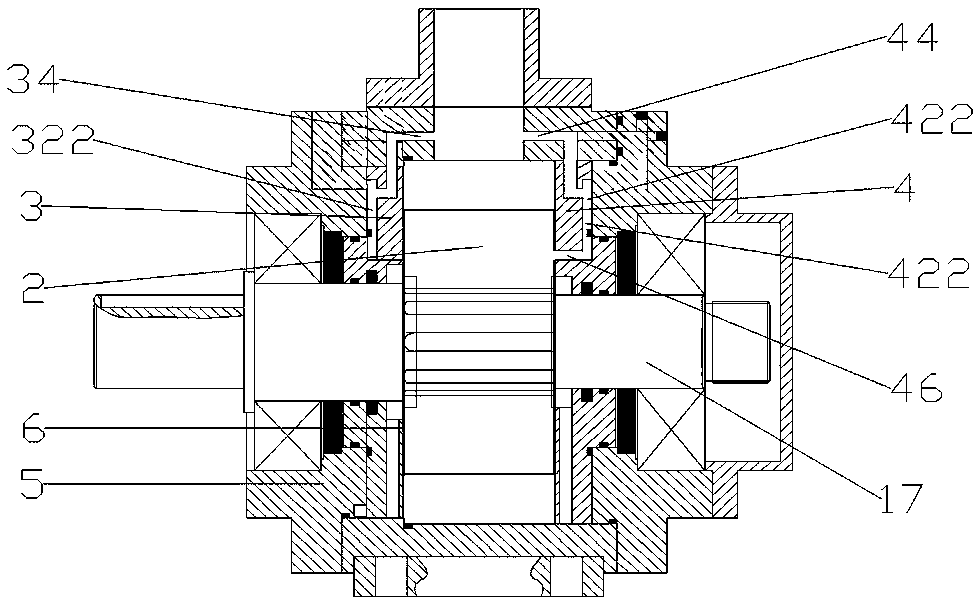

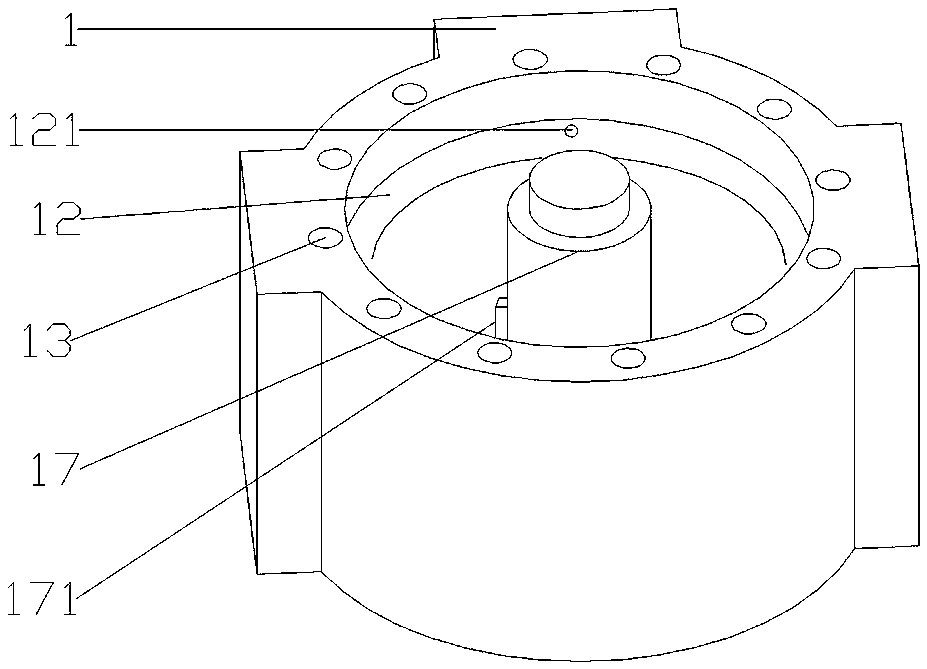

[0044] Such as Figure 1 to Figure 9 A volumetric high-pressure water pump with a slider structure shown includes a pump main body 1, a rotor 2, a left side plate 3, a right side plate 4, and an end cover 5. The pump main body 1 is provided with a water inlet 11, a stator 12, and an outlet. The water port 14, the drive shaft 17; the stator 12 is fixed inside the pump main body 1, and two inner pin holes 121 for installing the left side plate 3 and the right side plate 4 are respectively provided on both sides of the stator 12; the water inlet 1 and the outlet The water ports 14 are staggered and installed on the pump body, and the center line of the water inlet 11 and the center line of the water outlet 14 intersect at the center of the pump body, and the intersection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com