Fluidized bed reaction tower

A technology of fluidized bed reaction and reaction tower, applied in the direction of chemical/physical processes, chemical instruments and methods, etc., can solve problems such as fluidized bed fluctuations, reduce process efficiency, increase gas flow rate, etc., to avoid negative effects and stabilize Operating environment, effect of size reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

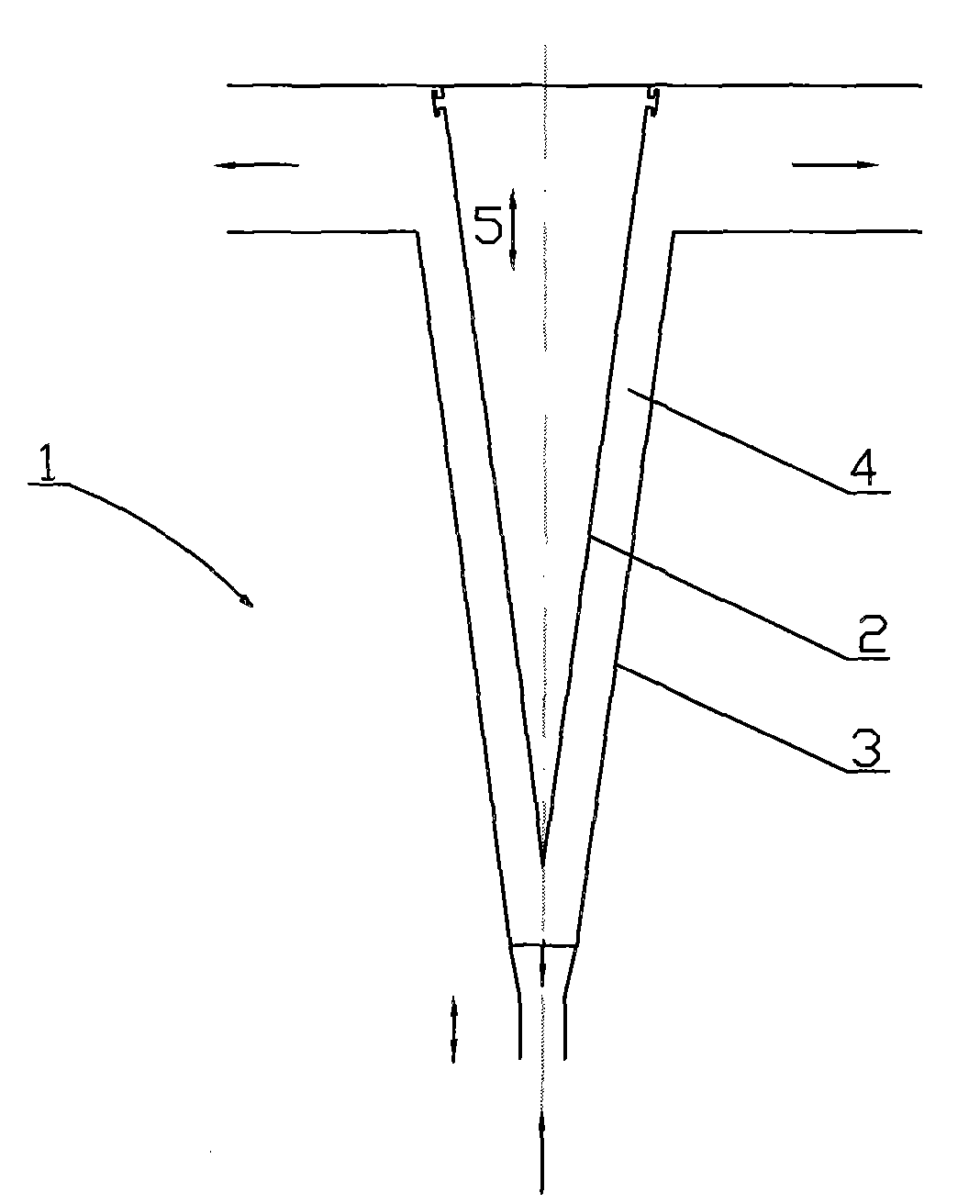

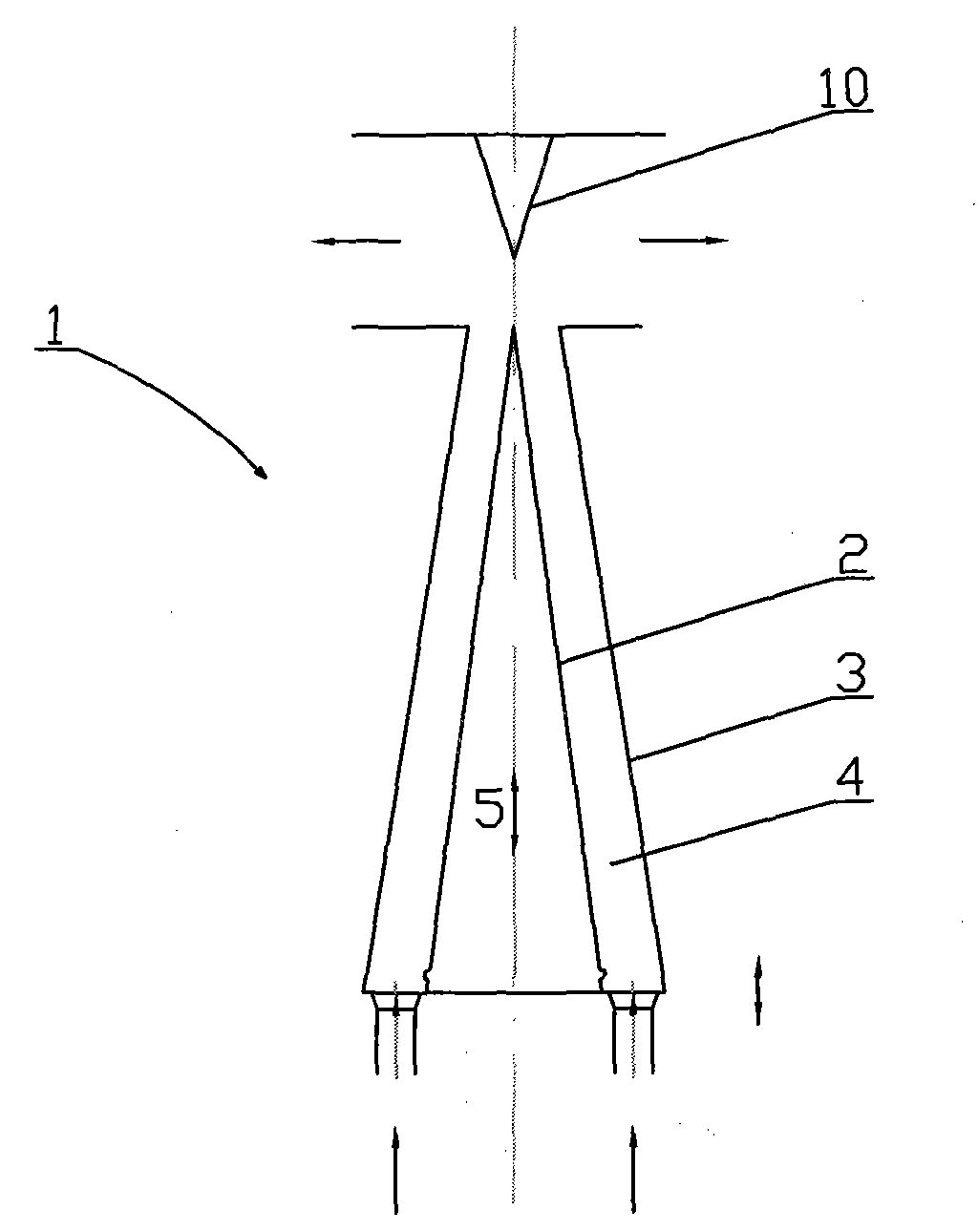

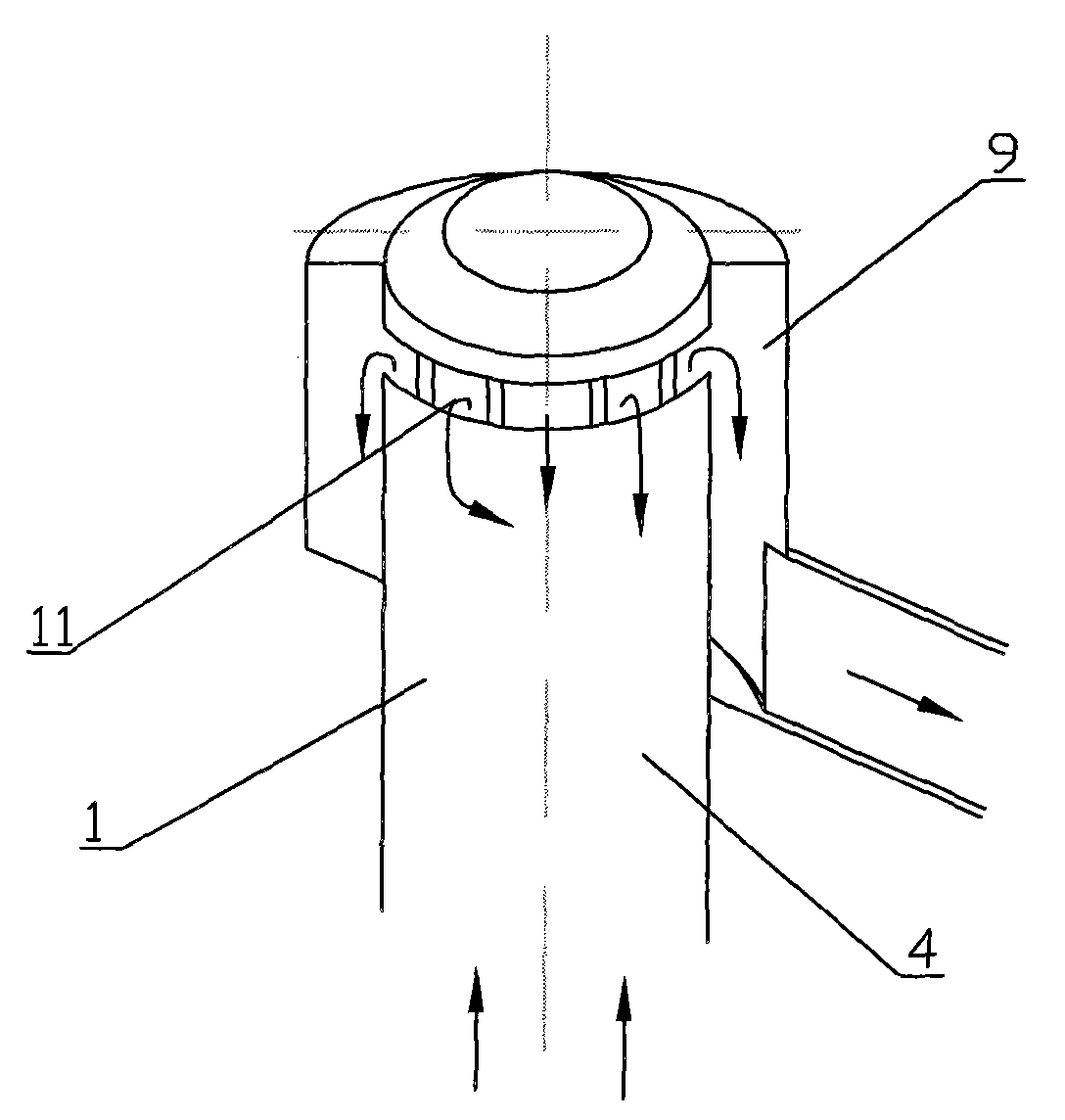

[0024] according to figure 1 or figure 2 The fluidization chamber 4 of the reaction tower 1 includes a conical or parabolic casing 3, which contains an insert 2 that is also conical or parabolic. Through this design, an annular space functioning as a fluidization chamber 4 is formed between the casing 3 and the insert 2. The annular space generates gas velocity, which can be kept constant or kept reduced Or keep increasing, depending on the geometry of the two components. So this kind of reaction tower can also be called a steady flow rate reaction tower.

[0025] By means of a regulating device (not shown in detail), the insert 2 is lowered or raised in the direction of the double arrow 5, and the geometry of the annular space is changed, so that the gas velocity in the fluidization chamber will increase or decrease. Therefore, when the gas flow velocity fed into the reaction tower changes, by reducing or increasing the insert 2, an almost stable gas flow velocity can be obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com