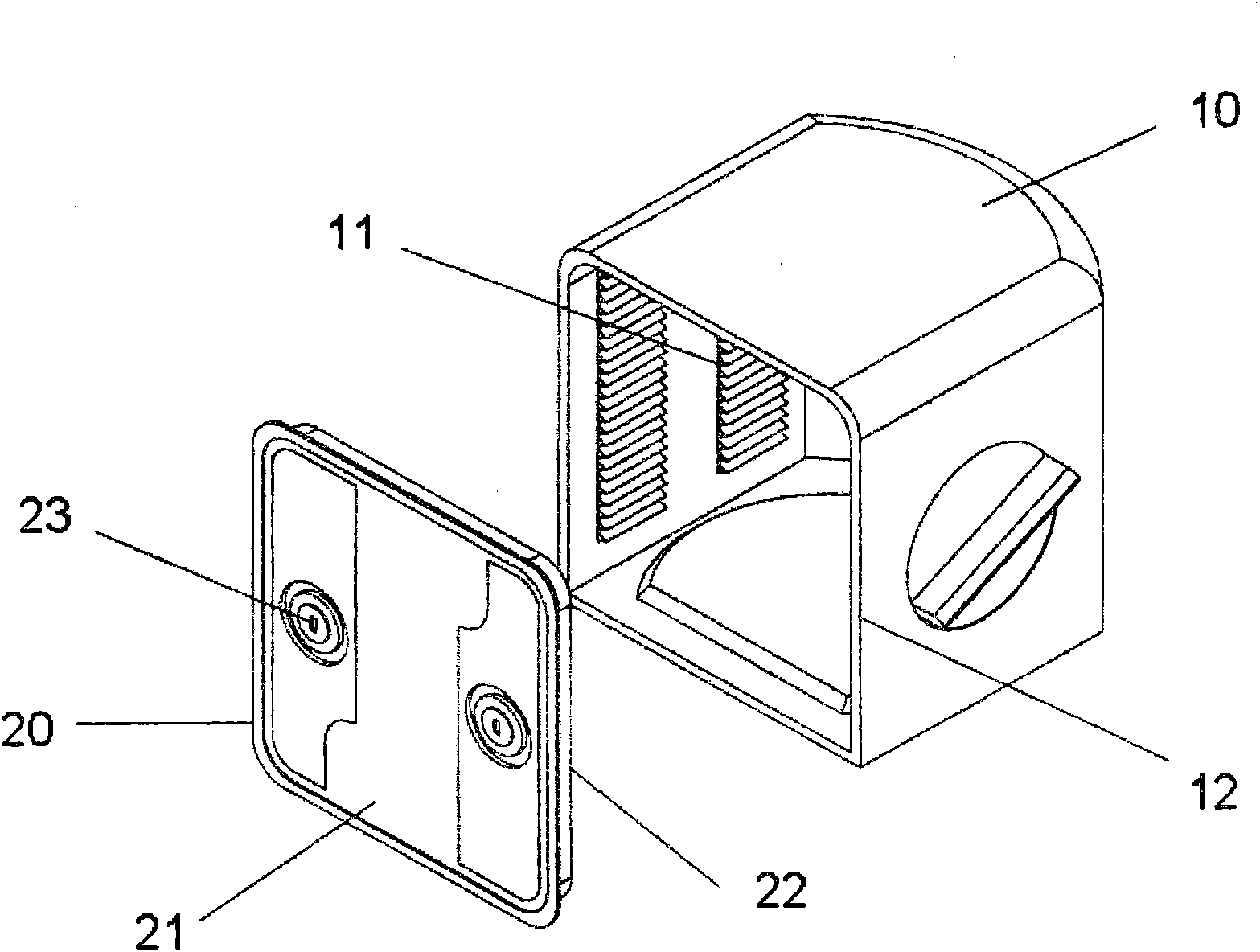

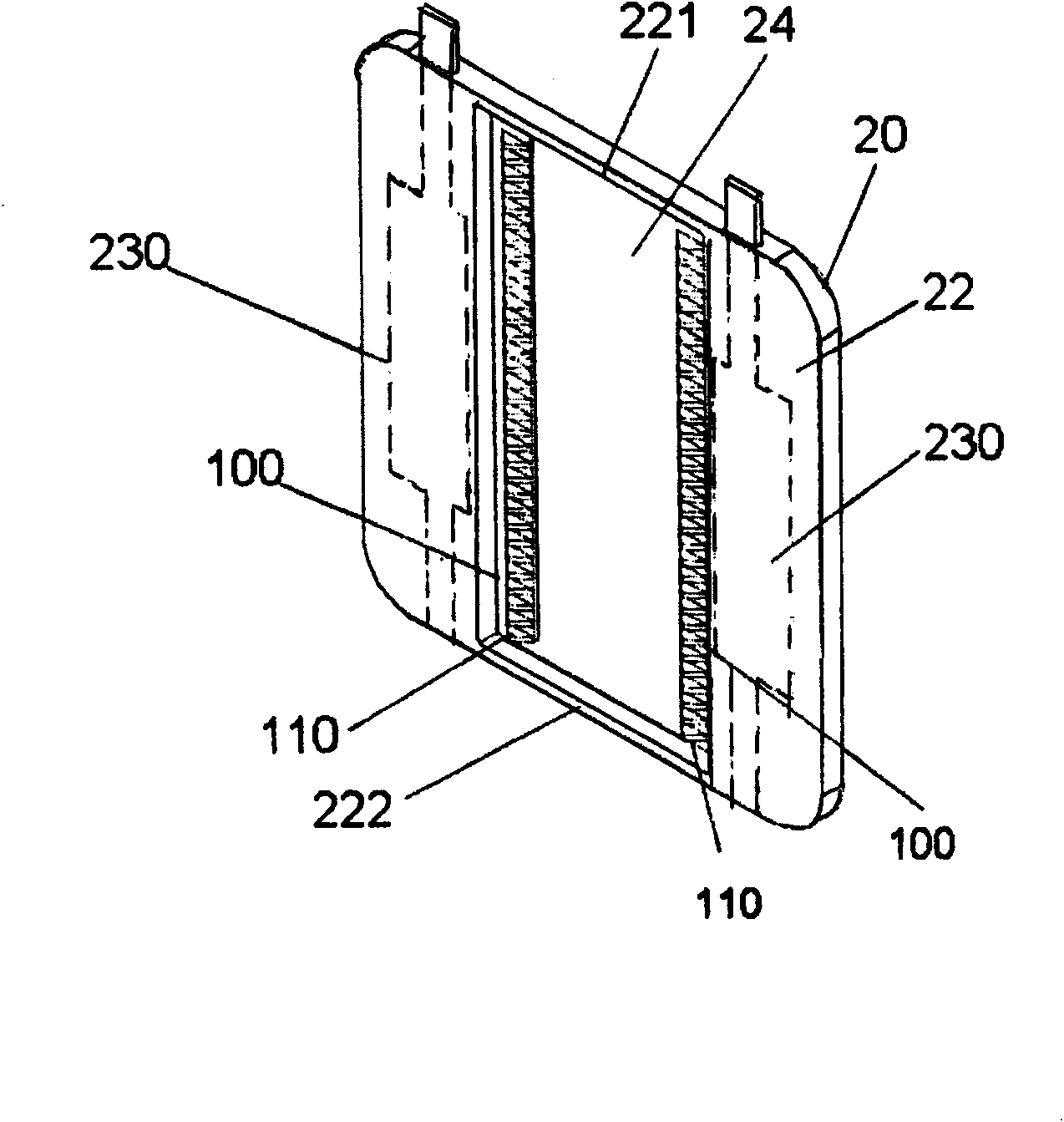

Front open type wafer box with latch and airtight structure

A front-opening wafer box, air-tight structure technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problem that the box body 10 cannot be stuck, the box body 10 and the door body 20 cannot be closed, and Issues such as increasing the manufacturing cost of front-opening wafer cassettes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

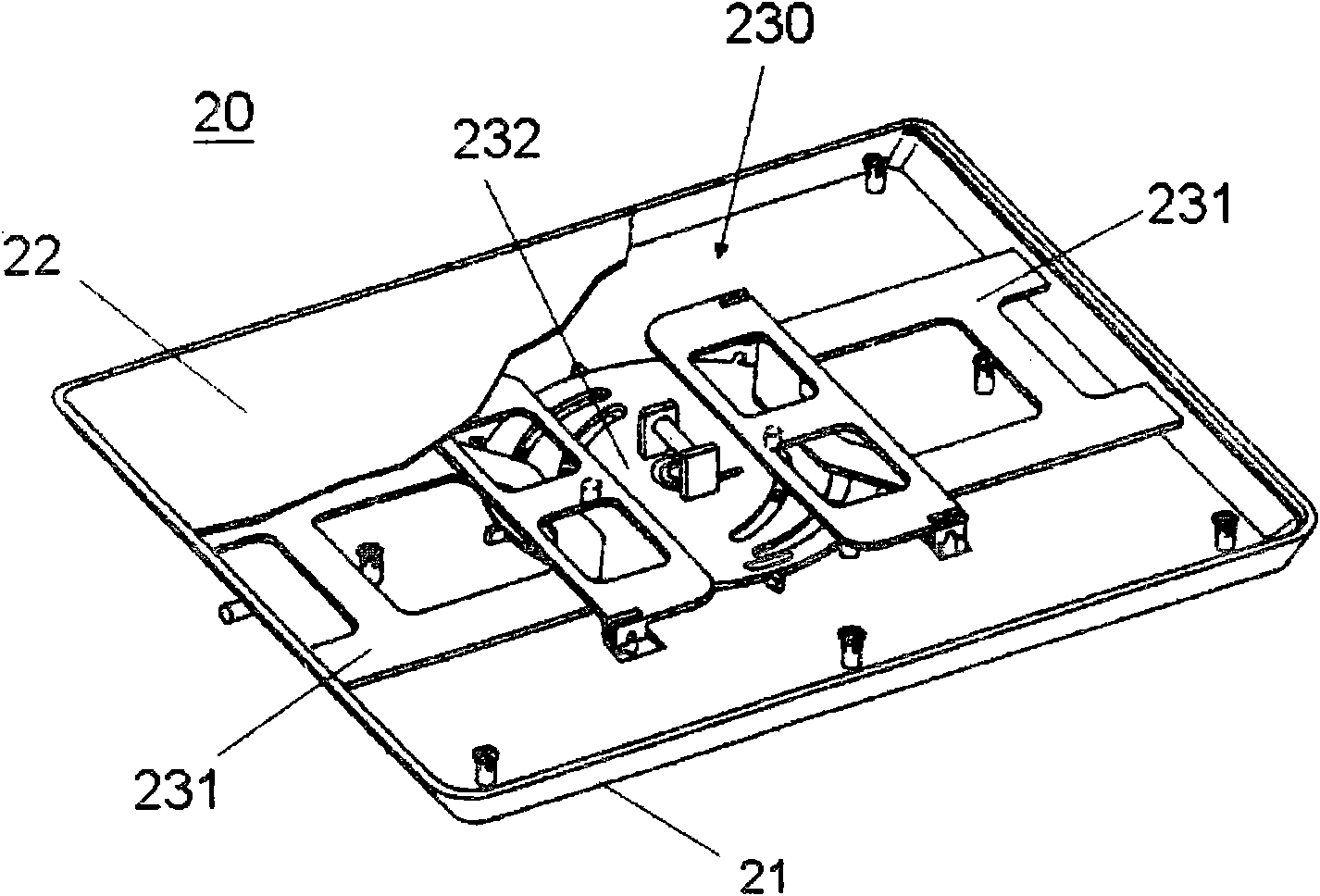

[0043] Please refer to Figure 5 , is a top view of a latch structure 60 of a door body 20 of the FOUP according to the present invention. Such as Figure 5 As shown, a pair of latch structures 60 are included between the outer surface and the inner surface of the door body 20, wherein each latch structure 60 is composed of an elliptical cam 62, a pair of sliding devices 64 in contact with the two ends of the elliptical cam 62, at least one The pulley 66 is disposed between the outer surface and the inner surface of the door body 20 and is embedded in the slide groove 642 of the sliding device 64 and at least one positioning elastic piece 68 integrally connected with the sliding device 64 . Next, please refer to Image 6 ,yes Figure 5 The enlarged schematic diagram of the contact end of the elliptical cam 62 and the sliding device 64 in FIG. Such as Image 6 As shown, in a preferred embodiment of the present invention, a positioning pulley 644 can be configured at the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com