Structure for vehicle body side section

A side and car body technology, applied in the field of car body side structure, can solve the problems of impossible formation of two ridge lines, complicated processing and manufacturing process, etc., and achieve the effects of improving mechanical strength and improving collision safety performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

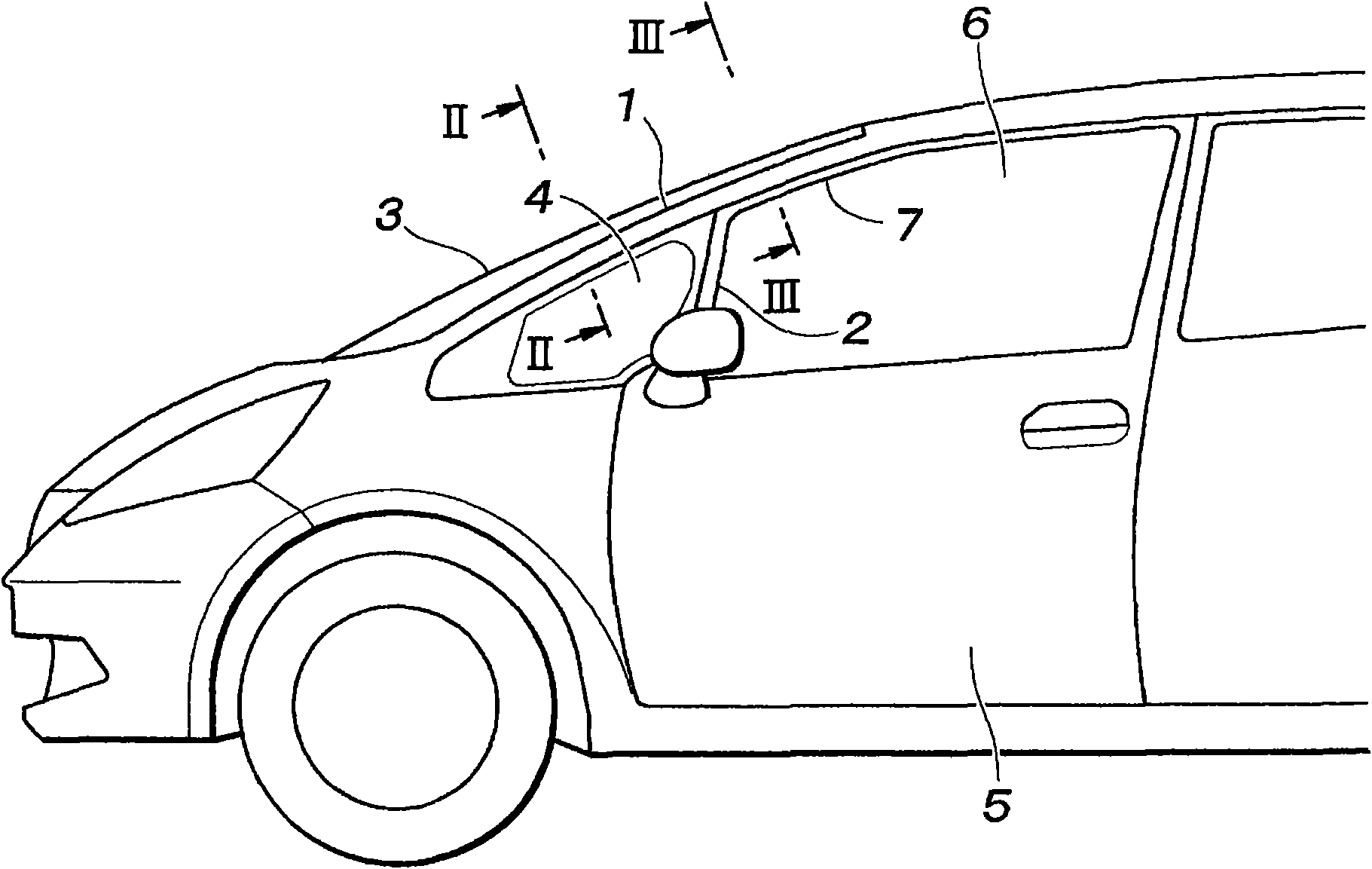

[0021] figure 1 It is a side view of a vehicle body incorporating a vehicle body side structure embodying the present invention. The vehicle body comprises sub-pillars 2 branching and hanging down from the middle portion of the front pillar 1 on each side of the vehicle body. A front windshield panel 3 is fitted between two front pillars 1 , and a triangular front triangular window glass panel 4 is fixedly fitted on each side in a triangular opening defined by the front pillar 1 and the sub-pillar 2 . The upper portion of the door sash 7 is located below the portion of the front pillar 1 extending behind the sub-pillar 2 and surrounds a door glass panel 6 that can be selectively rolled up and down from the door 5 .

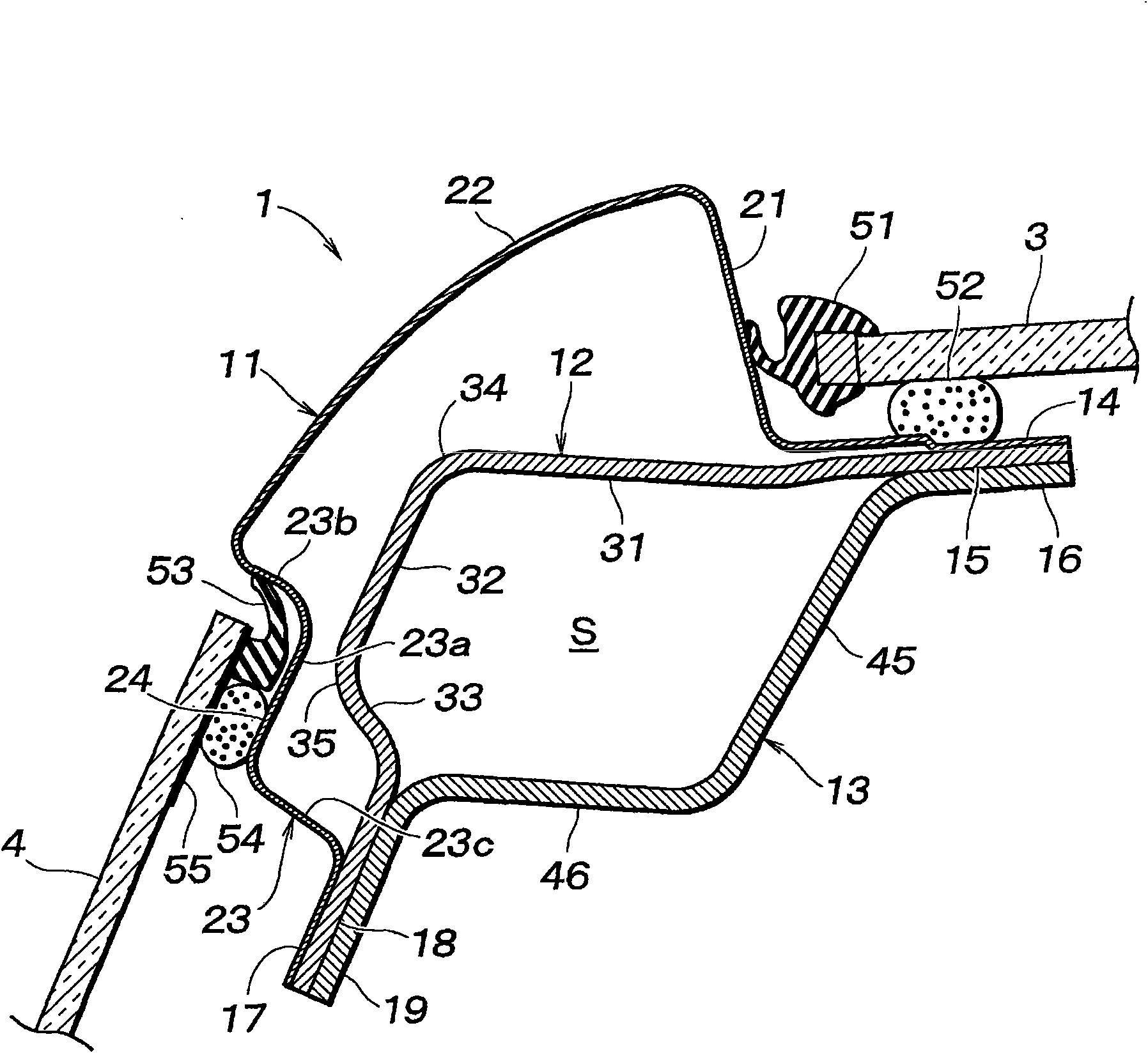

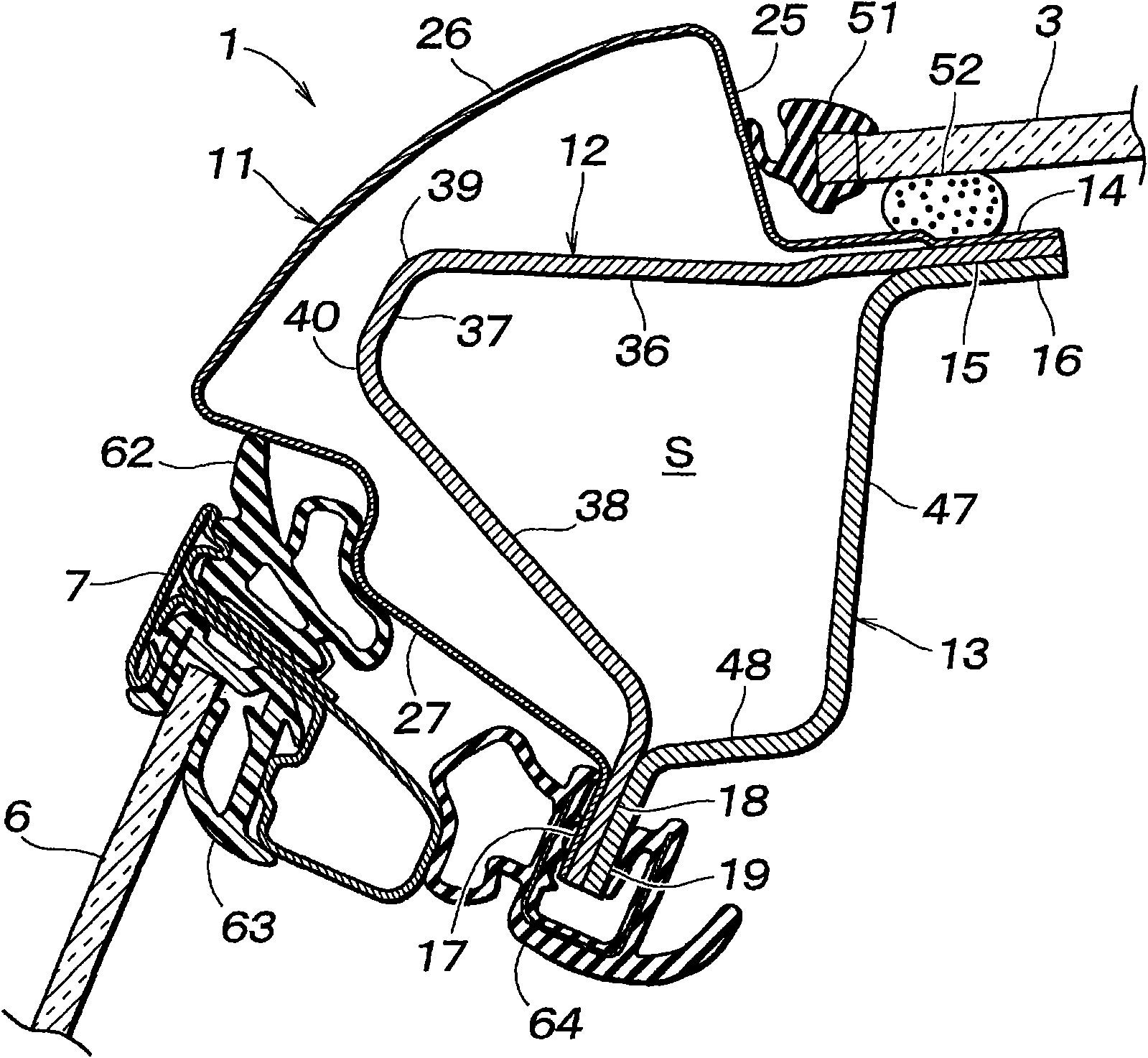

[0022] figure 2 for along figure 1 A sectional view of the front column 1 taken along line II-II, image 3 for along figure 1 A sectional view of the front pillar 1 taken along line III-III. Figure 4 a and 4b are cross-sectional views showing how the outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com