Ventilation structure

An air outlet and volute technology, applied in the field of ventilation equipment, can solve the problems of environmental noise pollution, strong noise, etc., and achieve the effects of reducing rotating noise, improving elimination efficiency, and reducing pulse force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

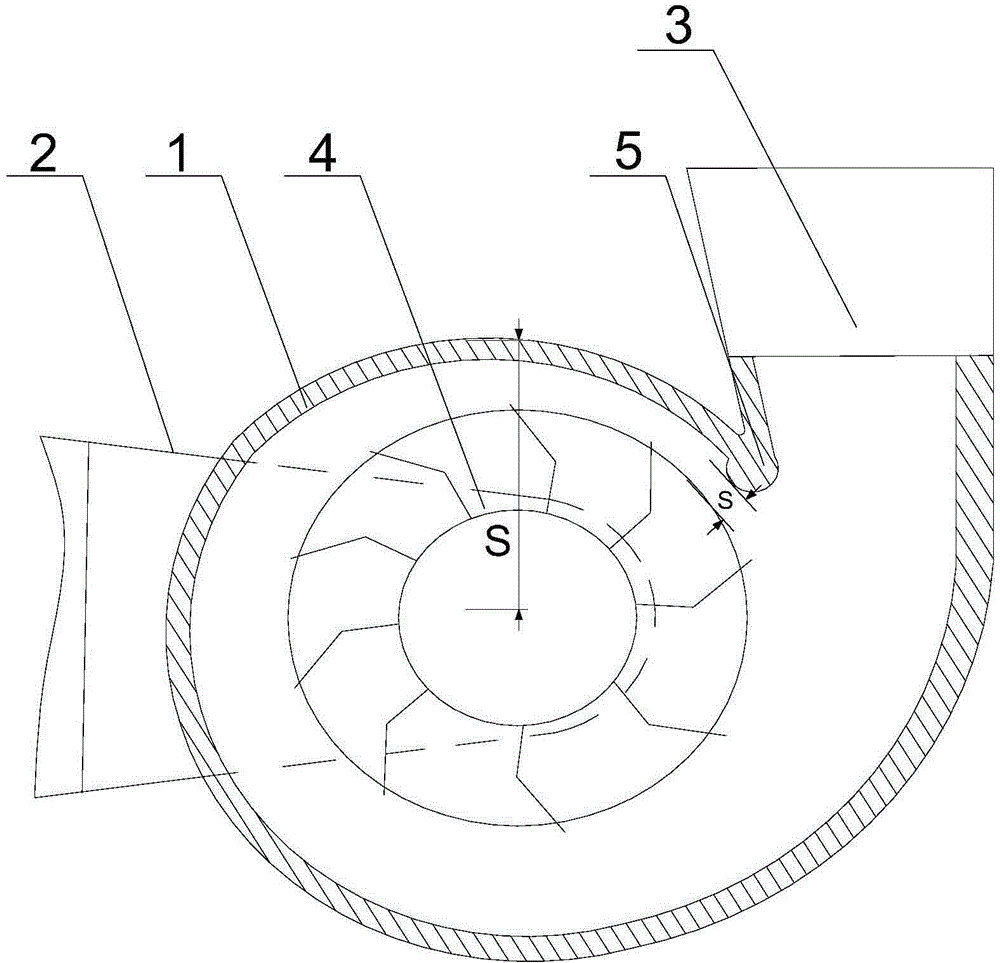

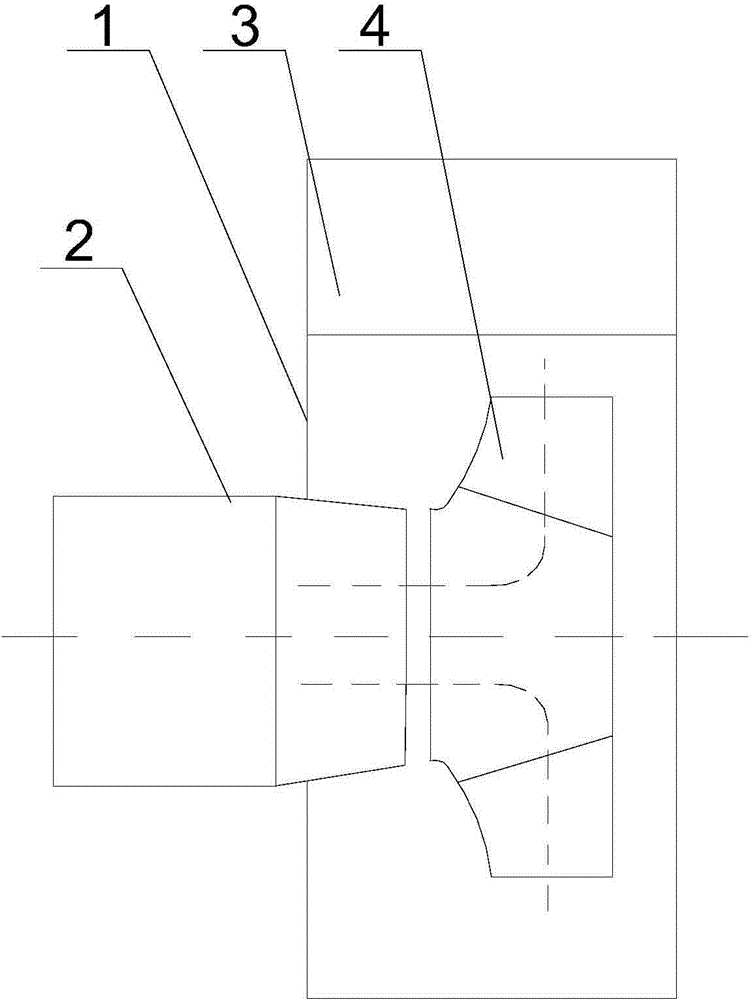

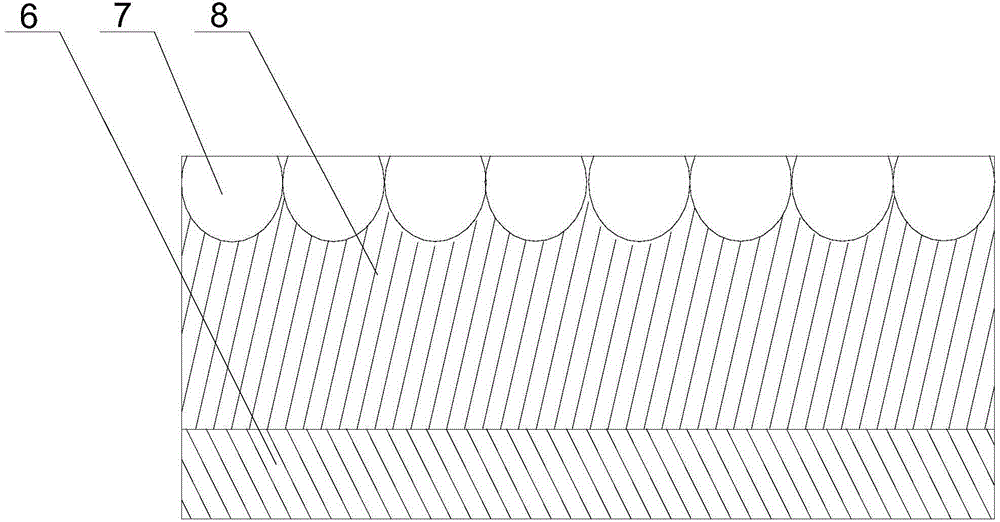

[0025] Such as Figure 1 to Figure 4As shown, this embodiment includes a volute 1 and an impeller 4 fixed in the volute 1, and the two sides of the volute 1 are respectively provided with a horizontal air inlet 2 and a vertical air outlet 3. A volute tongue 5 is arranged between the volute 1 and the air outlet 3, and the tongue tip of the volute 5 is inclined to the side close to the impeller 4, and the sound-absorbing cotton 8 is fixed on the inner wall of the volute 1 through the viscose layer 6, and on the The upper surface of the sound-absorbing cotton 8 is provided with a plurality of sound-absorbing blind holes 7 arranged side by side with a three-quarter circle longitudinal section; a sound-absorbing tube 9 is threadedly connected to the end of the air outlet 3, and a sound-absorbing tube 9 is threaded near the volute tongue. 5. A first muffler 10 is installed on one-half of the inner wall of the muffler cylinder 9 on one side, and a second muffler 11 is fixed on the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com