Pump unit with a main pump and a charging pump with a variable pump capacity

A technology of pump unit and booster pump, which is applied in the direction of pump, pump control, multi-cylinder pump, etc., to achieve the effect of adjusting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

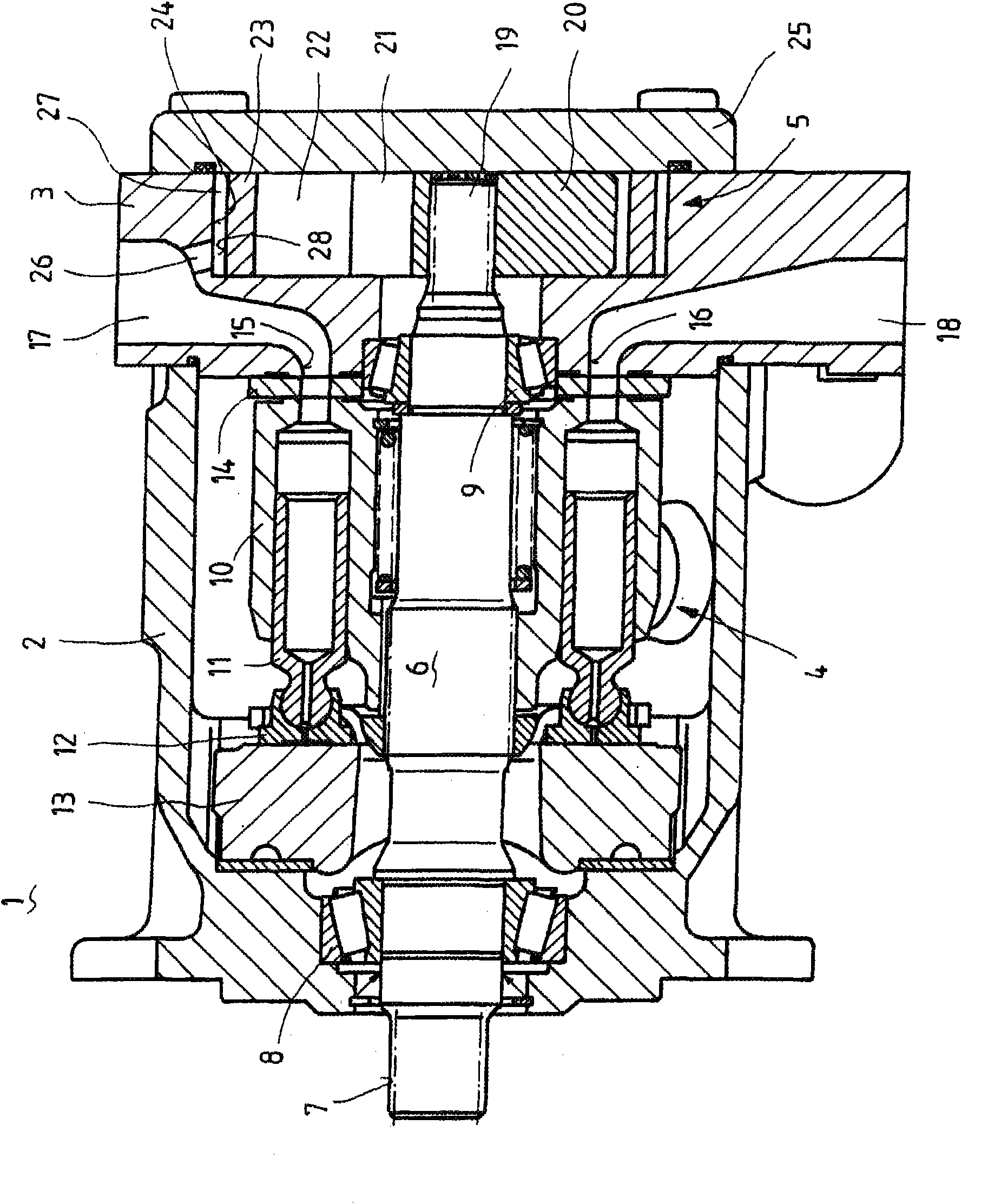

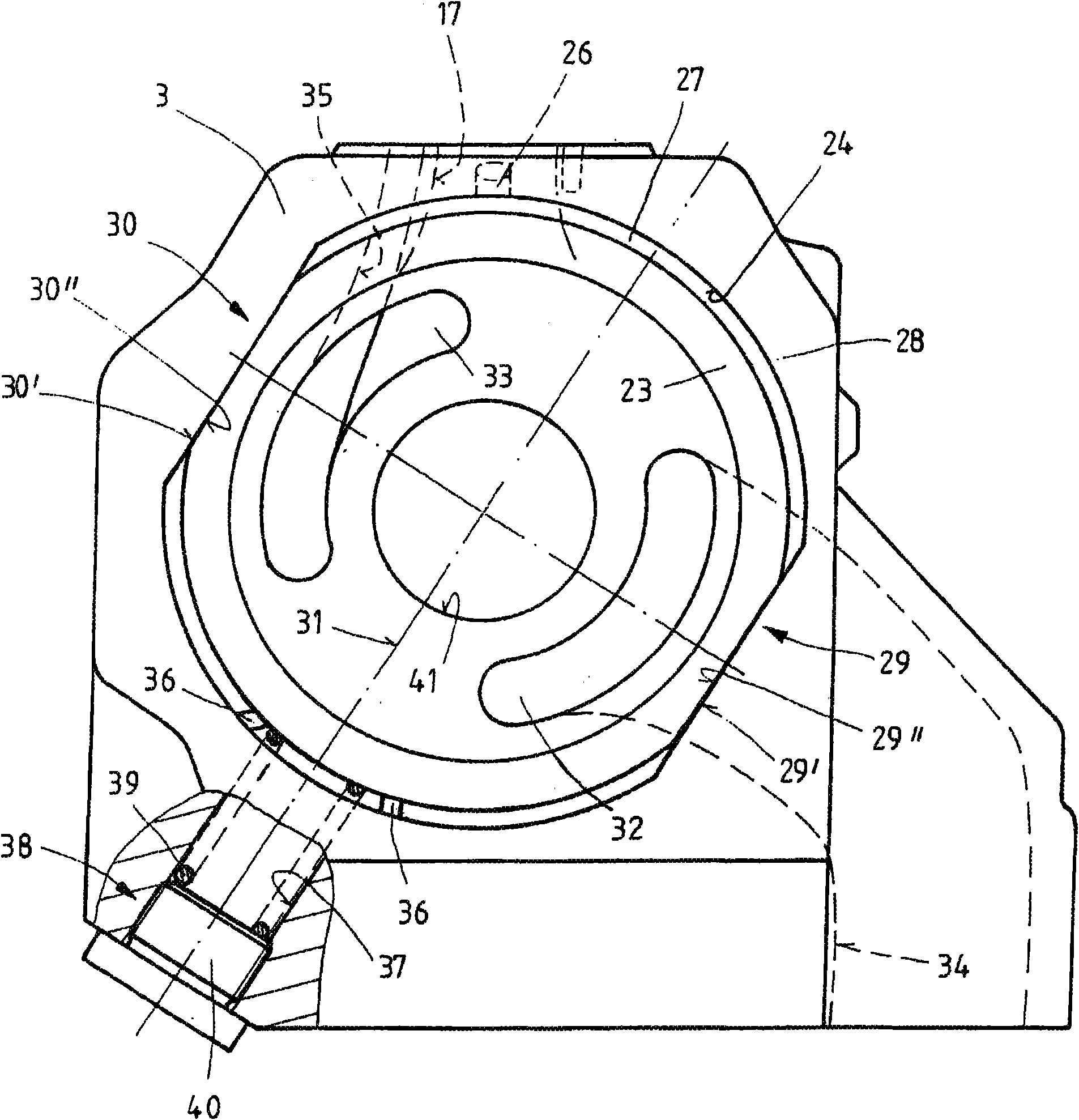

[0021] exist figure 1 A preferred embodiment of a pump unit 1 according to the invention is shown in , comprising a housing comprising a pot-shaped housing part 2 and a further housing part closing the pot-shaped housing part 2 . The other housing part is in the shape of the connecting plate 3 . A main pump 4 is arranged in the pot-shaped housing part 2 . The booster pump 5 is arranged on the side of the connecting plate 3 remote from the pot-shaped housing part 2 .

[0022] In the exemplary embodiment shown, the main pump 4 and the booster pump 5 in the form of axial piston machines are driven via a common drive shaft 6 . The drive shaft 6 has a shaft end protruding from the pot-shaped housing part 2 in the bottom region. A tooth portion 7 is formed on this shaft end of the drive shaft 6 . The toothing 7 serves to couple the drive shaft 6 in a rotationally fixed manner to a torque generator.

[0023] The common drive shaft 6 is rotatably supported in the housing of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com