Centrifugal fan volute for oil fume purification device

A centrifugal fan and oil fume purification technology, which is applied to the components of the pumping device for elastic fluid, mechanical equipment, machines/engines, etc., can solve the problems of increased noise, increased eddy current noise, and large rotation noise, etc., to achieve The effect of reducing the probability of backflow, reducing eddy current noise, and reducing rotation noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

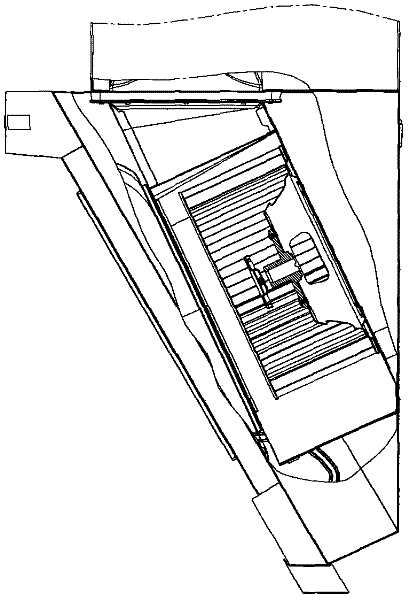

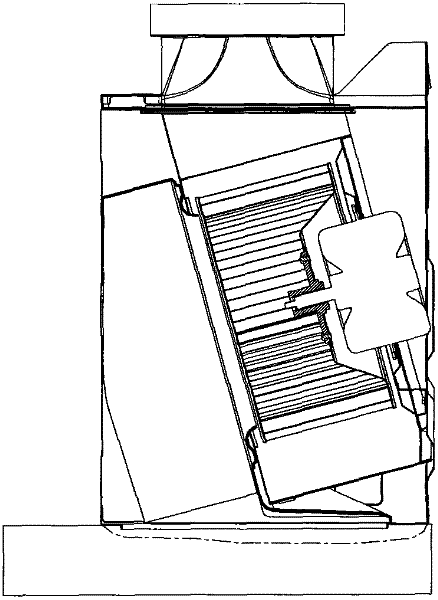

[0036] The structure diagram of the centrifugal fan volute of the oil fume purification device of the present invention is as follows Figure 5-10 , 12, including the volute top plate 1, the volute bottom plate 3, the volute coaming plate 2 and the volute flange 6, wherein the volute top plate 1 is provided with an air inlet 11, and the volute flange 6 is provided with an air outlet 61. The plane where the air outlet 61 is located is inclined toward the side of the volute bottom plate 3, and is not perpendicular to the plane where the air inlet 11 is located. Plate 2 connects the two with a twisted surface with a continuous smooth transition.

[0037] Such as Figure 9 As shown, the edge profile of the above-mentioned volute top plate 1 is composed of the first curve A1B1, the second curve B1C1, the transition arc C1D1, the logarithmic spiral D1E1, the first straight line E1F1, and the second straight line F1K1, forming the second straight line of the volute tongue A curve A...

Embodiment 2

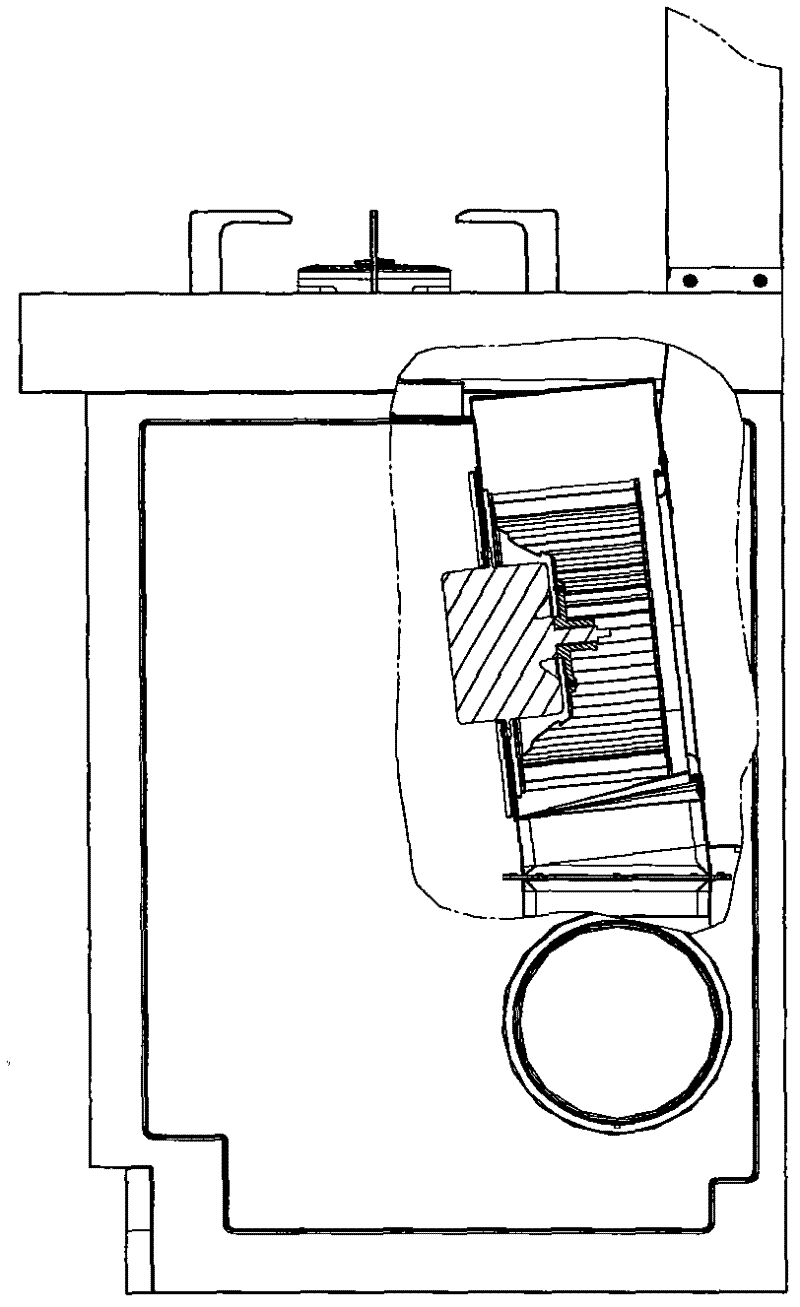

[0052] The structure diagram of the centrifugal fan volute of the oil fume purification device of the present invention is as follows Figure 5-9 , 11, 12, including volute top plate 1, volute bottom plate 3, volute coaming plate 2 and volute flange 6, wherein the volute top plate 1 is provided with an air inlet 11, and the volute flange 6 is provided with The air outlet 61, the plane where the air outlet 61 is located is inclined toward the side of the volute bottom plate 3, and is not perpendicular to the plane where the air inlet 11 is located. The volute top plate 1 and the volute bottom plate 3 have an asymmetric structure at the volute tongue, and the volute The shell coaming plate 2 connects the two with a twisted surface with continuous smooth transition.

[0053] Such as Figure 9 As shown, the edge profile of the above-mentioned volute top plate 1 is composed of the first curve A1B1, the second curve B1C1, the transition arc C1D1, the logarithmic spiral D1E1, the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com