Circuit board

A technology of circuit board and circuit layer, which is applied in the direction of electrical connection formation of printed components, can solve the problem of increasing the difficulty of wiring design in the power supply layer, and achieve the effect of increasing the usable area, facilitating wiring design, and reducing the area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

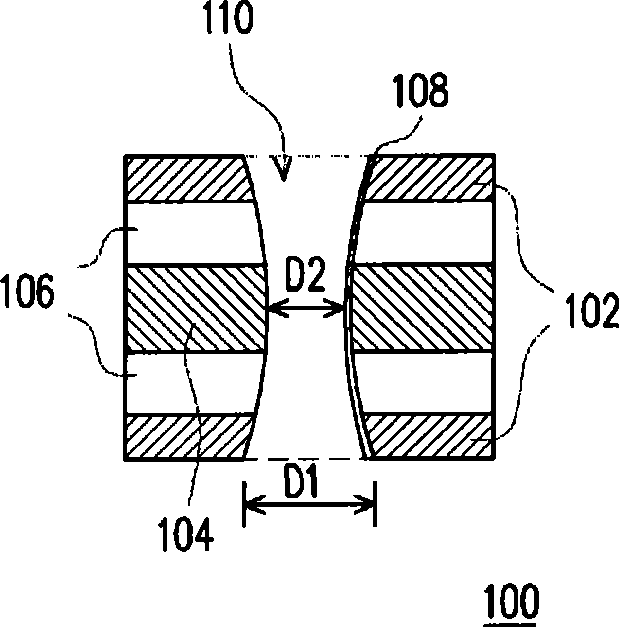

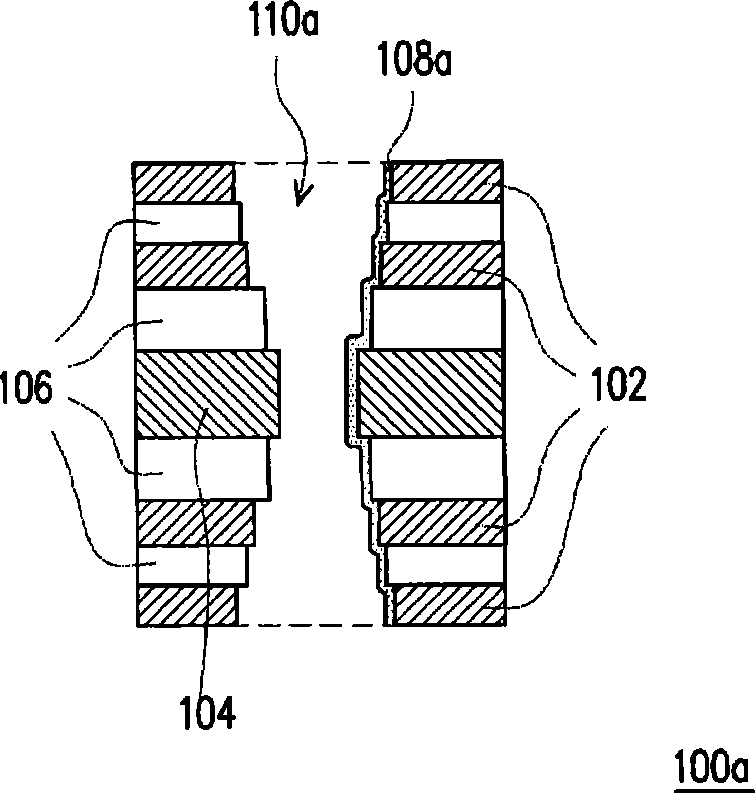

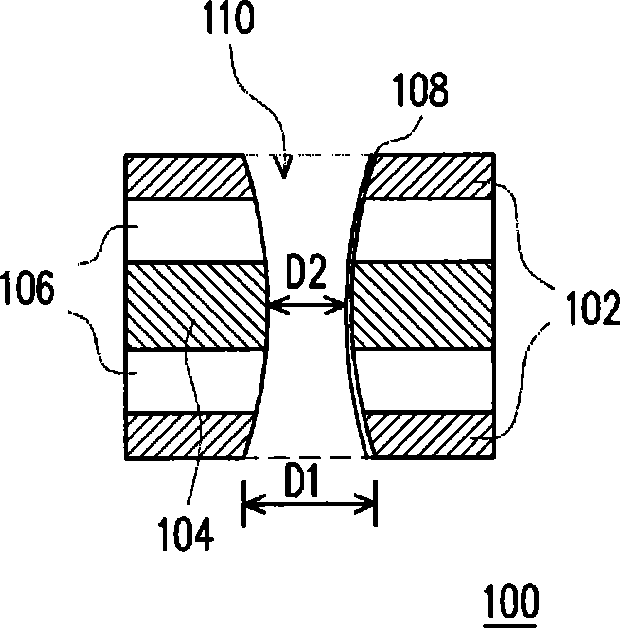

[0021] figure 1 Shown is a partial cross-sectional view of a circuit board according to an embodiment of the present invention. Please refer to figure 1 The circuit board 100 of this embodiment includes a plurality of circuit layers 102 (two are taken as an example here), a power layer 104 , a plurality of insulating layers 106 and a conductive pattern 108 . The power layer 104 is disposed between the two circuit layers 102 , and each insulating layer 106 is located between the adjacent power layer 104 and the circuit layer 102 . The circuit board 100 has at least one through hole 110 , but the number of the through holes 110 can also be increased as required. The through hole 110 penetrates through the insulating layer 106 , the circuit layer 102 and the power layer 104 . The aperture diameter of each portion of the through hole 110 increases as the distance between the portion and the power layer 104 increases. In this embodiment, the aperture D2 of the portion of the th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com