Underwater hydraulic axis-penetrating locking device

A locking device and a shaft-through technology, which is applied in water conservancy projects, sea area projects, coastline protection, etc., can solve the problems of low reliability, difficult to solve, and can only be installed on the gate embedded parts, so as to achieve strong adaptability to environmental conditions , On-site debugging is simple, the signal-to-noise ratio is safe and reliable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

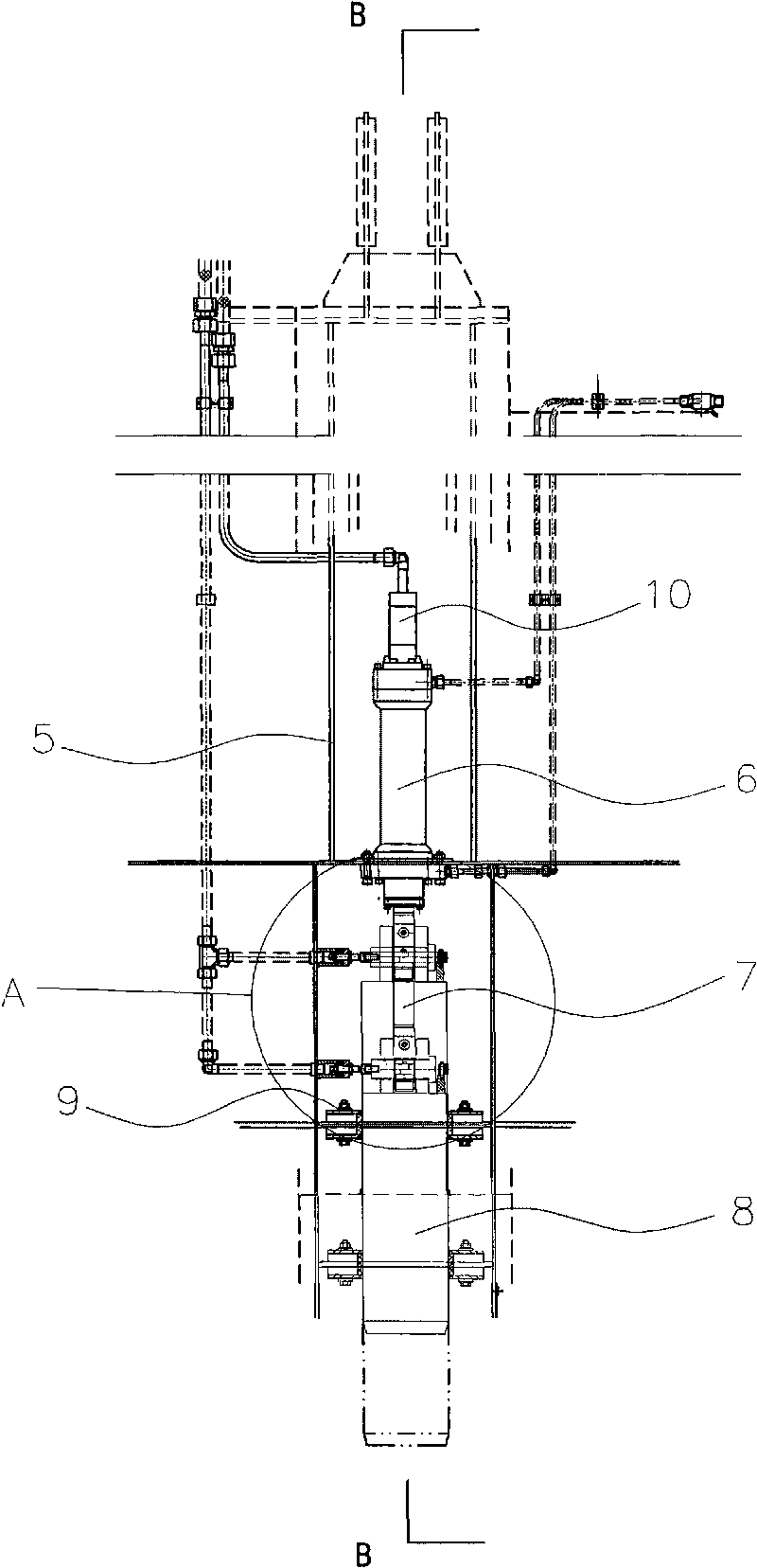

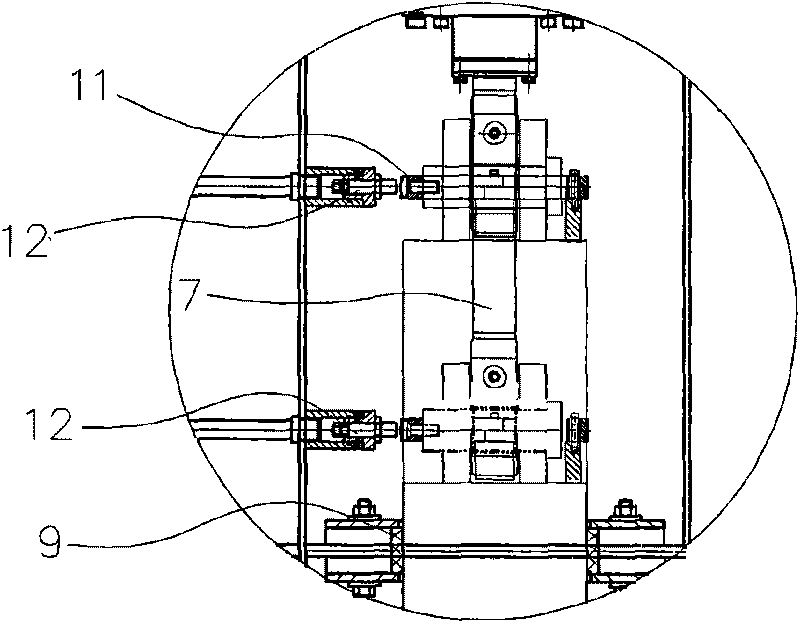

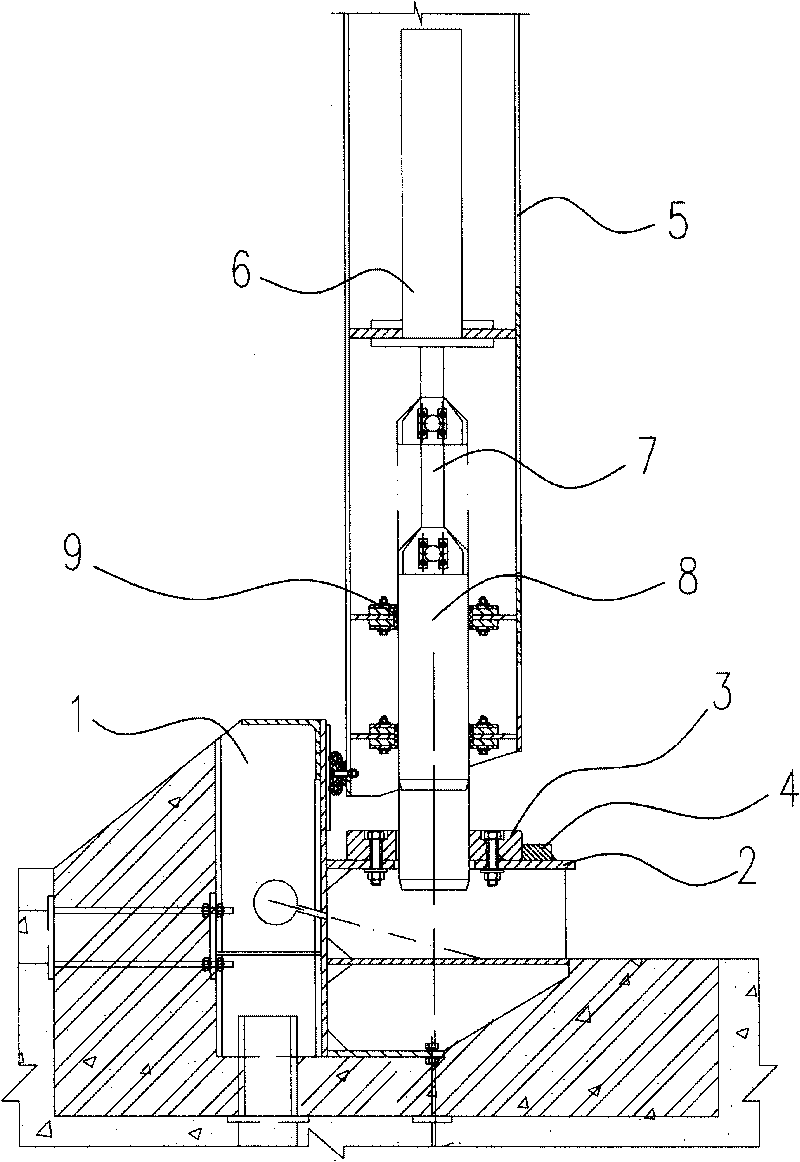

[0012] Such as figure 1 , 2 As shown in and 3, the underwater hydraulic shaft penetrating locking device of the present invention includes a locking cylinder 6 arranged at the lower end of the main girder 5 of the gate, and an underwater locking platform 2 arranged on the embedded part 1 of the gate; The upper end cover of the oil cylinder 6 is provided with a sealed anti-corrosion and pressure-resistant cover 10, and a magnetostrictive displacement sensor is arranged therein. The measuring rod of the magnetostrictive displacement sensor extends into the core hole of the hollow structure piston rod 7, and the induction ring is fixed on the On the piston 7; a locking plate 3 is arranged on the underwater locking platform 2, and a shear plate 4 is arranged on one side of the locking plate 3; Shaft 8, an induction measuring ring 11 for a limit sensor is arranged on the pin shaft, and two limit sensor seats 12 are arranged on the web of the gate; the locking shaft 8 is locked wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com