Methods of hydrolyzing soyabean protein to produce exorphins

A technology for hydrolyzing soybean protein and pepsin, applied in the direction of fermentation, can solve the problem of hydrolyzed soybean protein neglecting the physiological function of opioid peptides and hidden safety hazards, and achieve the effect of strong physiological function, glucagon secretion promotion and secretion improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0017] Specific embodiment one: the method for producing exorphins by hydrolyzing soybean protein in this embodiment is carried out as follows: using trypsin / alkaline enzyme, the pH value is 8.0, the temperature is 55 ° C, and the enzyme to substrate concentration ratio is 1: 3 under the conditions of enzymatic hydrolysis for 5h.

[0018] In this embodiment, the optimal dosage of trypsin is 8000U / g, and the optimal dosage of alkaline enzyme is 6000U / g.

[0019] The method of hydrolyzing soybean protein to produce exorphin in this embodiment The exorphin produced by hydrolyzing soybean protein is an antagonist, and the average peptide chain length is 7.85.

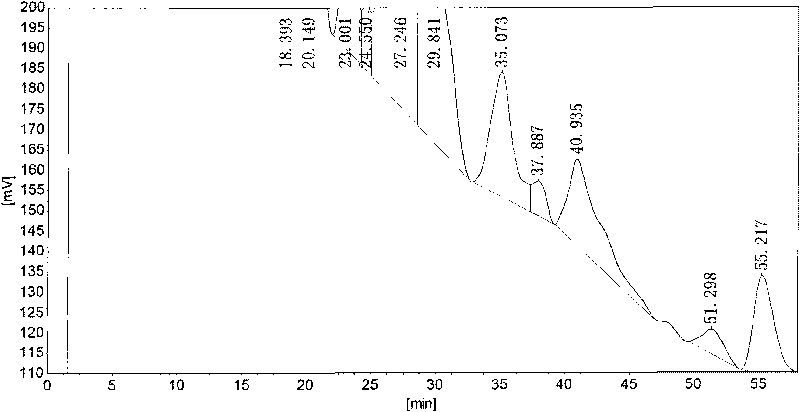

[0020] The liquid chromatogram of the hydrolyzate of the present embodiment is as figure 1 shown, from figure 1 It can be seen that the hydrolyzed soybean protein of this embodiment produces exorphins as antagonists.

specific Embodiment approach 2

[0021] Specific embodiment two: The method for producing exorphins by hydrolyzing soybean protein in this embodiment is carried out as follows: using trypsin / neutral enzyme, the pH value is 7.5, the temperature is 55 ° C, and the enzyme and substrate concentration ratio is 2: 1 under the condition of enzymatic hydrolysis for 5h.

[0022] In this embodiment, the optimal dosage of trypsin is 8000U / g, and the optimal dosage of neutral enzyme is 6000U / g.

[0023] The method of hydrolyzing soybean protein to produce exorphin in this embodiment hydrolyzes soybean protein to produce exorphin as an agonist, the target exorphin percentage is 0.007275%, and the average peptide chain length is 7.85.

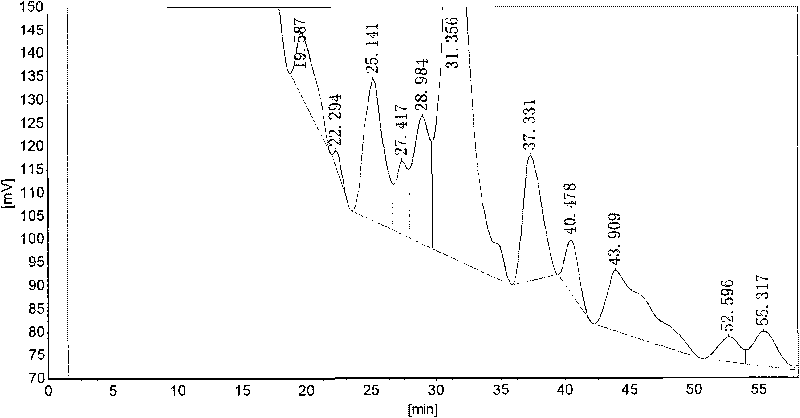

[0024] The liquid chromatogram of the hydrolyzate of the present embodiment is as figure 2 shown, from figure 2 It can be seen that the hydrolyzed soybean protein of this embodiment produces exorphins as agonists.

specific Embodiment approach 3

[0025] Specific embodiment three: the method for producing exorphins by hydrolyzing soybean protein in this embodiment is carried out as follows: using pancreatic alkaline enzyme / neutras (Alcalase / Neutras), at a pH value of 7.5, a temperature of 55 ° C, enzyme and Enzymolysis was carried out for 5 hours under the condition that the substrate concentration ratio was 3:1.

[0026] In this embodiment, the optimal dosage of alkaline enzyme is 6000U / g, and the optimal dosage of neutral enzyme is 6000U / g.

[0027] The method of hydrolyzing soybean protein to produce exorphin in this embodiment hydrolyzes soybean protein to produce exorphin as an agonist, the target exorphin percentage is 0.01228%, and the average peptide chain length is 6.68.

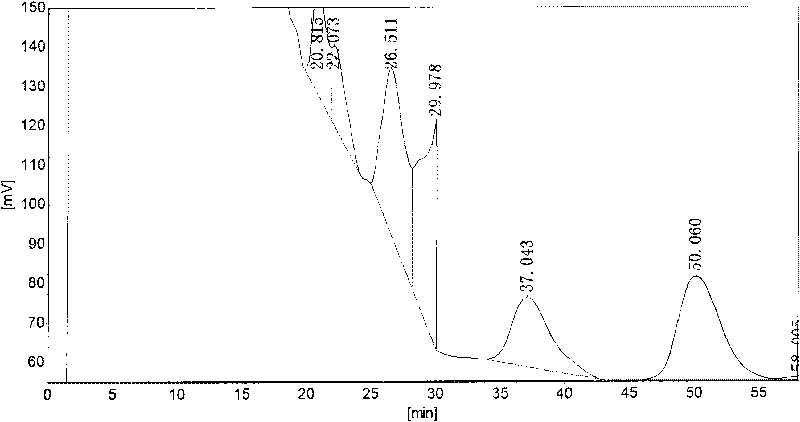

[0028] The liquid chromatogram of the hydrolyzate of the present embodiment is as image 3 shown, from image 3 It can be seen that the hydrolyzed soybean protein of this embodiment produces exorphins as agonists.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com