Fast hoisting-aligning method for Large-sized steel frames, and steel frame base structure

A steel frame and hoisting technology, applied in basic structure engineering, building construction, construction, etc., can solve the problems of long time, high shift cost and high construction cost of large cranes, and achieve convenient, fast, and reduced alignment work process. The effect of occupying time and reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the examples, but not as a limitation to the present invention.

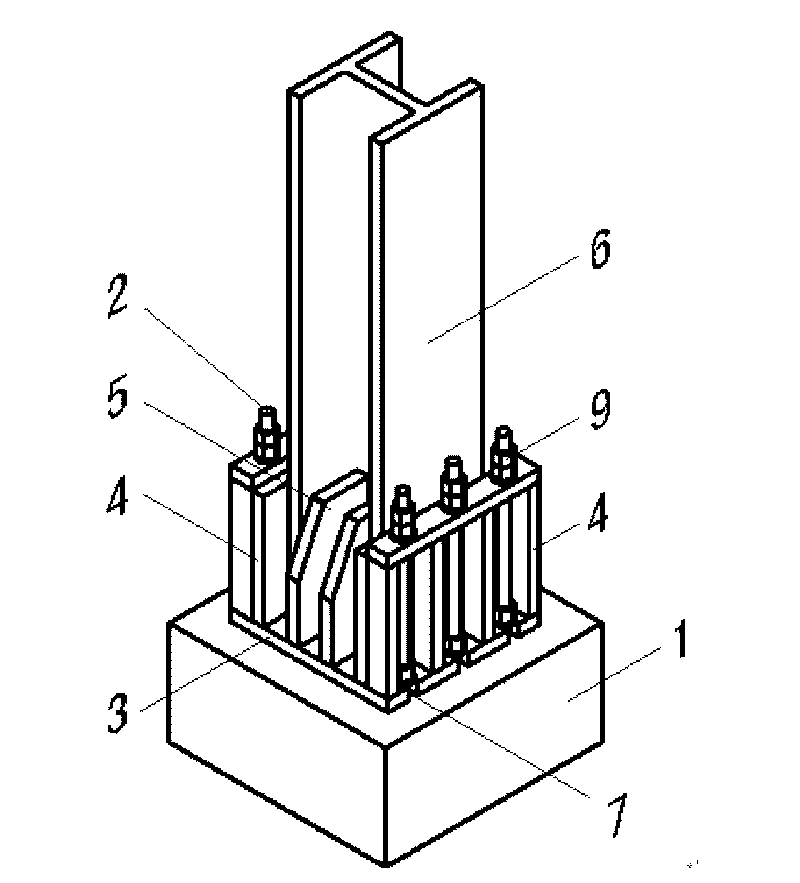

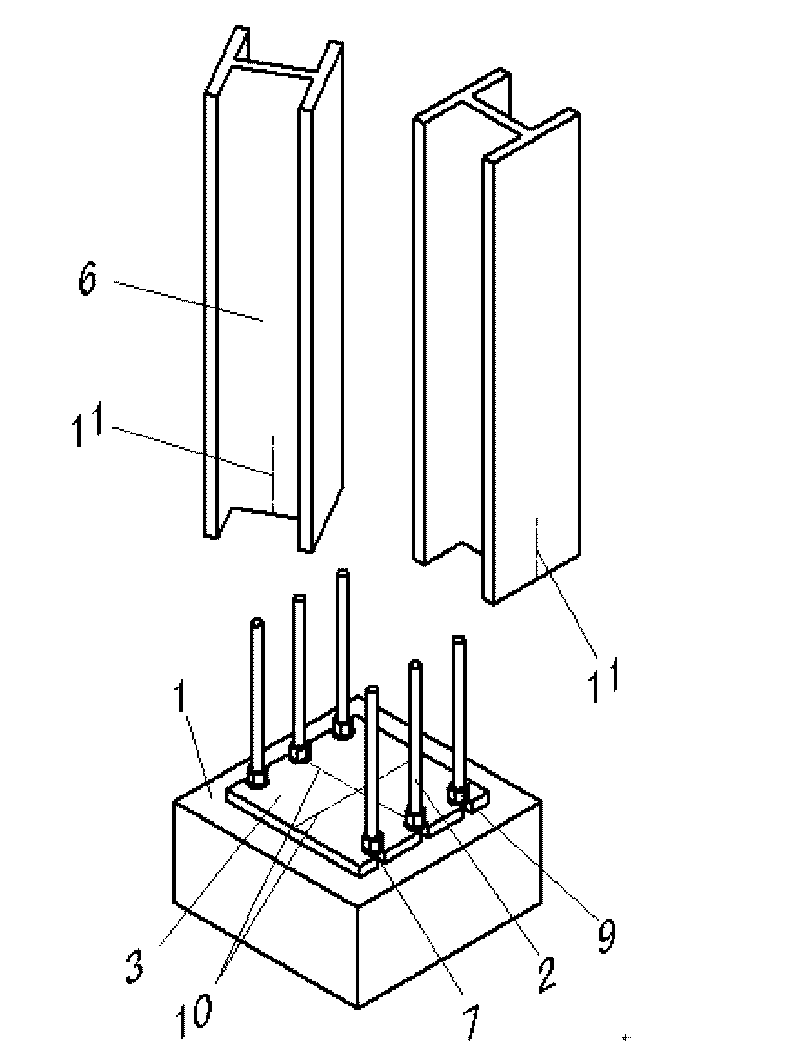

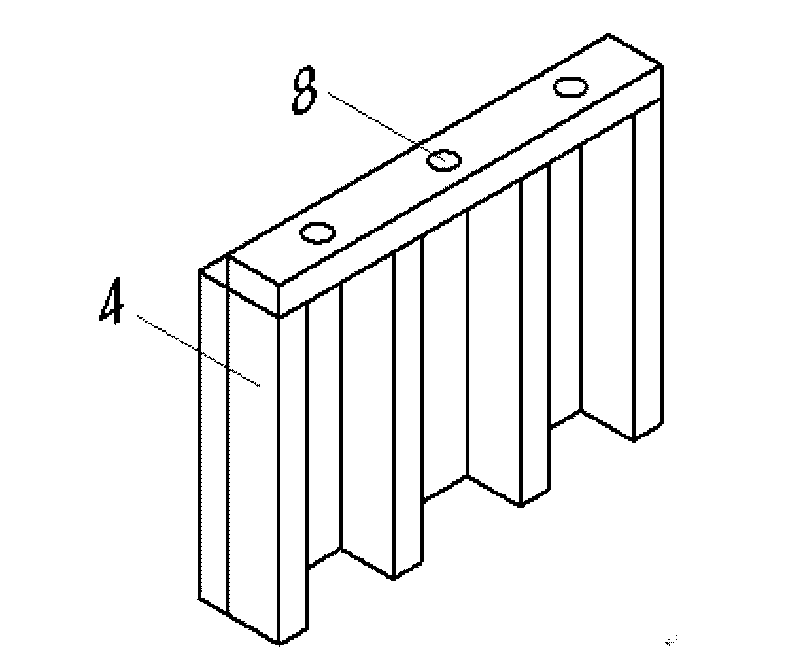

[0032] Embodiment of the present invention: this implementation example is to adopt the present invention to install the example of 400 tons / H diesel oil hydrogenation furnace large-duty steel frame to certain petrochemical plant, the height of 400 tons / H diesel hydrogenation furnace is more than 25 meters, and width is It is more than 13 meters long, and the design weight of single-piece combined hoisting is about 48 tons. Its foundation is composed of 12 reinforced concrete foundations 1 with 6 M40×1200mm anchor bolts embedded (such as Figure 4 shown). The previous hoisting method was to first weld all the bases under the large and heavy steel frame of the 400t / H diesel hydrogenation furnace. When hoisting, use the fixing holes on the base to align the anchor screws 2 on the reinforced concrete foundation 1. This metho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com